Bearing roller demagnetizer and usage thereof

A rolling body and demagnetization machine technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of good demagnetization effect and high degree of automation, and achieve the effect of good demagnetization effect, high degree of automation, and convenient mobile maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

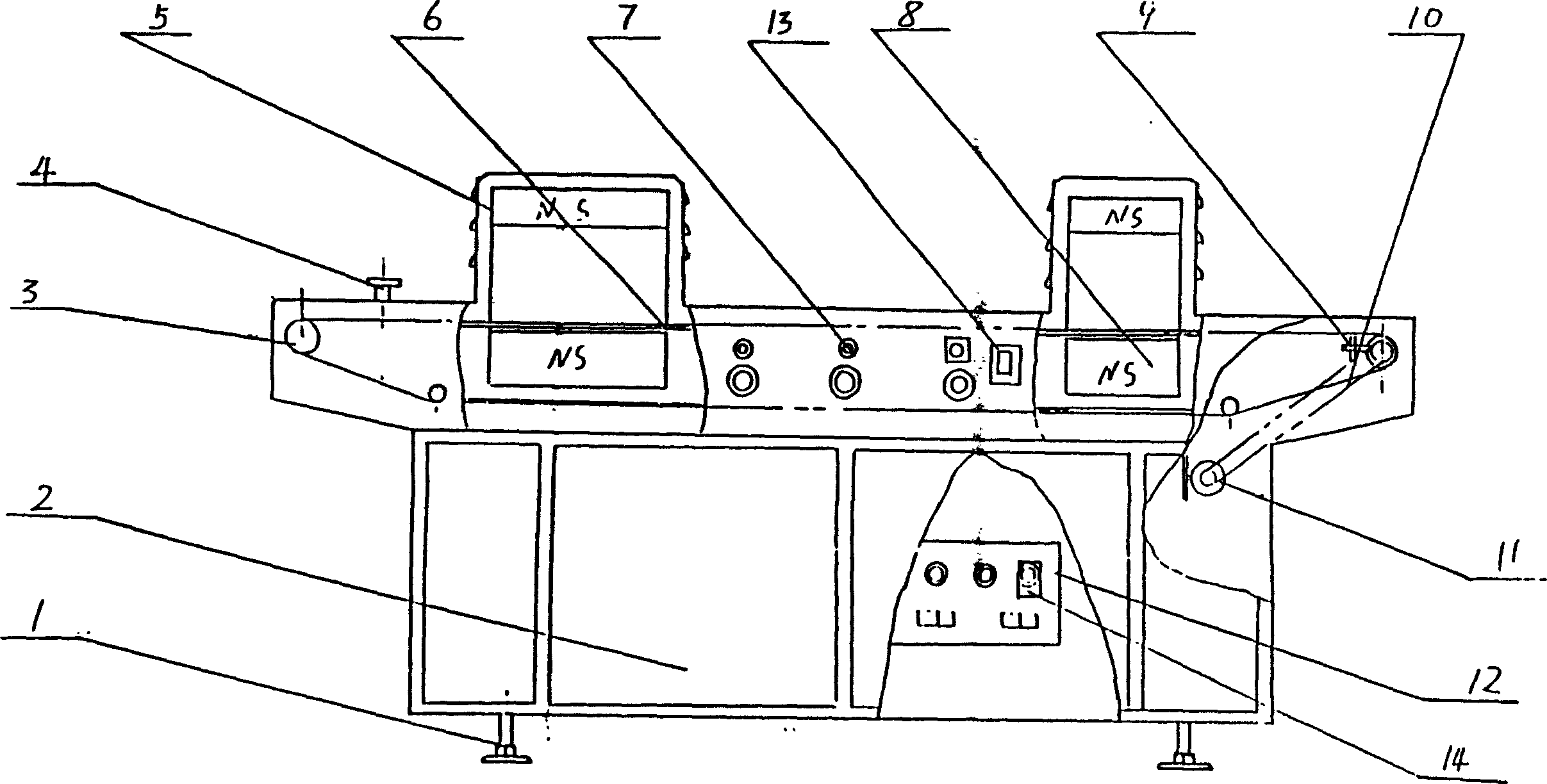

[0010] The conveyor belt 6 rotates circularly under the drive of the transmission motor 11 , the transmission chain 10 and the transmission shaft 3 . The number of revolutions is adjusted to 2m / min through the frequency converter 14, and the power of the demagnetization coil is adjusted to 65kw through the universal steering controller 13. The model of the frequency converter 14 is E2-201-H1, and the model of the universal steering controller 13 is LW5D-16YH3 / 3 , the outer diameter of the demagnetized workpiece is Φ150mm, driven by the conveyor belt 6, it passes through the fully enclosed hollow demagnetization coil 5 and the fully enclosed gantry demagnetization coil 8 at a constant speed to complete the demagnetization process.

[0011] According to actual needs, the working height of the demagnetization machine can be adjusted through the adjustable hoof 1, and the tightness or deviation of the conveyor belt 6 can be adjusted through the conveyor belt tensioning device 9 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com