Workpiece magnetic powder inspection device with hole in middle and complicated shape

A magnetic particle inspection and complex technology, applied in the field of workpiece magnetic particle inspection devices, can solve the problems of uneven magnetic field, missed inspection, inability to clearly display cracks, etc., and achieve the effect of good demagnetization effect and strong anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

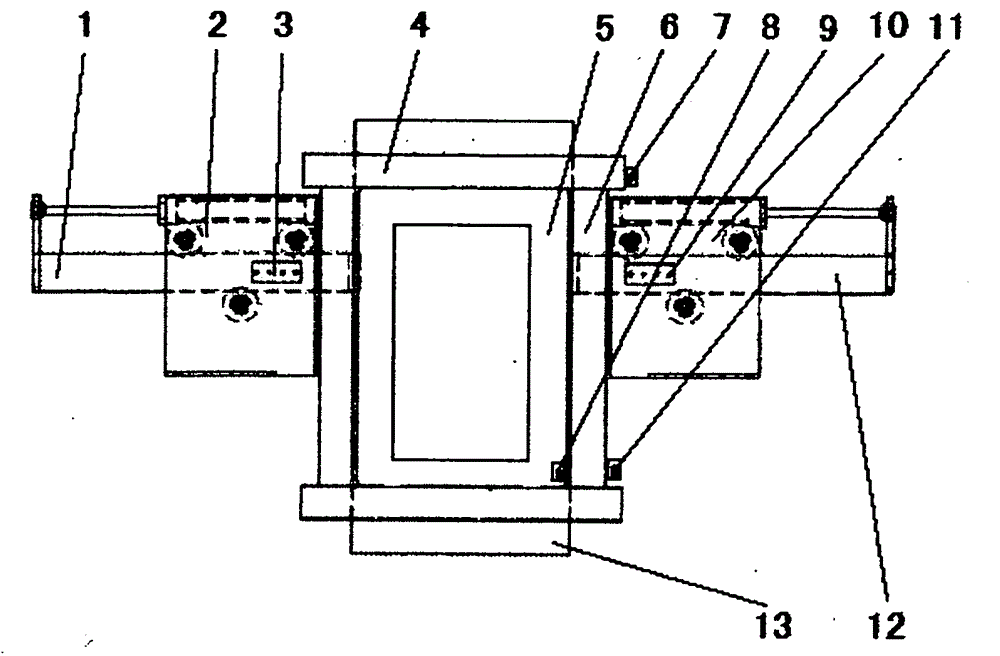

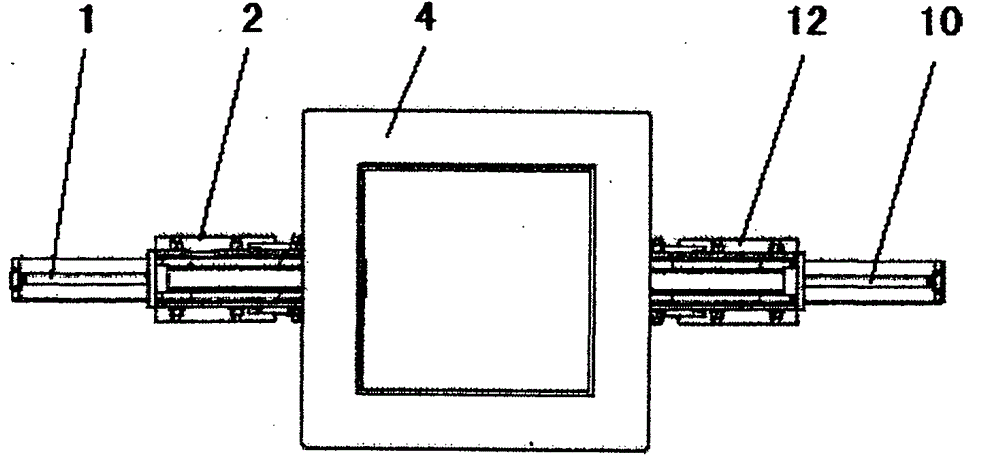

[0010] exist figure 1 Among them, upper and lower coils (4), front and rear coils (5), left and right coils (6) are fixed on the outside of the insulator skeleton (13), and the left silicon steel sheet electrode shaft (1) is connected with the left cylinder and the left moving coil (2). The electrode shaft penetrates the left coil in the left and right coils (6), and the electrode shaft after the right silicon steel sheet electrode shaft (12) is connected with the right cylinder and the right moving coil (10) penetrates the right coil in the left and right coils (6). On the left cylinder and the left moving coil (2) there is a left moving coil magnetization power input terminal (3), on the right cylinder and the right moving coil (10) there is a right moving coil magnetization power input end (9), and the left and right coils (6) There are upper and lower coils (4) on the upper and lower sides of the left and right coils (6), front and rear coils (5) are arranged on the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com