'V' type builti-in rotor of permanent megnet dynamo

A permanent magnet motor, built-in technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., to achieve the effect of increasing reactive reactance, reducing weight, and reducing iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

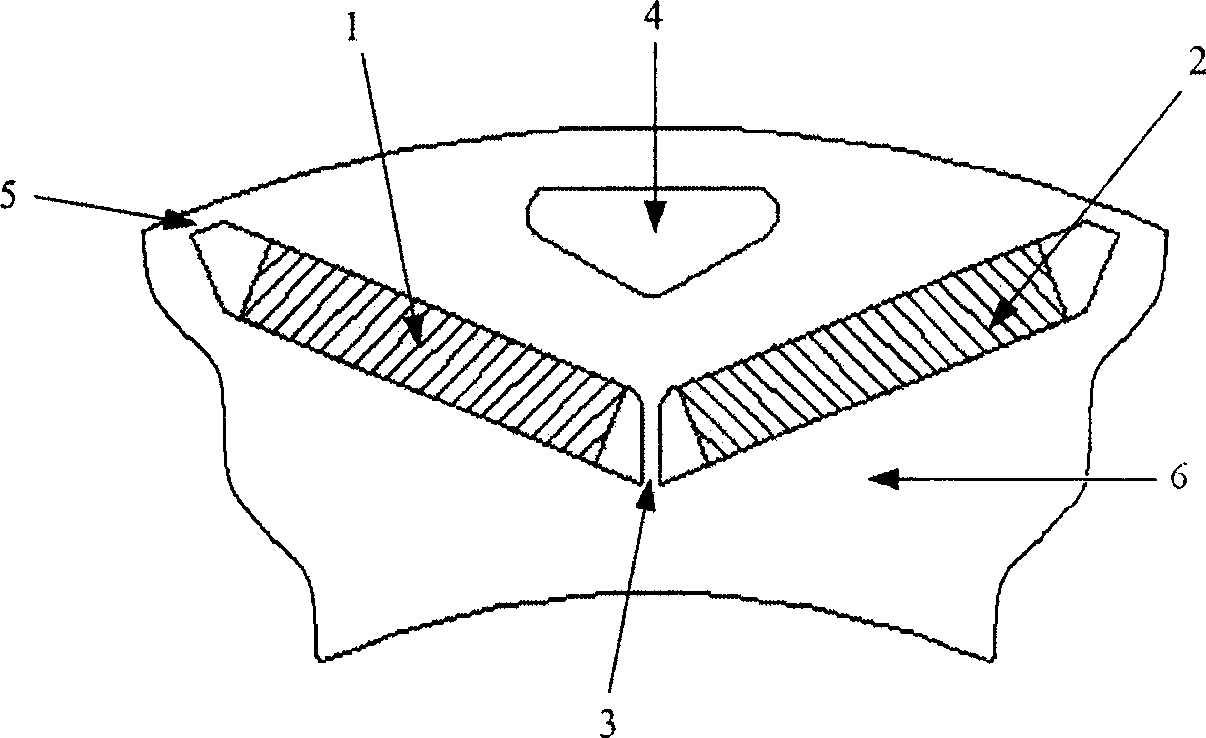

[0025] The "V" type built-in rotor structure of the permanent magnet motor of the present invention will be further described in detail in conjunction with the accompanying drawings and specific implementation examples:

[0026] see figure 2 In the "V" type built-in rotor of the permanent magnet motor, the lower permanent magnet poles of each pole are composed of two permanent magnets (1, 2) with the same shape and the same polarity embedded in the rotor core (6 ), the iron core part in the middle of the two permanent magnets (1, 2) is a reinforcing rib (3), and an auxiliary hole (4) is arranged directly above the reinforcing rib (3).

[0027] The polar arc coefficient of the permanent magnet and the angle between the permanent magnets and the size of the magnetic isolation bridge (5) and the rib (3) need to be analyzed by means of finite element analysis software for coupling simulation analysis of the motor magnetic field and the stress field, and try to make the opposite e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com