Grinder chuck magnetizing and demagnetizing controller

A grinding machine suction cup, charging and demagnetization technology, applied in the direction of magnetic objects, grinding workpiece supports, electrical components, etc., can solve problems such as electric corrosion, easy heating of devices, and large output power of the H-bridge of the main circuit, so as to reduce manufacturing costs and reduce Power consumption requirements, the effect of good demagnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

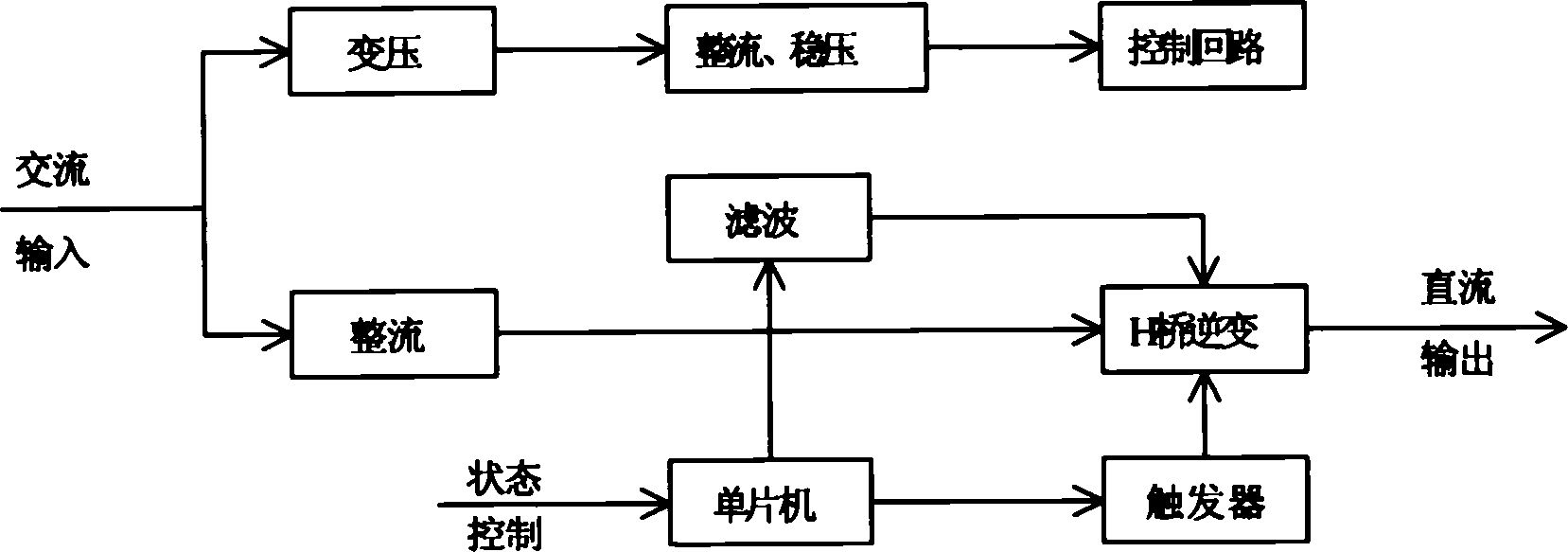

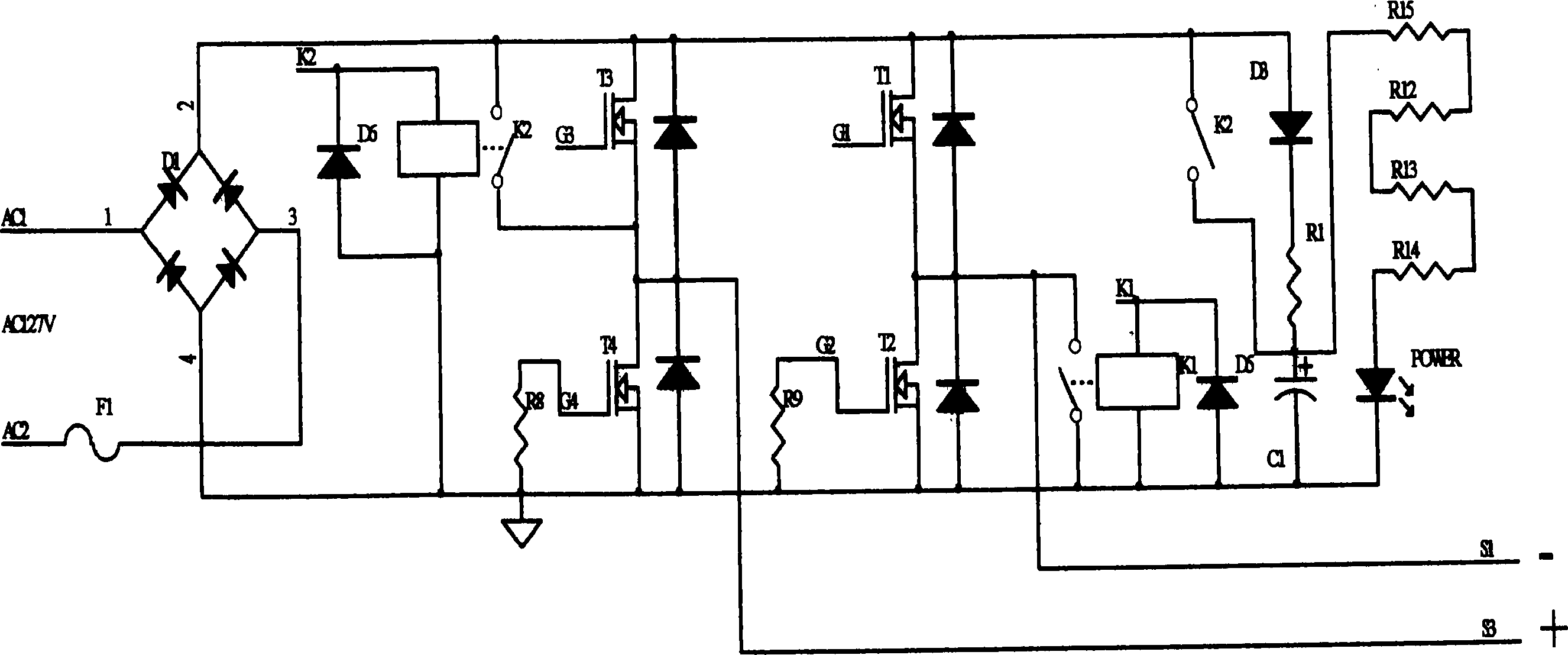

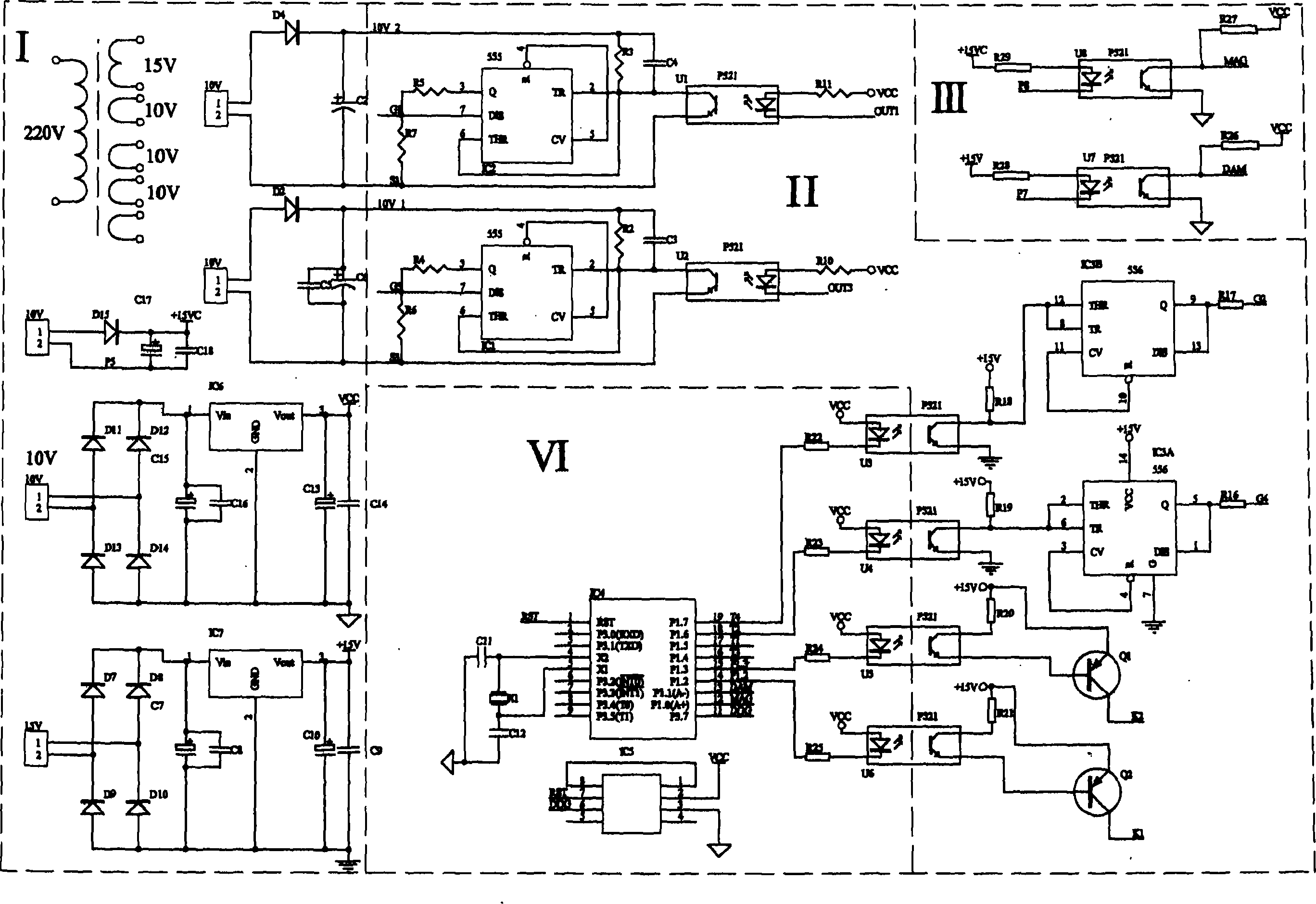

[0016] The idea of the technical solution of the present invention is: ① The magnetization of the grinding machine sucker is controlled by a single-chip microcomputer, the main circuit adopts a relay output, and the relay contacts are kept in a maintained state and switched infrequently, thereby avoiding electric erosion of the contacts. ②The demagnetization control is switched from the single-chip microcomputer to the demagnetization state, and the program determines the demagnetization cycle and demagnetization time that can meet the requirements according to the indicators of different chucks and the demagnetization curve requirements of different materials to achieve a good demagnetization effect. ③The circuit adopts single-chip PWM (Pulse-Width Modulation) mode to drive the H-bridge output demagnetization, and the demagnetization is completed within the specified time, which avoids the power tube being in the working state for a long time, thereby prolonging the life of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com