Modified grinder cupula magnetizing and demagnetization controller

A grinding machine sucker, charging and demagnetization technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of high output power of the main circuit H bridge, inability to demagnetize the workpiece, and adhesion, so as to enhance anti-interference and reliability, improve Effect of demagnetization accuracy and shortening demagnetization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Accompanying drawing is embodiment of the present invention.

[0016] The content of the present invention will be further described below in conjunction with accompanying drawing:

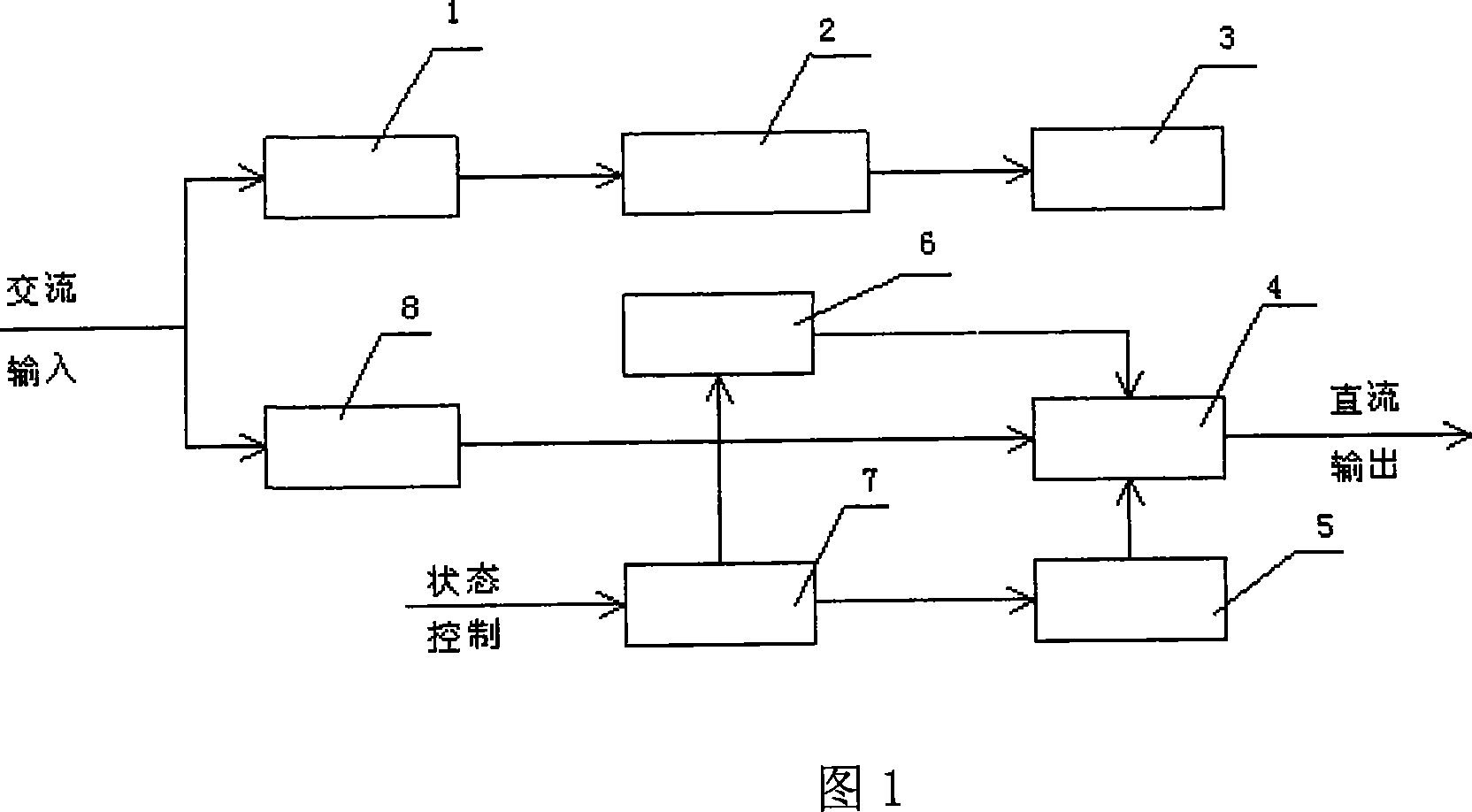

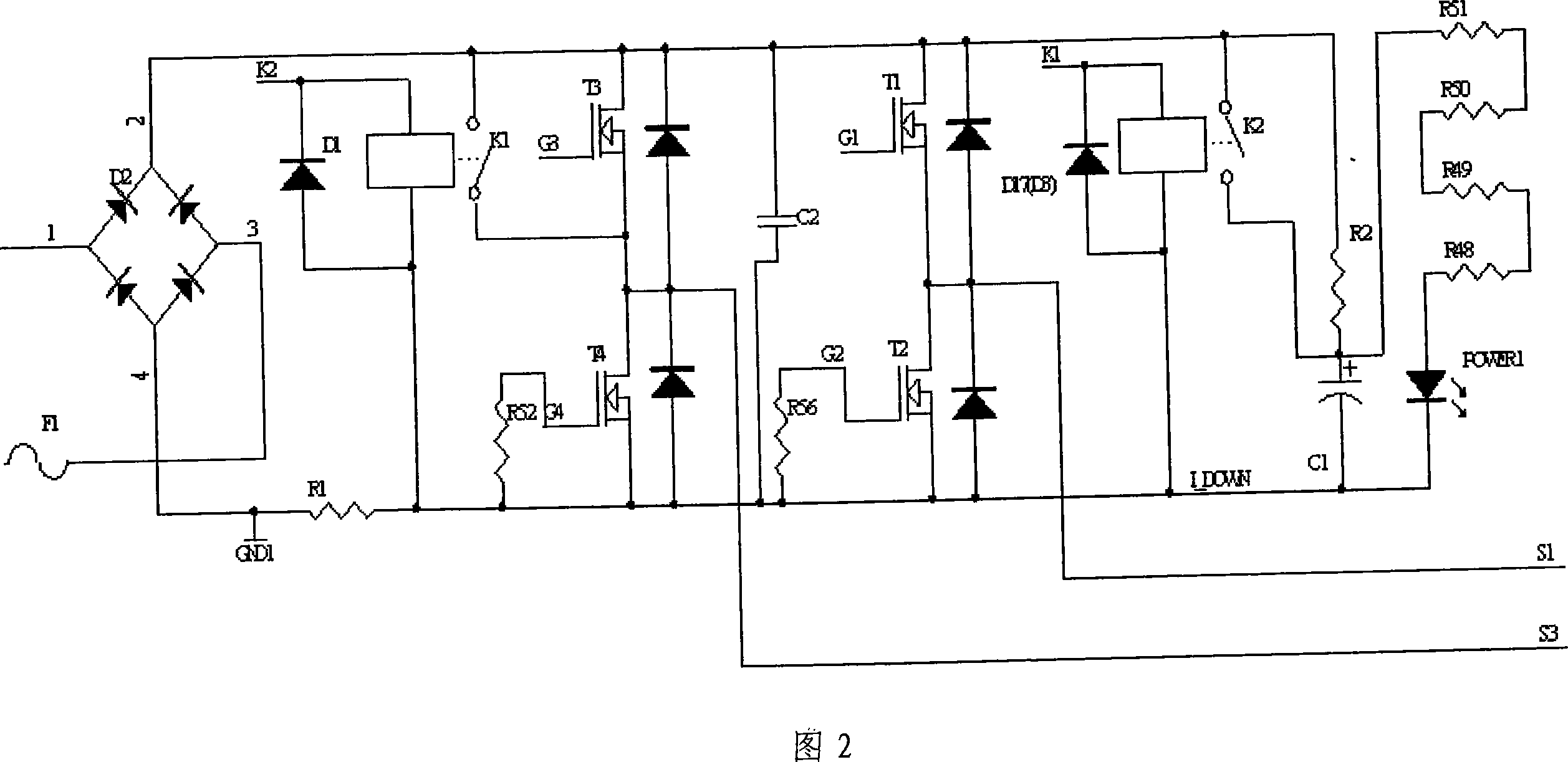

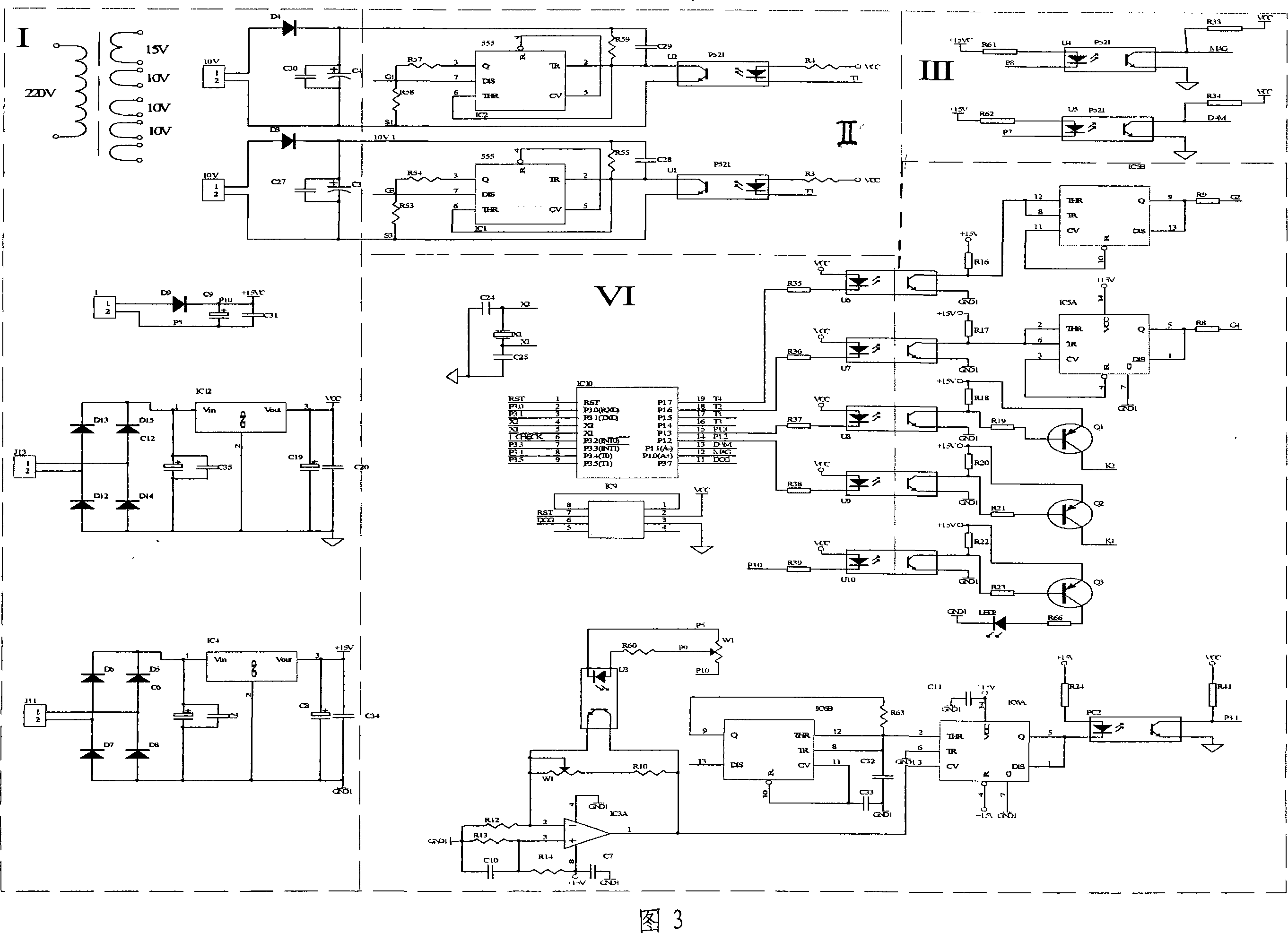

[0017] Referring to Figure 1, it consists of a main loop and a control loop. The main loop includes an H-bridge inverter circuit. The control loop includes output voltage forward and reverse switching control and output voltage amplitude control. The AC power supply is divided into two circuits and connected to transformer 1 and On the rectifier 8, the transformer 1 is connected with the rectification and voltage stabilization circuit 2, the rectification and voltage stabilization circuit 2 is connected with the control loop circuit 3, the rectifier 8 is connected with the H-bridge inverter 4, the state control 9 is connected with the single-chip microcomputer 7, and the single-chip microcomputer 7 is in turn The two circuits are respectively connected to the filter circuit 6 and the trigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com