Demagnetization device and method for telescopic guide sleeve of hub bearing

A wheel hub bearing, telescopic technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of insufficient demagnetization of bearing inner ring parts, reduced bearing service life, unsmooth bearing operation, etc., to achieve enhanced demagnetization effect, adaptability Strong, solve the effect of insufficient surface demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention. In order to simplify the model, the following description uses a two-stage magnetic guide sleeve structure to introduce the present invention in detail, and the actual application process is not limited to the two-stage magnetic guide sleeve structure.

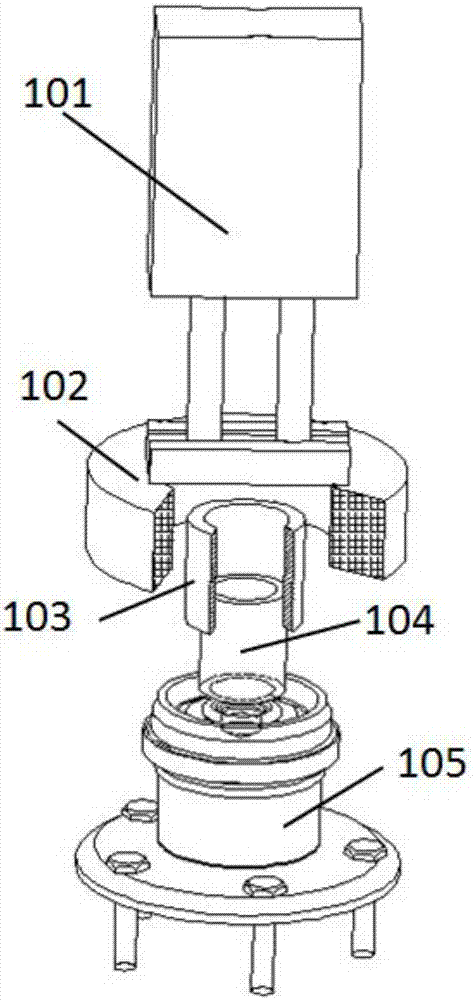

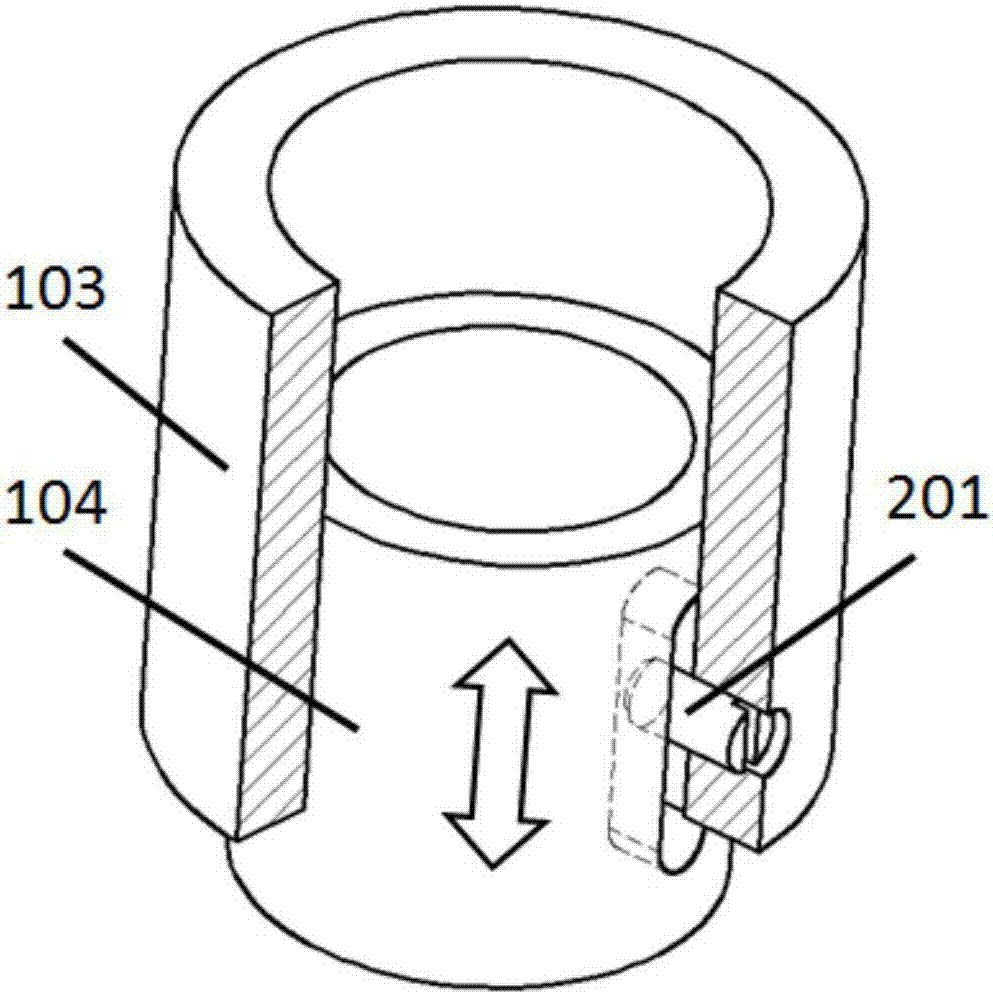

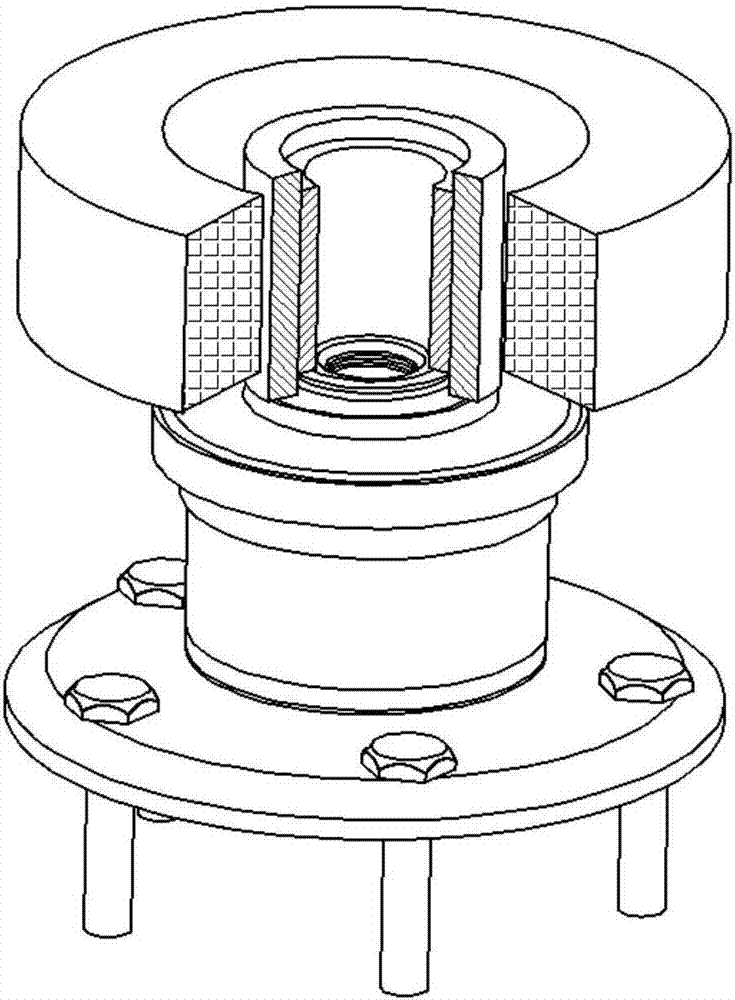

[0028] Such as figure 1 Shown is the wheel bearing telescopic guide sleeve demagnetization device of the present invention, which mainly includes a rod cylinder 101, an AC demagnetization coil 102, a telescopic magnetic guide sleeve and a hub bearing 105, and the piston rod of the rod cylinder 101 is connected to the The upper end surface of the AC demagnetization coil 102 is fixedly connected, and can drive the AC demagnetization coil 102 to move up and down. The tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com