Demagnetization method of high-strength steel narrow gap welding groove

A welding groove and narrow gap technology, applied in welding equipment, magnetic objects, arc welding equipment, etc., can solve the problems of high control requirements, adverse effects of weld penetration and weld formation, and low current density at the center of the weld and other problems, to achieve the effect of strong engineering adaptability, improved demagnetization effect, and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

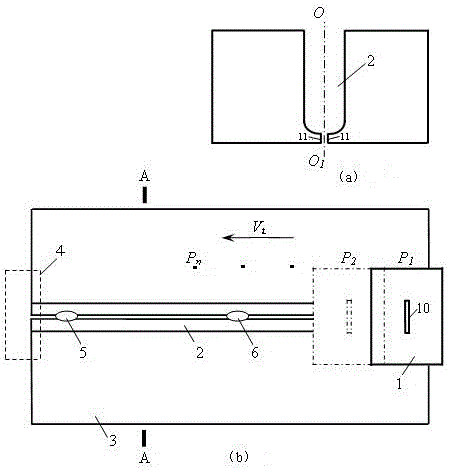

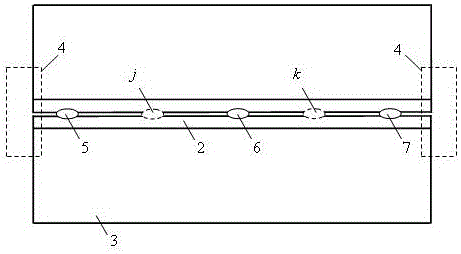

[0025] The implementation and implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited to the following examples. Before welding, the invention reduces the residual magnetism of the groove through specific point solid welding and the installation of an arc striker, and then uses a pulse demagnetizer to demagnetize the single-U or double-U-shaped groove several times according to different processes, and replaces it after each demagnetization The demagnetizer coil box moves in the direction until the residual magnetism of the groove drops below a certain value, and the demagnetization operation ends. details as follows:

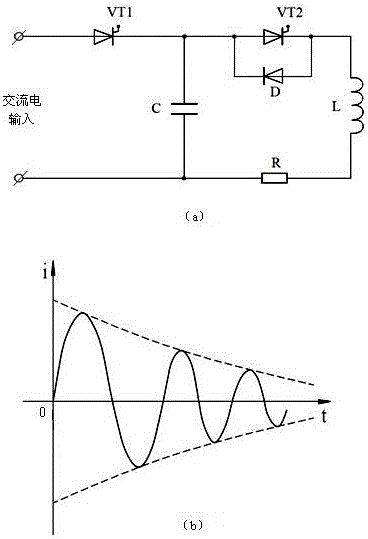

[0026] figure 1 Indicates the basic circuit principle of the pulse demagnetizer, where figure 1 (a) for the pulse demagnetizer RLC Oscillating circuit principle, figure 1 (b) is the oscillating current i decay cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com