Rotary demagnetization method for medium and large bearing ring under erection state

A bearing ring, demagnetization technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of inability to demagnetize, medium and large bearing rings without demagnetization device, waste and other problems, achieve convenient feeding and unloading, eliminate demagnetization Blind area, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

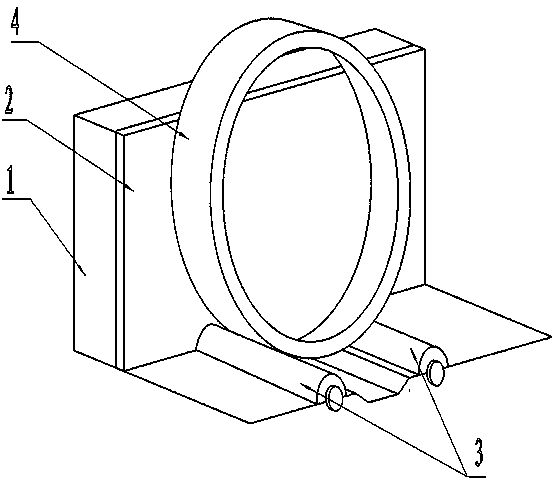

[0018] The invention is a rotating demagnetization method for medium and large bearing rings in a stand-up state, that is, a stand-up clinging + rotating demagnetization method. For the demagnetization range of large bearing rings or bearing rings of other specifications, the demagnetization efficiency is greatly improved.

[0019] In the present invention, the medium and large bearing rings refer to bearing rings with diameters ranging from 300 to 1000 mm. The maximum width of medium and large bearing rings is set to be D. The rotary demagnetization method involves a rotary demagnetization device, and the rotary demagnetization device Including the demagnetization box, the working panel and the driving guide roller, the volume of the demagnetization box is height G×width K×thickness H, and the H depends on the thickness of the magnetic pole configured by the conventional technology, which is surrounded by the G×K Take one of the two surfaces and call it the demagnetization su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com