Improved demagnetizing machine

An improved magnetic machine technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem of high material loss rate, achieve the effect of enhancing demagnetization ability, saving production cost, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

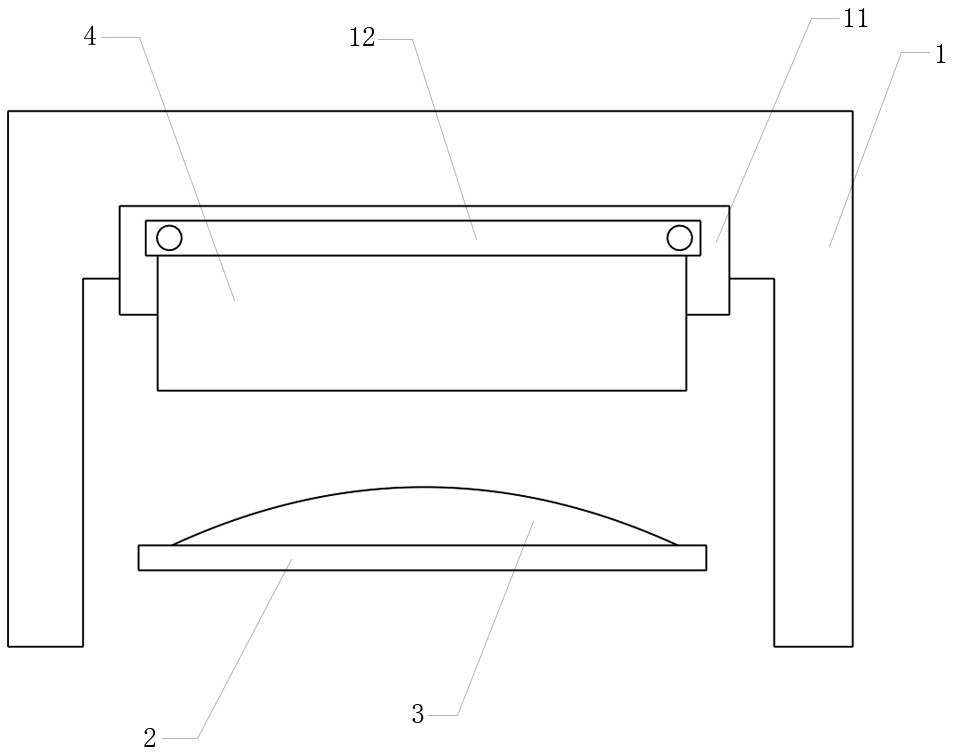

[0032] This embodiment provides an improved demagnetizer, as attached figure 1 As shown, it includes a stand 1, a mounting frame 11 arranged at the lower end of the stand 1, a demagnetization structure 4 installed at the lower end of the mounting frame 11, and a transmission structure 2 arranged at the lower end of the demagnetization structure 4, The installation frame 11 is provided with a fixed collection structure 12 for fixing the demagnetization structure 4 and cleaning and collecting the magnetic substances adsorbed on the demagnetization structure 4 .

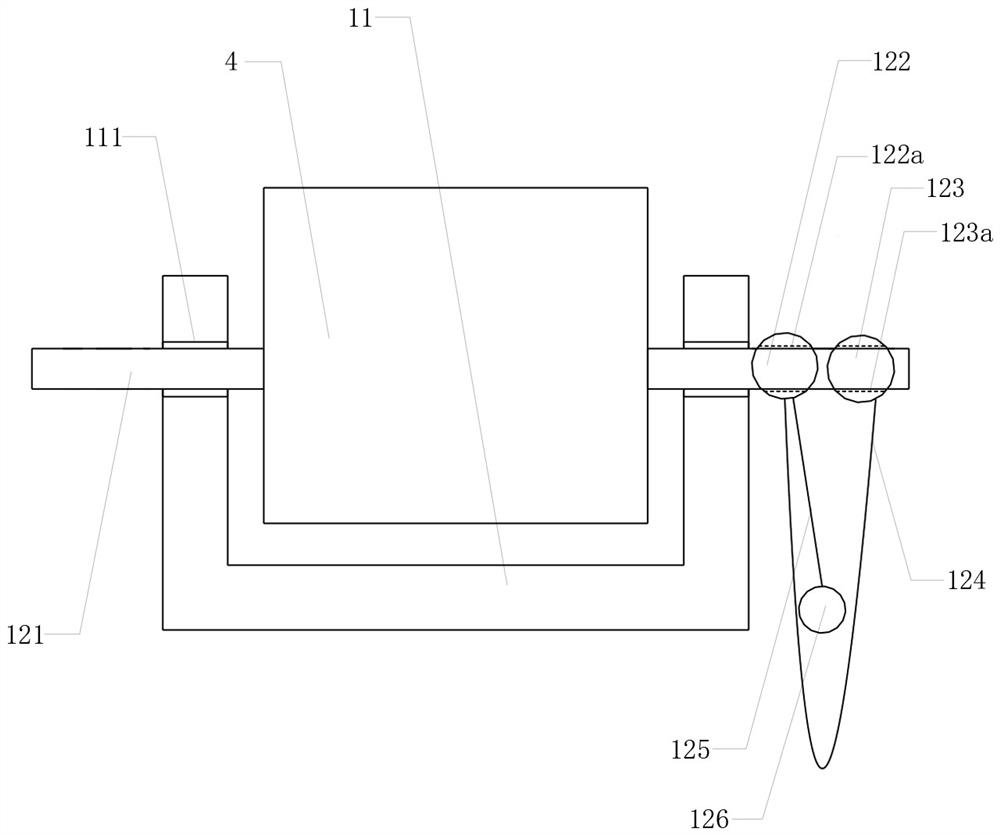

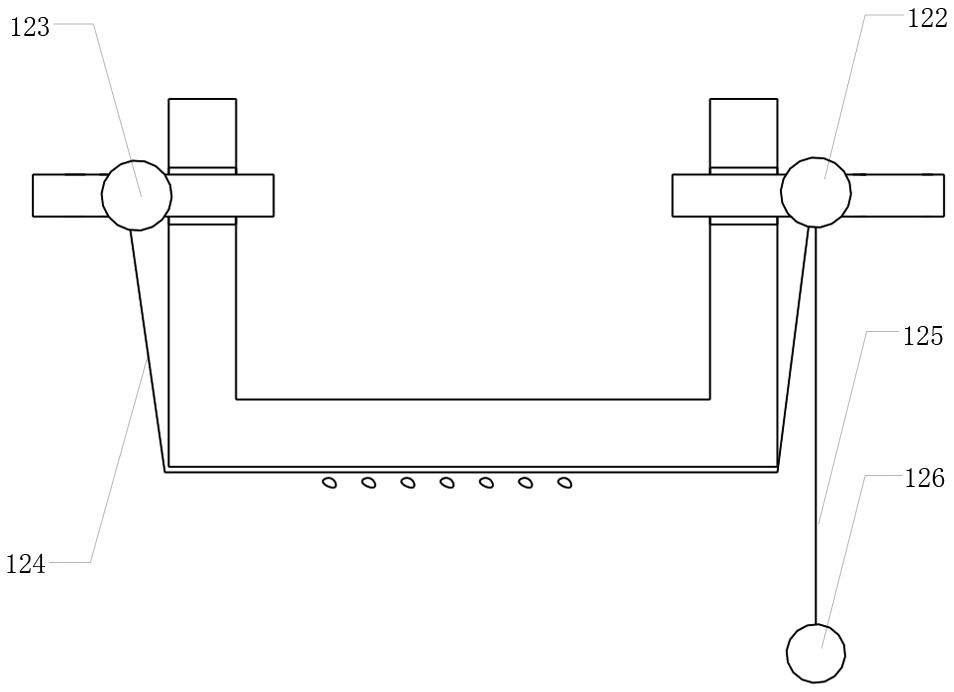

[0033] In this embodiment, as attached figure 2 As shown, the fixed collecting structure 12 includes a channel 111 that passes through the two ends of the mounting frame 11 and is used to fix the two sides of the demagnetizing structure 4. A fixing frame 121 is provided with a first mounting hole 122a The first installation rod 122 and the second installation rod 123 provided with the second installation hole 123a are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com