Compound wave demagnetizer

A composite wave and demagnetization technology, which is applied in the direction of magnetic separation, magnetic objects, chemical instruments and methods, etc., can solve problems affecting concentration, dehydration and filtration operations, deterioration of beneficiation indicators, and decline in separation accuracy, achieving good demagnetization effects , The demagnetization effect is obvious, and the effect of improving the grade and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention is described in detail below according to specific embodiments:

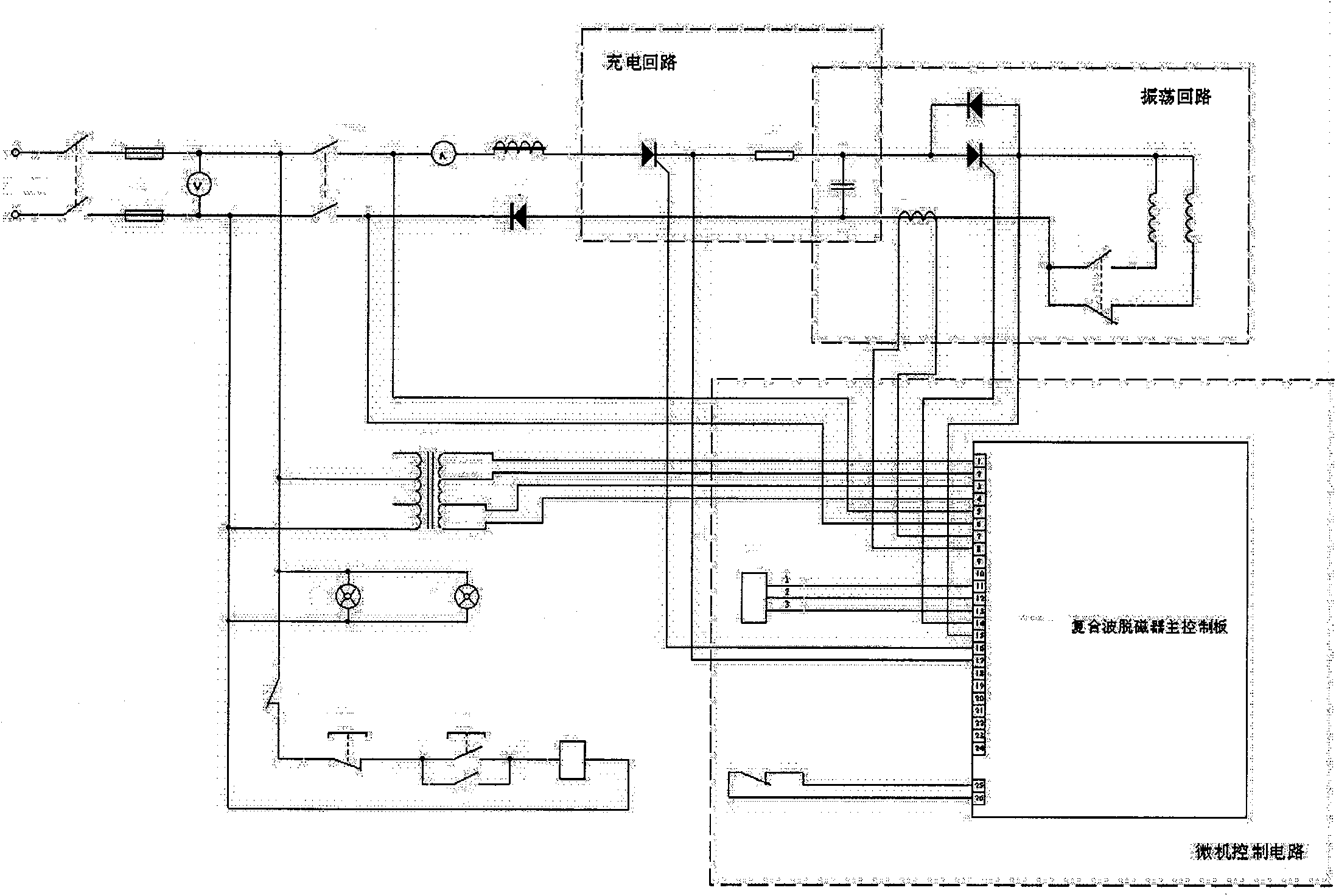

[0029] The composite wave demagnetizer is composed of charging circuit 2, oscillation circuit 3 and microcomputer control system 1. Microcomputer control system 1 uses capacitors and demagnetization coils to form and connect vibration circuits to generate damped oscillations. The first and second damped oscillation waves with different frequencies and amplitudes are generated through the intelligent control system, and synthesized to form composite waves. The composite wave of reciprocating oscillation produces an alternating magnetic field with small axial gradient and large field strength in the coil, so that the ore pulp flows through the coil to obtain demagnetization.

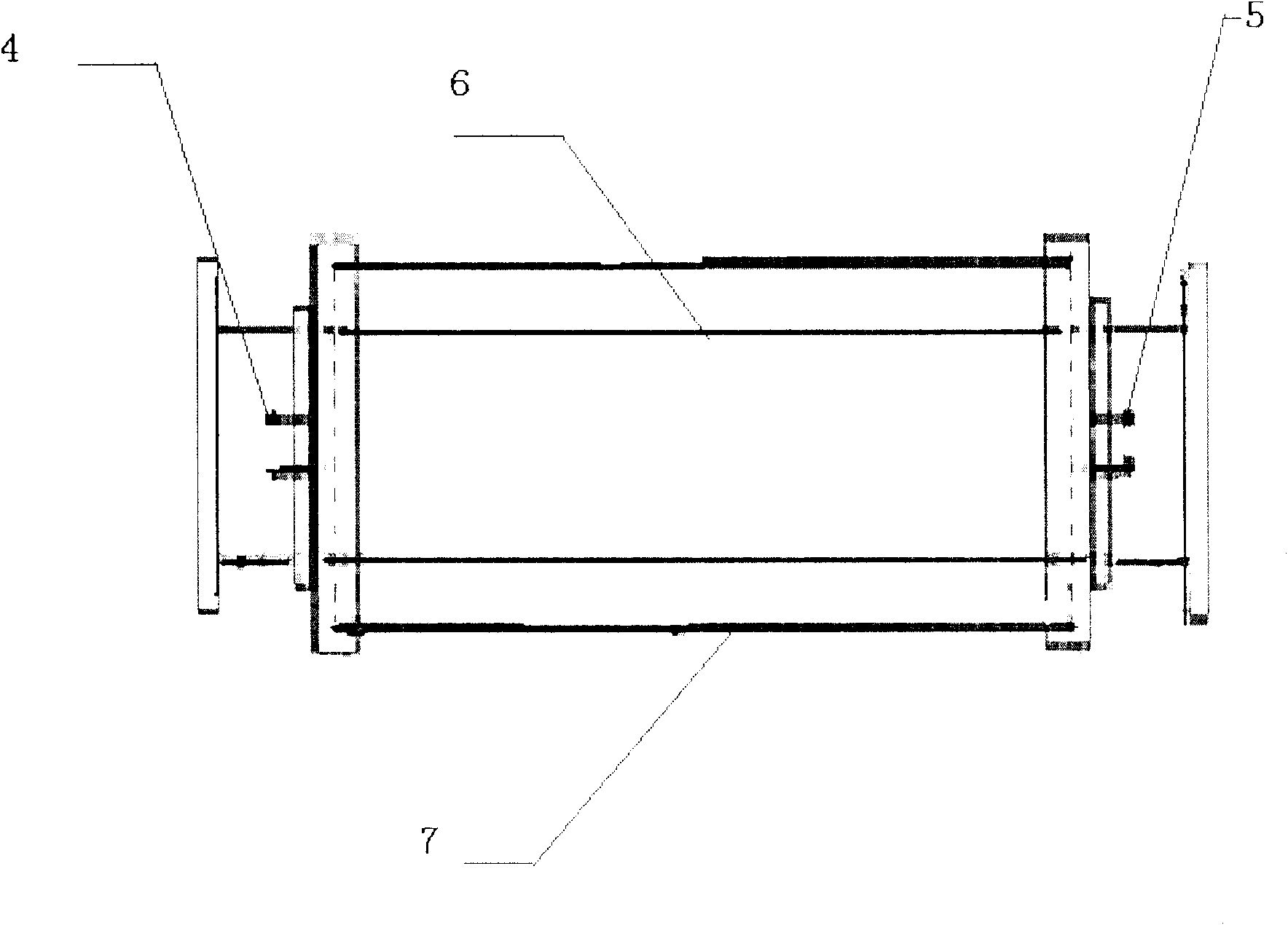

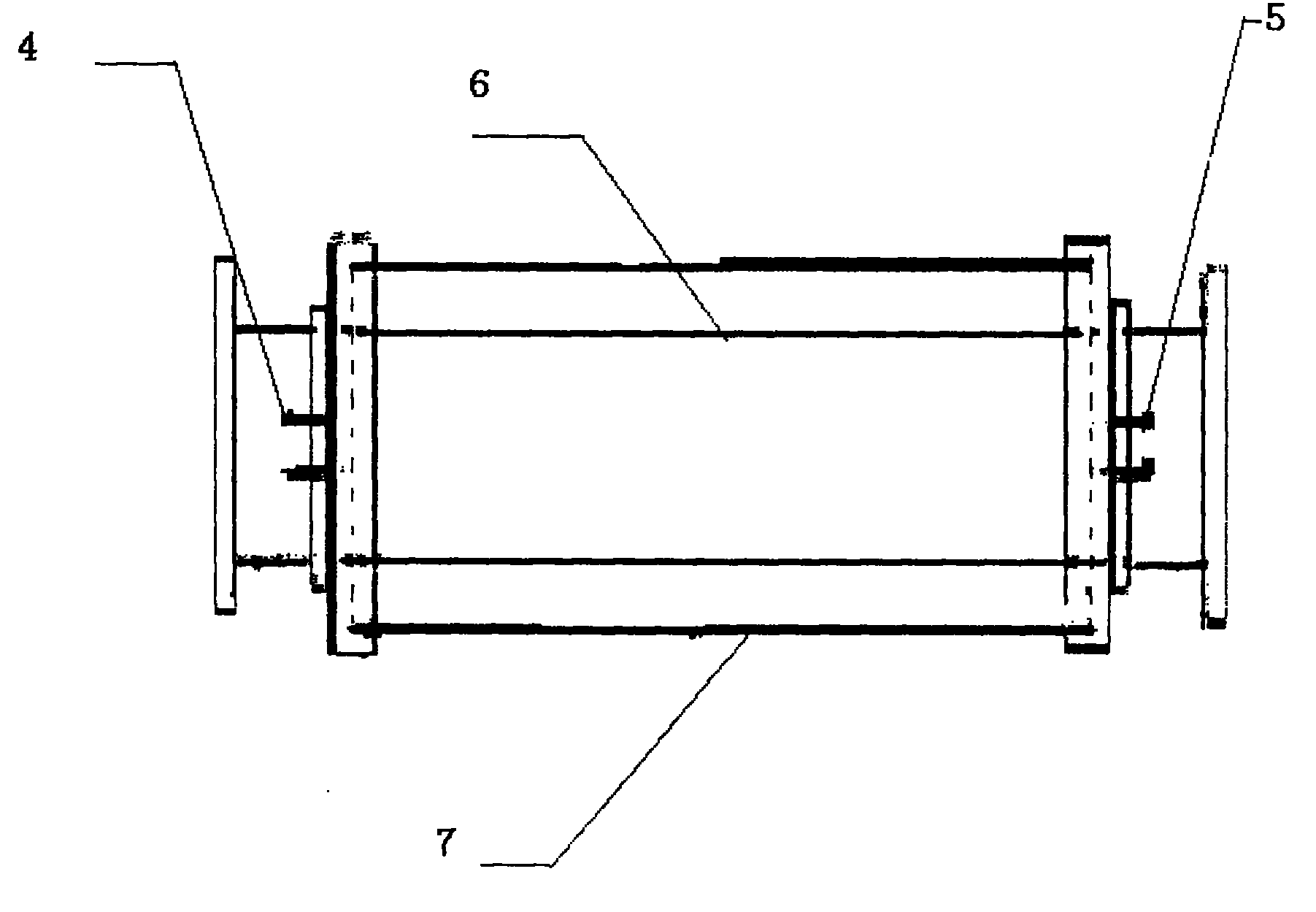

[0030] The technical scheme of the present invention adopts the alternate working mode of double demagnetization coils, and the non-metallic pulp pipe 6 adopts non-metallic materials, such as high molecular weight polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com