Patents

Literature

65results about How to "Improve demagnetization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

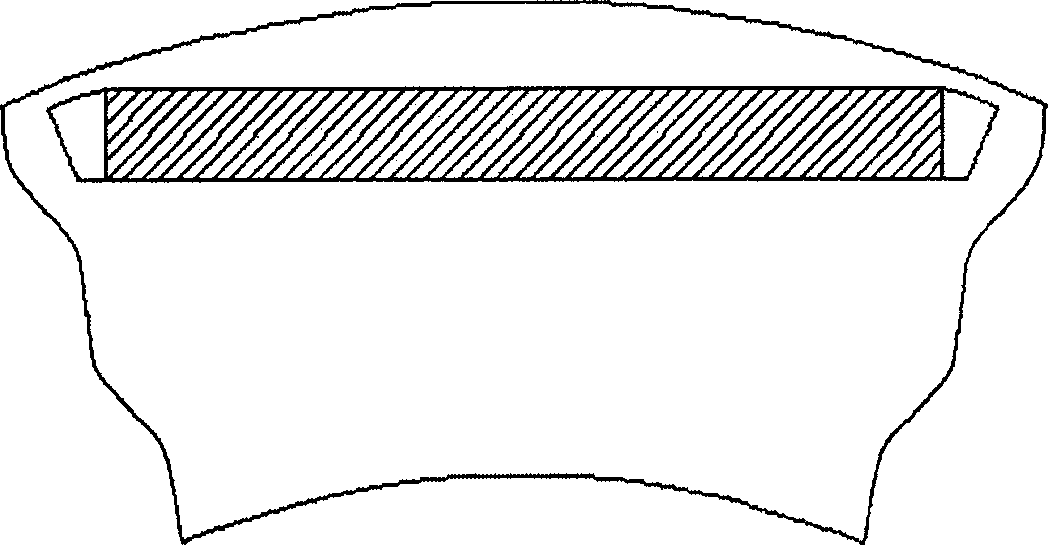

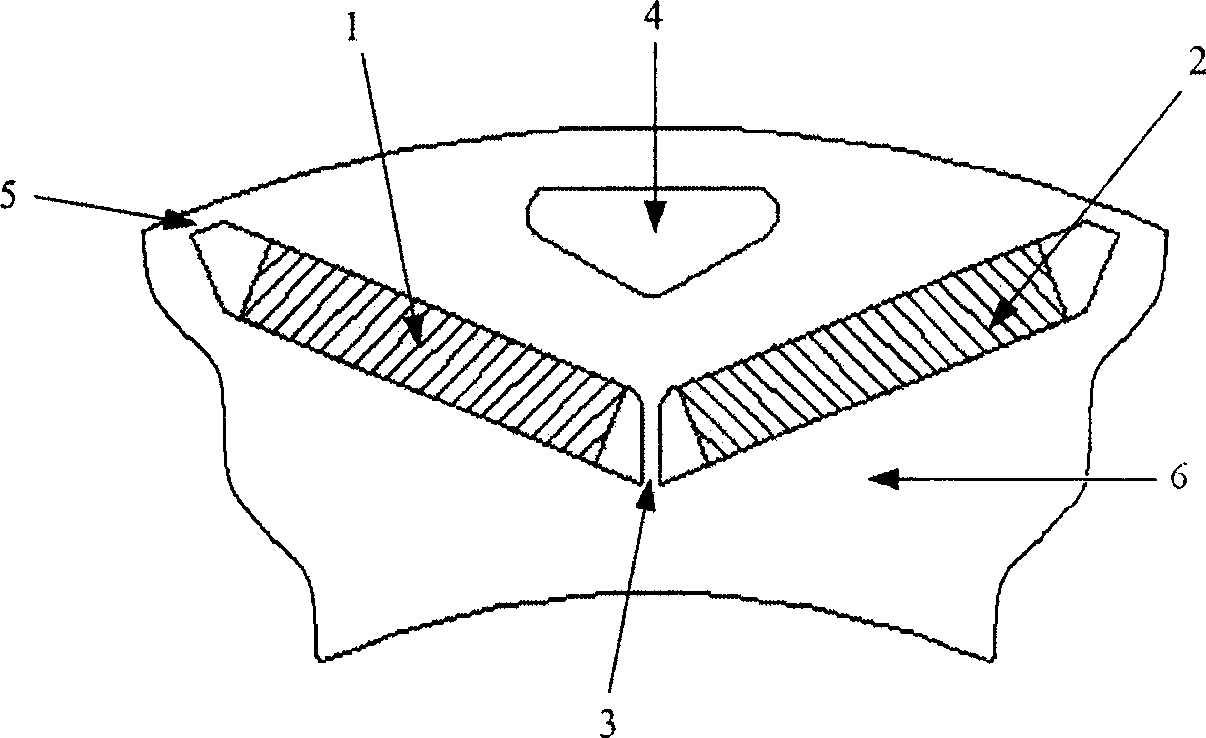

'V' type builti-in rotor of permanent megnet dynamo

InactiveCN1835340AIncrease the maximum safe operating speedReduce weightMagnetic circuit rotating partsStress pointWave shape

The invention converts built-in type rotor structure in conventional 'I'type to built-in type rotor structure in 'V'type, as well as sets up reinforced ribs between magnetic poles and sets up accessory pores above the said reinforced ribs. Changing distribution of deformation on surface of rotor diameter, the rotor structure in 'V'type makes maximal centrifugal stress point shift to reinforced ribs of rotor. The maximal centrifugal stress point is tensile stress restricted by tensile strength of material of rotor core. Since tensile strength of material of rotor core is larger than yield strength, thus, operating mechanical property of rotor at high speed is enhanced remarkably. Moreover, the said accessory pores can control waveform of air gap field, lightens weight of rotor, reduces centrifugal force, vibration and noise as well as improves operating mechanical property and other performances of motor.

Owner:SHANGHAI UNIV

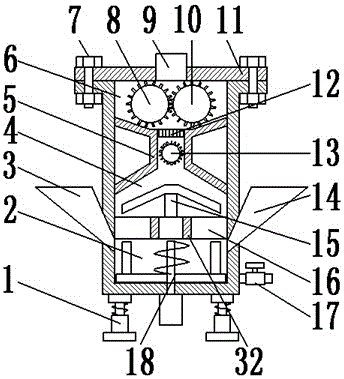

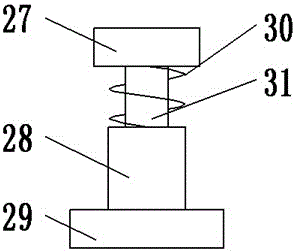

Battery cathode material mixing device with demagnetizer

InactiveCN106732141ADegaussing fastThe first effect is thoroughTransportation and packagingMixersElectrical batteryEngineering

The invention discloses a battery cathode material mixing device with a demagnetizer. The battery cathode material mixing device comprises a damping base, a mixing chamber is arranged at the top of the damping base, a discharge pipe and a second additive inlet pipe are arranged on the right side of the mixing chamber, a first additive inlet pipe is arranged on the left side of the mixing chamber, and the top of the mixing chamber is provided with a motor cover and a feed port. The battery cathode material mixing device is simple in structure, reasonable in design and convenient to use, materials enter the device through a feed pipe, crushed qualified materials are filtered by a filter plate after being crushed by a first crushing shaft and a second crushing shaft, and the materials are demagnetized in a demagnetizing pipe for the first time and uniformly scattered under the action of a scattering device to contact with the left inner wall and the right inner wall of the demagnetizing pipe, so that the materials are more thoroughly demagnetized. The materials fall onto the demagnetizer and are secondarily demagnetize, so that the materials are more rapidly demagnetized, demagnetizing effects are better, and the materials are conveyed into the mixing chamber through the feed port and stirred and mixed with additives.

Owner:SHENZHEN JUOCAN TECH CO LTD

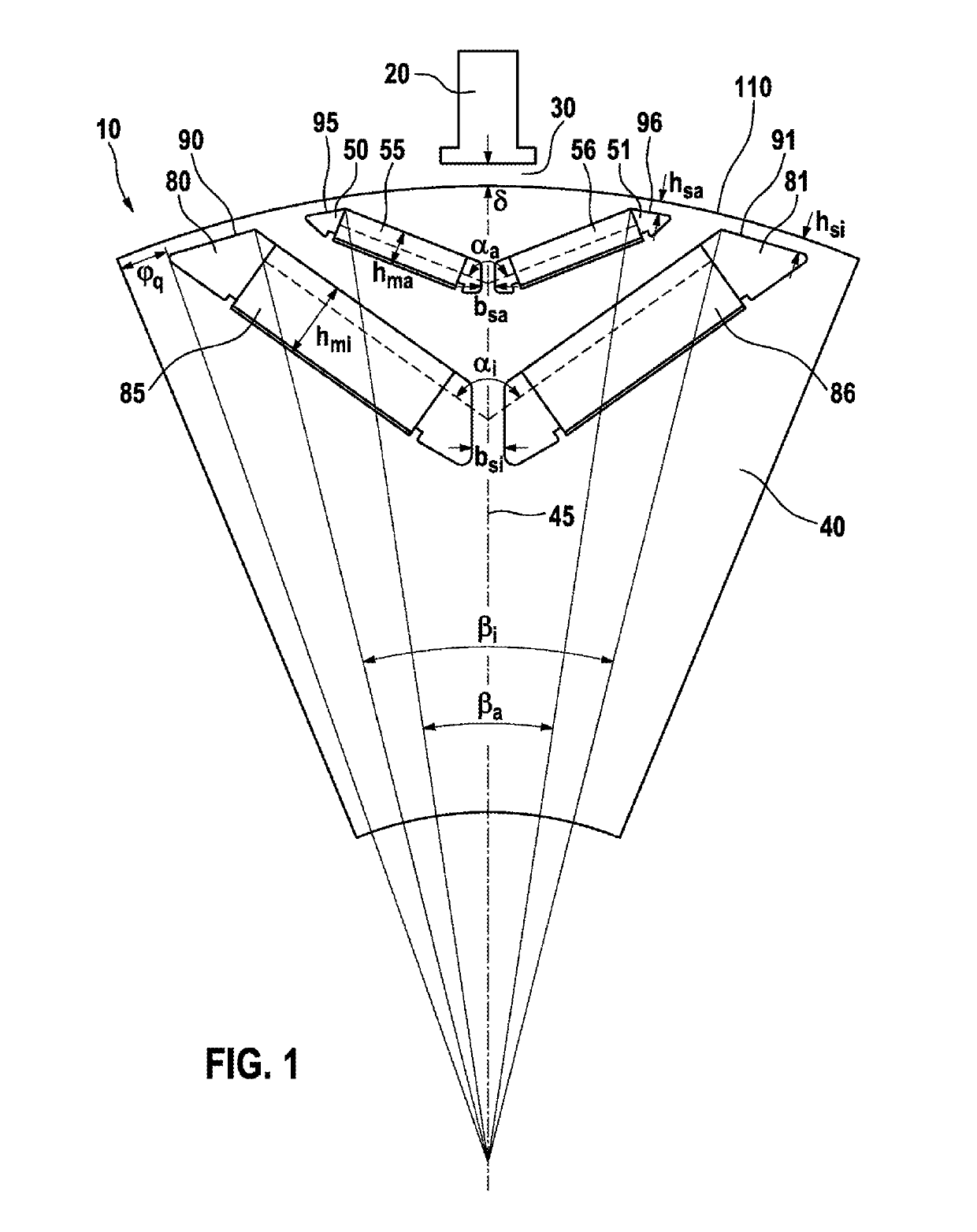

Electric machine comprising a rotor and a stator

ActiveUS20190238014A1Improve the level ofLow torque levelMagnetic circuit rotating partsRotational axisAxis of symmetry

The invention relates to an electric machine comprising a rotor (10) and a stator (20). The rotor (10) has magnet pockets for receiving permanent magnets (55, 56, 85, 86), and the magnet pockets comprise at least one first pair of magnet pockets (50, 51) and a second pair of magnet pockets (80, 11). The second pair (80, 81) is arranged further inwards than the first pair (50, 51) when viewed in a radial direction with respect to a rotational axis, and the magnet pockets of each pair of magnet pockets (50, 51, 80, 81) are arranged symmetrically to one another with respect to an axis of symmetry (45), wherein the axis of symmetry (45) runs in the radial direction and through the center of the rotor (10). The magnet pockets of each pair of magnet pockets (50, 51, 80, 81) are arranged such that the distance of each magnet pocket to the axis of symmetry (45) increases as the distance to the circumferential edge (110) of the rotor (10) decreases. The magnet pockets of the first pair (50, 51) are arranged at a first mechanical angle to one another, and the magnet pockets of the second pair (80, 81) are arranged at a second mechanical angle to one another. The invention is characterized in that the first angle ranges from ca. 100° to ca. 140°, in particular from ca. 120° to ca. 140°, and the second angle ranges from ca. 65° to ca. 112°, in particular from ca. 88° to ca. 112°.

Owner:ROBERT BOSCH GMBH

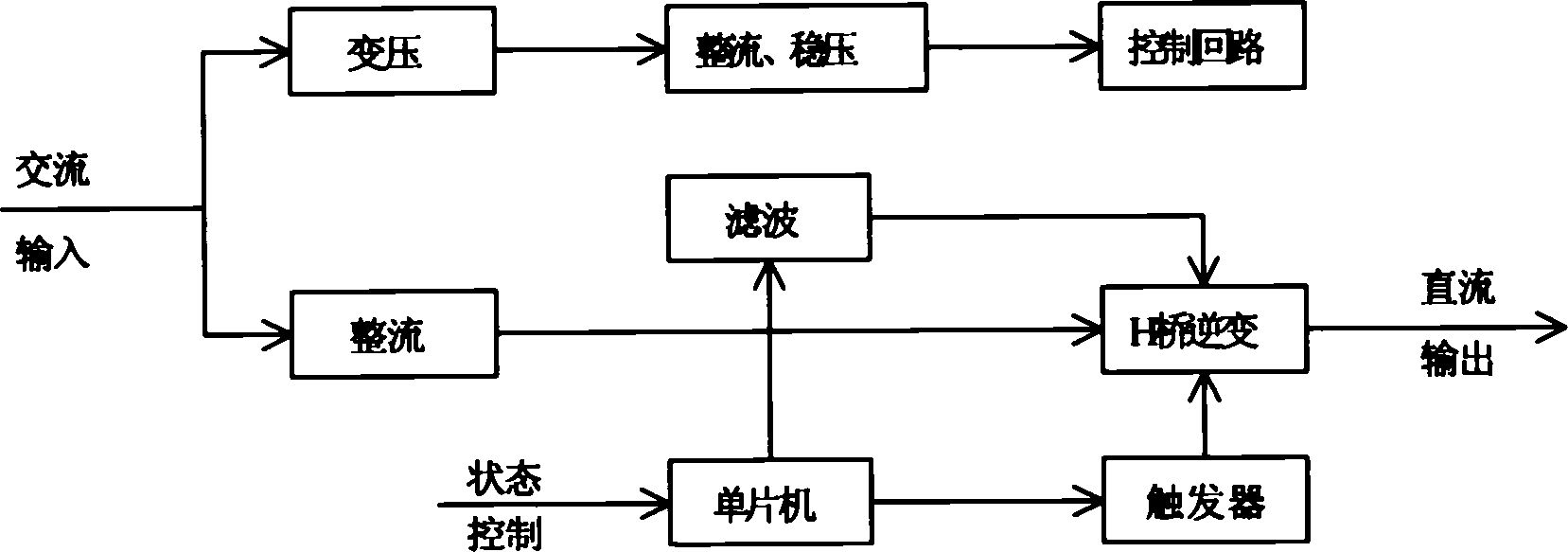

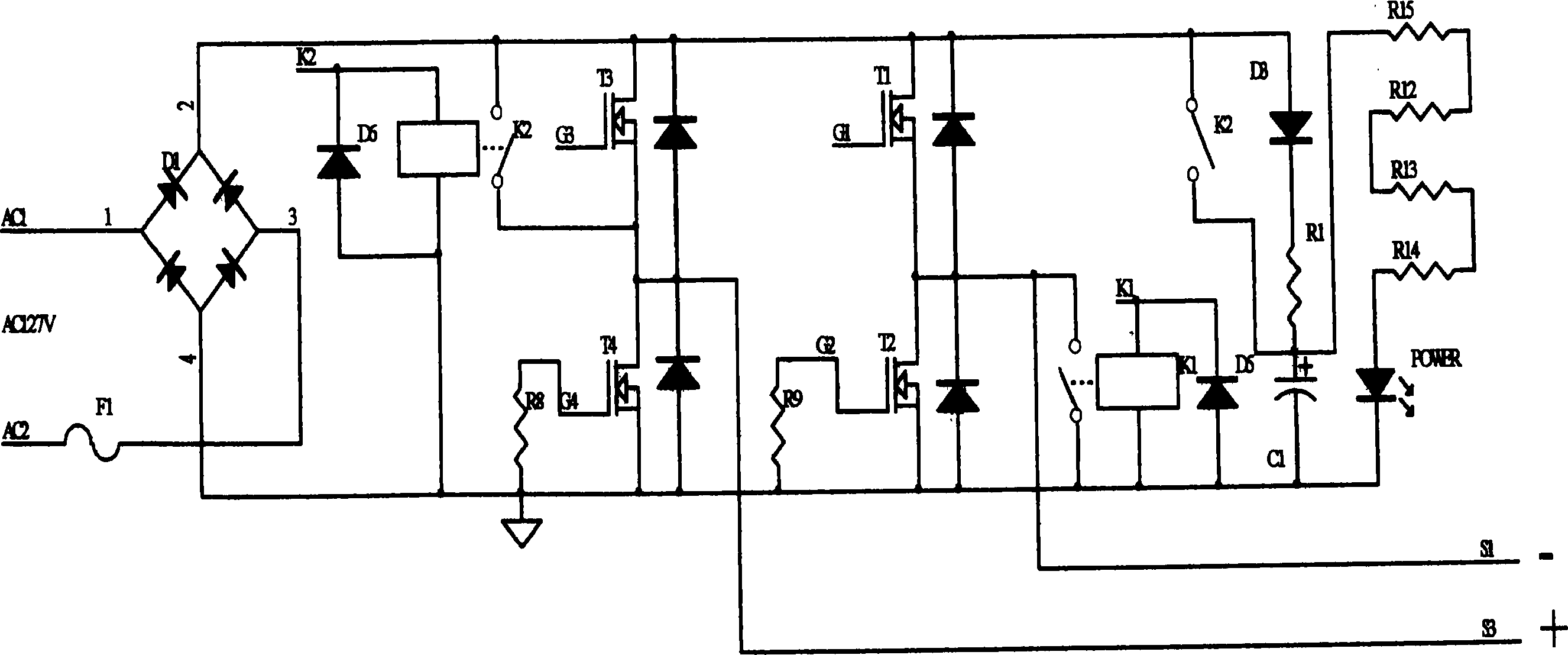

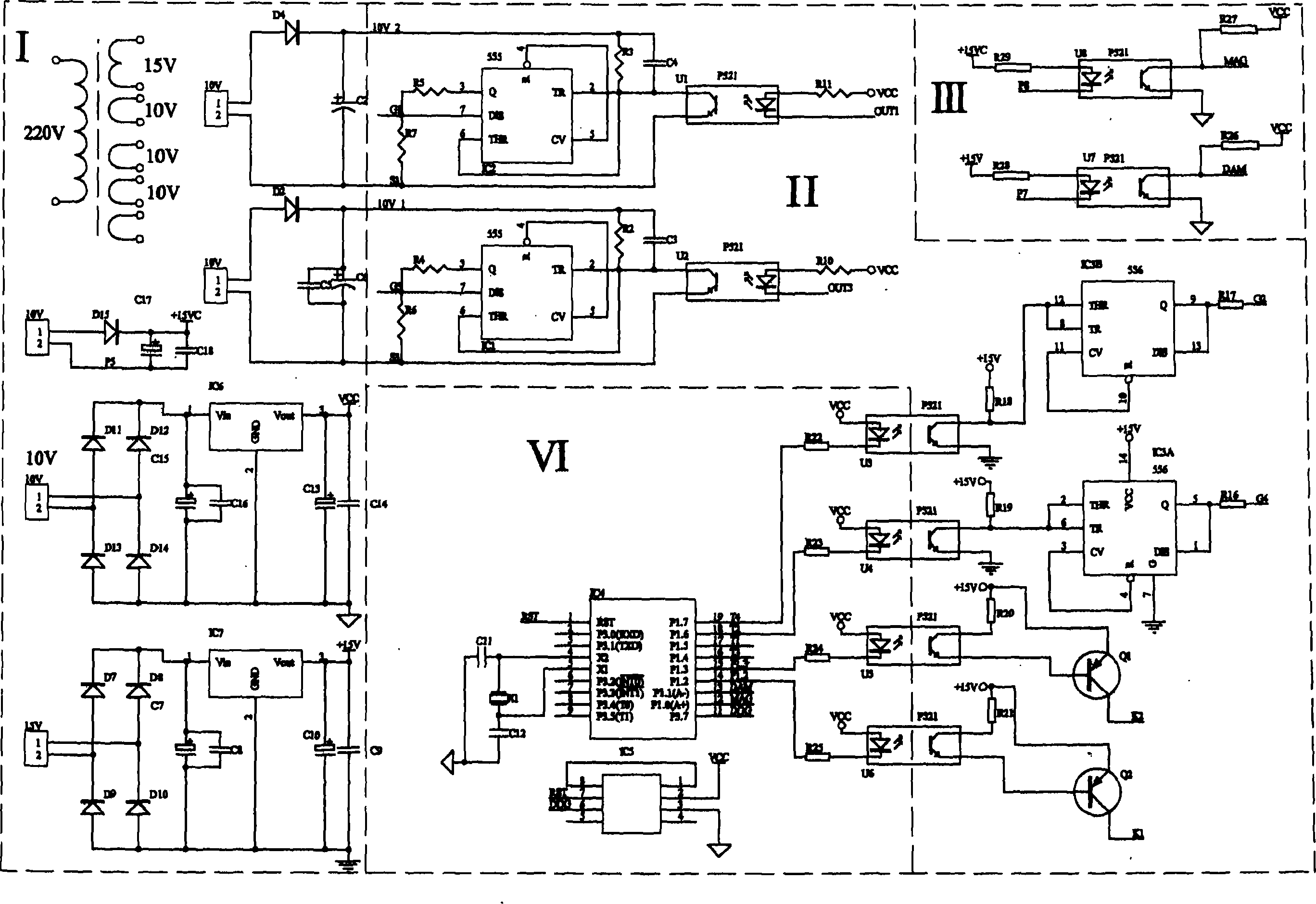

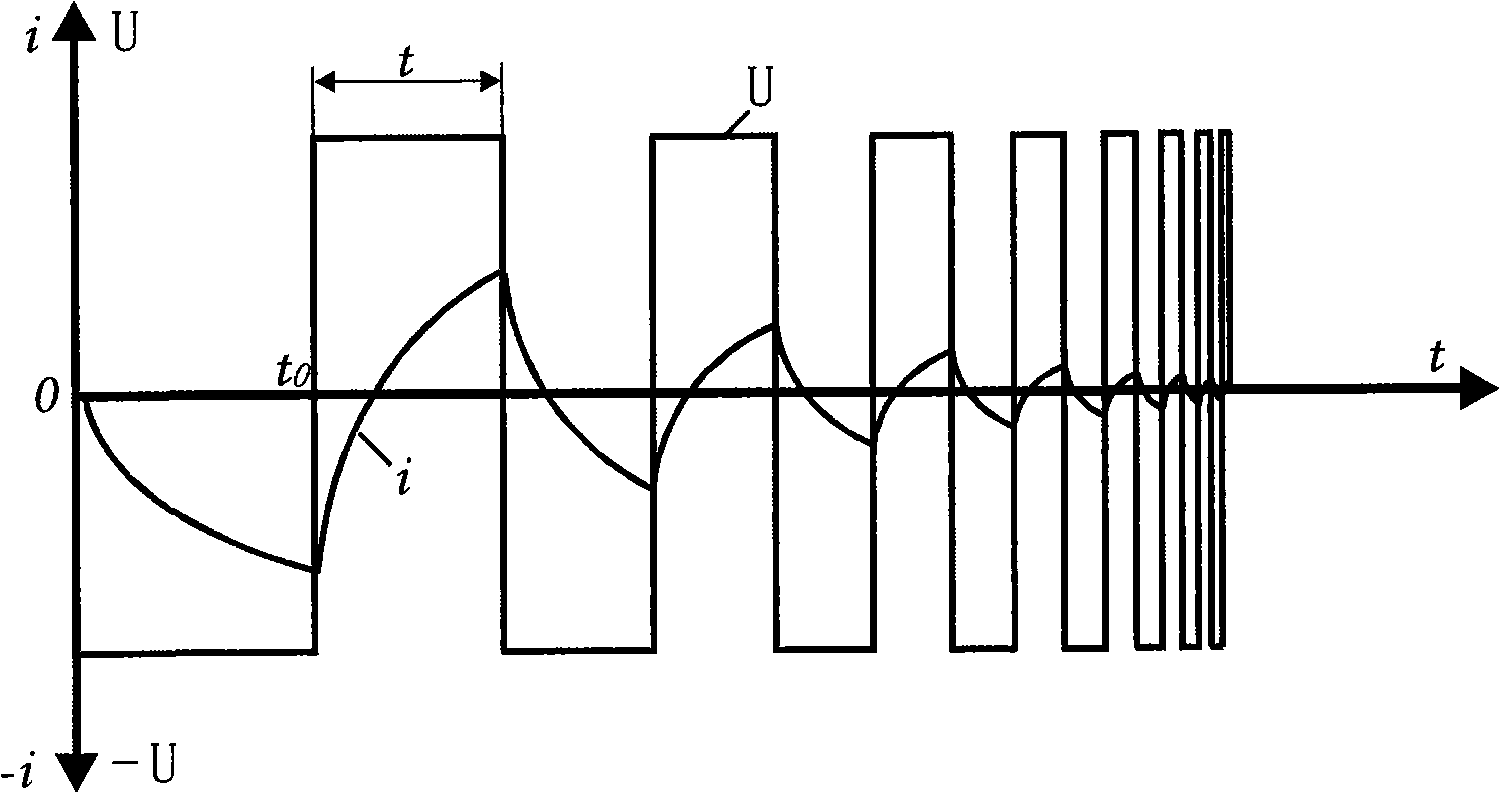

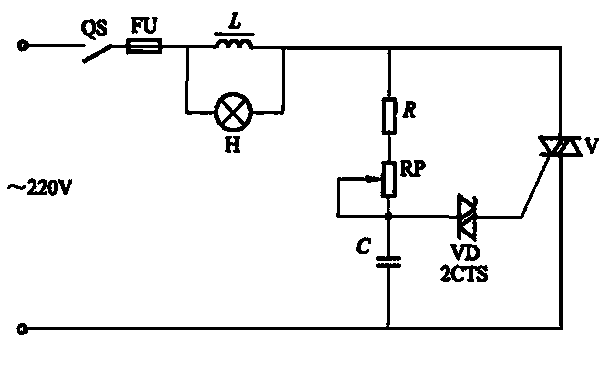

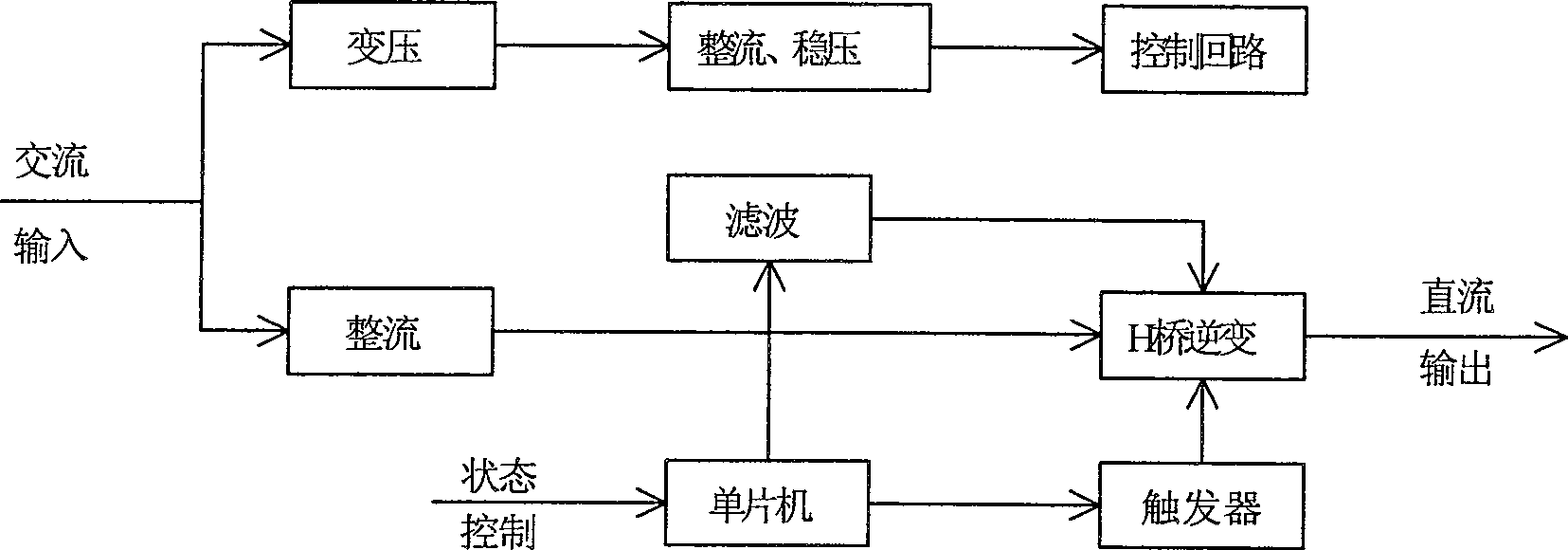

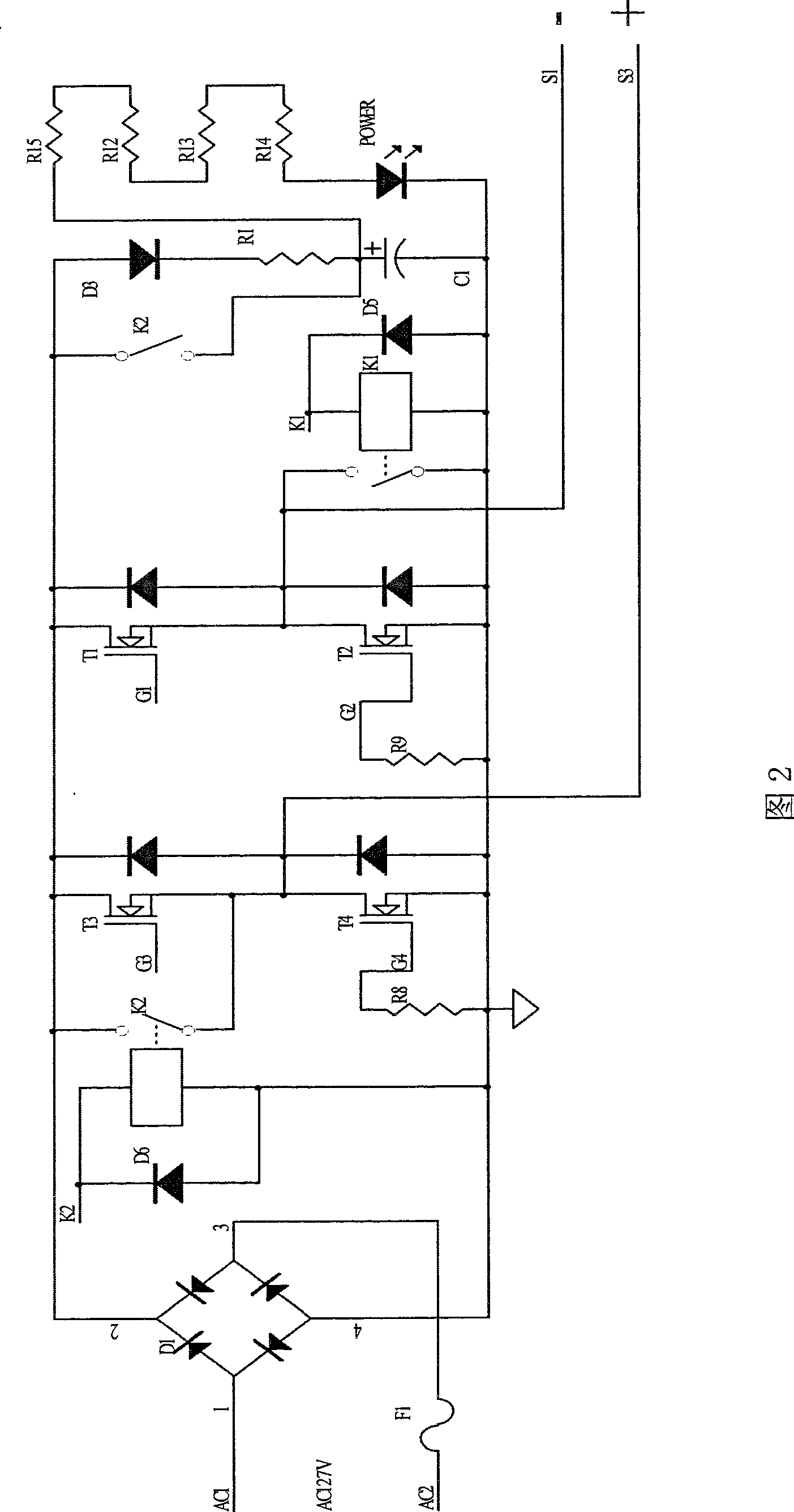

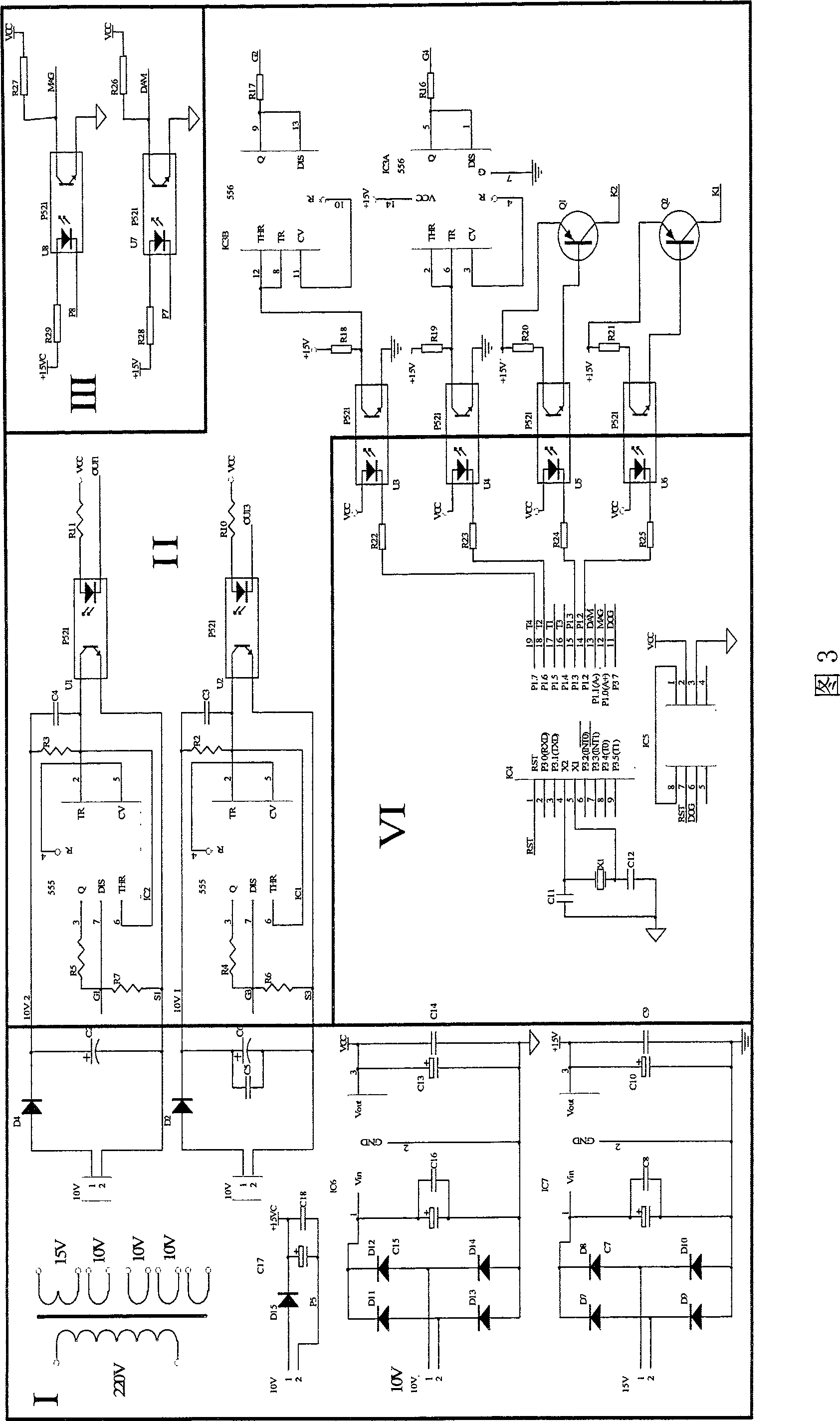

Grinder chuck magnetizing and demagnetizing controller

ActiveCN1887527AEliminate power consumptionImprove reliabilityMagnetic bodiesGrinding work supportsMicrocontrollerVoltage amplitude

The grinder chuck magnetizing and demagnetizing controller has one main loop and one monolithic computer control loop. The main loop includes one H-bridge inverter circuit and two relays connected to the opposite angle of the H-bridge inverter circuit. During magnetizing, DC voltage is output through the relays, and during demagnetizing, the output is switched to the H-bridge inverter circuit and connected to the electromagnetic chuck. The control loop with monolithic computer controls the switching of the output voltage and the control of the output voltage amplitude. The present invention has rectifying bridge plus relay has high voltage fluctuation resistance, high antijamming capability, excellent demagnetizing effect, greatly lowered magnetizing power consumption and other advantages.

Owner:西安鸣士机电开发有限公司

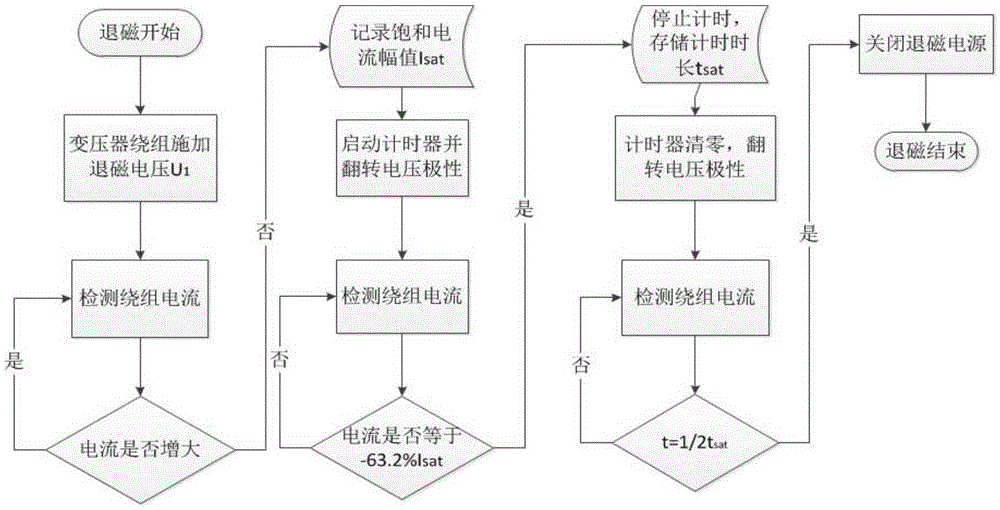

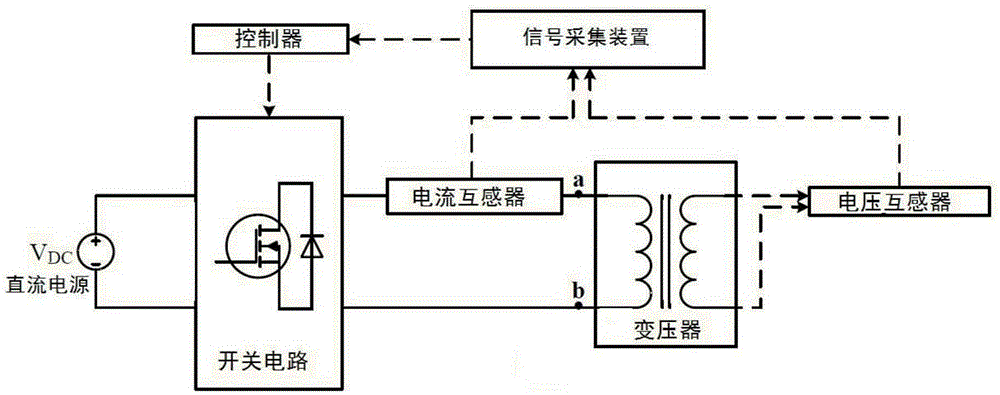

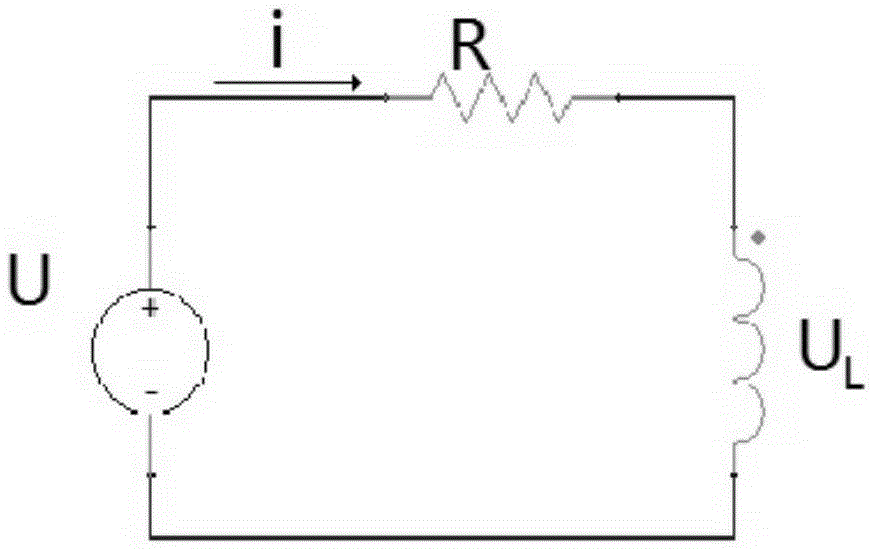

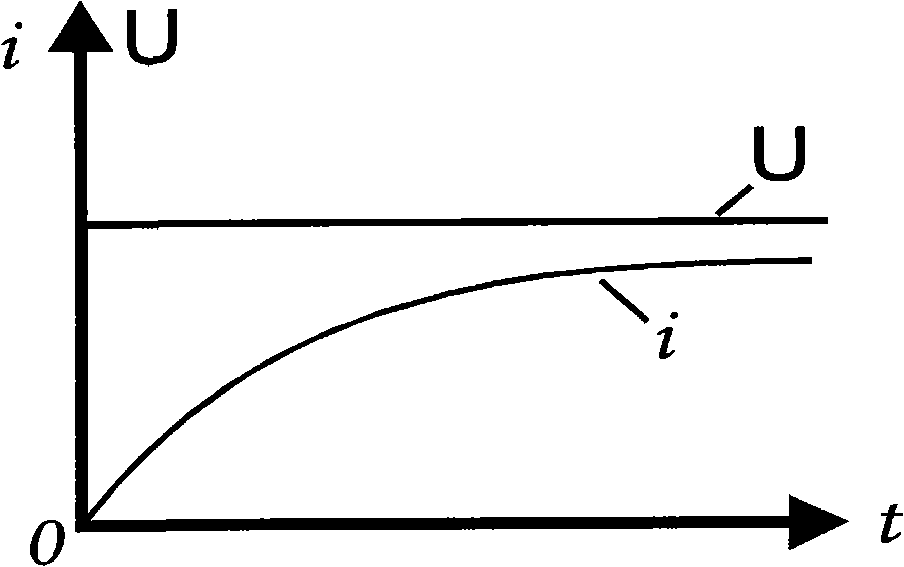

Transformer iron core demagnetization method

ActiveCN105280331AShort time required for demagnetizationImprove demagnetization effectMagnetic bodiesElectrical resistance and conductanceTransformer

The invention discloses a transformer iron core demagnetization method and especially provides a method for demagnetizing the iron core of a transformer after the DC resistance test. According to the invention, the voltage is applied onto the primary winding of a transformer by a DC power supply for three times, wherein the voltage-applying amplitude is the same each time and the polarity thereof is alternately changed. The voltage-applying duration is determined based on the acquired current waveform of the primary side of the transformer. During the first two times, the current applied onto the primary winding of the transformer reaches a forward peak value and a reverse peak value respectively. During the third time, the current applied onto the primary winding of the transformer occupies only half of the duration from the forward peak value to 63.2% of the reverse peak value. Through the above three voltage application processes, the iron core of the transformer is demagnetized. Based on the above method, the demagnetization duration is greatly shortened and the demagnetization effect is ensured at the same time. Meanwhile, the demagnetization equipment is small in power and good in practicality.

Owner:XI AN JIAOTONG UNIV +1

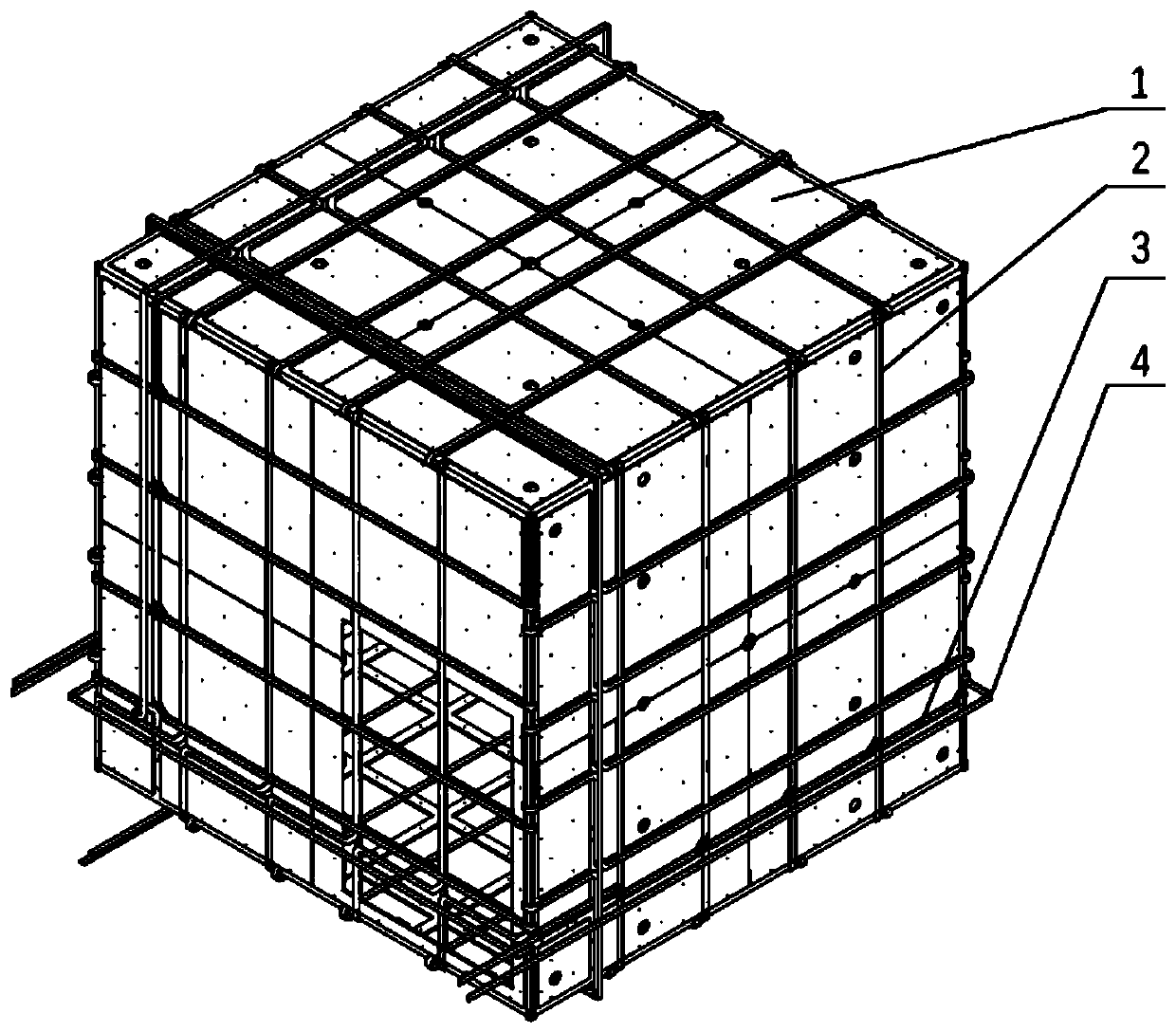

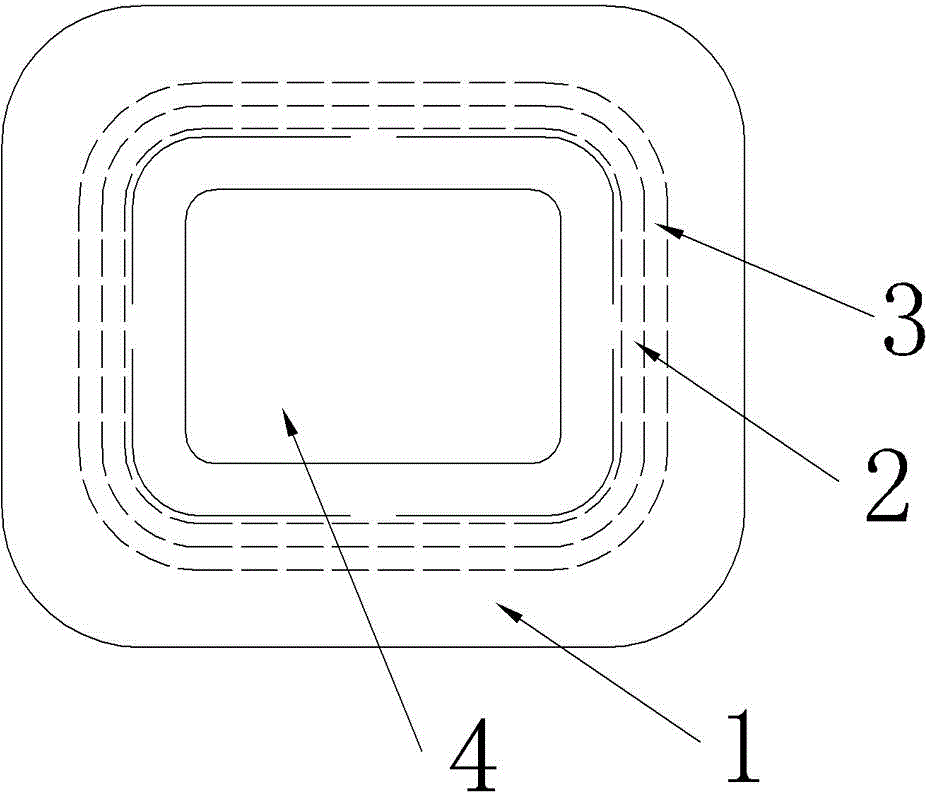

Demagnetizing method of multilayer shielding device

ActiveCN110970191AReduce static magnetic fieldAvoid satietyMagnetic bodiesEngineeringMechanical engineering

The invention relates to a demagnetization method of a multilayer shielding device; the demagnetization method realizes demagnetization based on a demagnetization coil system, and the demagnetizationcoil system comprises a multi-turn demagnetization coil, a plurality of connecting wires and a power supply module; the multi-layer shielding device comprises at least two layers of shielding bodies,the shielding bodies are sleeved layer by layer from inside to outside, multiple turns of demagnetization coils are wound on each layer of shielding body at intervals, one half of each turn of demagnetization coil is located on the inner side of the wound shielding body, and the other half of each turn of demagnetization coil is located on the outer side of the wound shielding body; each demagnetization coil is connected to the power supply module through a corresponding connecting wire; the power supply module comprises a controller, and the controller is connected with each connecting wire.The demagnetization method comprises the steps: introducing corresponding demagnetization currents into all the demagnetization coils, demagnetizing all the layers of shielding bodies layer by layer from inside to outside and then performing demagnetization layer by layer from outside to inside, wherein the intensity of the demagnetization currents is set according to the sizes of all the layers of shielding bodies. Compared with an existing demagnetization method, the method can effectively improve the demagnetization effect.

Owner:HARBIN INST OF TECH

Rotary classifying screen with de-magnetism function

InactiveCN106269245AWith demagnetization functionAvoid vibrationSievingScreeningEconomic benefitsPore diameter

The invention provides a rotary classifying screen with a de-magnetism function. The rotary classifying screen comprises a machine frame, a classifying device and de-magnetism devices. The classifying device comprises a power mechanism and a classifying mechanism. The power mechanism drives the classifying mechanism to operate. The classifying mechanism comprises a screen barrel and a screen body. A feeding hopper is arranged on the top of the screen barrel. An elastic supporting plate is arranged at the bottom of the screen barrel. The screen body is arranged inside the screen barrel. The screen body comprises a first screen face and a second screen face. The pore diameter of the first screen face is larger than that of the second screen face. A first discharging outlet, a second discharging outlet and a third discharging outlet are arranged in the lower sides, corresponding to the three regions partitioned by the two screen faces and the screen barrel, of the screen barrel. Each discharging outlet is correspondingly provided with a valve. The three regions partitioned by the two screen faces and the screen barrel are each provided with one de-magnetism device. Each de-magnetism device comprises a drawer-type frame and a plurality of magnetic rods. The screening process is stable, the classifying efficiency is high, the service life is long, de-magnetism is performed while screening is performed, the technological steps are simplified, the working efficiency is high, and economic benefits are good.

Owner:TIANJIN KAIFENGYI TECH CO LTD

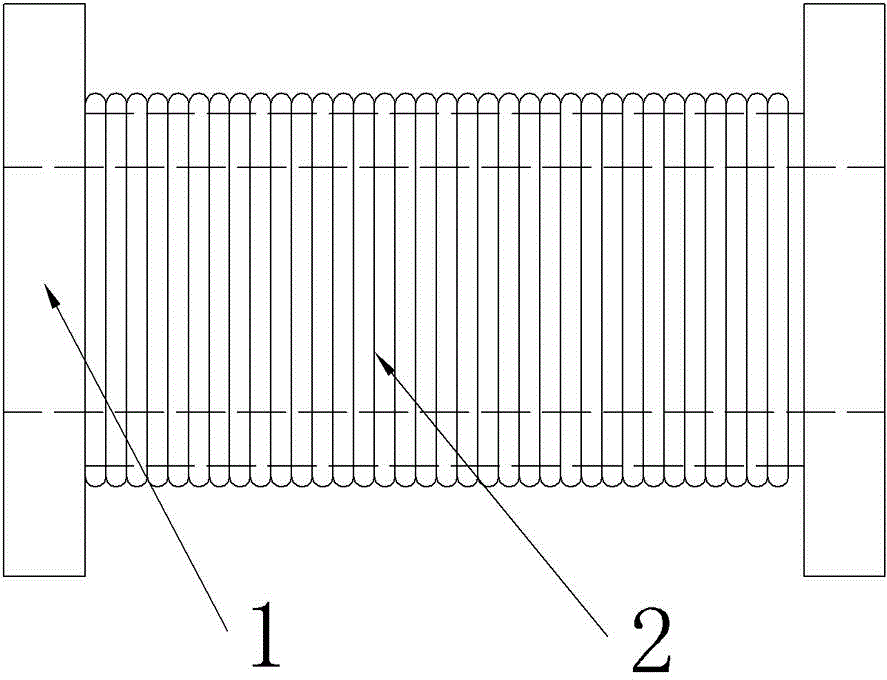

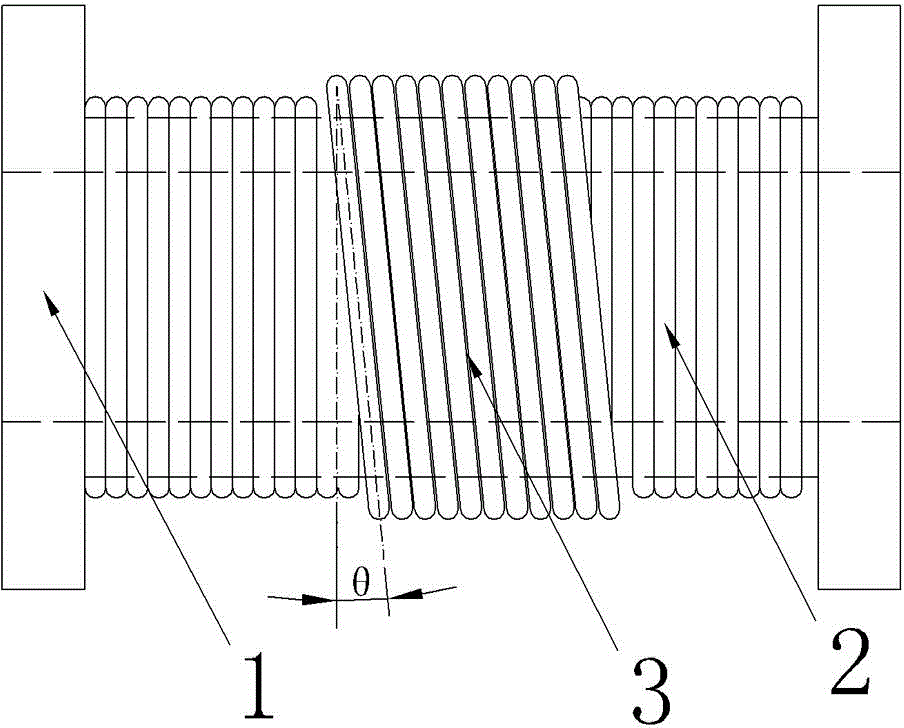

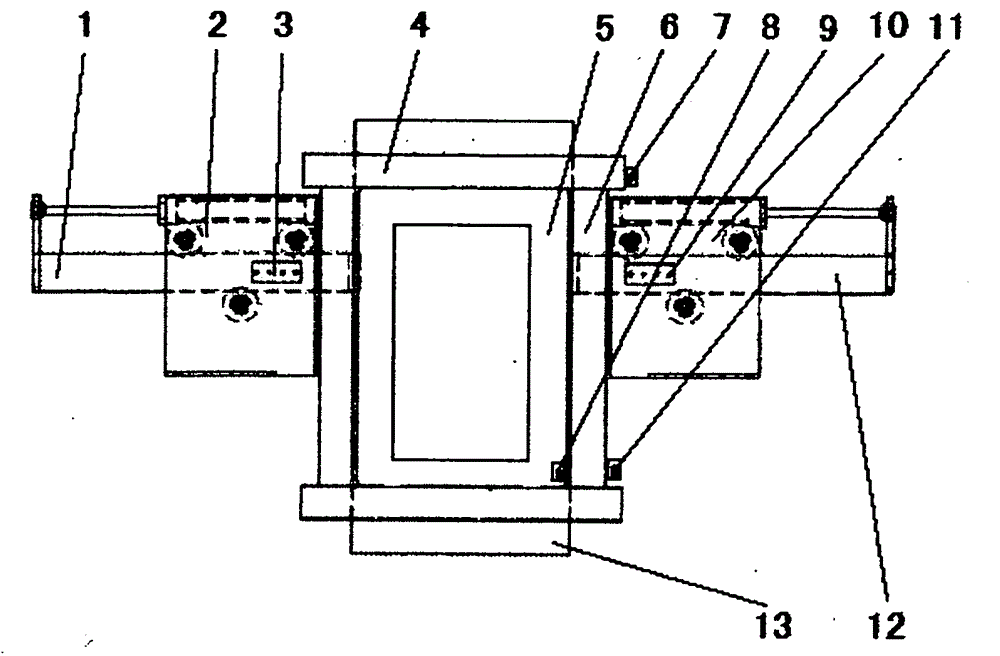

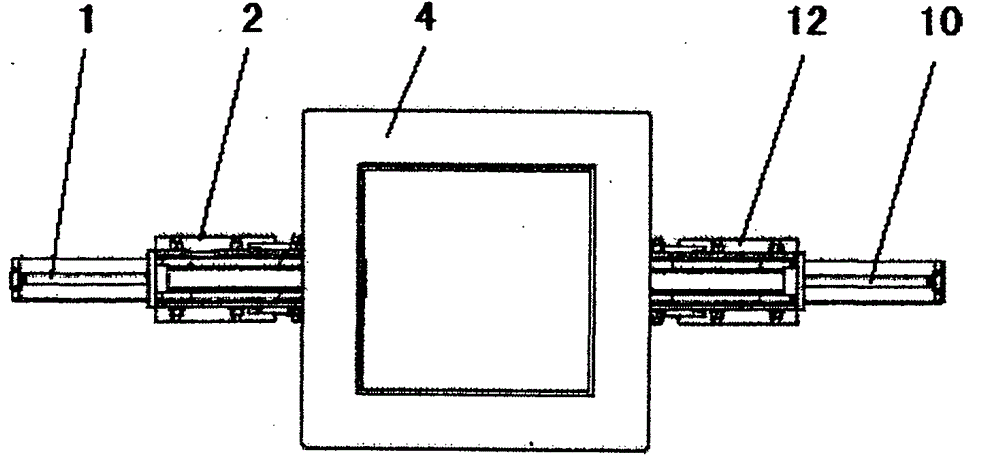

Bearing ring demagnetizing device

InactiveCN104538150ASolve the problem of excessive residual magnetismImprove demagnetization effectMagnetic bodiesDemagnetizing deviceRemanence

The invention relates to the field of bearing machining, in particular to a bearing ring demagnetizing device. A sensor in the bearing ring demagnetizing device is used for detecting an external bearing ring signal and transmitting the signal to a CPU. A data input and display unit inputs demagnetizing curve parameters to the CPU and displays demagnetizing parameter information. First and second drive circuits receive the demagnetizing curve parameters of the CPU and control current changes of first and second layer coils respectively, so that changes of a demagnetizing magnetic field are controlled for demagnetizing. The included angle between the winding direction of the second layer coil and the winding direction of the first layer coil ranges from 20 degrees to 45 degrees. The number of turns of the second layer coil is 30-40% that of the first layer coil. The first layer coil participates in the whole demagnetizing process, the second layer coil participates in demagnetizing only at the last stage of demagnetizing, namely during the period not exceeding 25% of the total time, and the second layer coil assists in eliminating the final residual magnetism intensity of bearing rings. The bearing ring demagnetizing device can well solve the problem of too much residual magnetism caused by incomplete demagnetizing of bearing ring demagnetizing equipment, is simple and small in structure, convenient to assemble and good in demagnetizing effect, and the residual magnetism of the device is smaller than 0.1 mT.

Owner:HENAN MECHANICAL & ELECTRICAL ENG COLLEGE

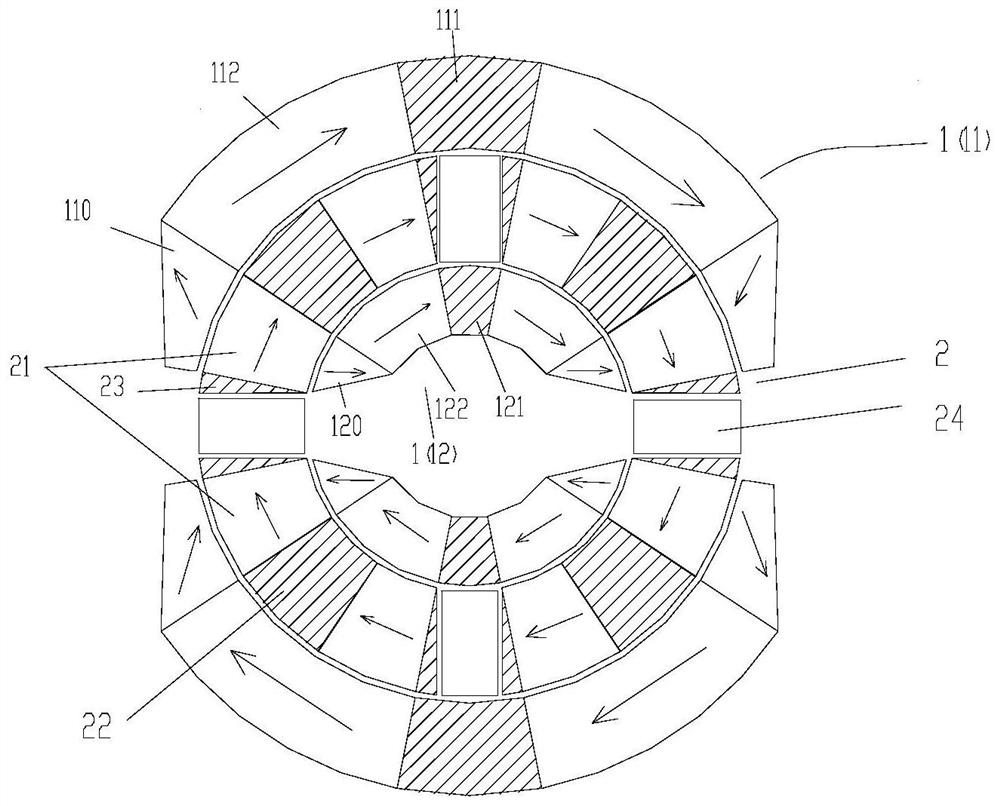

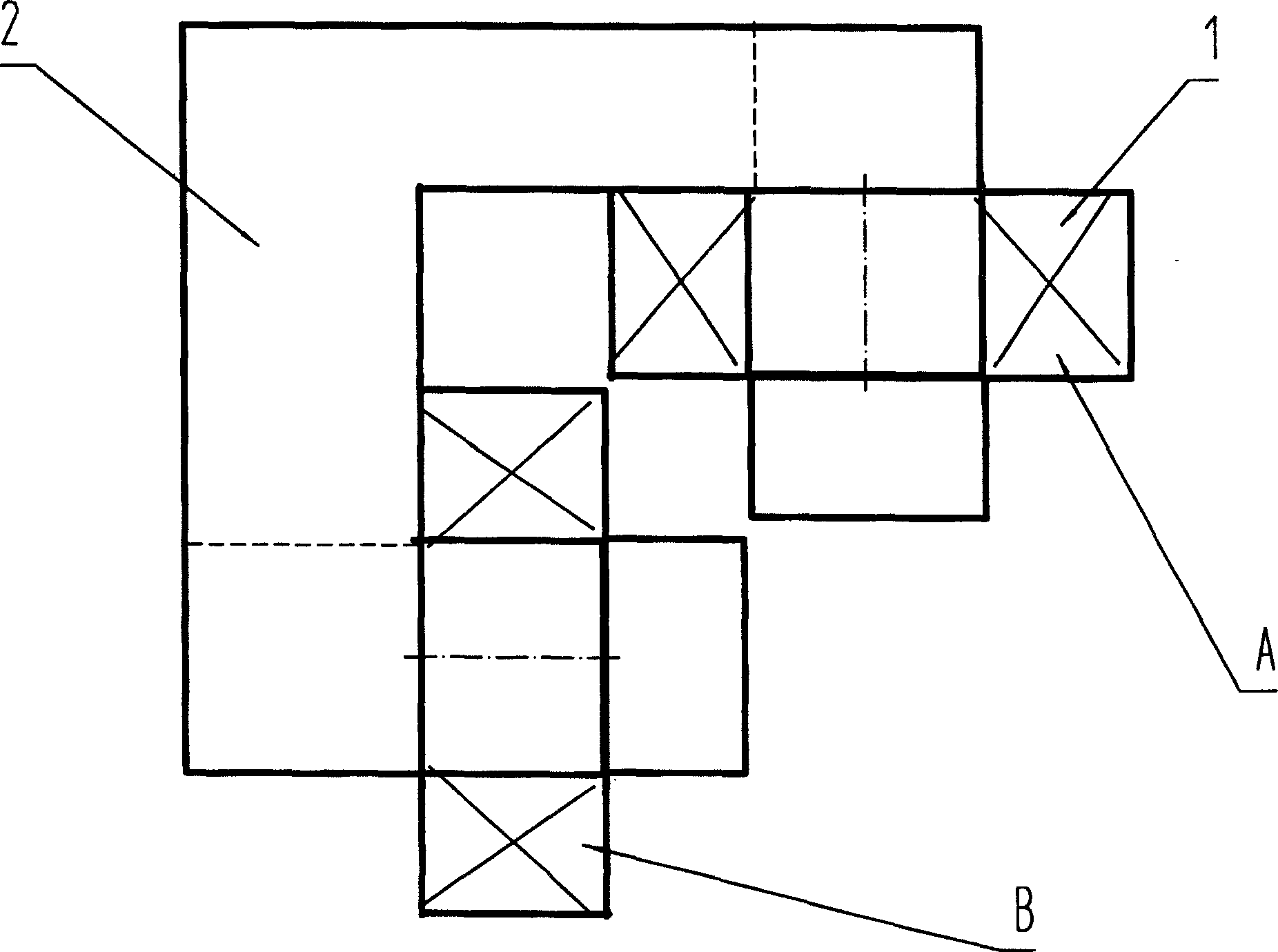

Magnetic refrigeration device

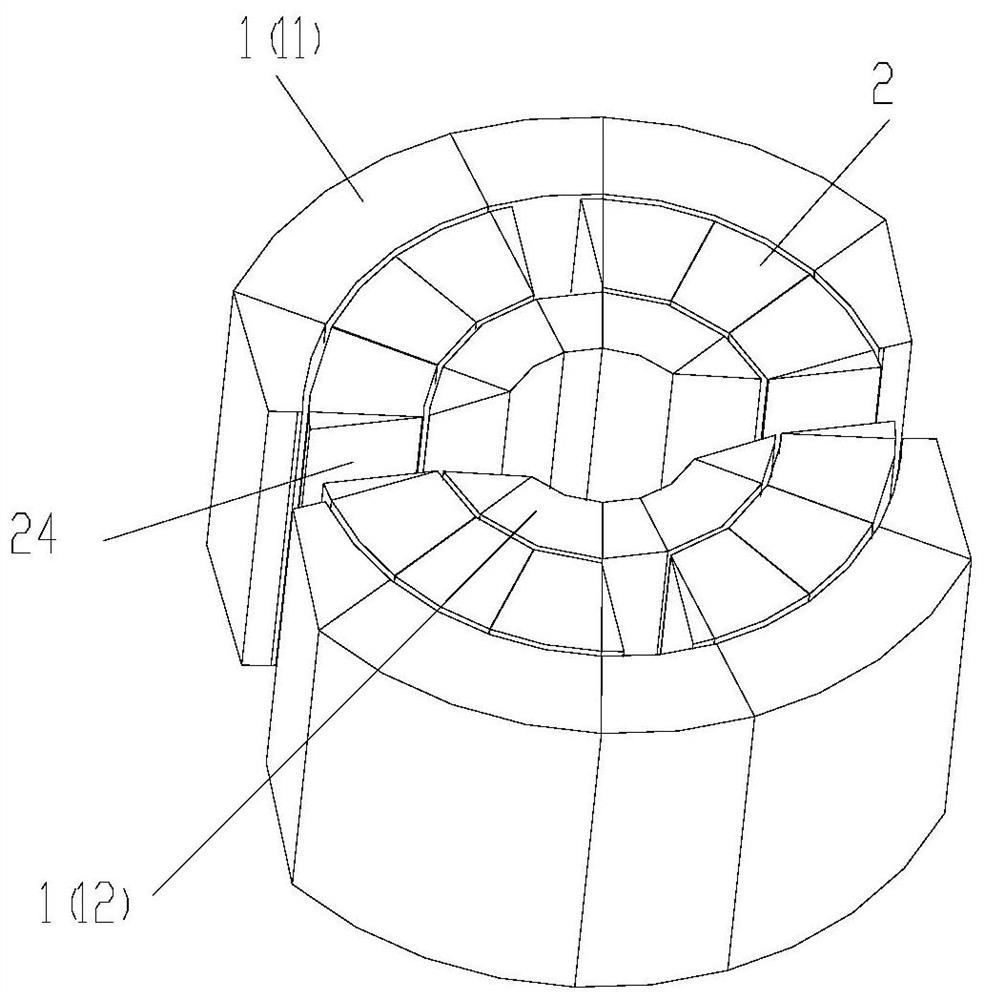

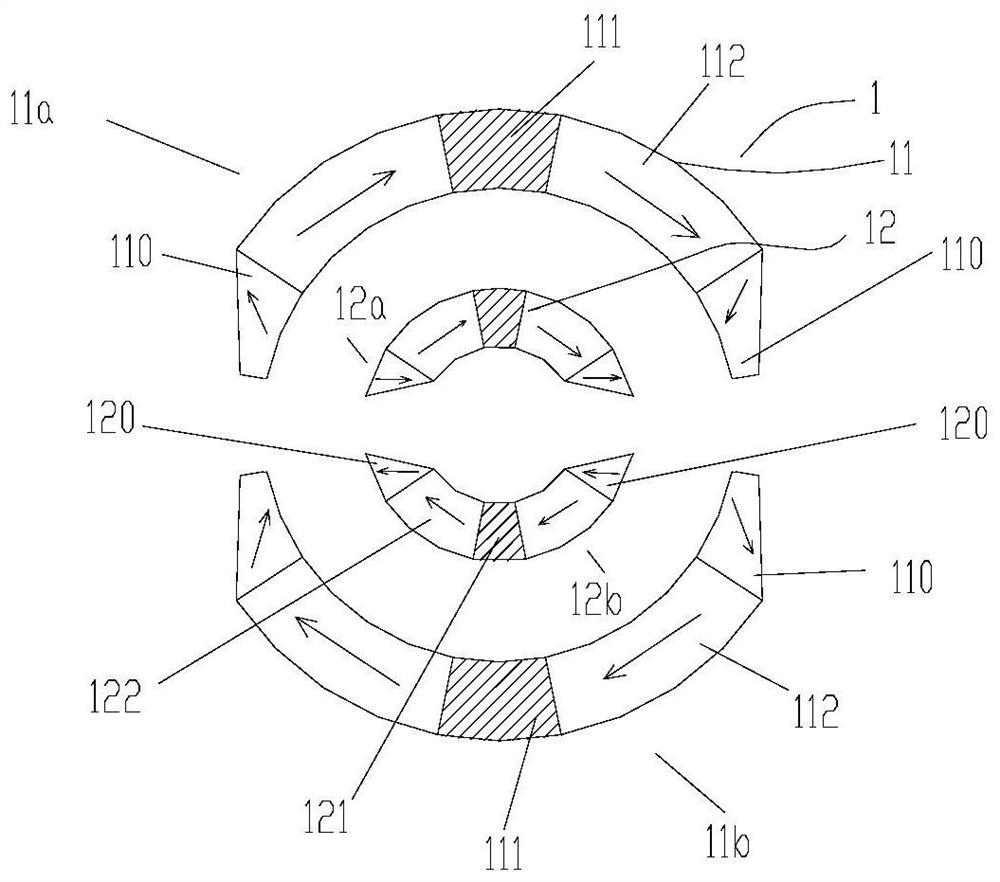

PendingCN111912136AIncrease the volume of the air gapIncrease the effective working spaceMagnetsMachines using electric/magnetic effectsPhysicsMagnetic line

The invention provides a magnetic refrigeration device which comprises a first assembly (1) and a second assembly (2). The second assembly (2) is an annular assembly, the first assembly (1) is locatedat the radial outer side or the radial inner side of the second assembly (2), the first assembly (1) is a first magnet assembly, and the second assembly (2) is provided with an air gap space capableof containing a magnetic working medium bed (24). The first assembly (1) and the second assembly (2) can do relative rotation motion, and the magnetic force line direction of the first magnet assemblyis distributed in the circumferential direction of the annular second assembly (2). According to the magnetic refrigeration device, the radial size of the second assembly can be made larger, the containing air gap volume of the magnetic working medium bed is increased, the quantity of magnetic working media or the actual effective working space of magnets is increased, the refrigeration or heating effect of the magnetic refrigeration device is improved, and the refrigeration or heating performance of the magnetic refrigeration device is improved.

Owner:GREE ELECTRIC APPLIANCES INC

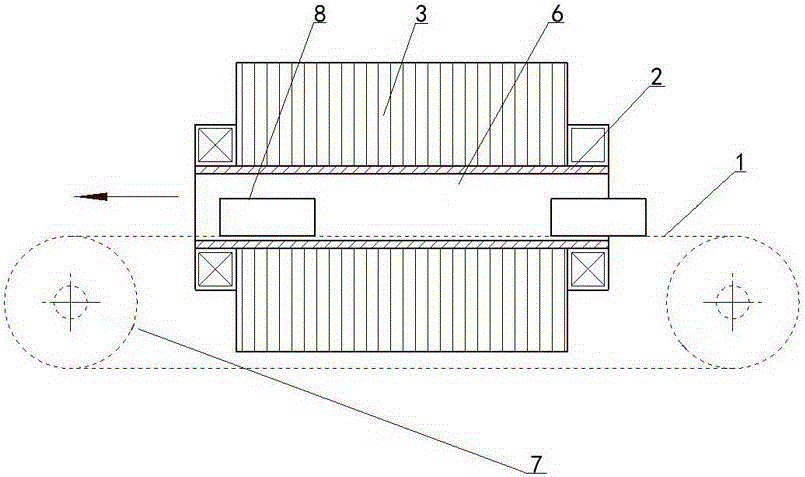

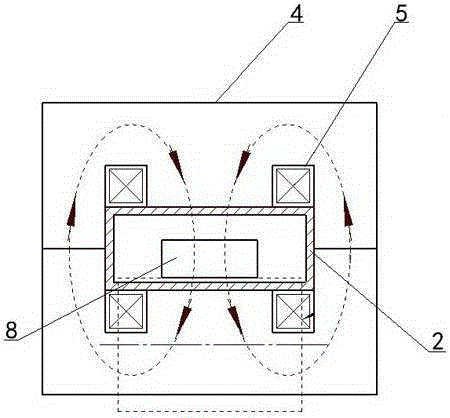

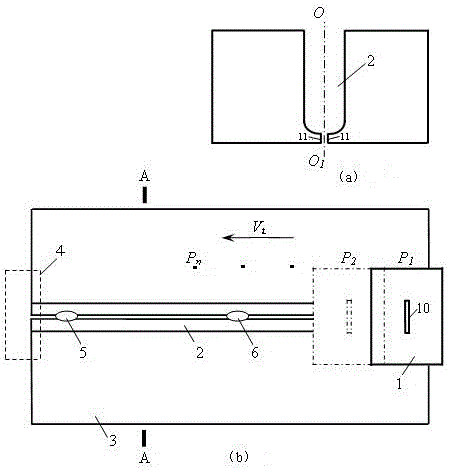

Magnetic gap channel pass-type demagnetizer

InactiveCN105225790ADemagnetization pass rate increasedAvoid influenceMagnetic bodiesEngineeringMechanical engineering

The invention relates to a magnetic gap channel pass-type demagnetizer, comprising a belt conveyer, a magnetic gap channel frame, and a demagnetization assembly. The demagnetization assembly comprises two E-shaped iron cores and coil windings matched with the iron cores. The E-shaped iron core is provided with three iron core columns, and the iron core column on the middle is shorter than the iron core columns on two ends. A coil winding is sleeved on the iron core column on the middle. The coil windings are connected with a demagnetization circuit. After openings of the two E-shaped iron cores are joined oppositely, a magnetic gap channel is formed. The magnetic gap channel frame passes through the magnetic gap channel. The conveyer belt on the upper end of the belt conveyer is arranged passing through the magnetic gap channel frame. Two guiding wheels of the belt conveyer are respectively arranged on two ends of the magnetic gap channel frame. The conveyer belt on the upper end of the belt conveyer is supported by the magnetic gap channel frame. The magnetic gap channel pass-type demagnetizer can improve magnetic field intensity of a magnetic field, and effectively improve demagnetization quality of workpiece, and reduce energy consumption, and improve processing precision of products.

Owner:LUOYANG BEARING SCI & TECH CO LTD

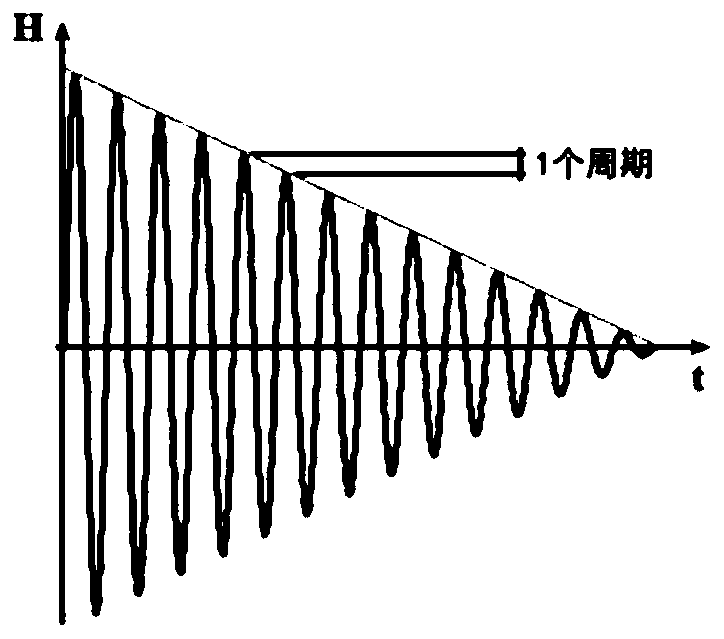

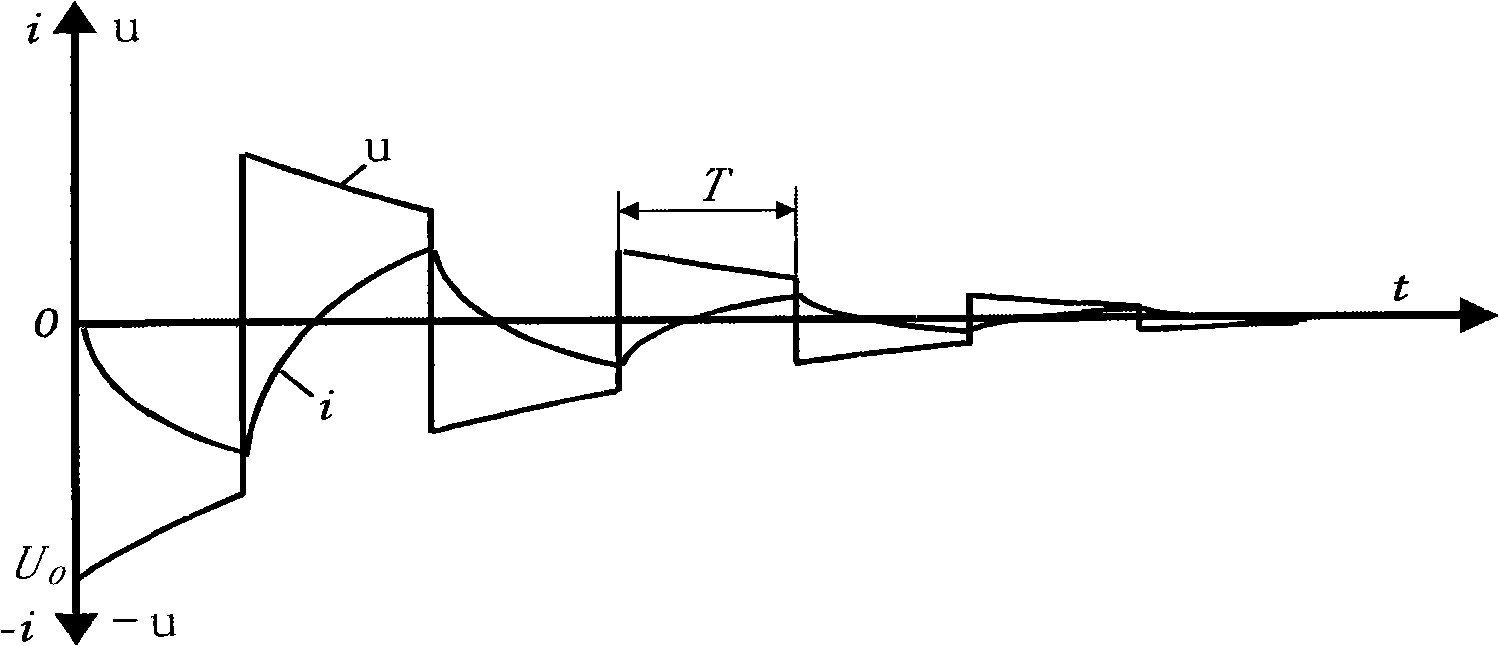

Method for frequency-adding and demagnetization for relatively static object

InactiveCN101325113AEasy to controlImprove efficiencyMagnetic bodiesElectrical polarityVoltage polarity

The invention discloses a method for performing frequency boosting and demagnetization to the relative static object. The key technology of the method lies in that a electromagnetic conversion device with inductance property and then a relative static object are provided; the method controls the current flowing through an electromagnetic conversion and demagnetization device by changing the time for applying voltage; the magnitude of the applied voltage is invariable during the process of a complete demagnetization, and the voltage polarities are alternately changed; the time for each applied polarity voltage is gradually reduced from long to short, and the frequency is gradually increased from low to high; as the frequency increases, the current of the electromagnetic conversion and demagnetization device is correspondingly reduced, thereby the electromagnetic conversion and demagnetization device generates the alternating magnetic field from strong to weak; under the action of the magnetic field, the electromagnetic conversion and demagnetization device as well as the static object to be demagnetized is demagnetized, and the method has the advantages of simple control, high efficiency and good and stable demagnetization effect: the identical demagnetization effect can be realized in a shorter time.

Owner:陈乃明

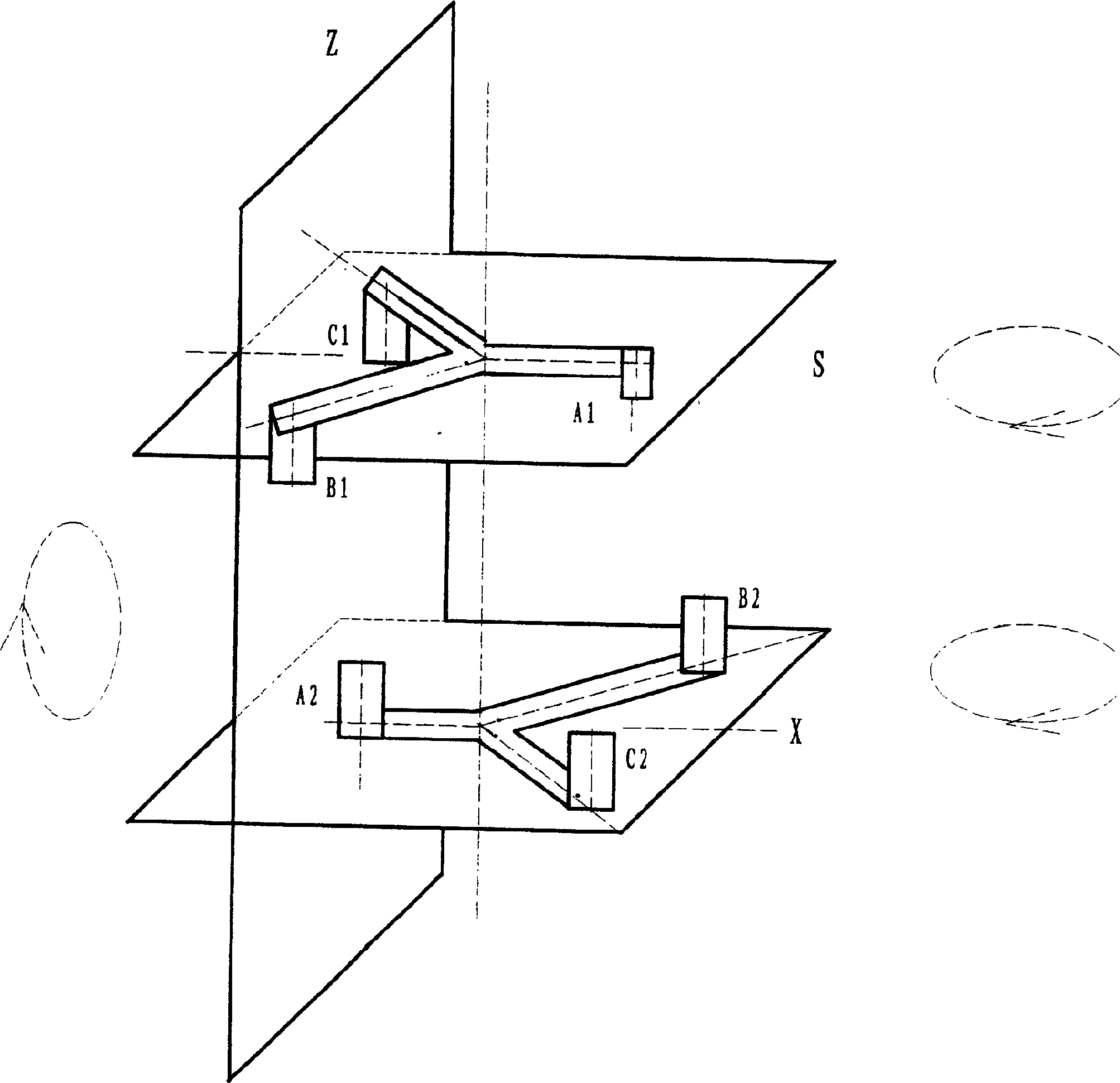

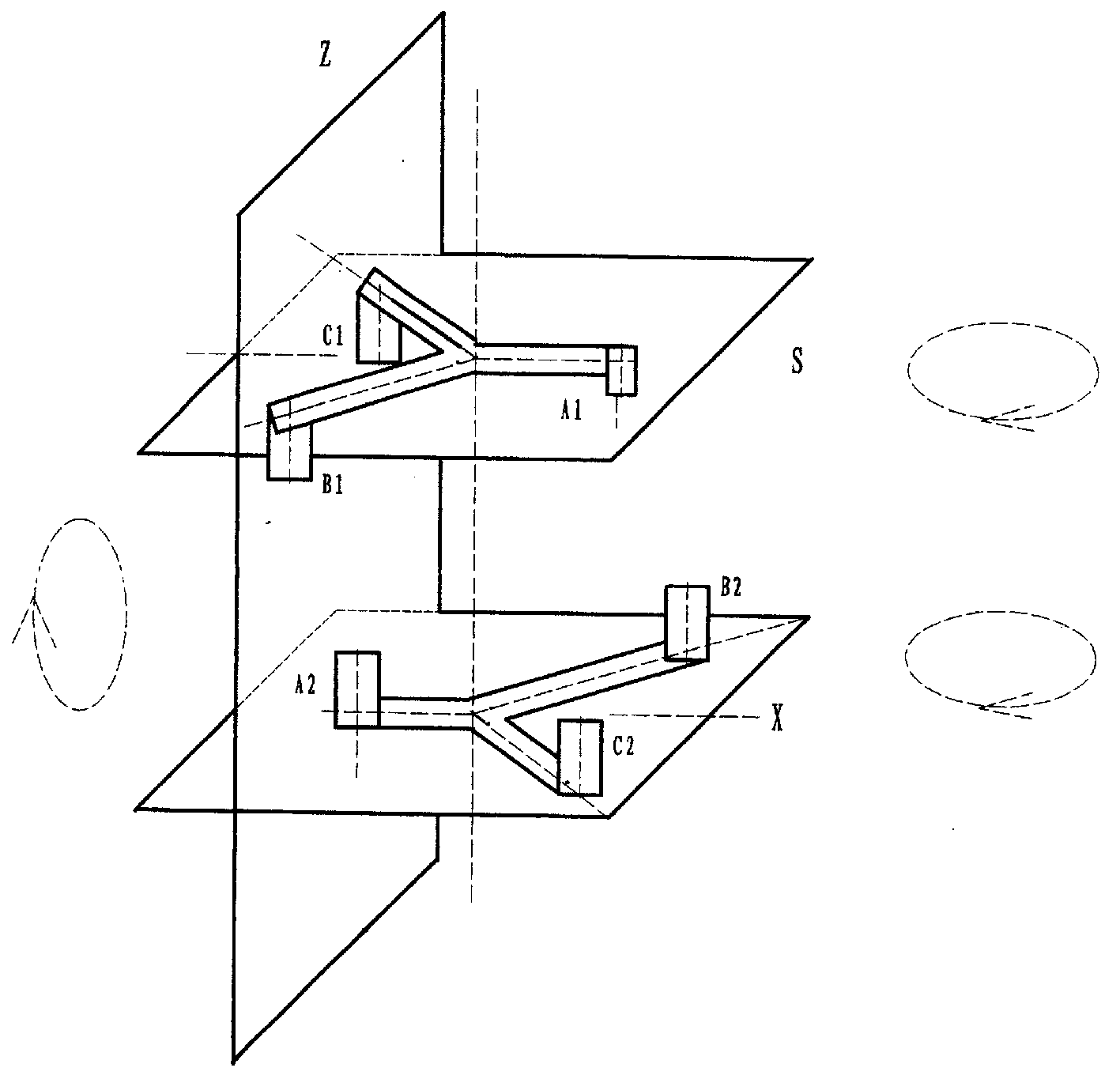

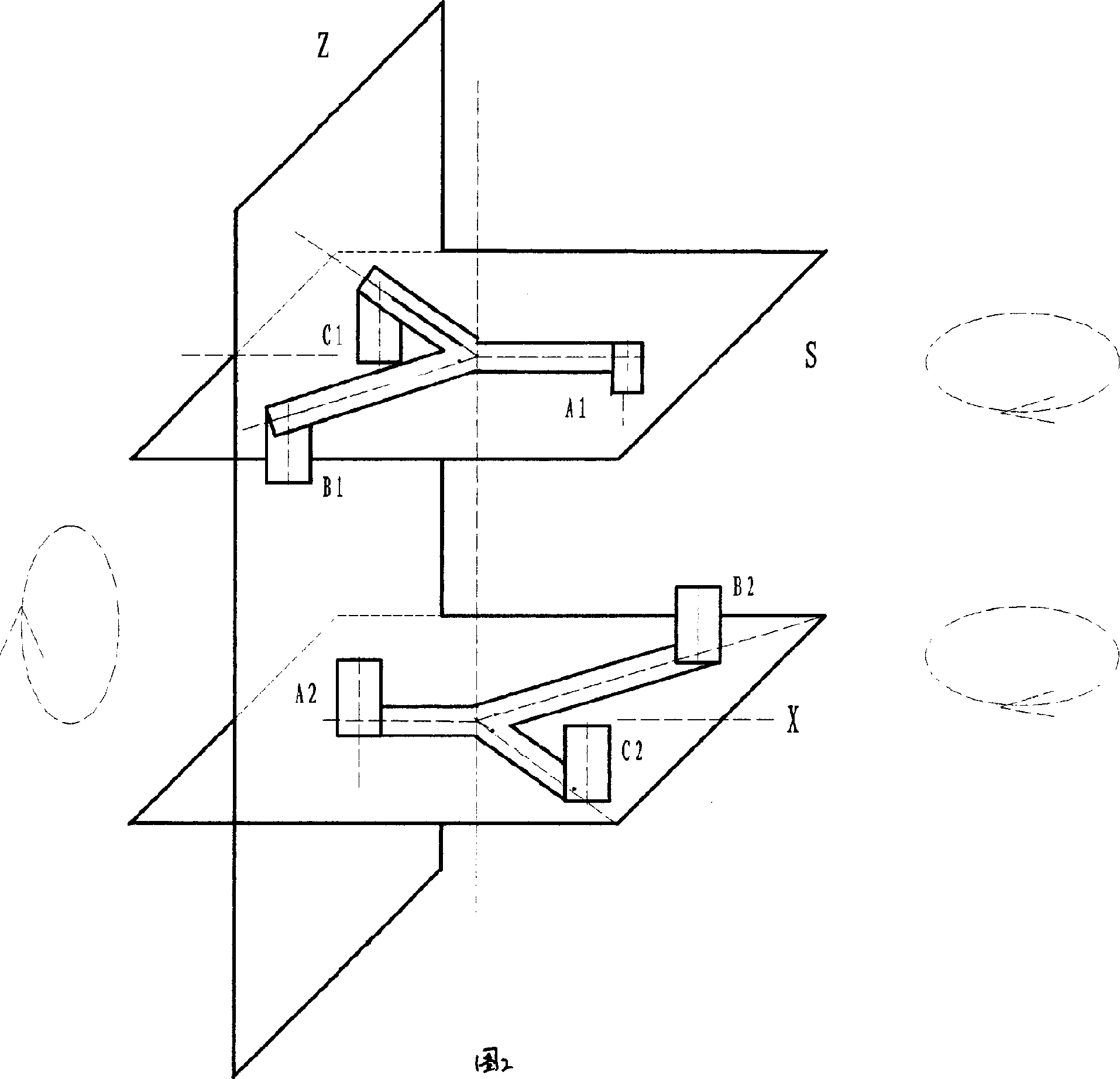

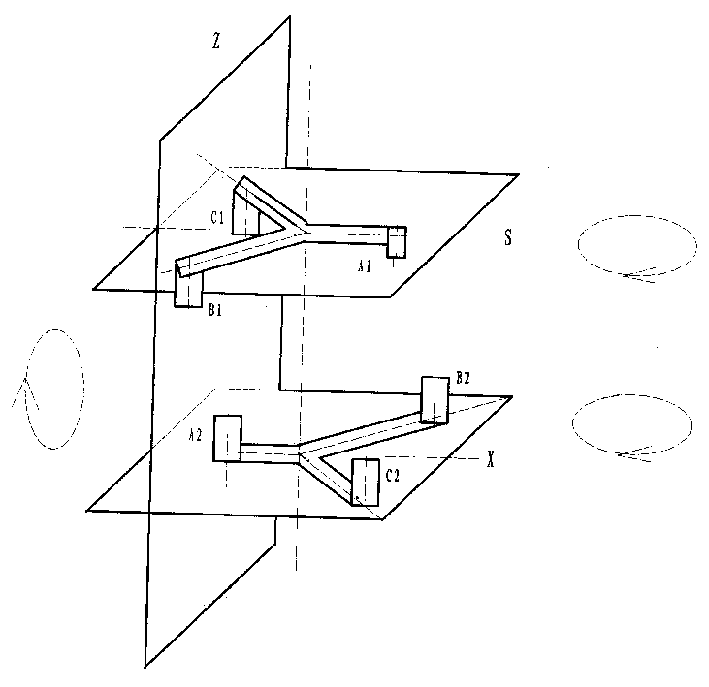

Space rotary alternating magnetic field demagnetizing pole set

InactiveCN1245727CSimplifies the demagnetization processImprove demagnetization work efficiencyMagnetic bodiesDemagnetizing fieldMagnetic poles

Disclosed demagnezing pole subassembly of spatial rotating alternating magnetic field includes one or two groups, and one demagnezing pole group includes multiple demagnezing poles. Being connected to AC power source in certain phase, pole winding is installed onto magnetic iron core constitutes a magnetic pole. Demagnezing poles are distributed in array, and each demagnezing pole is connected to AC power source in different phases. There are certain spatial distances between magnetic poles in demagnezing device so as to form spatial rotating alternating magnetic field. Thus, there are demagnetizing fields in space in any direction so that direction of residual magnetism in work piece does not need to be determined in advance. The invention raises demagnezing efficiency, applicable to fields such as milling process, detection of defects, precision work, instrument and meters.

Owner:夏恽

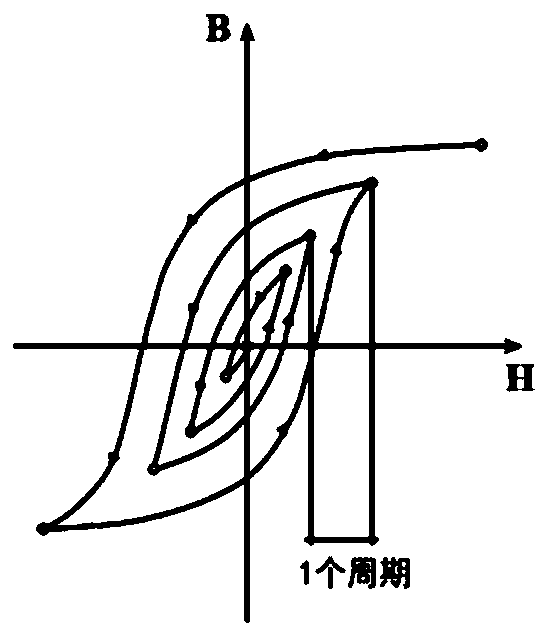

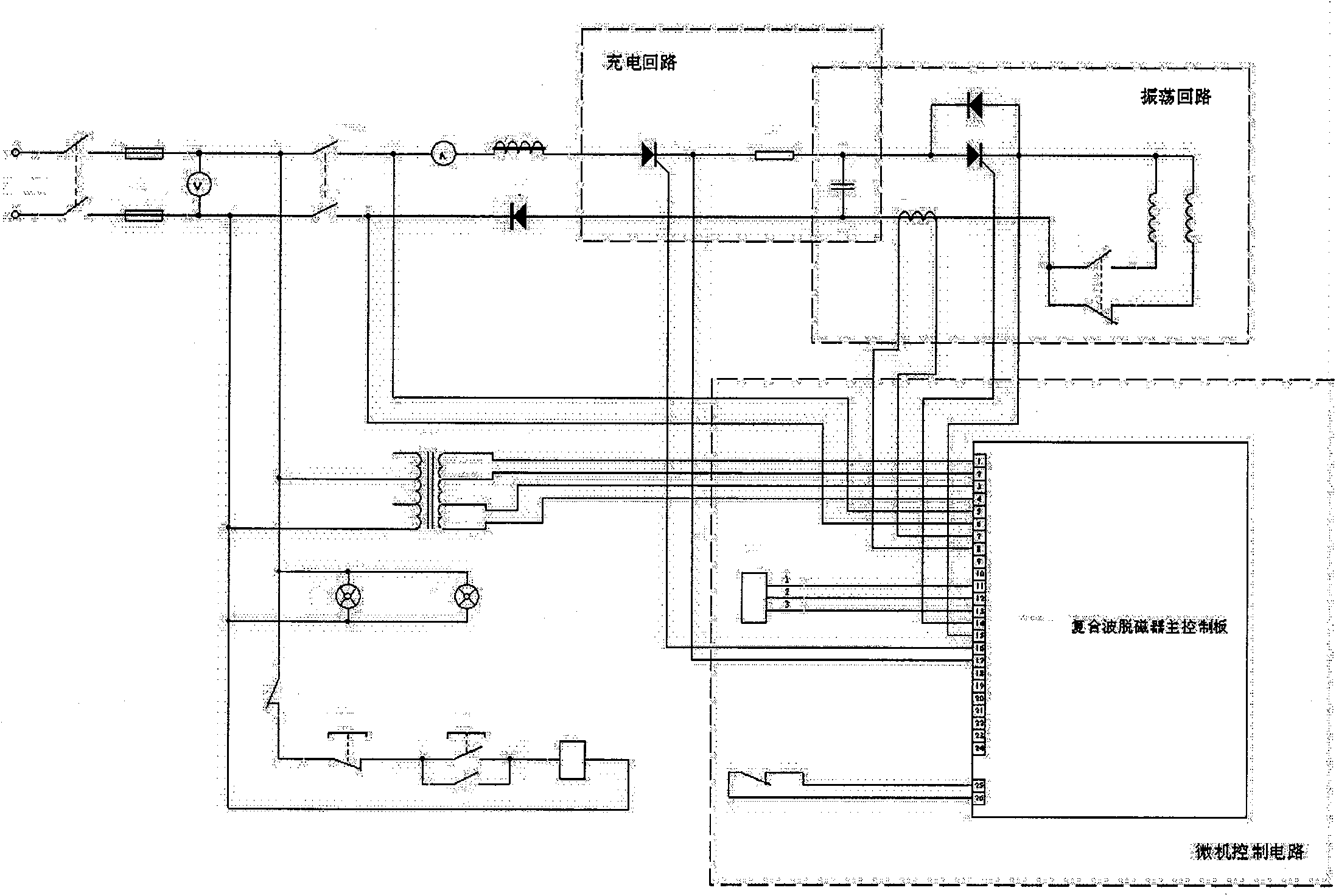

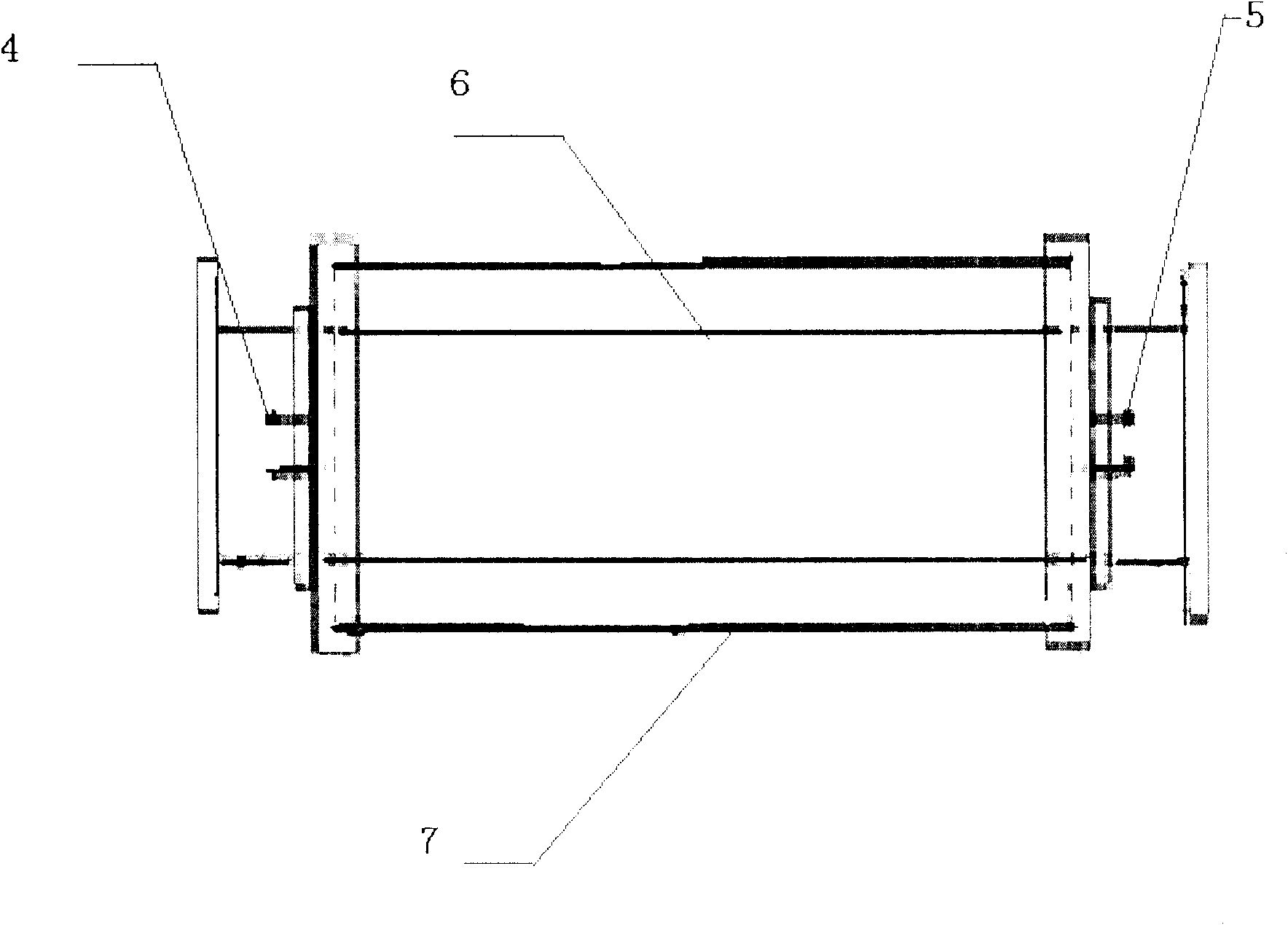

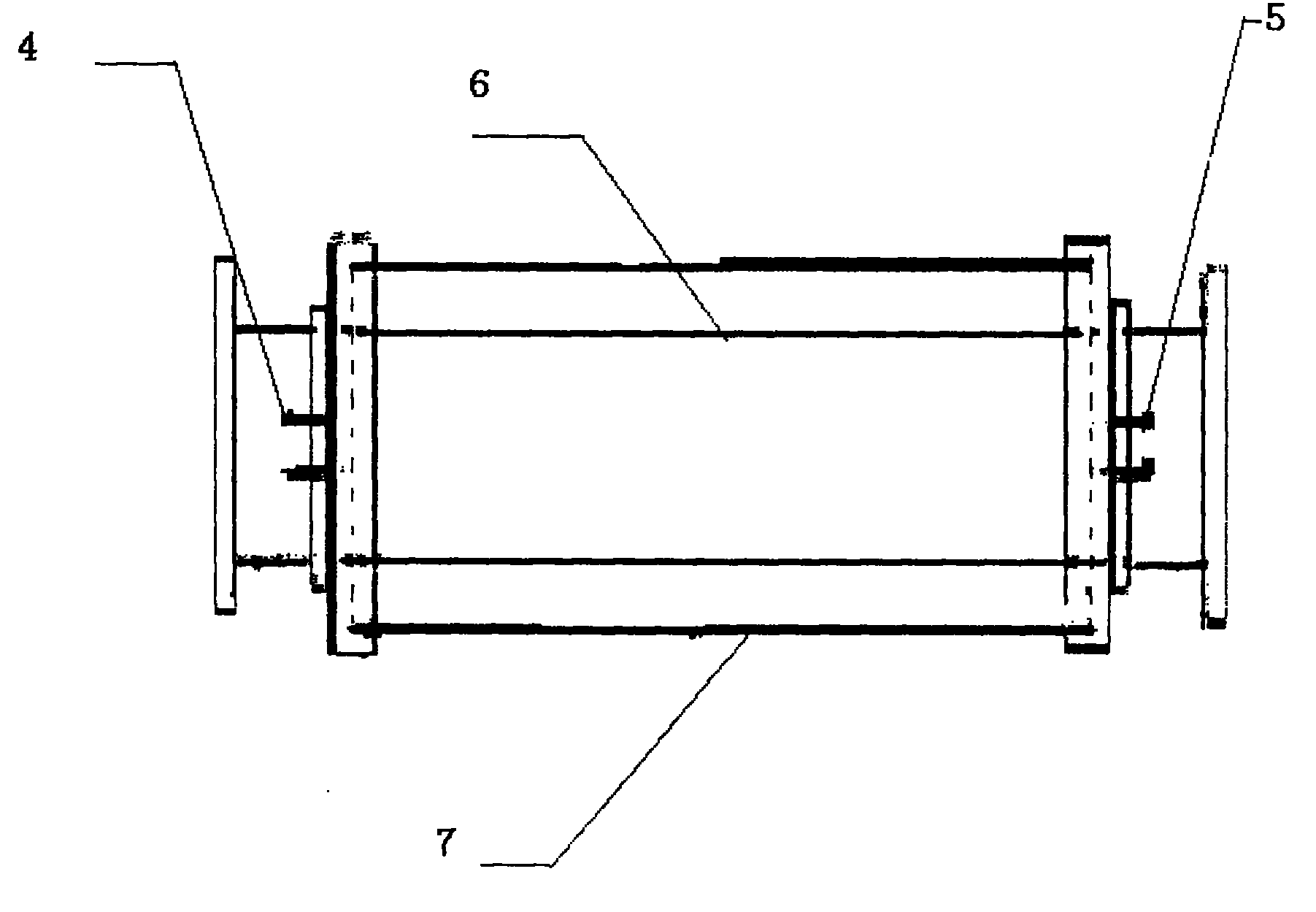

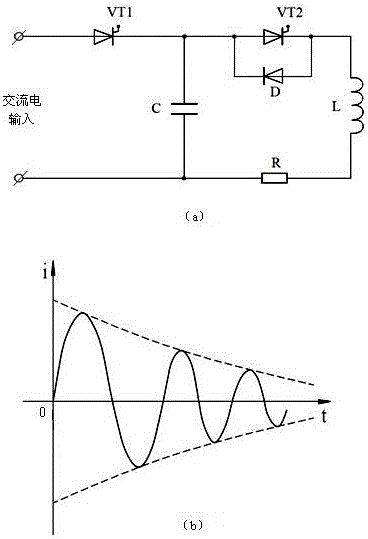

Compound wave demagnetizer

InactiveCN101923939AHighly integratedImprove interchangeabilityMagnetic bodiesMagnetic separationCapacitanceDual coil

The invention relates to a compound wave demagnetizer which comprises a charging circuit, an oscillation circuit and a microcomputer control system. The microcomputer control system is formed by using a capacitor and a demagnetizing coil and is connected with the oscillation circuit to produce damped oscillations, a first damped oscillation wave and a second damped oscillation with different frequencies and amplitudes are produced through the intelligent control system, and the two damped oscillation waves are synthesized to form a compound wave. The compound wave oscillating back and forth enables an alternating magnetic field with smaller axial gradient and larger field intensity to be produced in the coil, so that ore pulp is demagnetized after flowing across the coil. The alternate operating mode of dual demagnetizing coils is adopted, the ore pulp pipe is made of a nonmetal material, such as macromolecule polyethylene; the demagnetizing coils are divided into a group A and a group B. The coils have full specifications and are divided into a pipe type and a belt pipe. The compound wave demagnetizer has the advantages of high integration level, good interchangeability, simple operation, dual coil alternate operation, good demagnetizing effect and the like; and the input current is not greater than 3A, the demagnetizing field intensity is 80-160 kA / m, and the quality and the yield of iron powder in a metal mine can be effectively improved.

Owner:SHENYANG TGX MINE MACHINERY

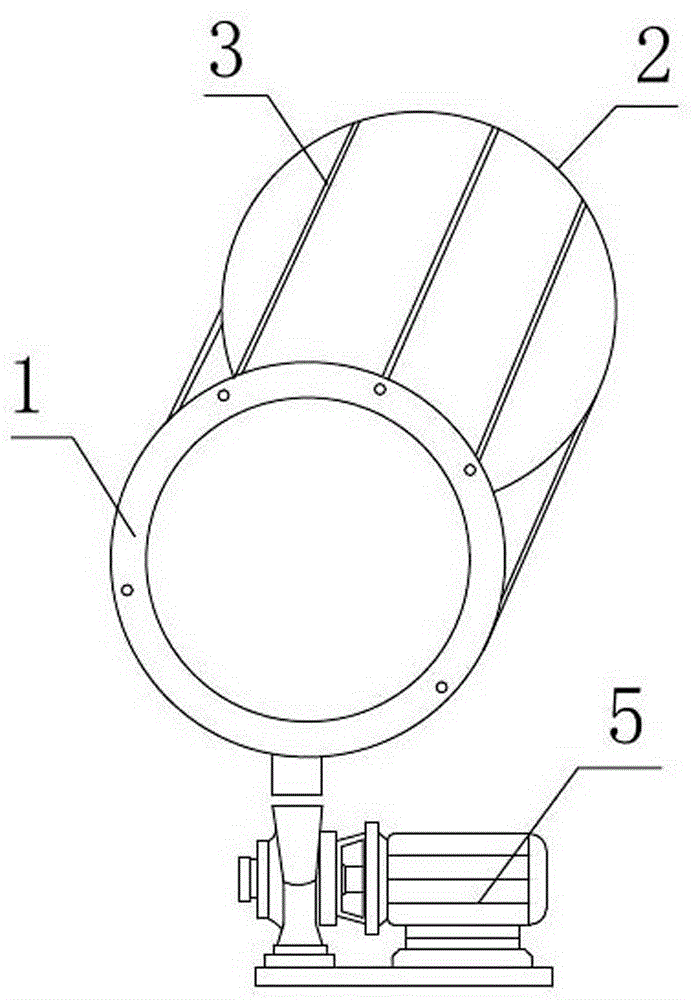

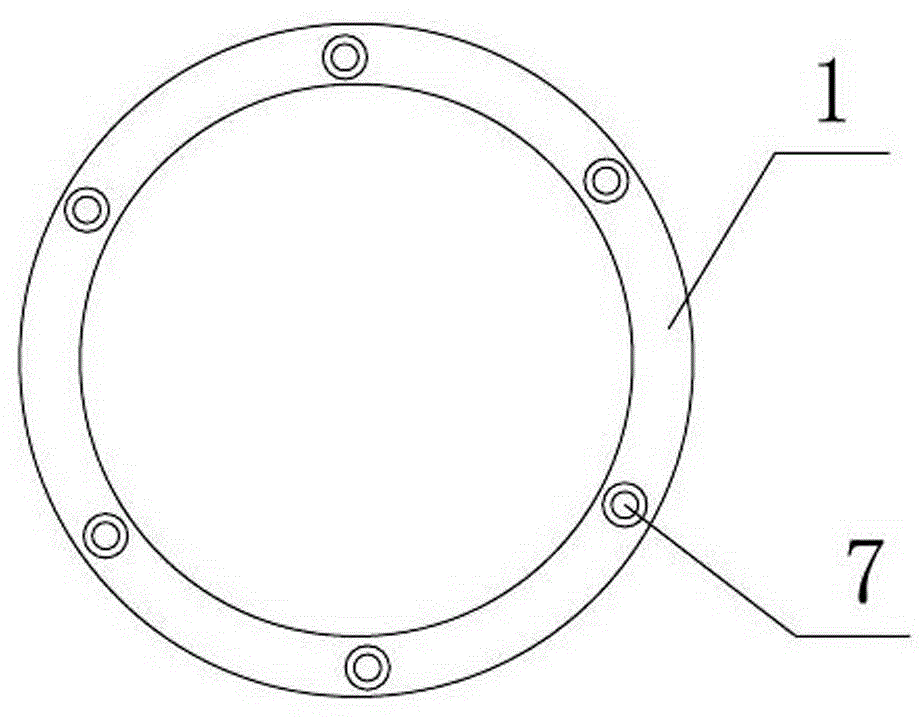

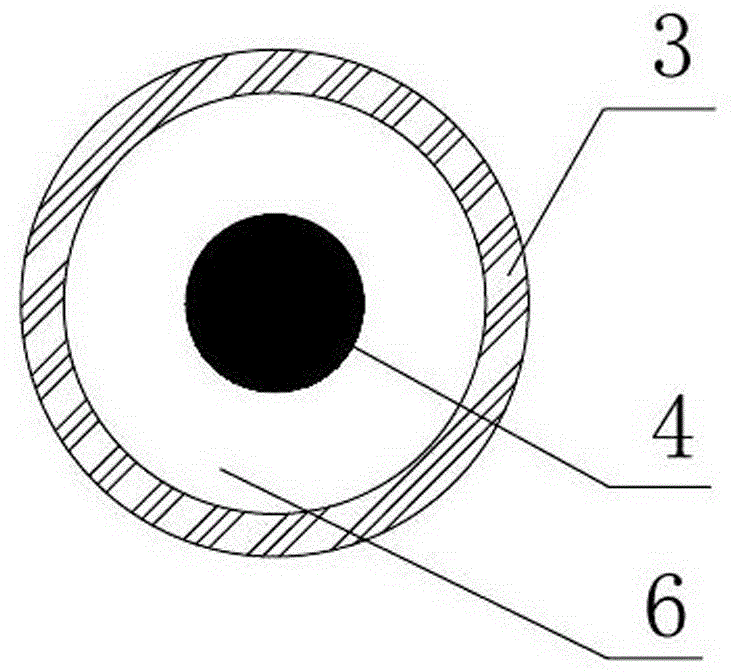

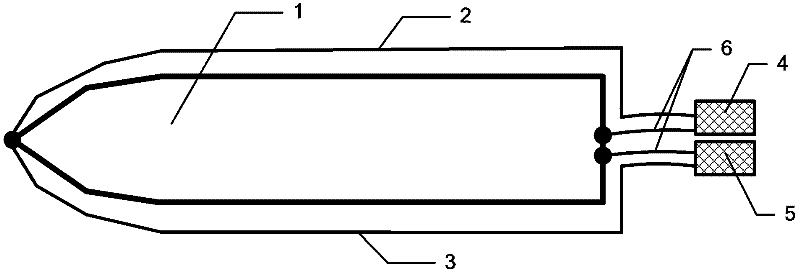

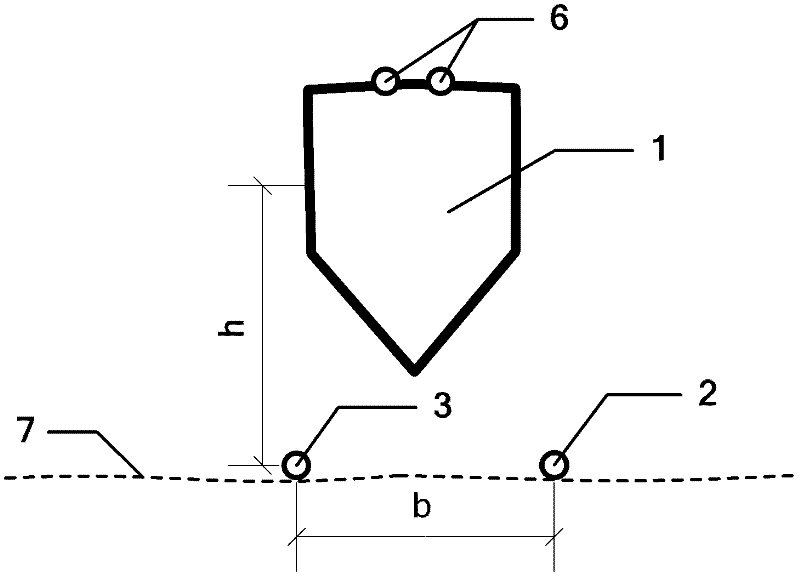

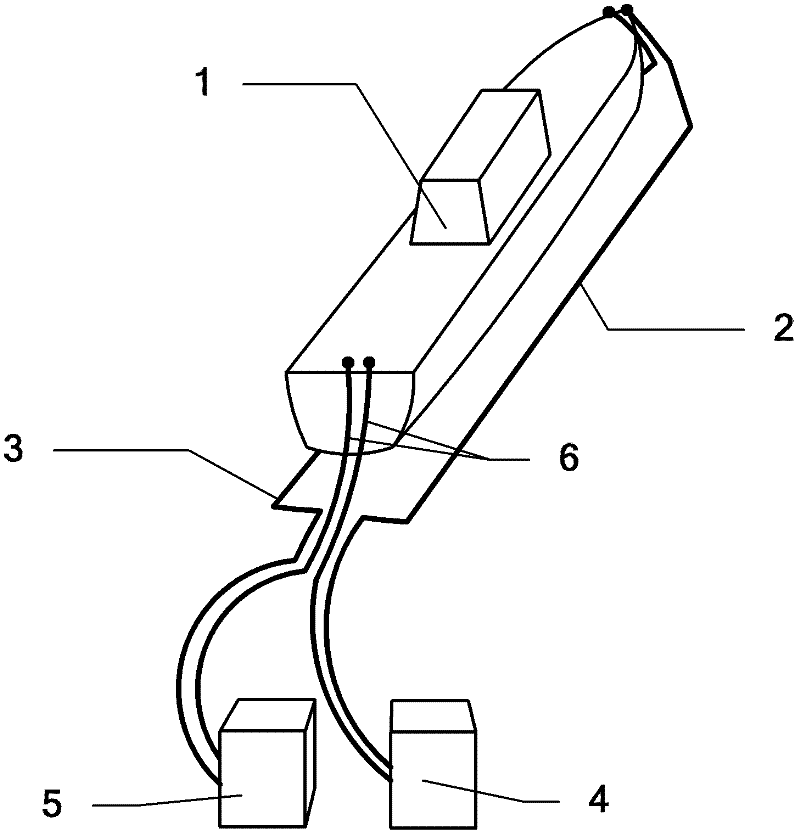

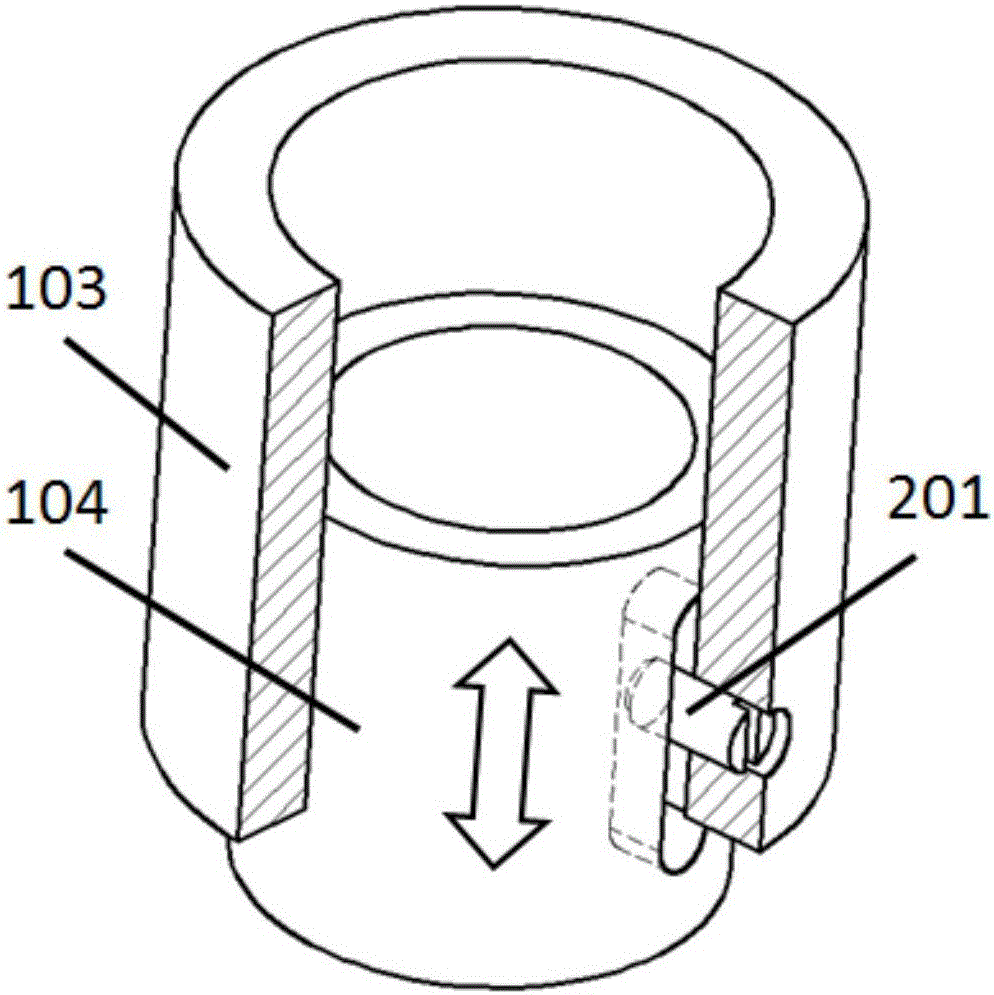

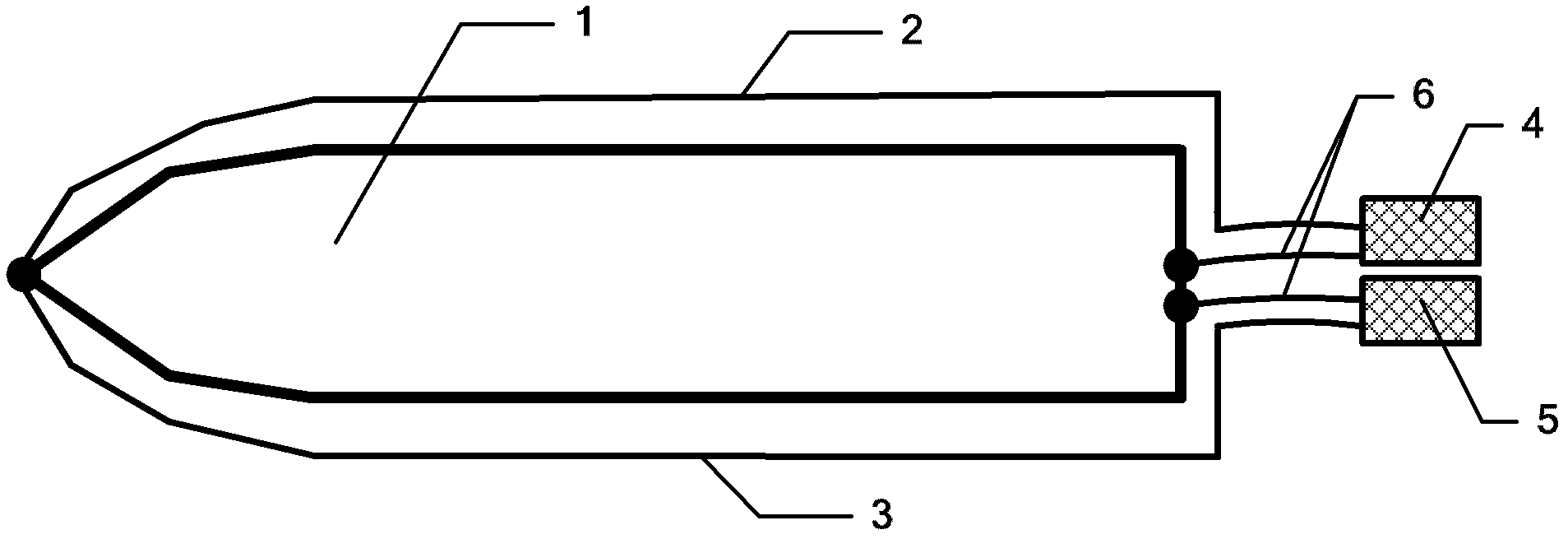

Rotary demagnetizer and lithium battery negative electrode material powder processing device

InactiveCN104599808AReduce volumeEasy to install and disassembleElectrode manufacturing processesMagnetic bodiesMetallurgyDemagnetizer

The invention provides a rotary demagnetizer and a lithium battery negative electrode material powder processing device. The rotary demagnetizer comprises an annular feeding disc and a discharging disc. The feeding disc corresponds to the discharging disc. Three to eight cylindrical stainless steel sleeves are arranged between the feeding disc and the discharging disc. An opening is formed in one end of each stainless steel sleeve, and movable magnetic bars are arranged in the stainless steel sleeves. The feeding disc or the discharging disc is connected with a motor providing rotation power. Magnetic matter in negative electrode material powder can be effectively removed, the quality of negative electrode materials is greatly improved, and the rotary demagnetizer has high application and popularization value.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

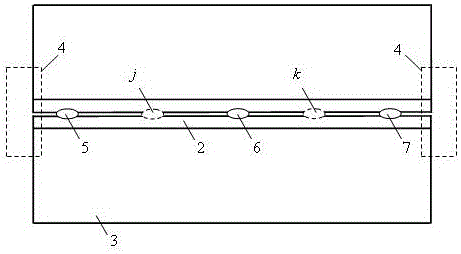

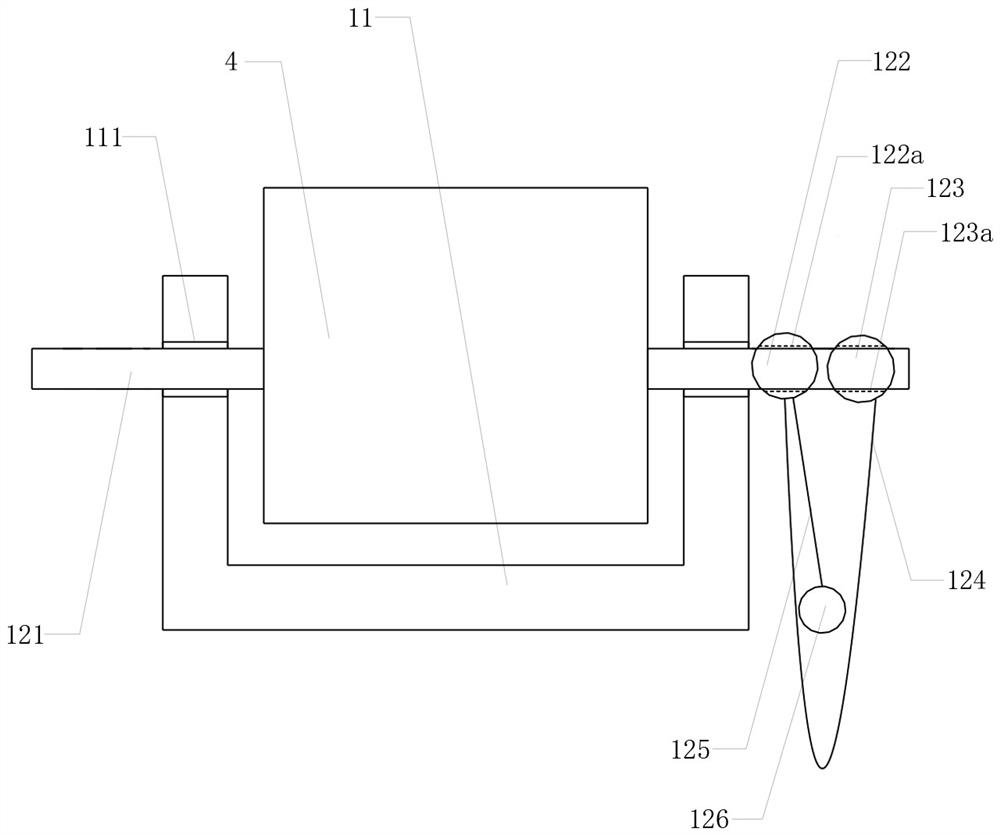

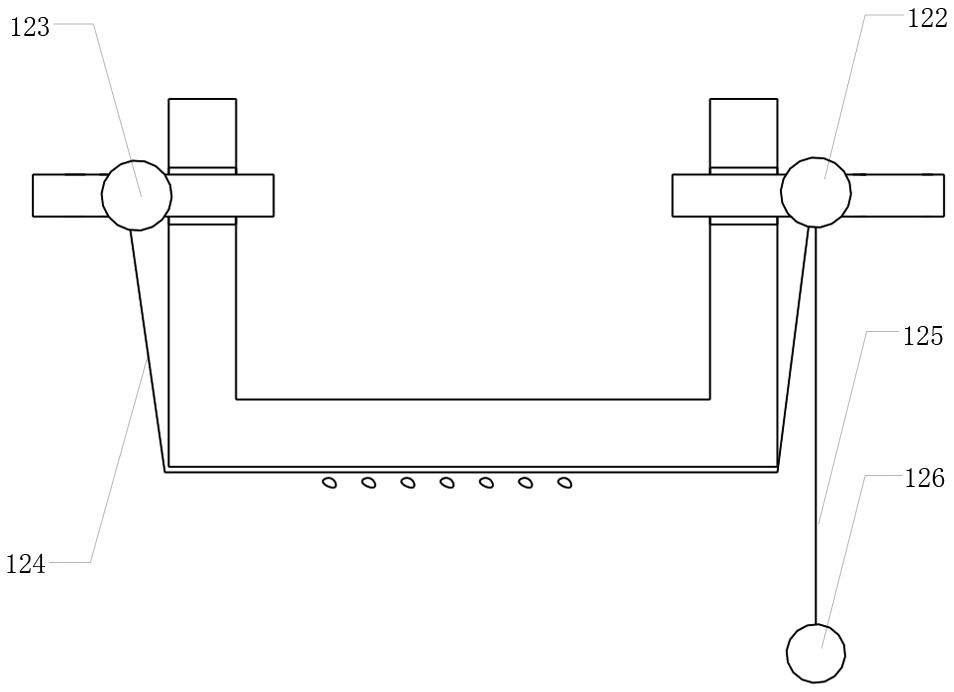

Double-track frame demagnetizer

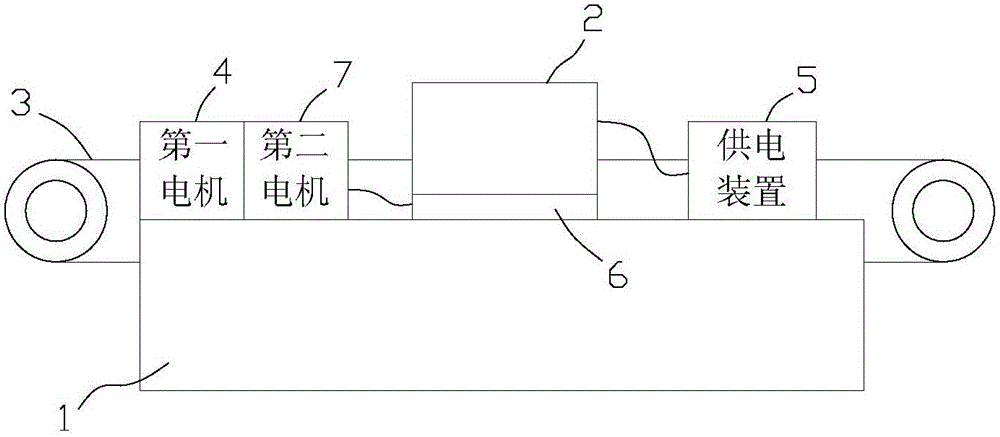

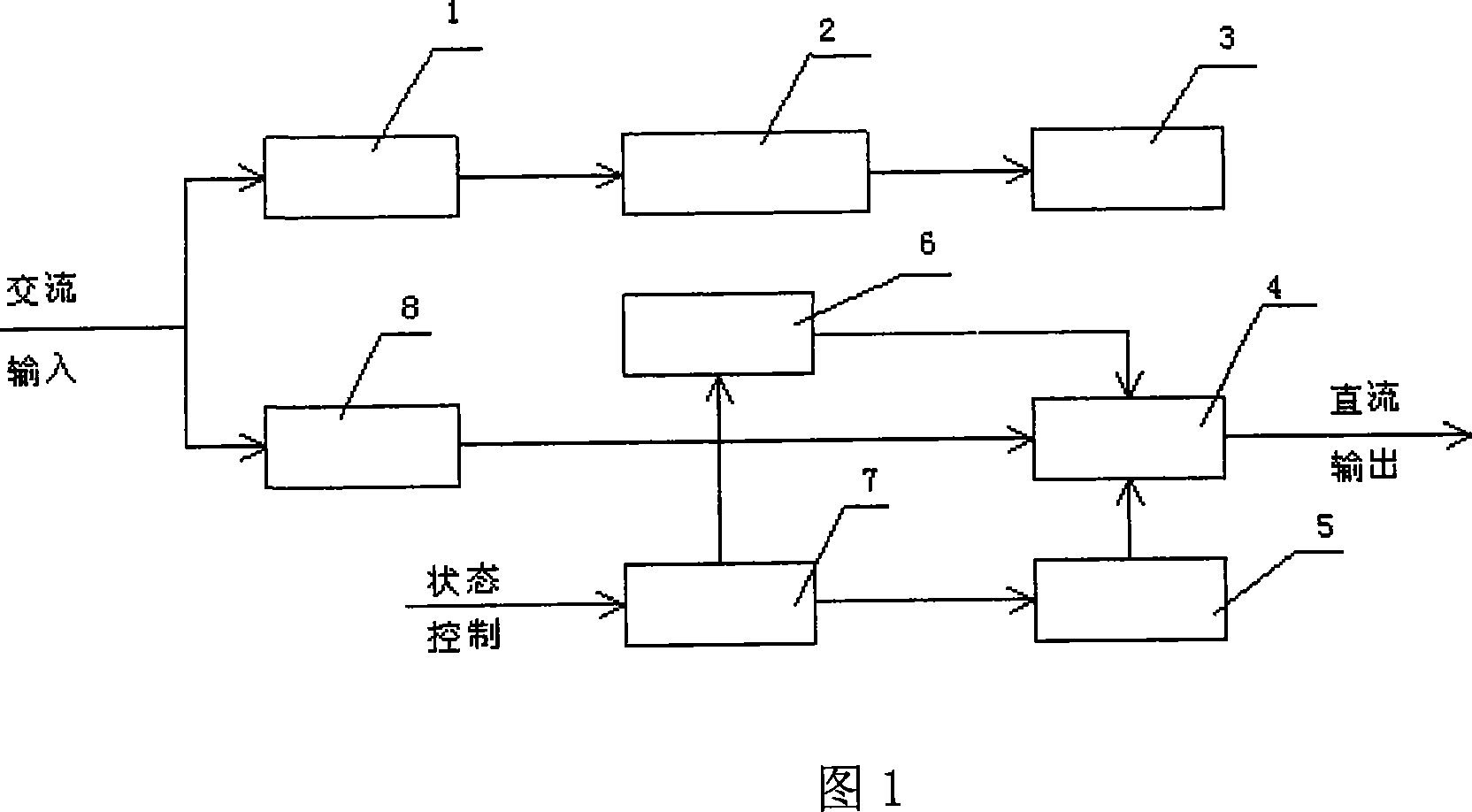

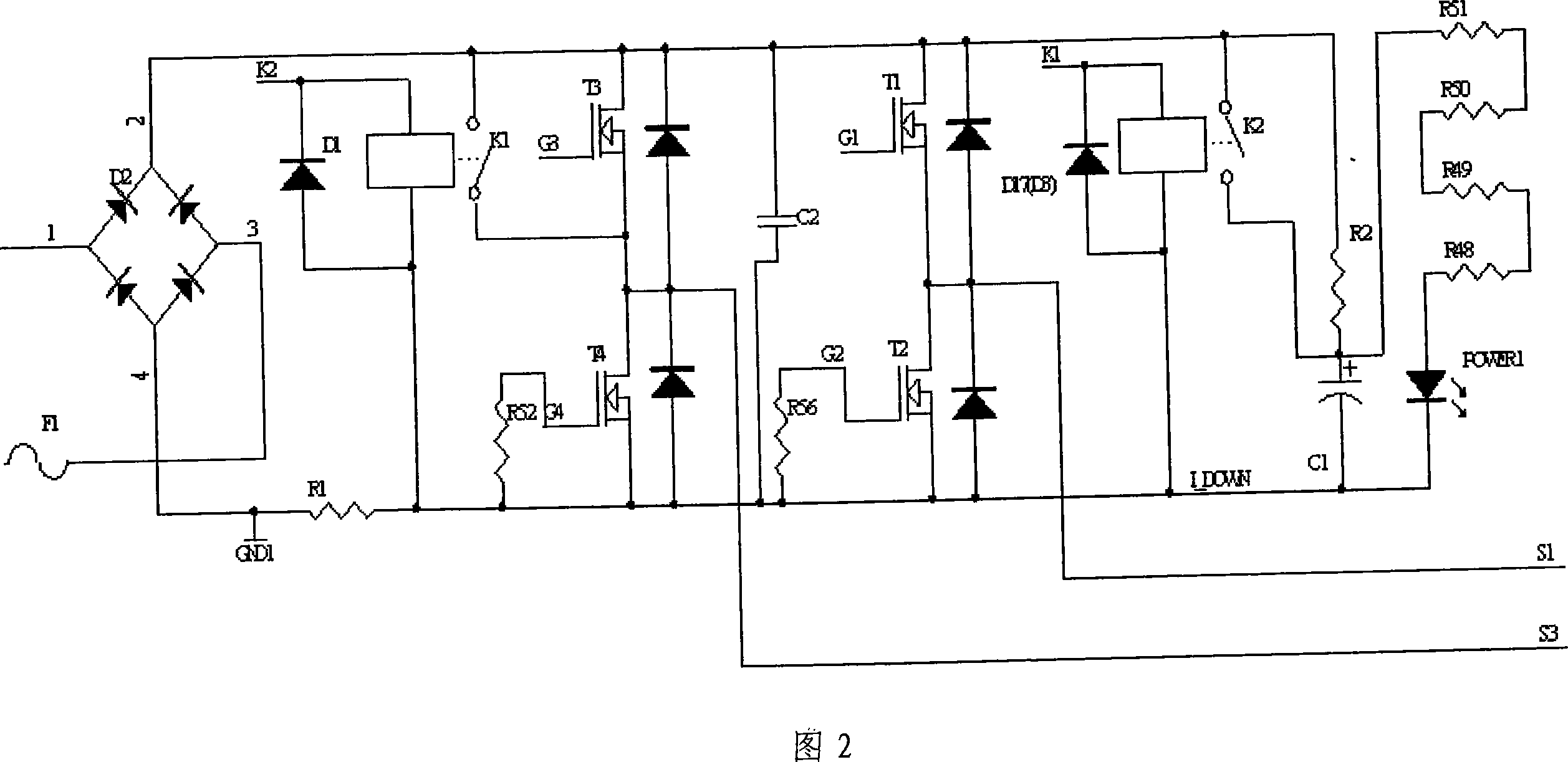

The invention discloses a double-track frame demagnetizer, which comprises a rack, a frame demagnetizing coil, a conveyor belt, a first motor and a power supply device, wherein the first motor drives the conveyor belt to move; the power supply device supplies electricity to the frame demagnetizing coil to control the frame demagnetizing coil to work; the first motor is fixed on the rack; a support member capable of carrying out linear movement along the rack and a second motor for driving the support member to move are arranged on the rack; the frame demagnetizing coil is fixed on the support member; and the conveyer belt passes through the frame demagnetizing coil and can move in the direction parallel to the movement direction of the support member. According to the double-track frame demagnetizer, the conveyor belt can displace and the demagnetizing coil can also move; and when the double-track frame demagnetizer is used, a bearing part with a fixed position can be demagnetized only by controlling the demagnetizing coil to move. The position can be kept invariable when the bearing part is demagnetized, so that the control is relatively convenient when station transferring on the bearing part is carried out through a mechanical arm; the overall configuration is relatively simple; and when the double-track frame demagnetizer works, the effect of strengthening demagnetizing can also be put into a play through coordinating movement of the conveyer belt and the demagnetizing coil.

Owner:WUHU HAILIAN MACHINERY INSTALLATION

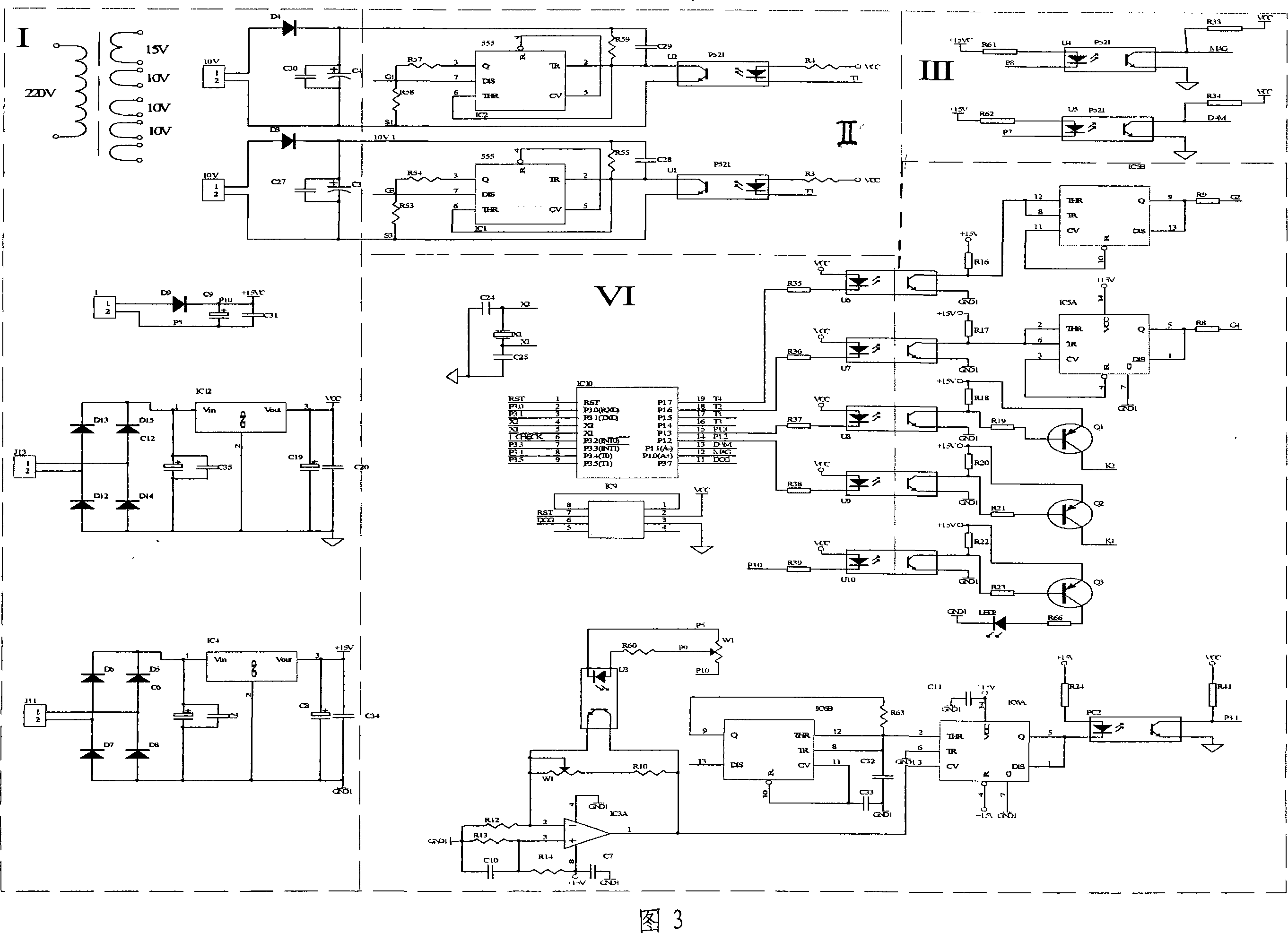

Modified grinder cupula magnetizing and demagnetization controller

InactiveCN101106008APrevent Galvanic CorrosionExtend your lifeMagnetic bodiesVoltage amplitudeOpto electronic

The invention provides an improved grinder sucker magnetizing and demagnetizing controller, which consists of a main circuit and a control circuit. The main circuit includes an H-bridge inverting circuit, and the control circuit includes positive and negative switch control and amplitude control of output voltage. The upper tube at one side of the H-bridge inverting circuit is connected with a relay at the two ends respectively, which is in parallel connection with a power tube and in connection with a filtering circuit. In magnetizing, the invention transmits adjustable DC voltage through relay and power tube, and in demagnetizing, the invention transmits adjustable voltage after alternative connection, and is connected with electromagnetic sucker directly; the control circuit consists of a SCM, a photoelectric coupler, and a timer, which are connected with each other. The control circuit makes positive and negative switch on output voltage and transmits the voltage amplitude. By making magnetizing voltage adjustable, the invention enhances the magnetizing precision, lowers magnetizing power consumption, and reinforces the performances of anti-disturbance and liability. The H-bridge transmits adjustable and excellent demagnetizing effect; after tests, all performance indexes are proved to be superior to those of prior arts. Furthermore, the invention has the advantages of high reliability, good anti-disturbance, simple structure, and convenient installation.

Owner:西安鸣士机电开发有限公司

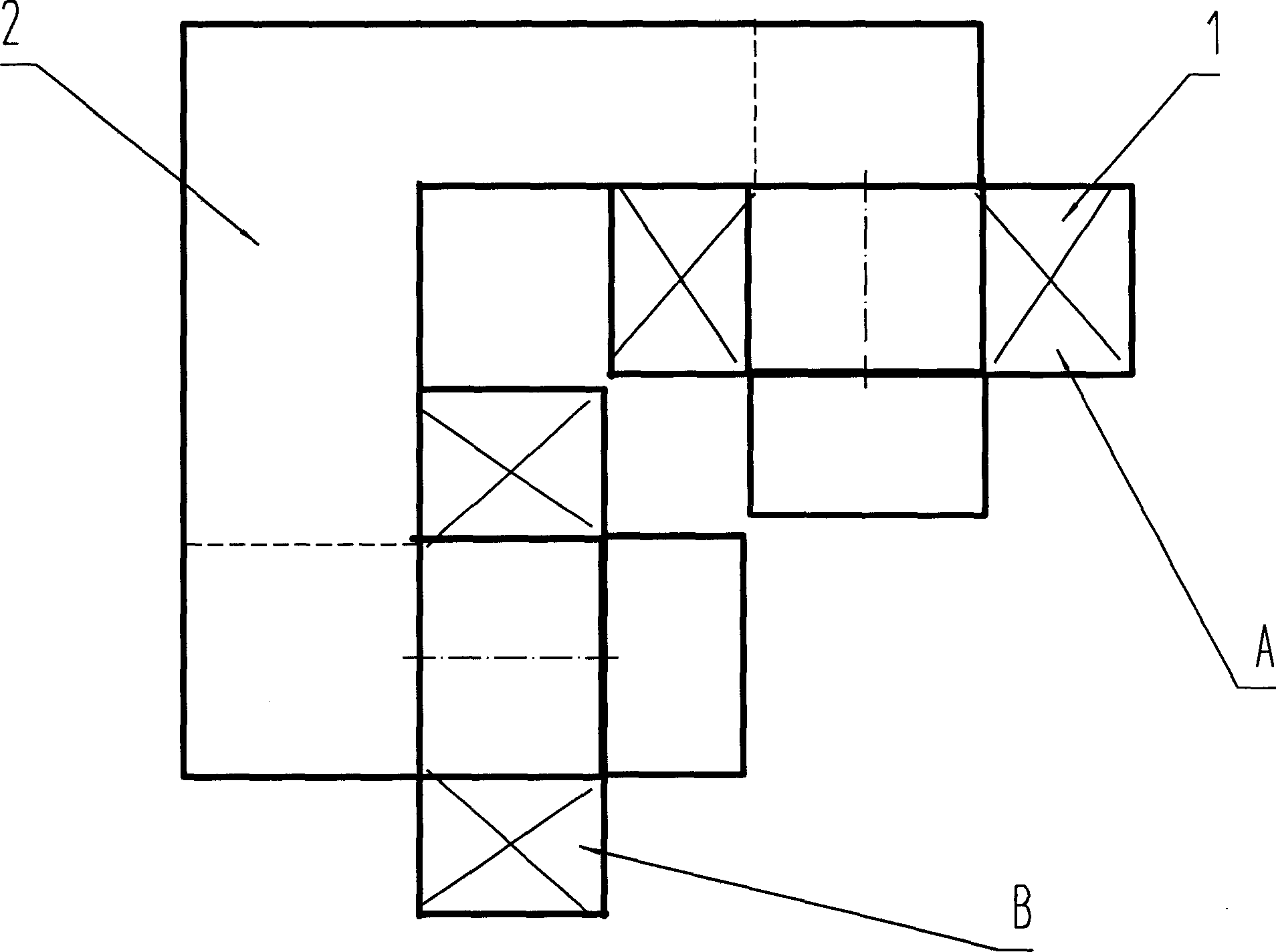

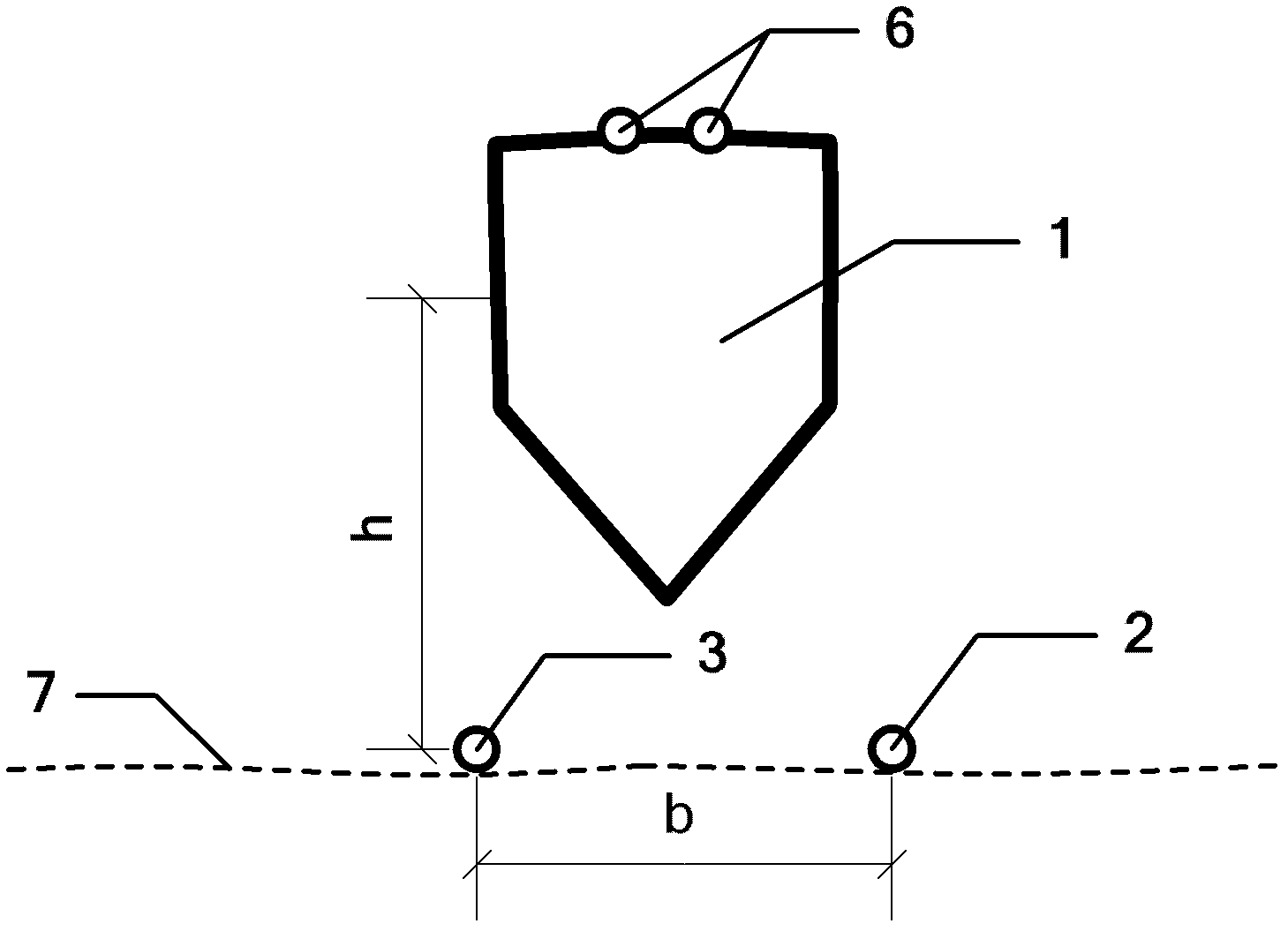

Vessel demagnetizing method

InactiveCN102530208AQuickly untieReduce labor intensityDefensive equipmentOffensive equipmentOcean bottomProblem of time

A vessel demagnetizing method belongs to the field of vessel demagnetization and solves the problem of time and labor consumption of existing vessel demagnetizing methods. The vessel demagnetizing method includes steps: firstly, laying submarine cables, namely laying left and right submarine cables on the sea floor, and anchoring a demagnetized vessel above the left and right submarine cables; secondly, forming a loop, namely using the cables to connecting one pole of a left pulse power source and one pole of a right pulse power source with the stern of the demagnetized vessel, and connecting the other pole of the left pulse power source and the other pole of the right pulse power source with the stem of the demagnetized vessel through the left and right submarine cables; and thirdly, electrifying for demagnetizing, namely using the left pulse power source and the right pulse power source to supply pulse current of superimposed direct-current component to the left and right submarine cables. Winding of the cables is not needed, a vessel body is directly electrified for demagnetizing, labor intensity is relieved, demagnetizing time is shortened, and expenditure is saved. Further, the vessel demagnetizing method is effective in demagnetization and low in energy consumption, the demagnetized vessel is easy in maneuvering, and the vessel demagnetizing method is especially suitable for demagnetization of a great quantity of vessels in emergency, and has fine emergency benefit and economic value.

Owner:NAVAL UNIV OF ENG PLA

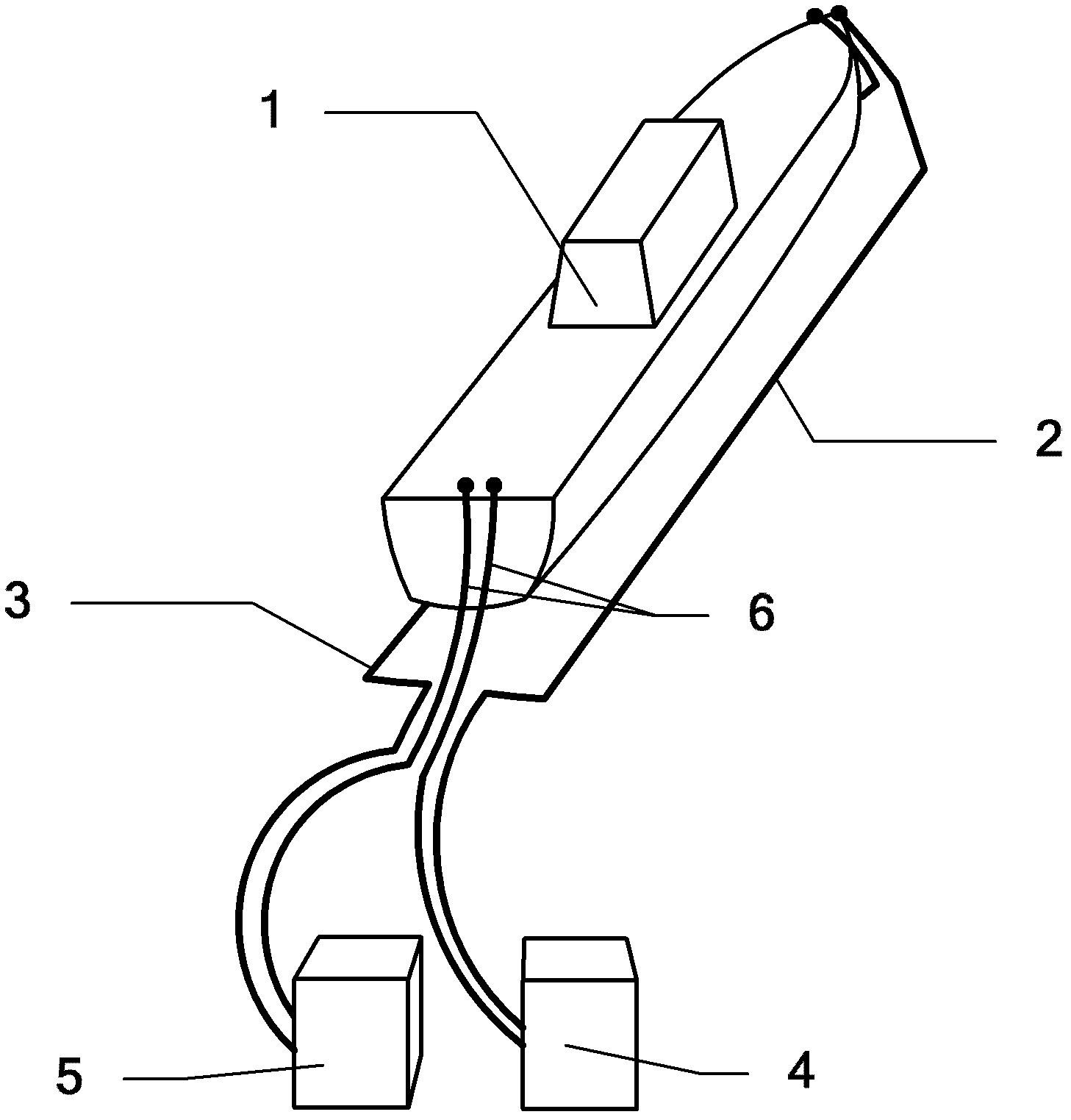

Demagnetization method of high-strength steel narrow gap welding groove

ActiveCN103456457BImprove demagnetization effectImprove portabilityMagnetic bodiesArc welding apparatusEngineeringSpot welding

Owner:JIANGSU UNIV OF SCI & TECH

Space rotary alternating magnetic field demagnetizing pole set

InactiveCN1581374ASimplifies the demagnetization processImprove demagnetization work efficiencyMagnetic bodiesDemagnetizing fieldMagnetic poles

Disclosed demagnezing pole subassembly of spatial rotating alternating magnetic field includes one or two groups, and one demagnezing pole group includes multiple demagnezing poles. Being connected to AC power source in certain phase, pole winding is installed onto magnetic iron core constitutes a magnetic pole. Demagnezing poles are distributed in array, and each demagnezing pole is connected to AC power source in different phases. There are certain spatial distances between magnetic poles in demagnezing device so as to form spatial rotating alternating magnetic field. Thus, there are demagnetizing fields in space in any direction so that direction of residual magnetism in work piece does not need to be determined in advance. The invention raises demagnezing efficiency, applicable to fields such as milling process, detection of defects, precision work, instrument and meters.

Owner:夏恽

Workpiece magnetic powder inspection device with hole in middle and complicated shape

InactiveCN105301094AClearly show cracksImprove anti-interference abilityMaterial magnetic variablesSiliconMaterials science

The invention relates to a device, particularly to a workpiece magnetic powder inspection device with a hole in the middle and a complicated shape. The workpiece magnetic powder inspection device is characterized in that after being connected with a left air cylinder and a left movable coil, a left silicon steel sheet electrode shaft penetrates into the left coil of left-right coils; after being connected with a right air cylinder and a right movable coil, a right silicon steel sheet electrode shaft penetrates into the right coil of the left-right coils; up-down coils are arranged above and below the left-right coils; front-back coils are arranged in front of or in the rear of the left-right coils; left-right coil magnetized power supply input terminals are arranged on the left-right coils; up-down coil magnetized power supply input terminals are arranged on the up-down coils; front-back coil magnetized power supply input terminals are arranged on the front-back coils. As the technical scheme is adopted, the workpiece magnetic powder inspection device has the following advantages and benefits: six fixed coils and two movable coils are adopted, so that a rotary magnetic field is formed in the device, cracks on a workpiece can be clearly displayed, and the magnetizing and demagnetizing effects are excellent.

Owner:朱丽娟

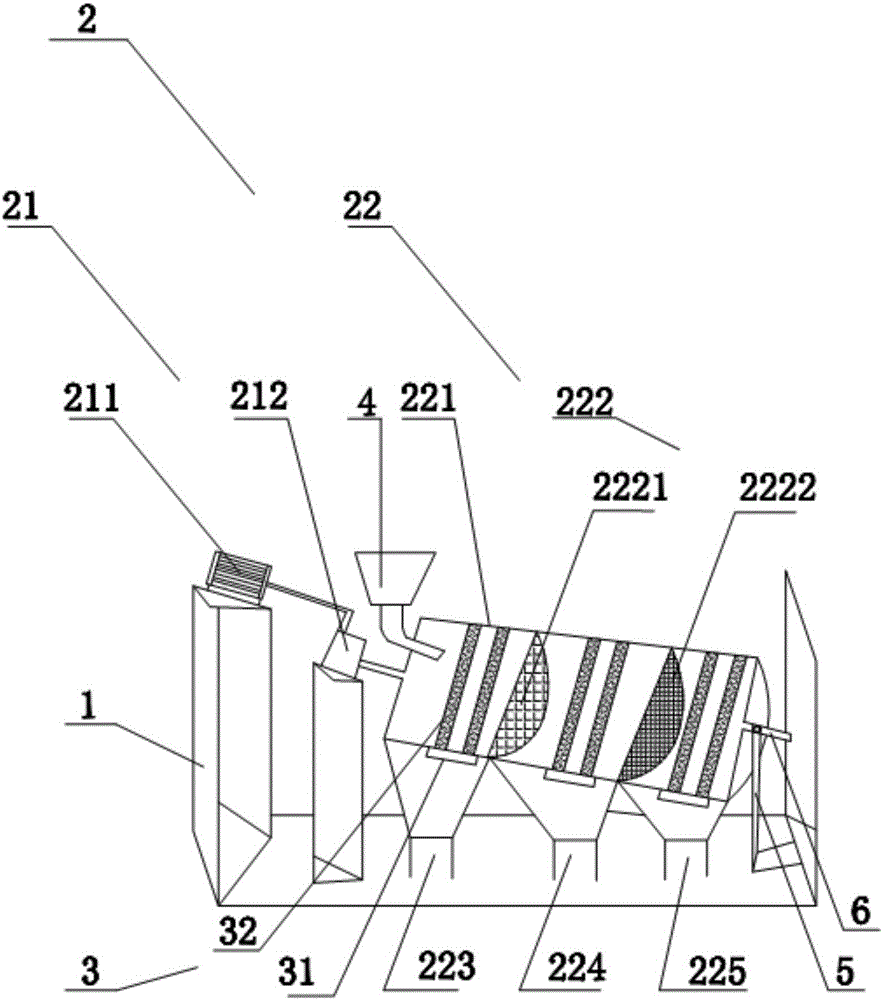

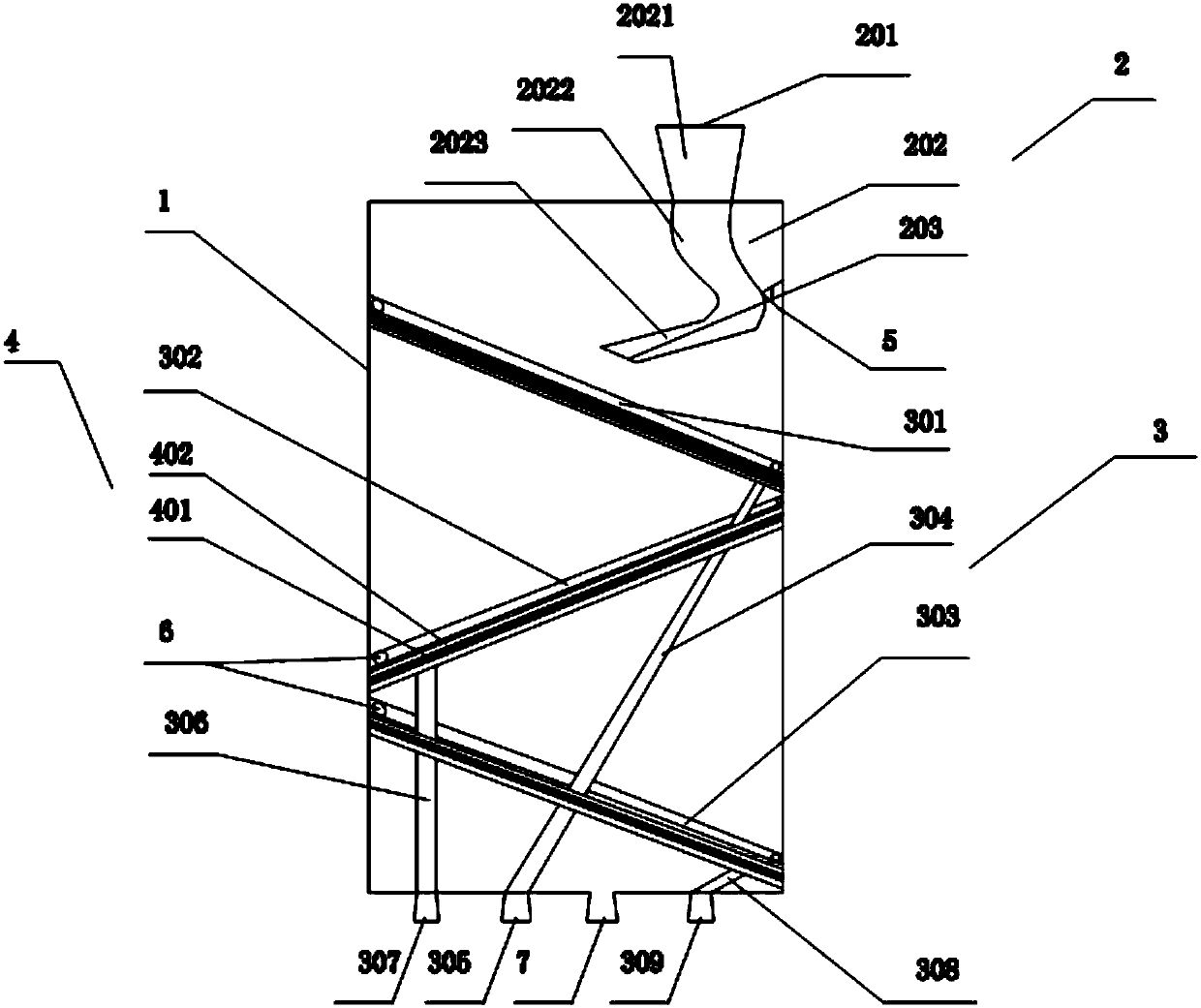

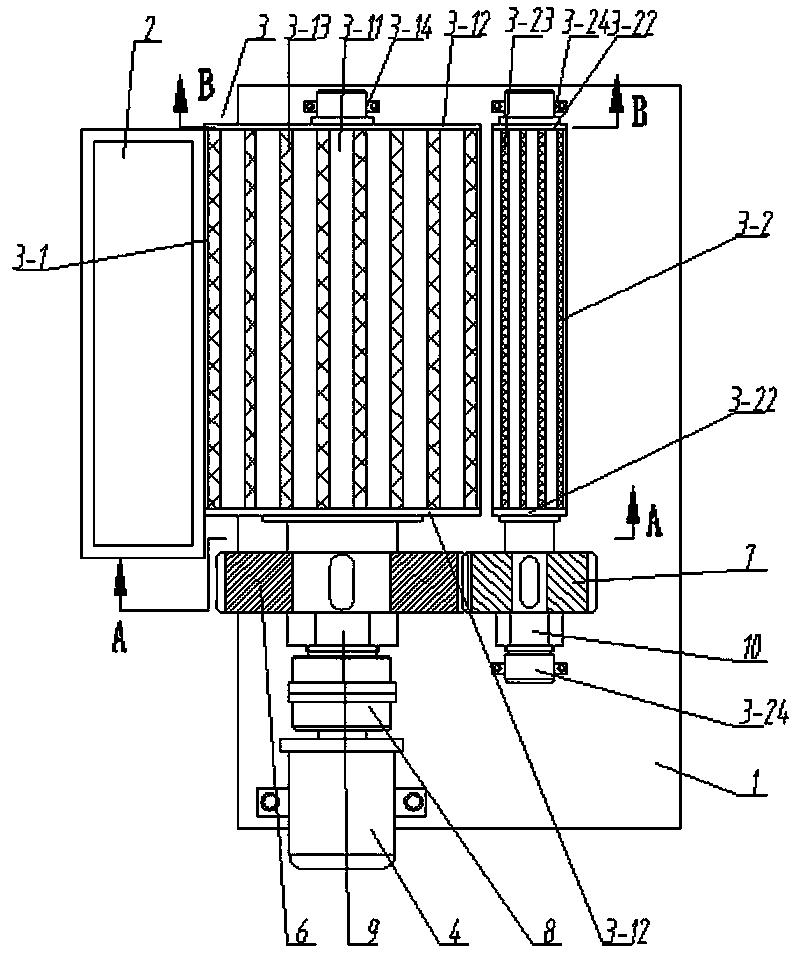

Automatic powder demagnetization equipment

PendingCN108014917AAvoid accumulationSimple structureSievingScreeningMachining vibrationsScreening effect

The invention provides automatic powder demagnetization equipment. According to the automatic powder demagnetization equipment, a spiral buffer mechanism is arranged, and therefore the material falling speed is reduced, the particle collision time is prolonged, meanwhile, in the process that particles are changed from movable to static, a tangential-velocity component is achieved, completely inelastic collision is avoided, shearing crushing of powder particles is effectively prevented, tiny particles such as dust attached to the surfaces of the powder particles can be separated, materials areprevented from falling on a screen net and prevented from being accumulated, and the screening effect is good; a screening mechanism is arranged, and therefore accumulation of a large amount of powderon the screen net can be avoided, the grading efficiency is high, overall machine vibration is avoided, and the service life is prolonged; a demagnetization mechanism is arranged, and therefore the demagnetization effect is good, demagnetization is carried out while screening is carried out, screening is carried out while demagnetization is carried out, the number of process steps is smaller, theworking efficiency is high, and economic returns are good; and the structure is simple, and operation is easy and convenient.

Owner:TIANJIN RUIHAI PENGXIANG TRADING

Simple demagnetization circuit

InactiveCN104078190AFast demagnetizationImprove demagnetization effectMagnetic bodiesCapacitanceAlternating current

The invention discloses a simple demagnetization circuit. A demagnetizing coil, a resistor, a potentiometer and a capacitor are orderly connected in series to a 220V alternating current circuit; the two ends of the resistor, the potentiometer and the capacitor all connected in series previously are connected in parallel with a bidirectional thyristor; one end, connected with the bidirectional thyristor, of the capacitor is connected to one end of an alternating-current power source; a bidirectional trigger diode is arranged between one end, connected with the potentiometer, of the capacitor and the control electrode of the bidirectional thyristor, and the triggering of the bidirectional thyristor is controlled by the bidirectional trigger diode. The simple demagnetization circuit can be composed of conventional components, and is high in demagnetization speed, good in demagnetization effect, high in reliability and good in stability.

Owner:SUZHOU GUJI ELECTRONICS TECH

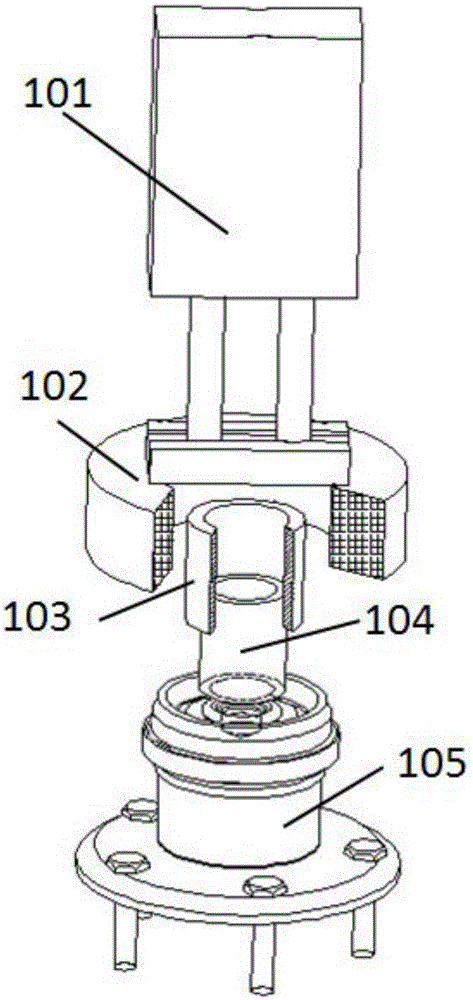

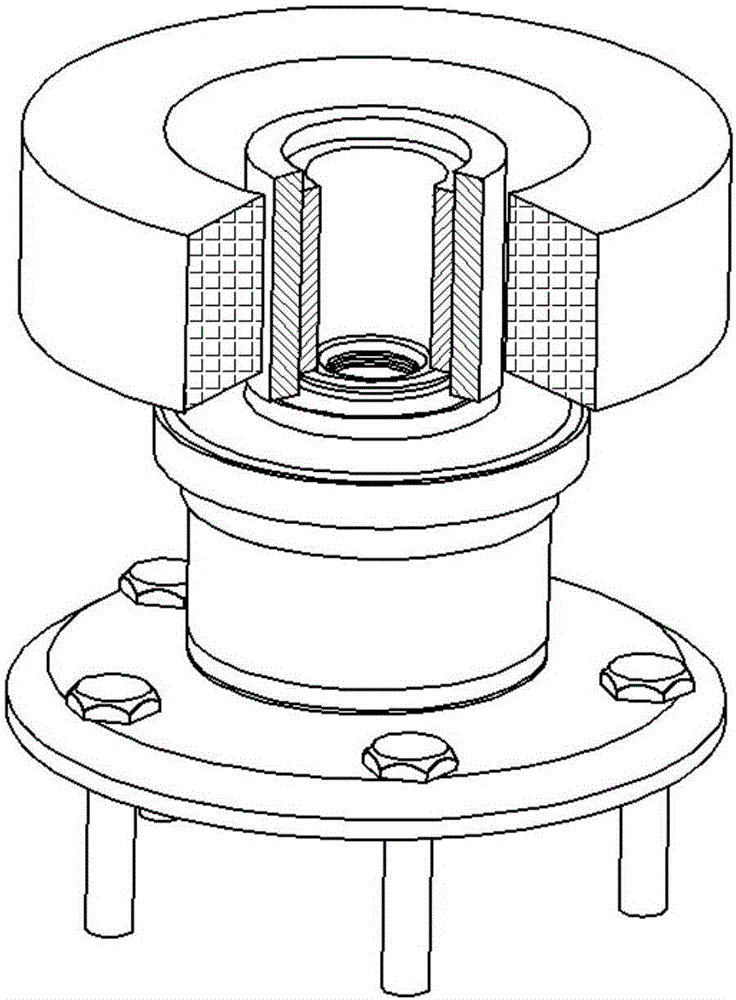

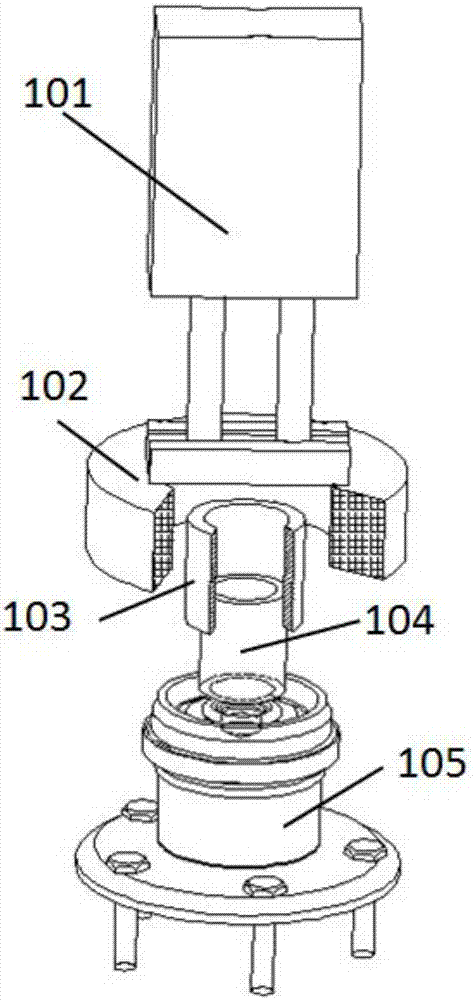

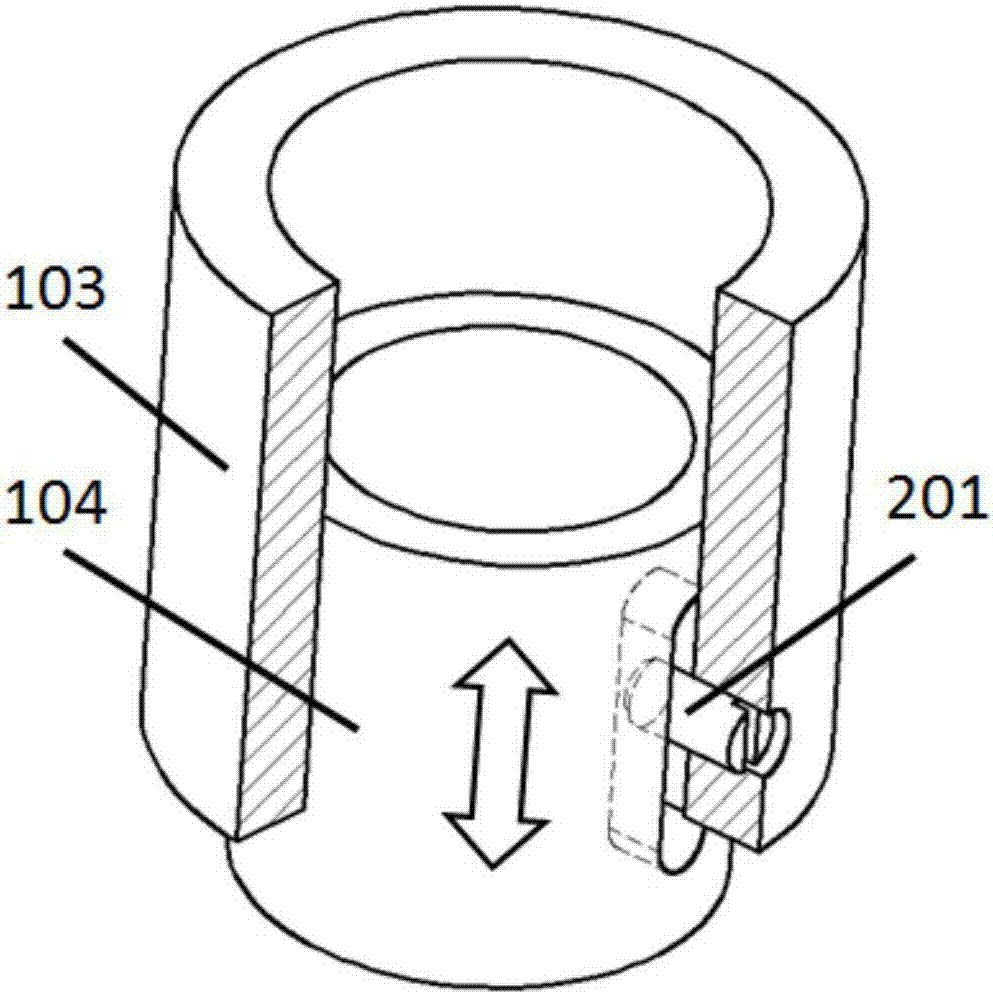

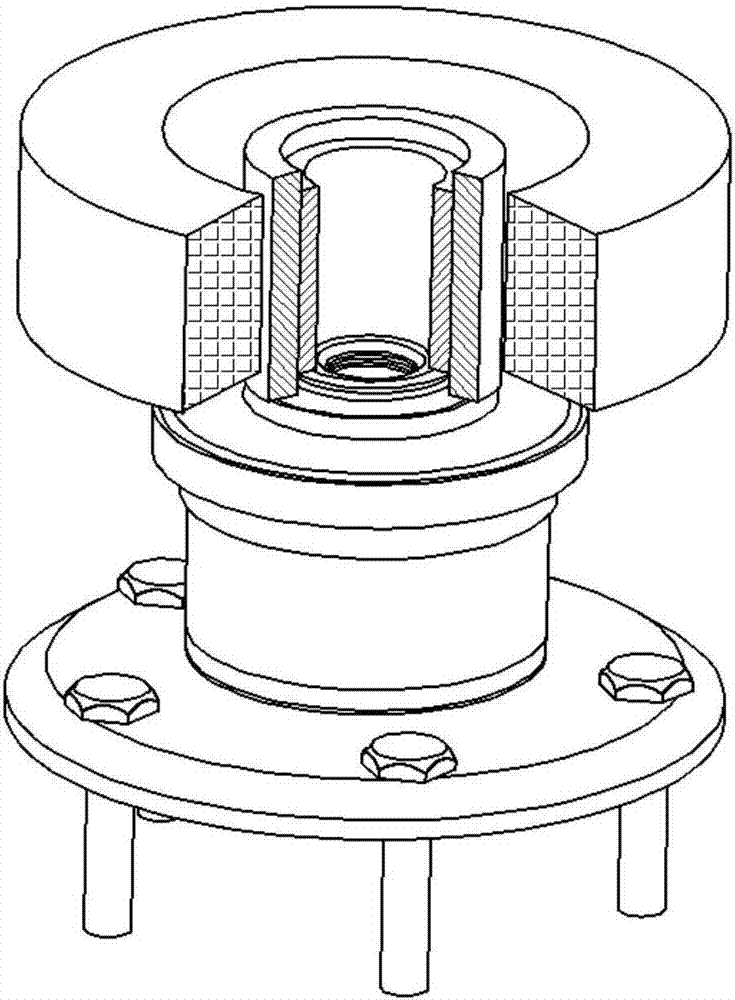

Telescopic guide sleeve demagnetizing device and method of wheel hub bearing

ActiveCN105957688AImprove demagnetization effectAdaptableMagnetic bodiesDemagnetizing deviceUltrasound attenuation

The invention belongs to a demagnetizing technology, in particular to a telescopic guide sleeve demagnetizing device and method of a wheel hub bearing. The device comprises an AC demagnetizing coil, a telescopic magnetic guide sleeve and a drawbar air cylinder, wherein the magnetic guide sleeve is arranged at the center of the AC demagnetizing coil. Through step-by-step lamination of a telescopic structure and a spinning surface of the wheel hub bearing, a complex surface is changed into a regular magnetic conductor; the magnetic guide sleeve is separated step by step when separated; and asynchronous attenuation of a magnetic field at the inner ring end surface of the wheel hub bearing is controlled, so that uniform demagnetization of inner ring parts of the wheel hub bearing is achieved. By an AC demagnetizing method, the magnetic field acts on the inner ring parts of the wheel hub bearing through cooperation with the telescopic guide sleeve; and the telescopic guide sleeve demagnetizing device and method are especially suitable for demagnetization of complex curved parts, in an inner cavity of an assembly body, similar to the spinning surface of the wheel hub bearing, and have the characteristics of high efficiency, high space adaptability and the like.

Owner:WUHAN HUAYUYIMU TESTING EQUIP CO LTD

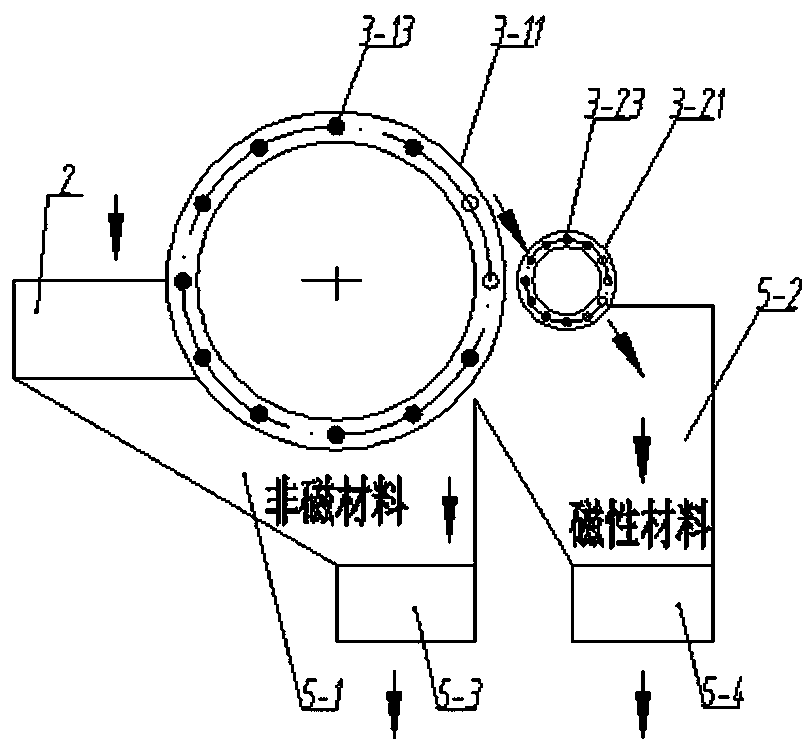

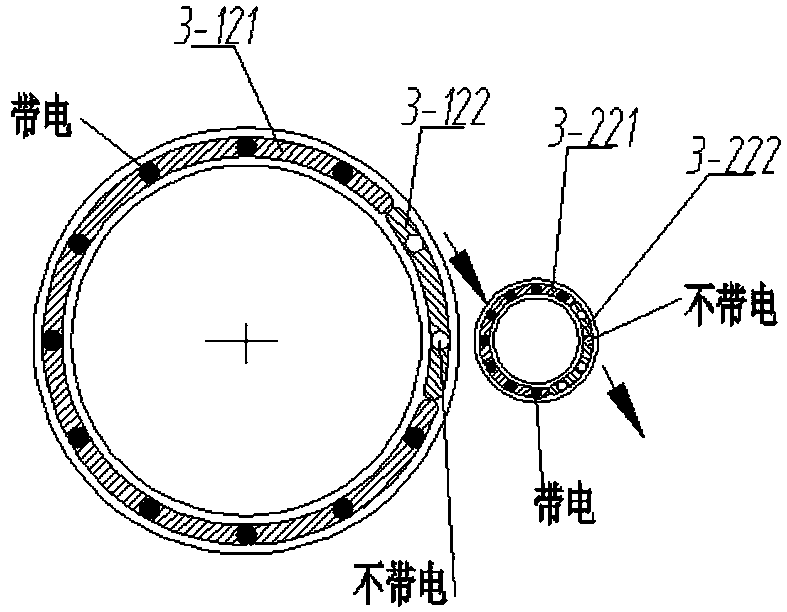

Brushless magnetic separation device and method

PendingCN109701738AGood demagnetization effectGood energy saving effectMagnetic separationDrive motorMaterial Separation

The invention relates to a brushless magnetic separation device and method. The device comprises a rack, a feeding hopper, a magnetic separation device, a driving motor and a material separation bin.The magnetic separation device is arranged above the material separation bin and comprises an iron separation device and an iron discharging device, the feeding hopper is located at a feeding side ofthe iron separation device, and the iron discharging device is located at an discharging side of the iron separation device. The iron separation device and the iron discharging device are driven by adriving motor to operate and rotate oppositely. A material enters the material separation bin from the feeding hopper, wherein non-ferrous materials are directly discharged from a discharging openingof the material separation bin, and ferrous materials are adsorbed by the iron separation device, conveyed to the iron discharging device and conveyed to an iron discharging opening of the material separation bin through the iron discharging device for discharging. The magnetic discharge effect is good, and incomplete magnetic discharge caused by insufficient sweeping force is avoided. The magnetic separation part is of a double-roller structure, and has clear magnetic selection and magnetic discharge functions and materials are discharged from different channels. A single motor is used for driving in the magnetic separation process, and the energy-saving effect is good. A magnetic control device is adopted, and magnetic materials can be automatically sorted.

Owner:LIUPANSHUI NORMAL UNIV

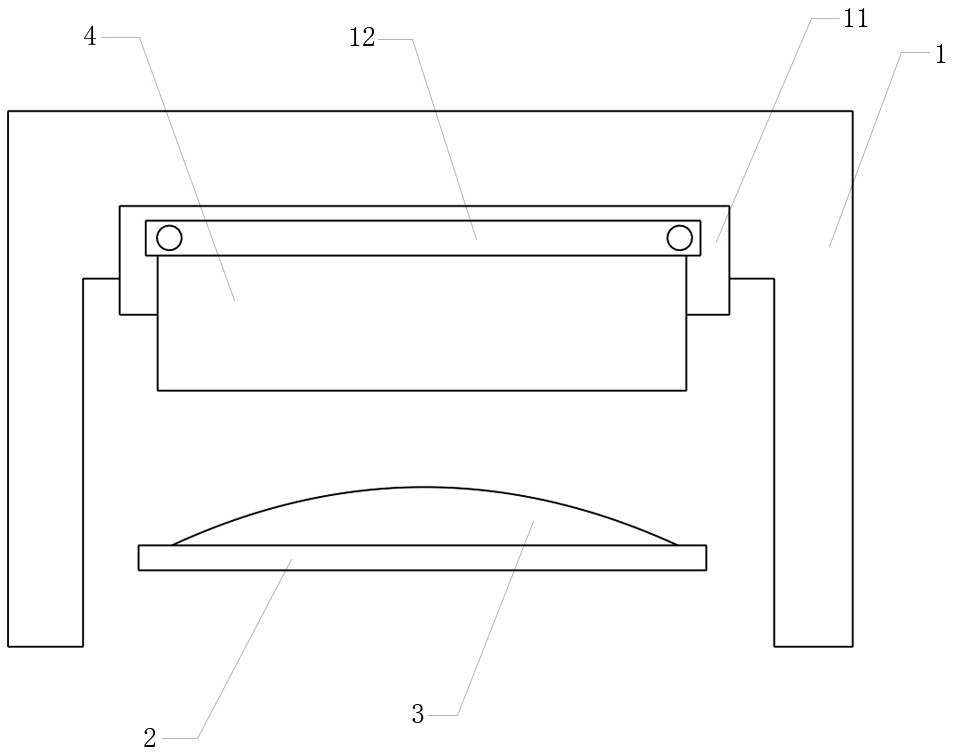

Improved demagnetizing machine

PendingCN112844820ANo wear and tearHigh removal rateMagnetic separationEngineeringMechanical engineering

An improved demagnetizing machine comprises a vertical frame, a mounting frame arranged at the lower end of the vertical frame, a demagnetizing structure mounted at the lower end of the mounting frame and a conveying structure arranged at the lower end of the demagnetizing structure. The mounting frame is provided with a fixing and collecting structure which is used for fixing the demagnetizing structure and is used for cleaning and collecting magnetic substances adsorbed on the demagnetizing structure. According to the device, the removal rate of magnetic substances in materials is high, the adsorbed magnetic substances can be effectively cleaned and collected, and material loss is hardly generated in the cleaning and collecting process; the device is simple in structure and convenient to install, and has a good application prospect.

Owner:湖州凯金新能源科技有限公司

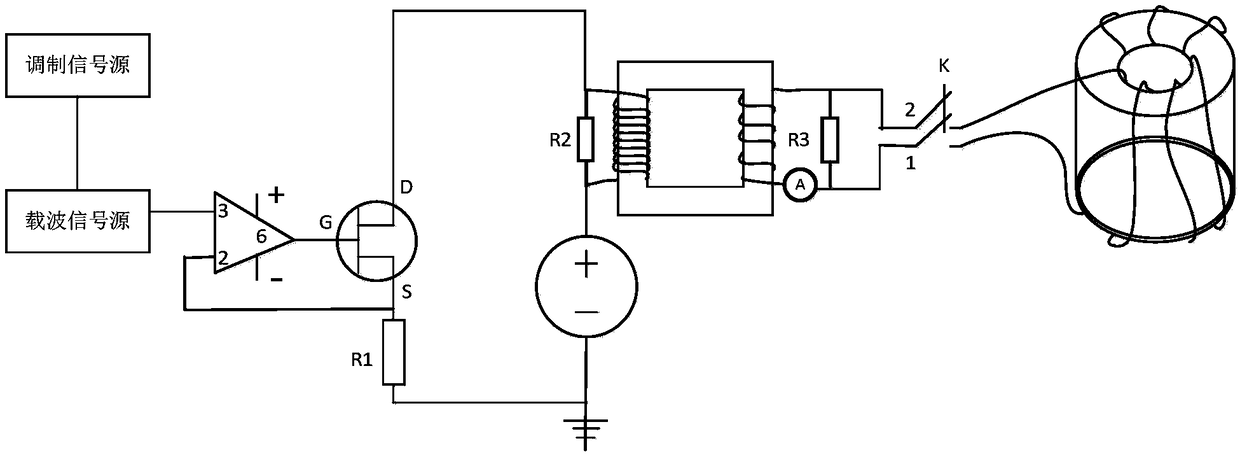

Automatic demagnetizing device for cylindrical magnetic shielding of atomic clock

ActiveCN108565089ASafe and reliable demagnetization processSmooth and delicate current changesMagnetic bodiesDemagnetizing devicePower flow

Provided is an automatic demagnetizing device for cylindrical magnetic shielding of an atomic clock. An output end of a modulation signal source is connected with a modulation end of a carrier wave signal source. An output end of the carrier wave signal source is connected with an input end of a controlled current loop. An output end of the controlled current loop is connected with a demagnetization current loop. The controlled current loop is formed in such a manner that a driving circuit, a direct-current power supply and an input end of a transformer are connected in series. An input end ofthe driving circuit is connected with the output end of the carrier wave signal source. The demagnetization current loop is formed in such a manner than an output end of the transformer, a knife switch and a demagnetization coil are connected in series. The demagnetization coil winds around a magnetic shielding cylinder. The automatic demagnetizing device for cylindrical magnetic shielding of theatomic clock is advantaged by being simple in structure and convenient in operation and is safe and reliable.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

Demagnetization device and method for telescopic guide sleeve of hub bearing

ActiveCN105957688BImprove demagnetization effectAdaptableMagnetic bodiesUltrasound attenuationDemagnetizing device

The invention belongs to a demagnetizing technology, in particular to a telescopic guide sleeve demagnetizing device and method of a wheel hub bearing. The device comprises an AC demagnetizing coil, a telescopic magnetic guide sleeve and a drawbar air cylinder, wherein the magnetic guide sleeve is arranged at the center of the AC demagnetizing coil. Through step-by-step lamination of a telescopic structure and a spinning surface of the wheel hub bearing, a complex surface is changed into a regular magnetic conductor; the magnetic guide sleeve is separated step by step when separated; and asynchronous attenuation of a magnetic field at the inner ring end surface of the wheel hub bearing is controlled, so that uniform demagnetization of inner ring parts of the wheel hub bearing is achieved. By an AC demagnetizing method, the magnetic field acts on the inner ring parts of the wheel hub bearing through cooperation with the telescopic guide sleeve; and the telescopic guide sleeve demagnetizing device and method are especially suitable for demagnetization of complex curved parts, in an inner cavity of an assembly body, similar to the spinning surface of the wheel hub bearing, and have the characteristics of high efficiency, high space adaptability and the like.

Owner:WUHAN HUAYUYIMU TESTING EQUIP CO LTD

Grinder chuck magnetizing and demagnetizing controller

ActiveCN100485831CEliminate power consumptionImprove reliabilityMagnetic bodiesGrinding work supportsMicrocontrollerVoltage amplitude

Owner:西安鸣士机电开发有限公司

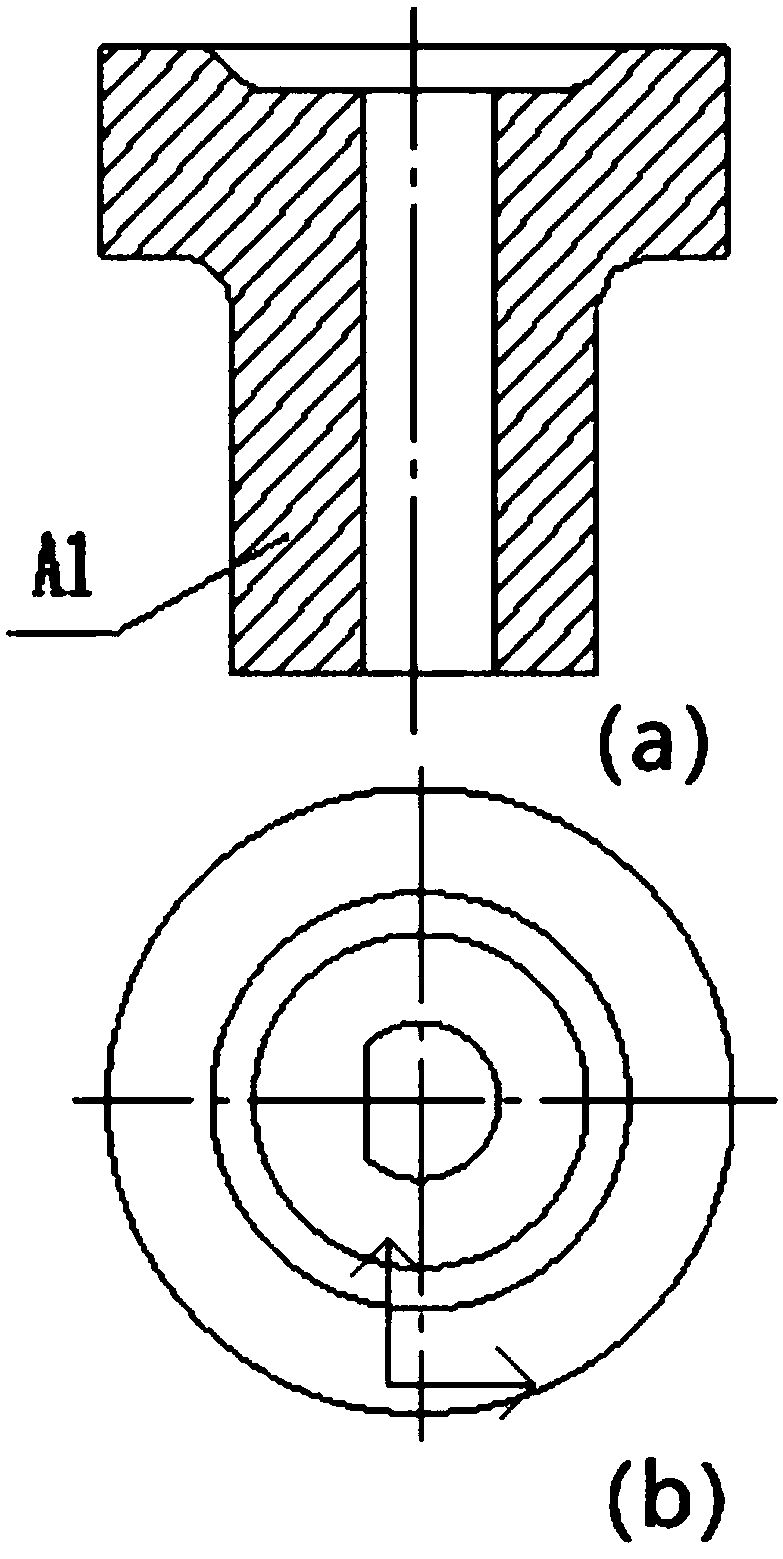

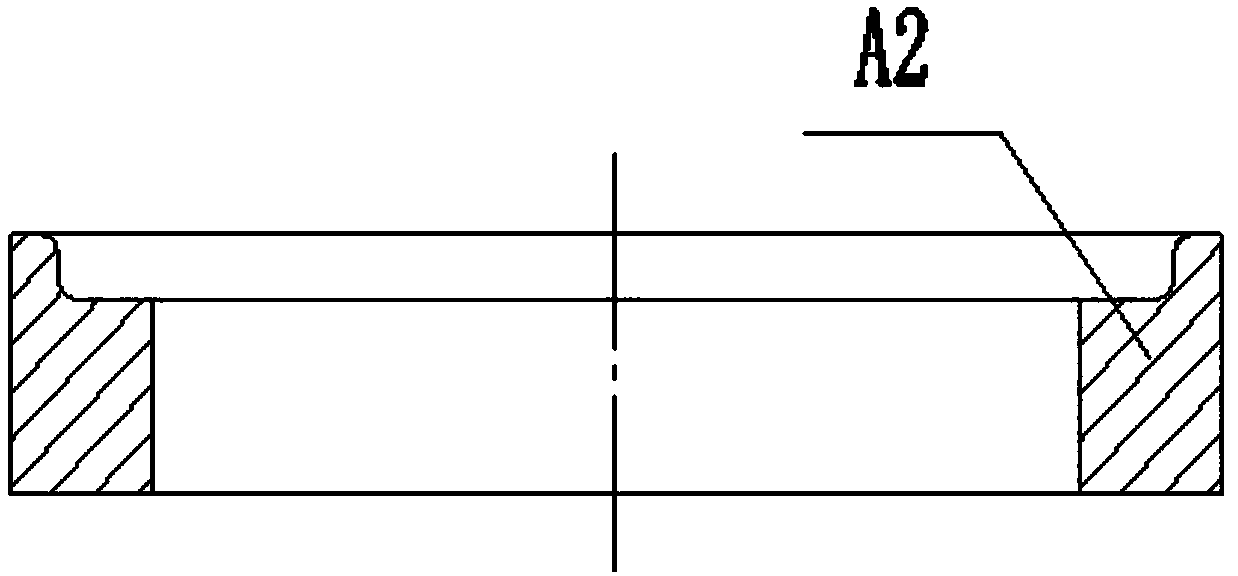

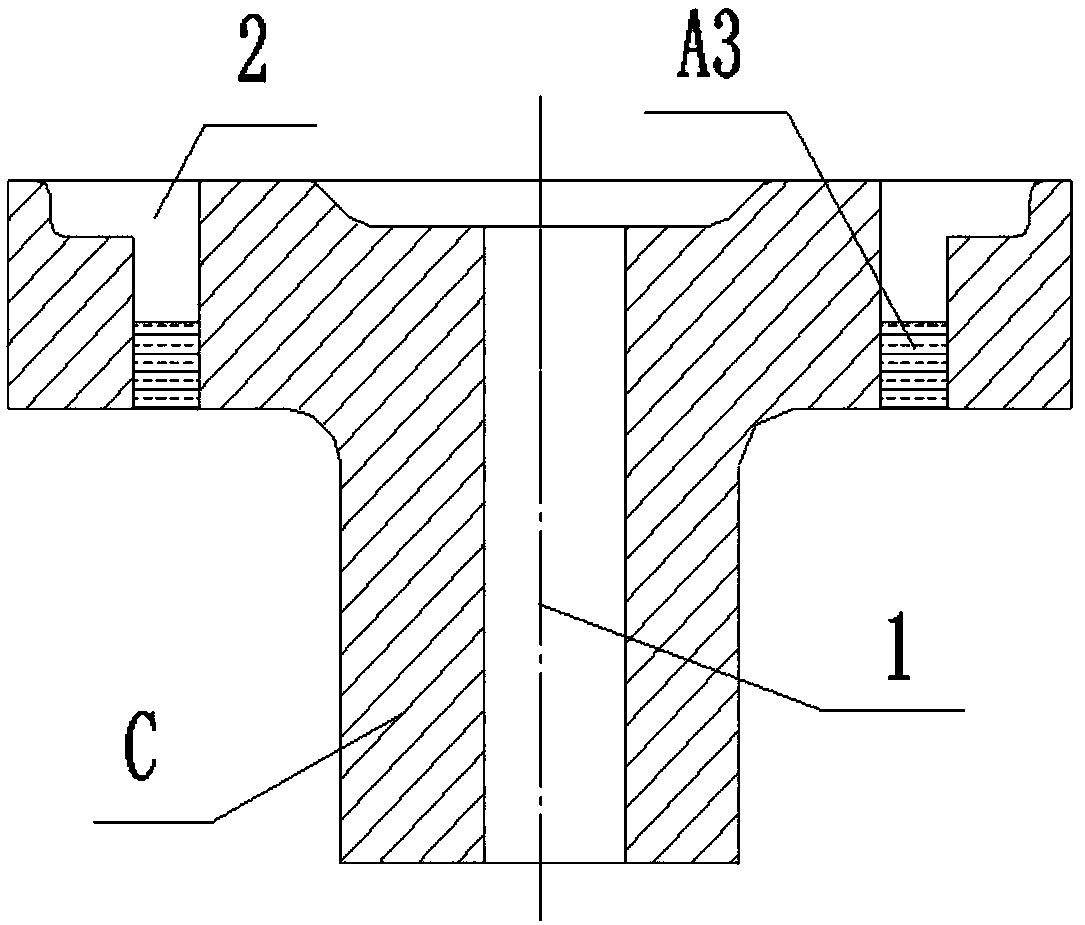

Preparation method of iron-based powder metallurgy friction wheel

ActiveCN108526471AEliminate shedding etc.Sintered tightly bondedTransportation and packagingMetal-working apparatusRubber ringHydrogen

The invention discloses a preparation method of an iron-based powder metallurgy friction wheel. The preparation method comprises the steps that a blank A1 and a blank A2 are made from iron powder softmagnetic material, the blank A1 and the blank A2 are sintered in a continuous sintering furnace under the protective atmosphere of ammonia decomposition and liquid nitrogen mixed gas, a blank A3 is made from FWCuSn6Zn6Pb3-Tin bronze powder, A1, A2 and A3 are connected together to form a composite part C, the composite part C is put into a hydrogen sintering furnace for sintering and is dischargedafter cooling, a semicircular inner hole of the sintered part C is subjected to fine shaping treatment, and a rubber ring is bonded into an annular groove of the part C to obtain a finished product.Due to different atmosphere protection and secondary sintering, the sintering of a tin bronze ring and soft magnetic matrix material of the friction wheel is closely combined, the phenomenon of copperring falling off in the use of the friction wheel of a machined inlaid copper ring is eliminated, and the characteristics that the preparation method is simple, the material is saved and the production efficiency is high are achieved.

Owner:陕西华夏粉末冶金有限责任公司

Vessel demagnetizing method

InactiveCN102530208BQuickly untieReduce labor intensityDefensive equipmentOffensive equipmentOcean bottomProblem of time

Owner:NAVAL UNIV OF ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com