Magnetic gap channel pass-type demagnetizer

A magnetic gap and demagnetization technology, which is applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of excessive residual magnetism, dirty demagnetization of bearing rings, reduced processing accuracy and product quality, and achieves the improvement of demagnetization pass rate, The demagnetization effect is stable and the effect of reducing the residual magnetism of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

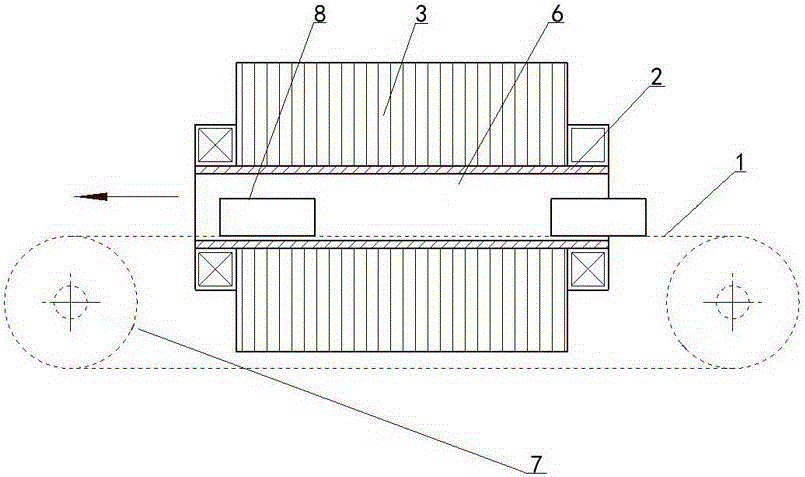

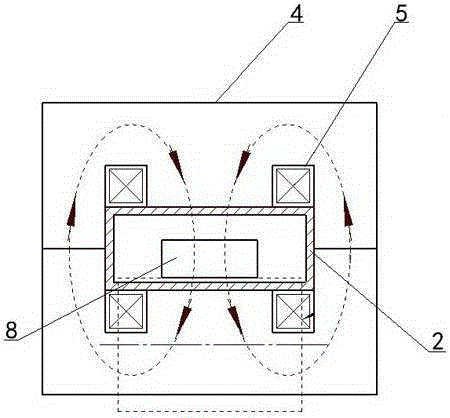

[0013] As shown in the figure: a magnetic gap channel pass-through demagnetization device, including a belt conveyor 1, a magnetic gap channel frame 2 and a demagnetization assembly 3, the belt conveyor 1 is used to transport the workpiece 8 to be demagnetized, and the magnetic gap channel frame 2 The material is bakelite board or phenolic board. The demagnetization assembly 3 includes two "E" shaped iron cores 4 and coil windings 5 matched with the iron cores 4. The "E" shaped iron core 4 has three iron core columns located in the middle The iron core column is shorter than the iron core column at both ends, and the coil winding 5 is sleeved on the iron core column in the middle, and the coil winding 5 is connected to the demagnetization circuit, and the openings of the two "E" shaped iron cores 4 are opposite to each other. After the docking, a magnetic gap channel 6 is formed, and the magnetic gap channel frame 2 is penetrated in the magnetic gap channel 6, and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com