Space rotary alternating magnetic field demagnetizing pole set

A technology of alternating magnetic field and space rotation, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of poor demagnetization effect, impossible to solve the diversification of residual magnetism of workpieces, and impossible demagnetization of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

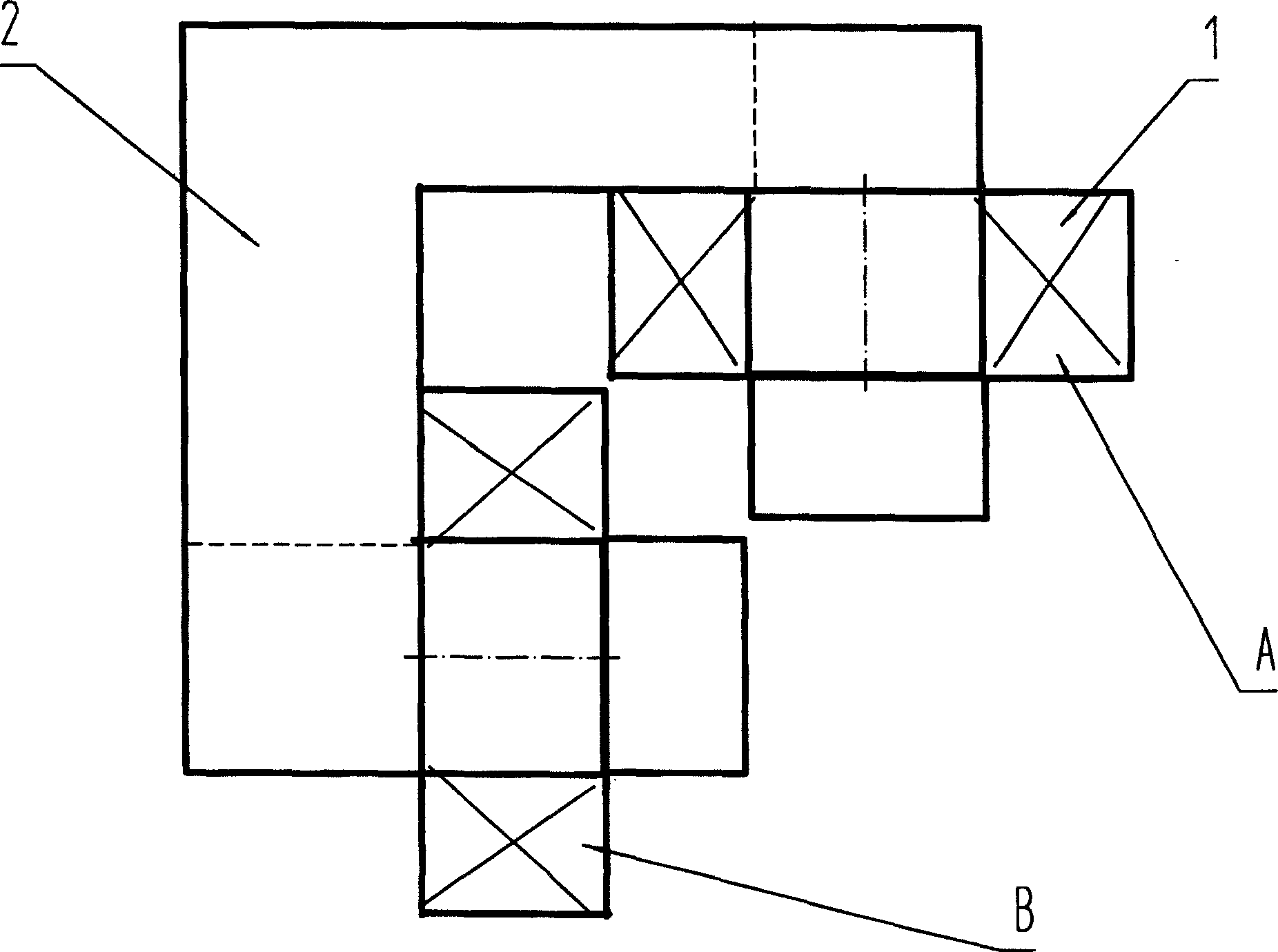

[0014] Such as figure 1 The one shown adopts a set of two-phase demagnetization pole groups, which is composed of demagnetization pole A and demagnetization pole B. The coil 1 installed on the iron core 2 is connected to the two-phase power supply. The two demagnetization poles are on the same plane, and the included angle is 90 degrees. .

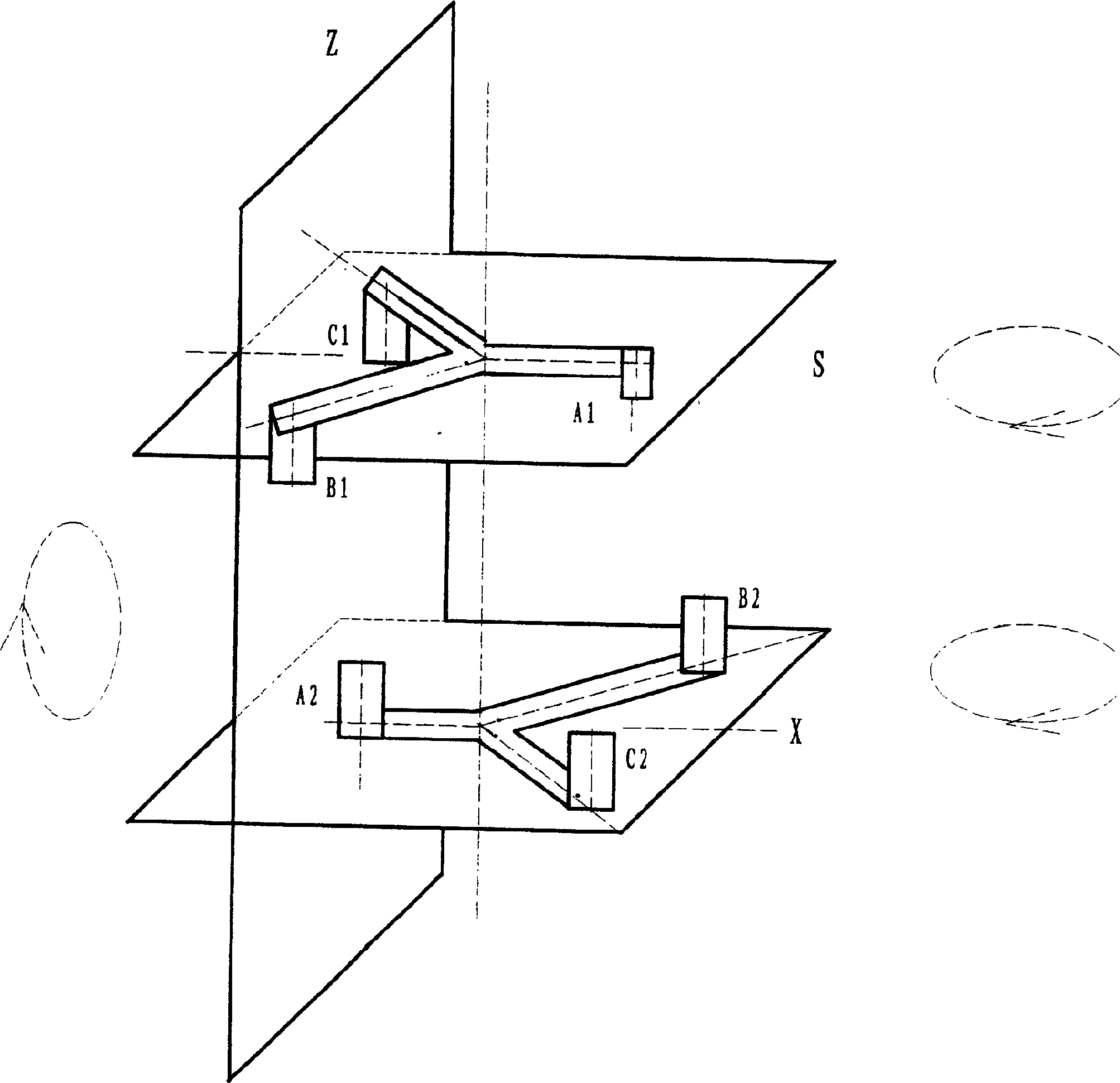

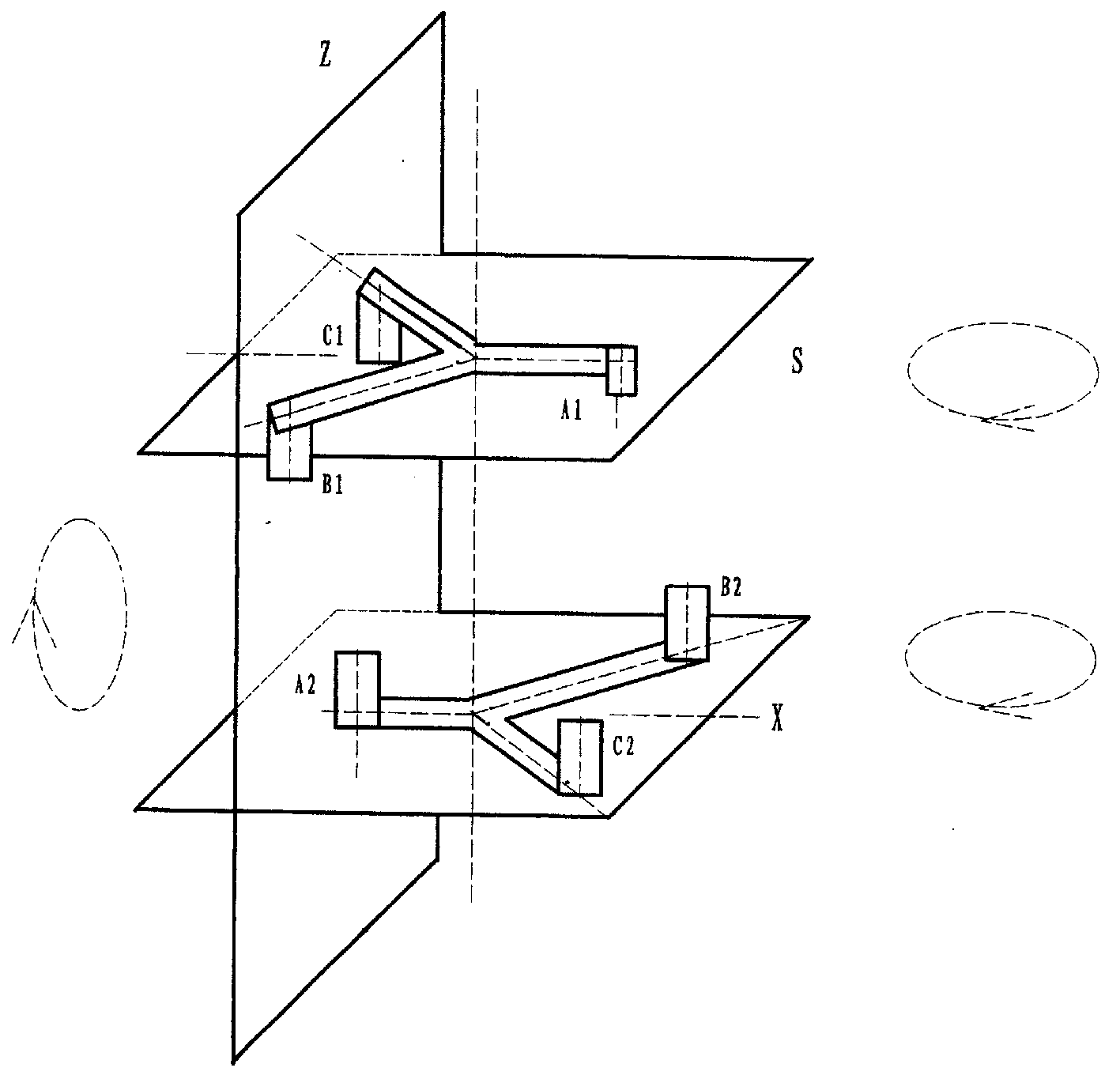

[0015] Such as figure 2 As shown, two groups of demagnetization pole groups are used, and each group of demagnetization poles is composed of three demagnetization poles. The demagnetization coils are arranged in a "Y"-shaped array, and can also be arranged in a "△"-shaped array, forming A1 and B1 on the S surface. , C1 three demagnetization poles, there are A2, B2, C2 three demagnetization poles on the X surface, the three demagnetization poles form a plane rotating magnetic field, and the coils on the three magnetic poles are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com