Cathode material of mesotherm solid oxide fuel battery and preparation method thereof

A fuel cell cathode and solid oxide technology, which is applied to battery electrodes, cobalt oxide/cobalt hydroxide, circuits, etc., can solve the problems of expensive rare earth elements, cathode layer battery shedding, poor thermal matching, etc., and achieve good oxygen ion Conductivity, avoidance of impurity phase problems, effects of high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 cathode material optimum component of the present invention

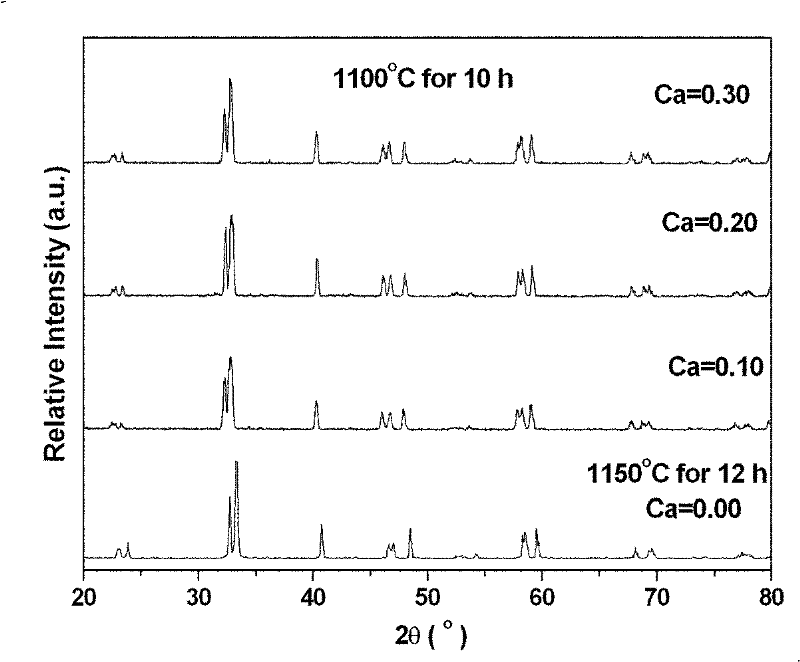

[0026] The rare earth element Ln is selected as Sm, and a series of cathode materials Sm in which the alkaline earth metal element A is Ca is prepared according to different molar ratios. 1-x Ca x BaCo 2 o 5+δ (x=0.1, 0.2, 0.3), compare the prepared intermediate temperature solid oxide fuel cell cathode material Sm 1-x Ca x BaCo 2 o 5+δ (x=0.1, 0.2, 0.3) properties, see figure 1 and Table 1.

[0027] figure 1The cathode material Sm prepared by sintering at 1100℃ for 10 hours 1-x Ca x BaCo 2 o 5+δ (x=0.1, 0.2, 0.3) XRD spectrum of the sample. From figure 1 It can be seen from the figure that the single-phase double perovskite structure cathode material Sm can be obtained from the sample obtained by sintering at 1100°C for 10 hours. 1-x Ca x BaCo 2 o 5+δ .

[0028] Table 1 is the Sm obtained by sintering at 1100°C for 10 hours 1-x Ca x BaCo 2 o 5+δ Sample, the average thermal...

Embodiment 2

[0031] Embodiment 2 The preparation method of cathode material of the present invention

[0032] Press Sm 1-x Ca x BaCo 2 o 5+δ Stoichiometric ratio weighed Sm 2 o 3 , CaCO 3 , BaCO 3 and Co 2 o 3 Wait for the raw materials, put the weighed raw materials in an agate mortar and add alcohol to grind for 1 hour; then press to form at 200-350MPa, calcined at 1000°C for 10 hours; crush the pre-fired samples and grind for 1 hour, Compressed at 200-350MPa, calcined for the second time at 1050°C for 10 hours; crush and grind the sample after the second calcined for 1 hour, press-molded at 200-350MPa, and sintered at 1150°C for 10 hours , obtained Sm 1-x Ca x BaCo 2 o 5+δ series of cathode materials.

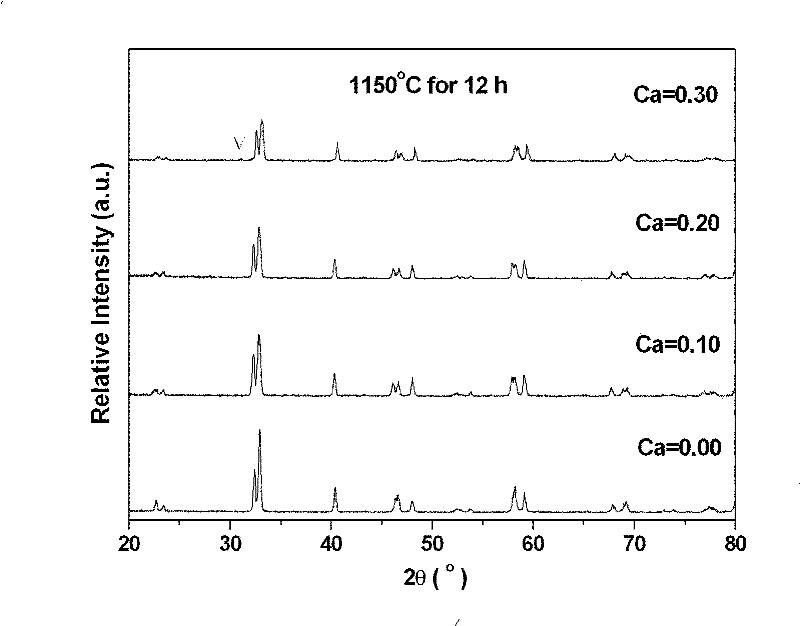

[0033] figure 2 It is Sm sintered at 1150℃ for 12 hours 1-x Ca x BaCo 2 o 5+δ XRD spectrum of (x=0.1, 0.2, 0.3). From figure 2 It can be seen that when x=0.3, there are impurity phase components in the XRD spectrum of the sample. It shows that when x=0.3, the samp...

Embodiment 3

[0034] Embodiment 3 The preparation method of cathode material of the present invention

[0035] 1. Follow Y 1-x Sr x BaCo 2 o 5+δ The stoichiometric ratio of Y 2 o 3 , BaCO 3 , SrCO 3 and Co 3 o 4 , Put the above oxide powder into an agate mortar and add alcohol to grind it thoroughly for 1 hour, then press it at 200-350MPa and place it in a furnace for calcination at 1000°C for 12 hours. The pre-calcined sample was crushed and ground for 1 hour, pressed and formed at 200-350 MPa, and calcined for the second time at 1050°C for 12 hours.

[0036] 2. Grind the above-mentioned calcined sample into powder, press molding at 220-350MPa, and finally put it in a muffle furnace for sintering at 1100°C for 20 hours, and cool it down to room temperature to obtain a double perovskite structure Y 1-x Sr x BaCo 2 o 5+δ cathode material.

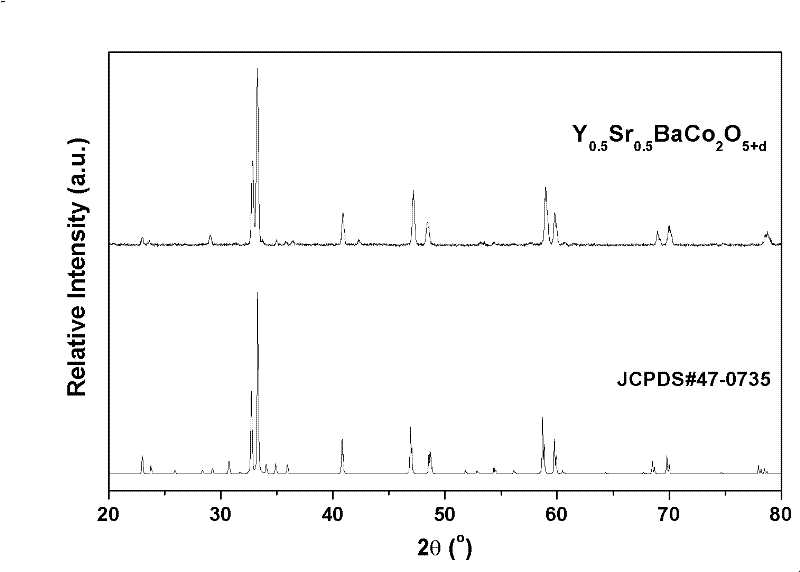

[0037] image 3 Y is obtained by sintering at 1100°C for 20 hours 0.5 Sr 0.5 BaCo 2 o 5+δ The XRD spectrum, from image 3 It can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com