Double-track frame demagnetizer

A demagnetizer and double-track technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve problems such as difficult to meet the use requirements and single function of the demagnetizer, and achieve the effects of convenient control, enhanced demagnetization, and simple overall configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the embodiments.

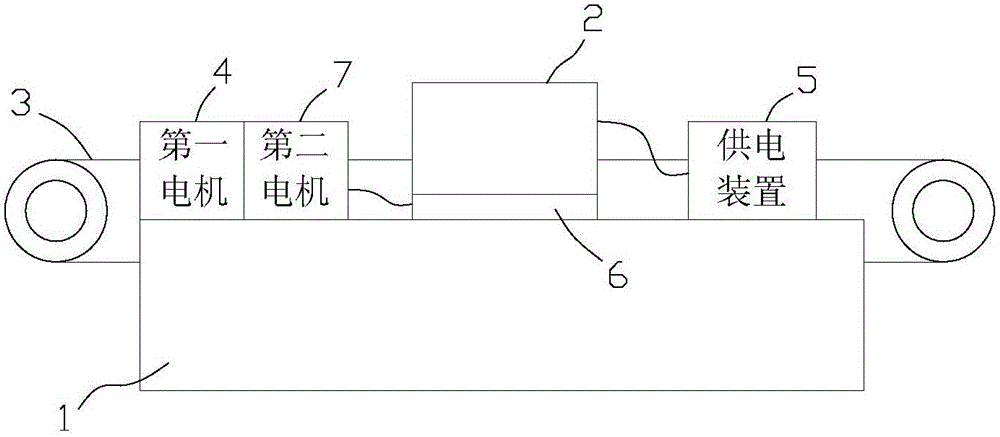

[0014] refer to figure 1 , The frame-type demagnetizer of the present invention is mainly composed of a frame 1, a frame-type demagnetization coil 2, a conveyor belt 3, a first motor 4, a power supply device 5, a support member 6 and a second motor 7. The first motor 4 is fixed on the frame 1 and is used to drive the conveyor belt 3 to move. When working, the bearing parts that need to be demagnetized are placed on the conveyor belt 3 and follow the movement of the conveyor belt 3 . The frame-type demagnetization coil 2 is powered by a power supply device 5. The power supply device 5 includes a transformer. By supplying alternating current to the frame-type demagnetization coil 2, the coil 2 generates a magnetic field. When the bearing passes through the magnetic field, the residual magnetism inside it will be eliminated. . In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com