Roller bearing unit

A rolling bearing and axial technology, applied in the field of rolling bearing units, can solve problems such as the temperature rise of the outer ring 2 and the hub 3, the gap between the fitting parts, etc., and achieve the effects of reducing weight, preventing electric corrosion, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

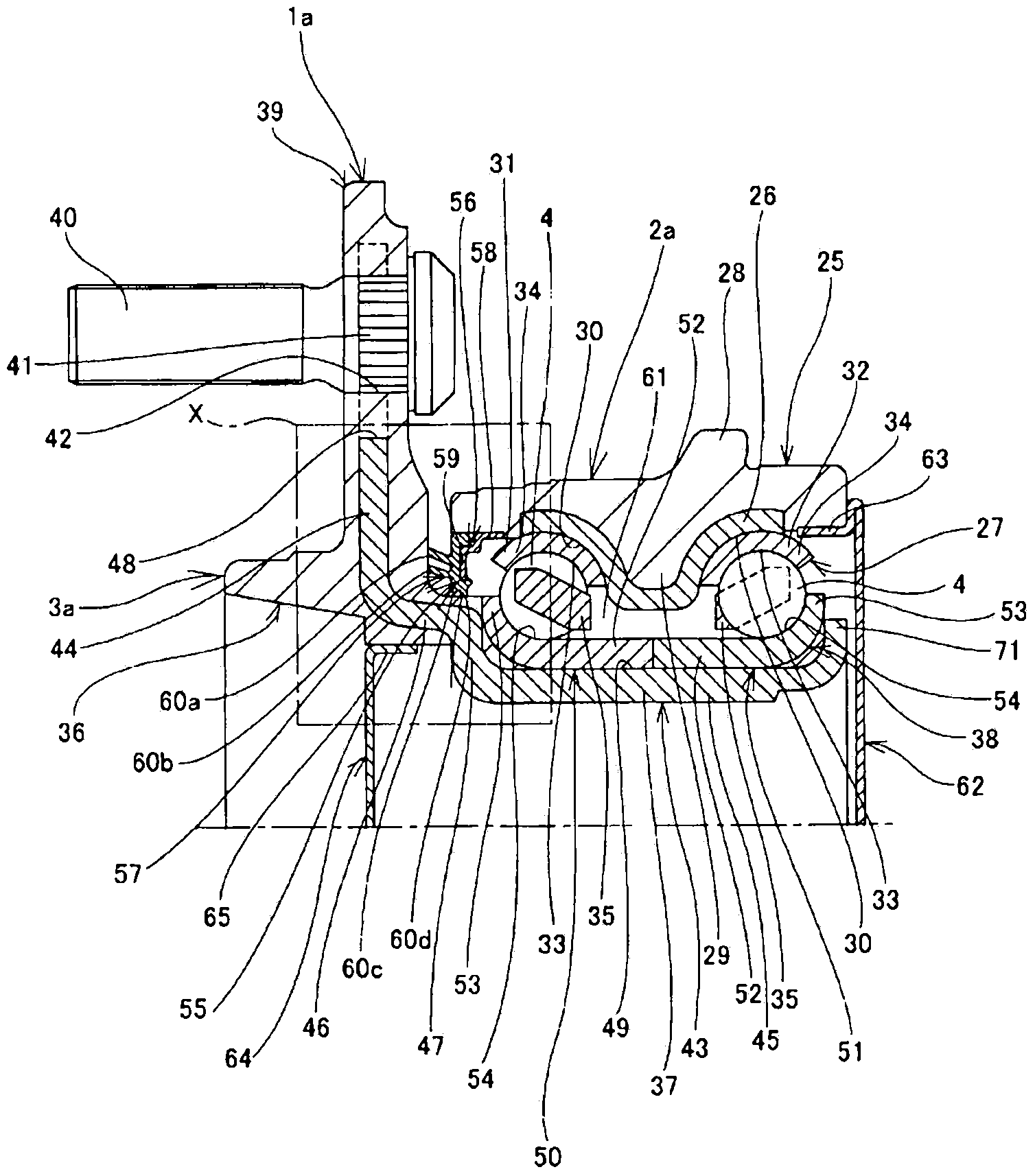

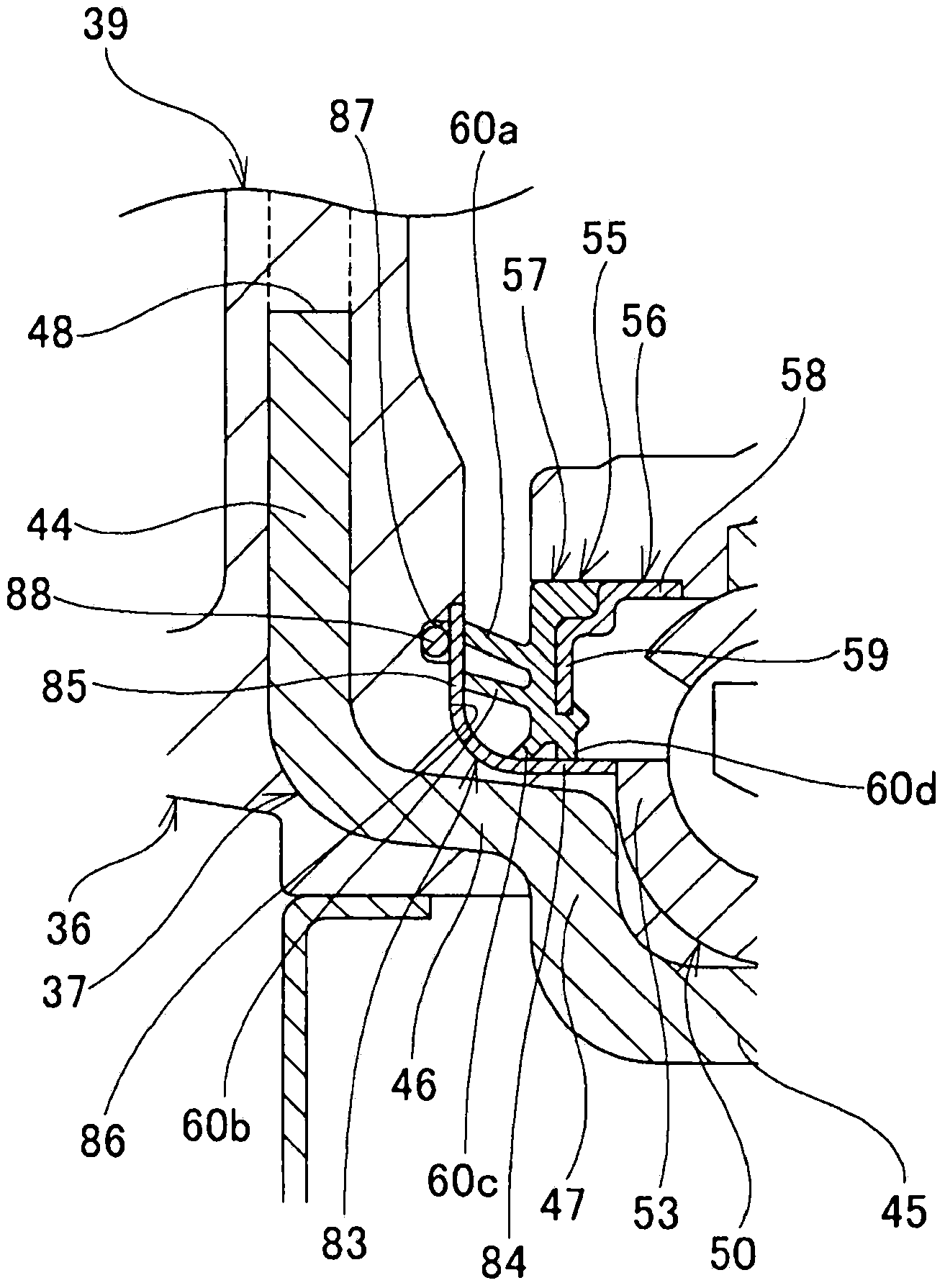

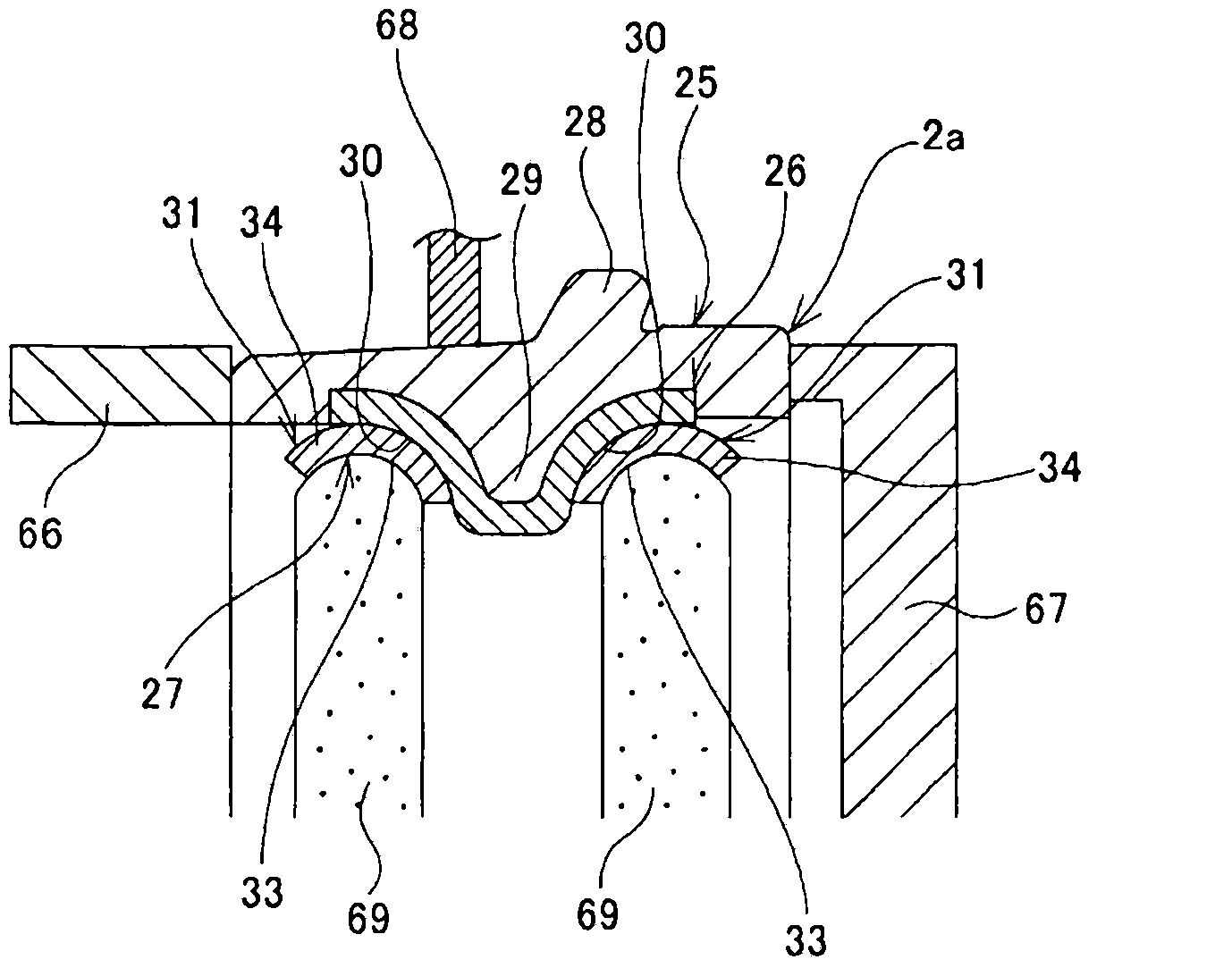

[0060] Hereinafter, the rolling bearing unit of the present invention will be described by taking several embodiments of the hub unit for supporting a wheel as examples. The rolling bearing unit of the present invention is characterized in that, in order to achieve both weight reduction and durability improvement, materials capable of weight reduction are used as its constituent parts, and the structure of the stationary side raceway ring and / or the rotation side raceway ring is considered.

[0061] [First example of embodiment]

[0062] Figure 1 to Figure 6 The first example of the embodiment of the present invention is shown. The hub unit 1a for supporting a wheel of this example is used for a driven wheel and has the same Figure 11 The shown conventional structure has the same basic structure. The hub unit 1a for supporting a wheel has: an outer ring 2a that is a stationary side raceway; a hub 3a that is a rotating side raceway arranged on the inner diameter side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com