Rotary demagnetizer and lithium battery negative electrode material powder processing device

A technology of demagnetization device and rotating power, applied in electrode manufacturing, circuits, magnetic objects, etc., can solve the problems of large size of demagnetization device, difficult cleaning, unfavorable installation, etc., to improve the effect of demagnetization, increase the contact area, The effect of easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

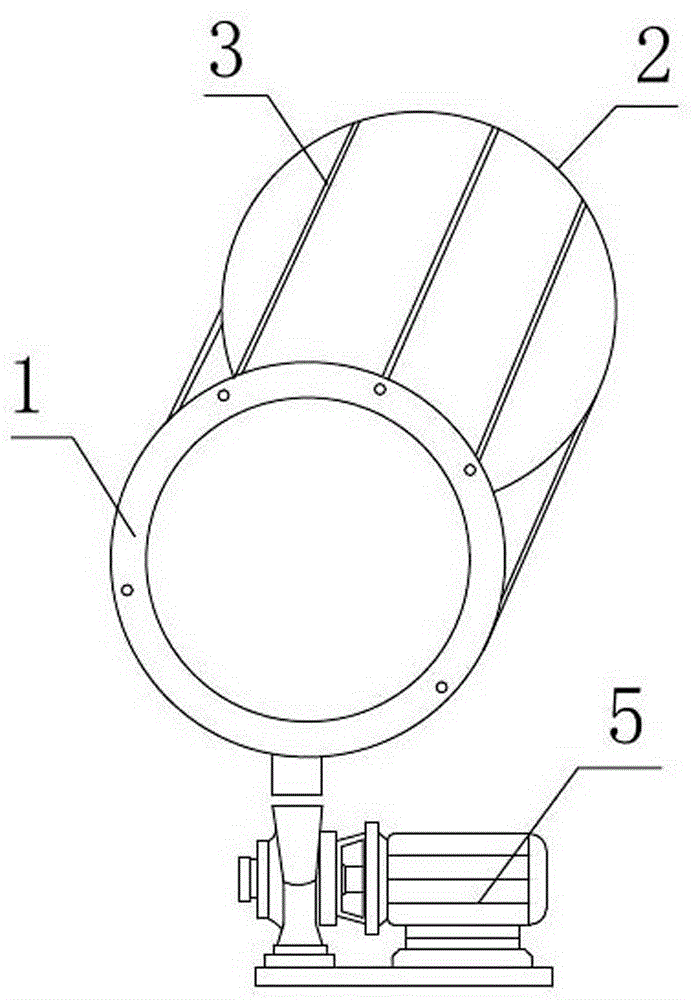

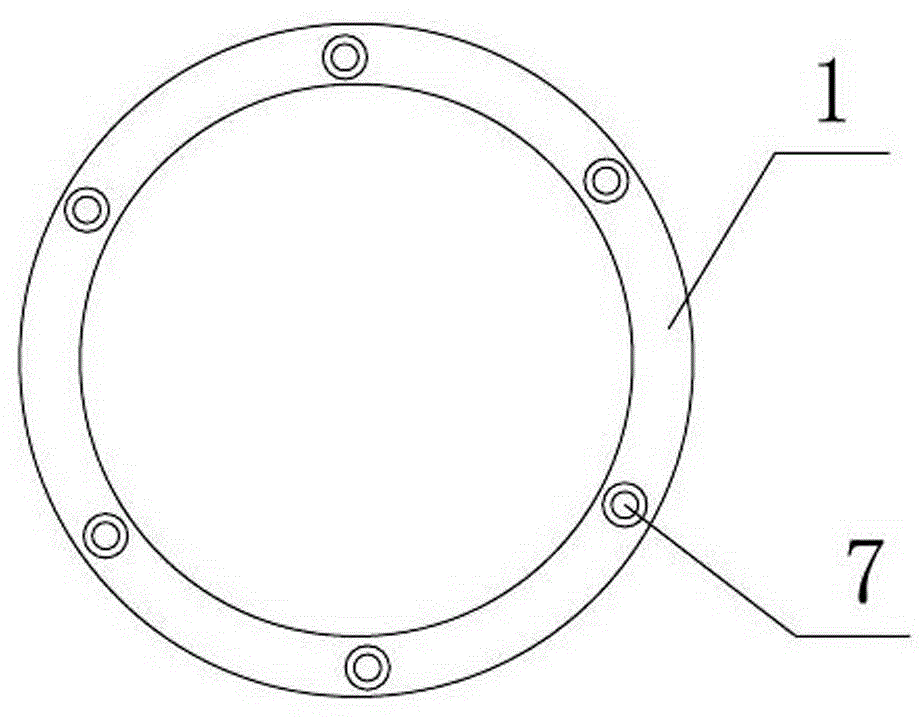

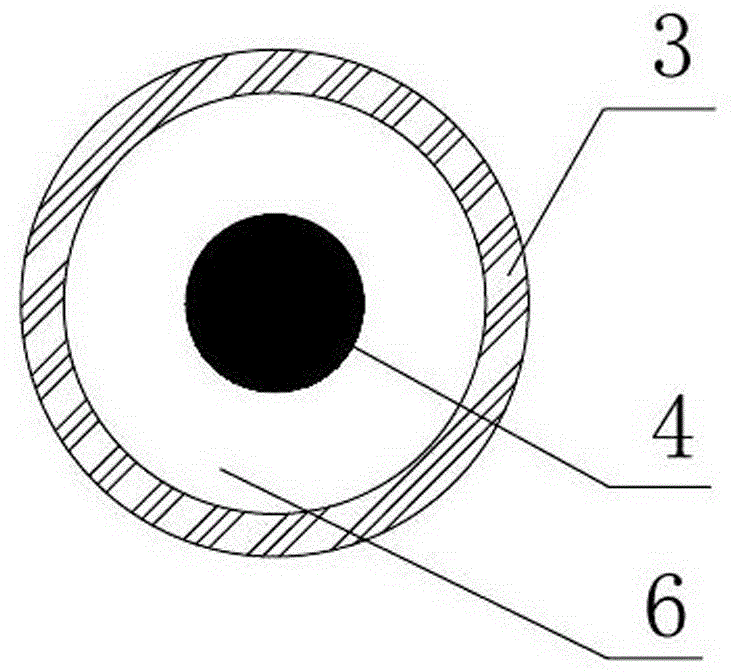

[0031] A rotary demagnetization device, comprising an annular feed tray 1 and a discharge tray 2, the feed tray 1 and the discharge tray 2 correspond to each other; 6 cylinders are arranged between the feed tray 1 and the discharge tray 2 Shaped stainless steel sleeve 3, one end of stainless steel sleeve 3 is provided with opening, is provided with the magnetic bar 4 that activity puts in and takes out in stainless steel sleeve 3;

[0032] One end of the stainless steel sleeve 3 is fixed on the feeding tray 1, and the other end is provided with an opening 6 for putting in or taking out the magnetic bar, and is movable and fixed on the discharging tray 2.

[0033] 6 stainless steel sleeves are evenly distributed on the rings of the feed tray 1 and the discharge tray 2.

[0034] The opening 6 of the stainless steel sleeve 3 is provided with a sealing plug 7

Embodiment 2

[0036] A rotary demagnetization device, comprising an annular feed tray 1 and a discharge tray 2, the feed tray 1 and the discharge tray 2 correspond to each other; 6 cylinders are arranged between the feed tray 1 and the discharge tray 2 Shaped stainless steel sleeve 3, one end of stainless steel sleeve 3 is provided with opening, is provided with the magnetic bar 4 that activity puts in and takes out in stainless steel sleeve 3;

[0037] The two ends of the stainless steel sleeve 3 are movable and fixed on the feed tray 1 and the discharge tray 2 respectively, and the stainless steel sleeve 3 is provided with an opening 6 for putting in or taking out the magnetic bar at one end of the feed tray 1 .

[0038] Six stainless steel casing pipes 3 are evenly distributed on the rings of the feeding tray 1 and the discharging tray 2.

[0039] The opening of the stainless steel sleeve 3 is provided with a sealing plug.

Embodiment 3

[0041] A rotary demagnetization device, comprising an annular feed tray 1 and a discharge tray 2, the feed tray 1 and the discharge tray 2 correspond to each other; 6 cylinders are arranged between the feed tray 1 and the discharge tray 2 Shaped stainless steel sleeve 3, one end of stainless steel sleeve 3 is provided with opening, is provided with the magnetic bar 4 that activity puts in and takes out in stainless steel sleeve 3;

[0042] Both ends of the stainless steel sleeve 3 are respectively fixed on the feed tray 1 and the discharge tray 2, wherein the stainless steel sleeve 3 is provided with an opening 6 at one end of the discharge tray 2 for putting in or taking out the magnetic bar.

[0043] Six stainless steel casing pipes 3 are evenly distributed on the rings of the feeding tray 1 and the discharging tray 2.

[0044] The opening 6 of the stainless steel sleeve 3 is provided with a sealing plug 7 .

[0045] Working principle of the present invention is:

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com