Transformer iron core demagnetization method

A transformer core and transformer technology, applied in the field of transformer residual magnetism, can solve the problems of long demagnetization time, demagnetization failure, hysteresis loop offset, etc., and achieve the effect of short demagnetization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

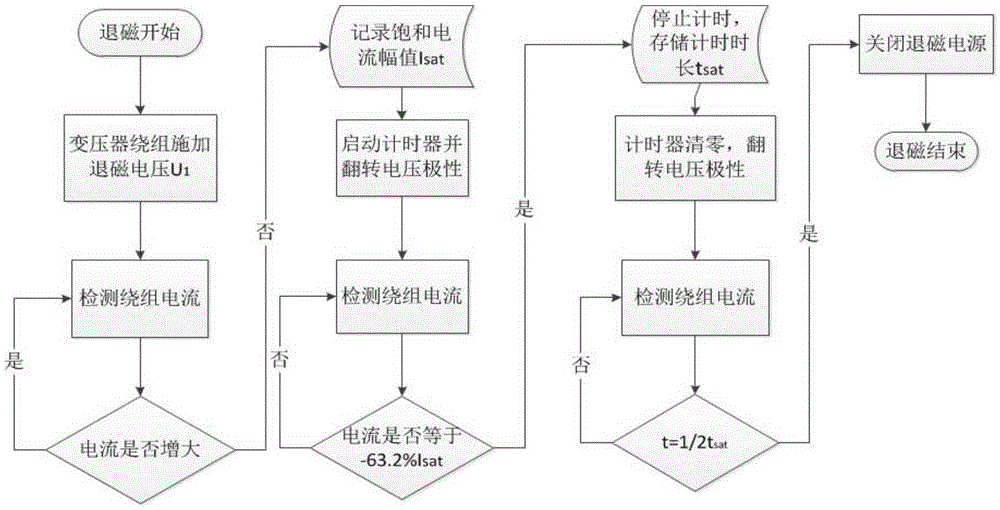

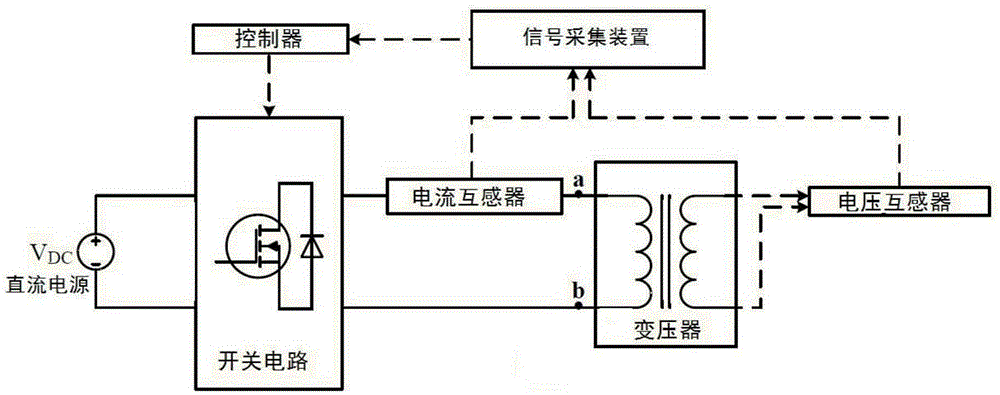

Method used

Image

Examples

Embodiment

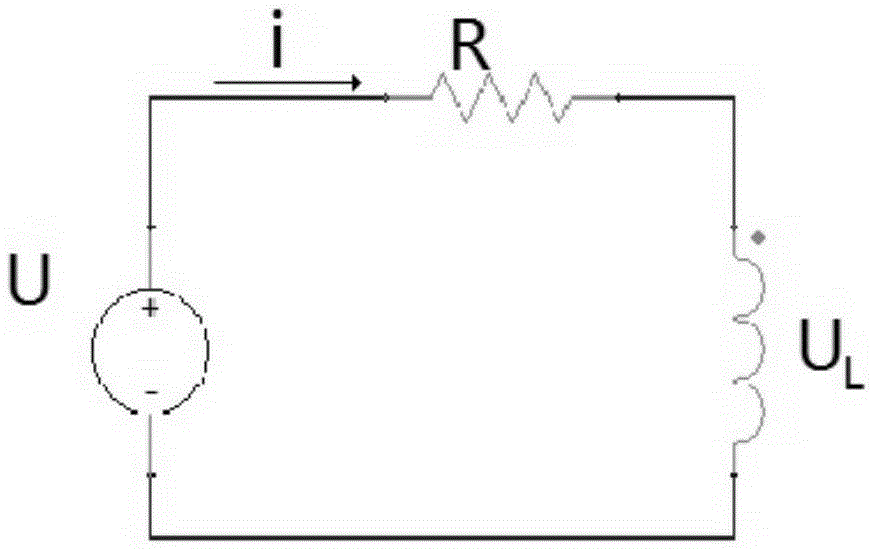

[0040] Take a single-phase transformer demagnetization as an example, build as Figure 4 The simulation model shown in the figure: U represents the DC power supply, R represents the DC resistance of the transformer, n represents the transformation ratio of the transformer, L 1 Indicates the transformer leakage inductance, L 2 Indicates the equivalent excitation inductance of the transformer, P indicates the high-voltage side of the transformer, and S indicates the low-voltage side of the transformer; the rated capacity of the transformer is 403MVA, the rated voltage is 199.18kV / 162.64kV, the rated magnetic flux of the high-voltage side is 634V*s, and the DC resistance of the transformer is 0.08Ω , demagnetize from the high-voltage side of the transformer, the demagnetization DC voltage amplitude is 8V, and the initial residual magnetism is -500V*s, and the demagnetization is carried out according to the method of the present invention. Figure 5 is the demagnetization DC volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com