Preparation method of iron-based powder metallurgy friction wheel

An iron-based powder metallurgy and friction wheel technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of large material loss, low production efficiency, and many processes, so as to improve production efficiency, eliminate copper ring shedding, and process The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Use -100 mesh iron powder soft magnetic material with a Fe purity content of 98.5%, add a forming agent zinc stearate accounting for 0.4% of the total mass, fully mix in a V-shaped mixer, and loosely pack the powder The density is controlled at 2.6g / cm3,

[0026] Step 2: Use FWCuSn6Zn6Pb3-Ⅲ tin bronze powder, add a forming agent zinc stearate accounting for 0.5% of the total mass, and mix well in a V-type mixer, and the bulk density of the material is controlled at 3.5g / cm3.

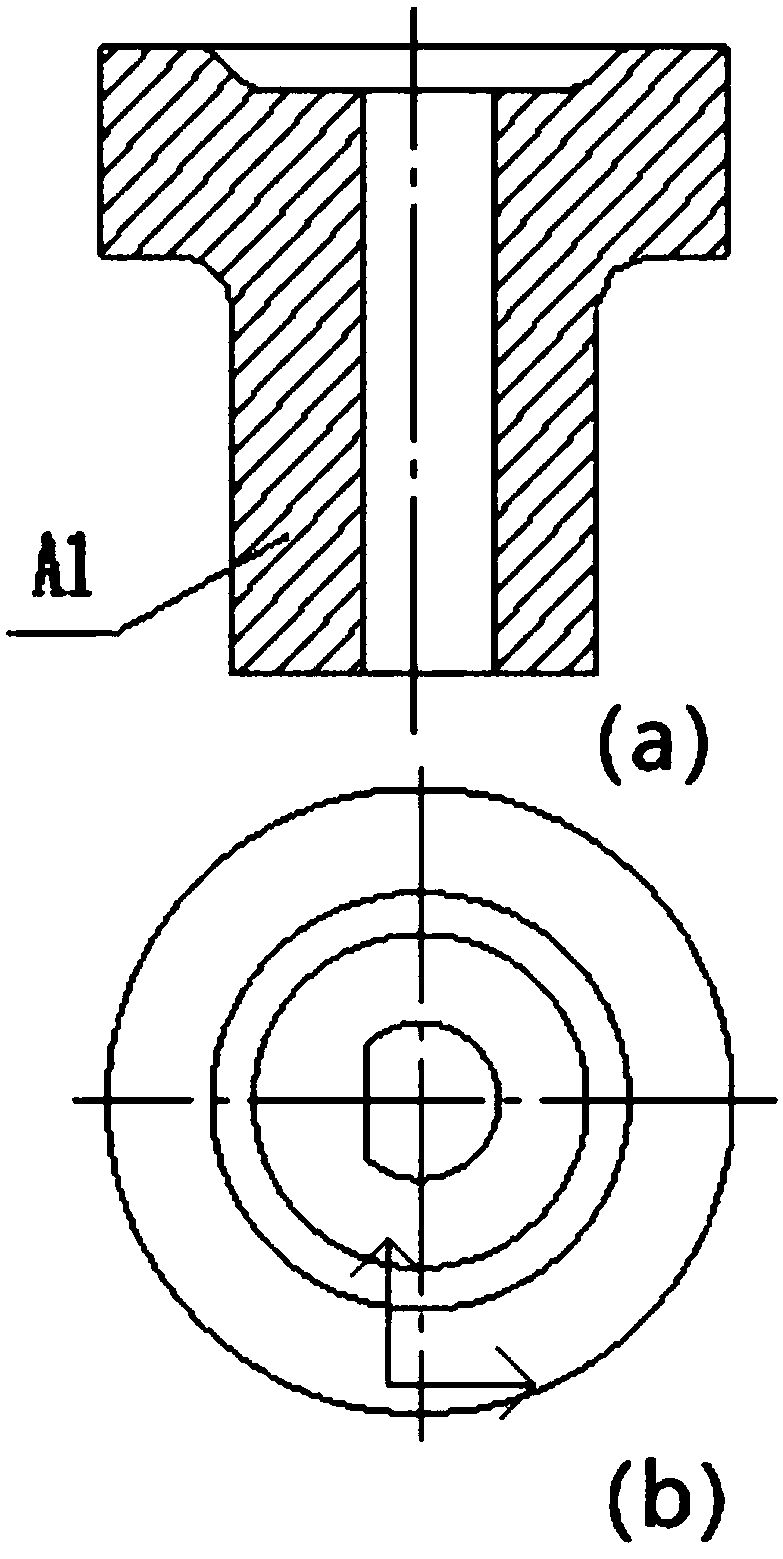

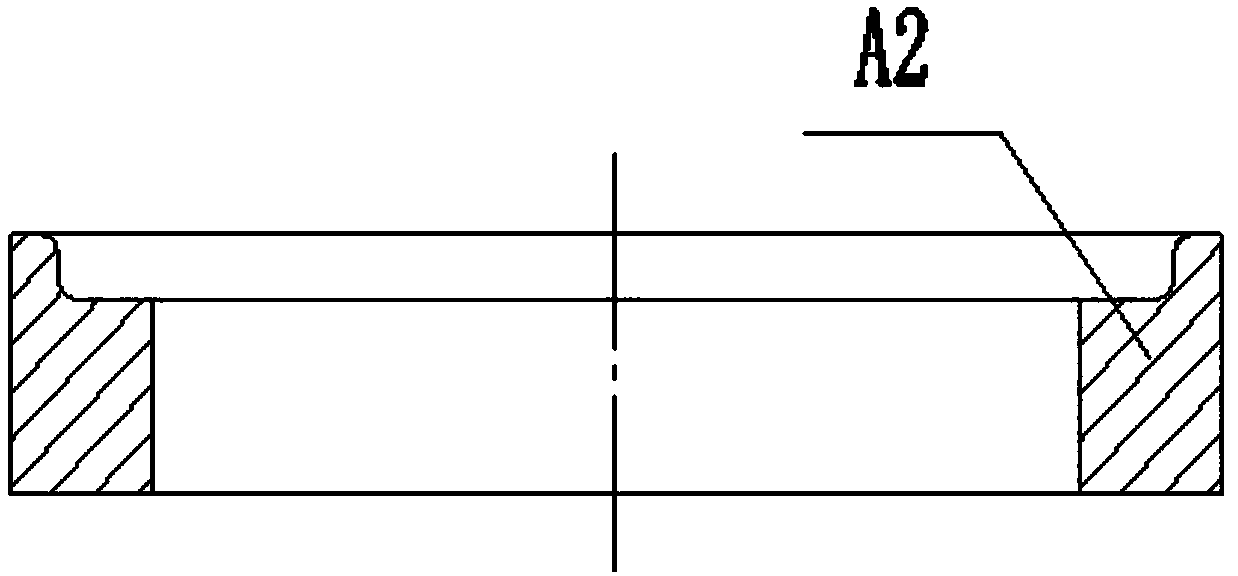

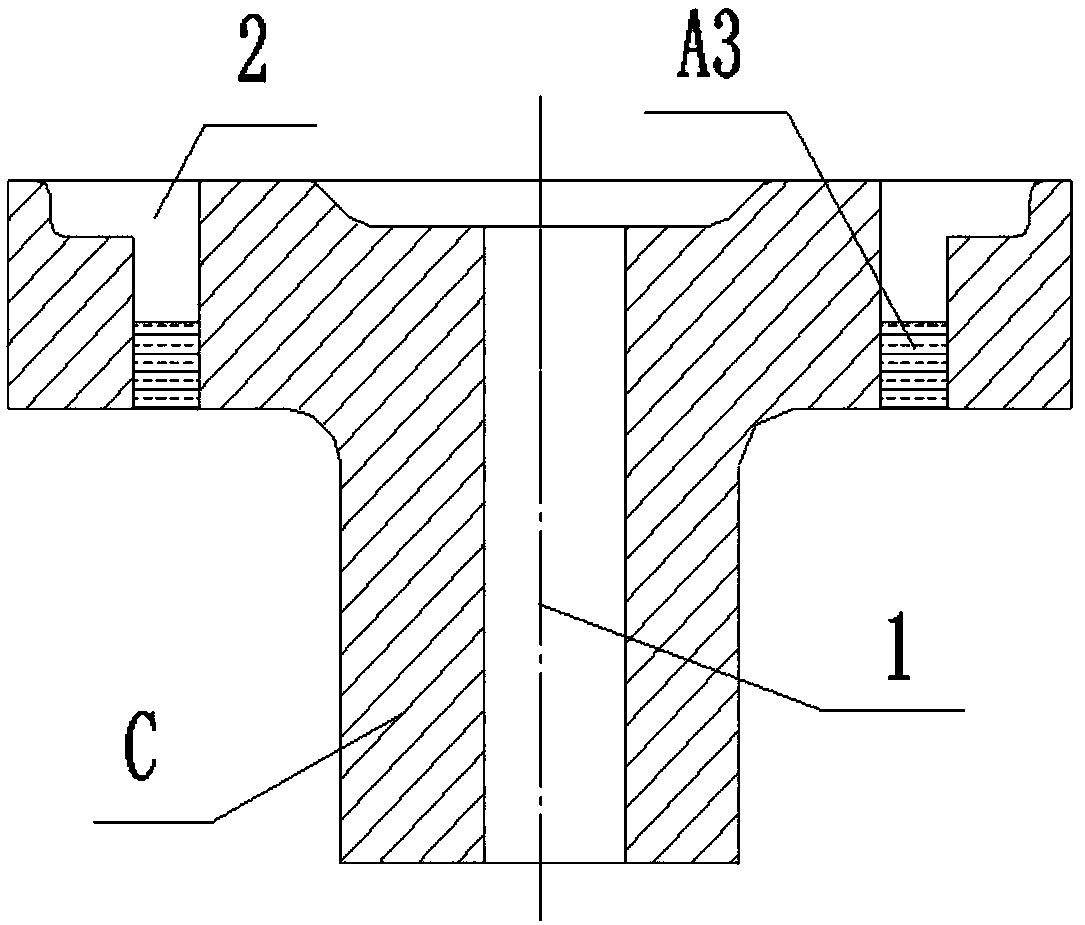

[0027] Step Three: See figure 1 , figure 2 , put the powder material in step 1 into the female mold cavity of the mold, and the unit pressing pressure is 5-7T / cm 2 Under the conditions of pressing and forming, the blanks A1 and A2 are made, and the density of the blank is controlled at 6.4-6.6g / cm 3 ,

[0028] Step 4: The blanks A1 and A2 are sintered in a continuous sintering furnace under a protective atmosphere of a mixed gas of 40% liquid nitrogen gas and 60% ammonia decomposition...

Embodiment 2

[0034] Step 1: Use -100 mesh iron powder soft magnetic material with a Fe purity content of 99.5%, add a forming agent accounting for 0.6% of the total mass, and fully mix it in a V-type mixer, and the bulk density of the powder is controlled at 2.8 g / cm3,

[0035] Step 2: Use FWCuSn6Zn6Pb3-Ⅲ tin bronze powder, add 0.7% of the total mass of forming agent, fully mix in a V-shaped mixer, and control the bulk density of the material at 4.4g / cm3,

[0036] Step Three: See figure 1 , figure 2 , put the powder material in step 1 into the female mold cavity of the mold, press and form under the condition of unit pressing pressure 7T / cm2, and make blanks A1 and A2, and the density of the pressed blanks is controlled at 6.6g / cm3,

[0037] Step 4: The blanks A1 and A2 are sintered in a continuous sintering furnace under a protective atmosphere of a mixed gas of 40% liquid nitrogen gas and 60% ammonia decomposition gas. The blanks first enter the pre-sintering zone, the pre-sintering t...

Embodiment 3

[0043] Step 1: Use -100 mesh iron powder soft magnetic material with a Fe purity content of 99.%, add a forming agent zinc stearate accounting for 0.5% of the total material, and mix well in a V-shaped mixer until the powder is loose The packing density is controlled at 2.7g / cm3,

[0044] Step 2: Use FWCuSn6Zn6Pb3-Ⅲ tin bronze powder, add 0.6% of the forming agent zinc stearate in the total material, and fully mix in a V-shaped mixer to obtain a powder material. The bulk density of the material is controlled at 4g / cm3.

[0045] Step Three: See figure 1 , figure 2 , put the powder material in step 1 into the female mold cavity of the mold, press and form under the condition of unit pressing pressure 6T / cm2, and make blanks A1 and A2, and the density of the pressed blanks is controlled at 6.5g / cm3,

[0046]Step 4: The blanks A1 and A2 are sintered in a continuous sintering furnace under a protective atmosphere of a mixed gas of 40% liquid nitrogen gas and 60% ammonia decompos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com