Magnetic refrigeration device

A magnetic refrigeration and permanent magnet technology, which is applied in refrigerators, refrigeration and liquefaction, magnets, etc., can solve the problem of small air gap for magnetic working medium, limited radial air gap size, refrigeration or heating of magnetic refrigeration devices Low performance and other problems, to achieve the effect of increasing the volume of the air gap, increasing the effective working space, and improving the cooling or heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

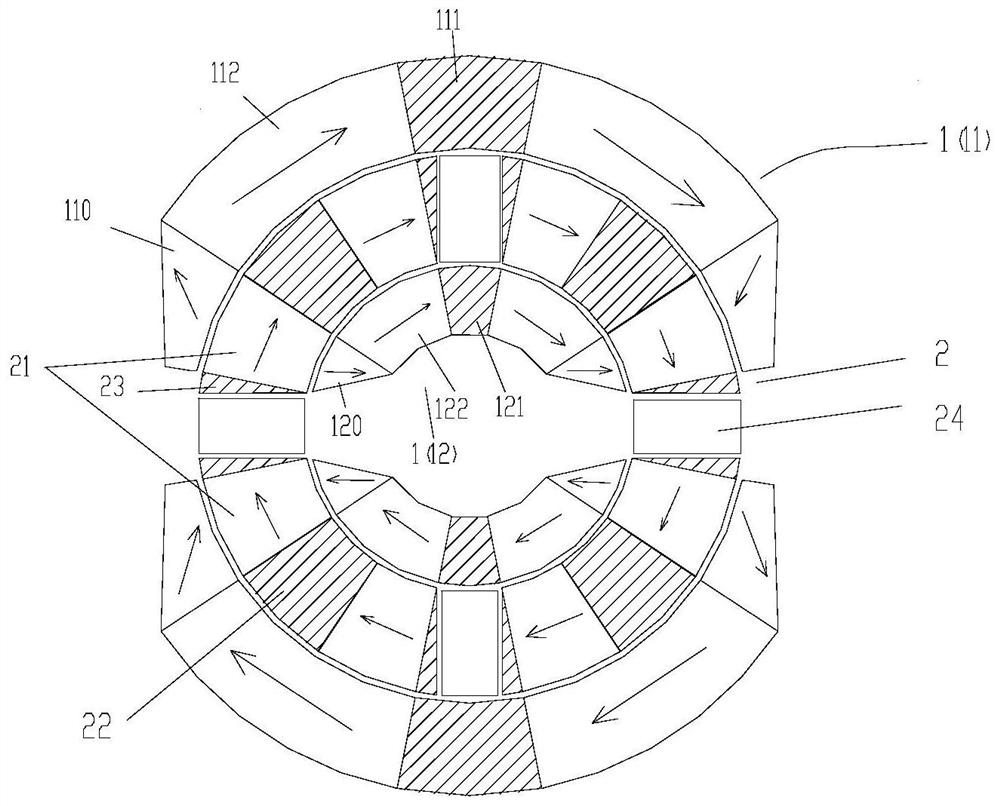

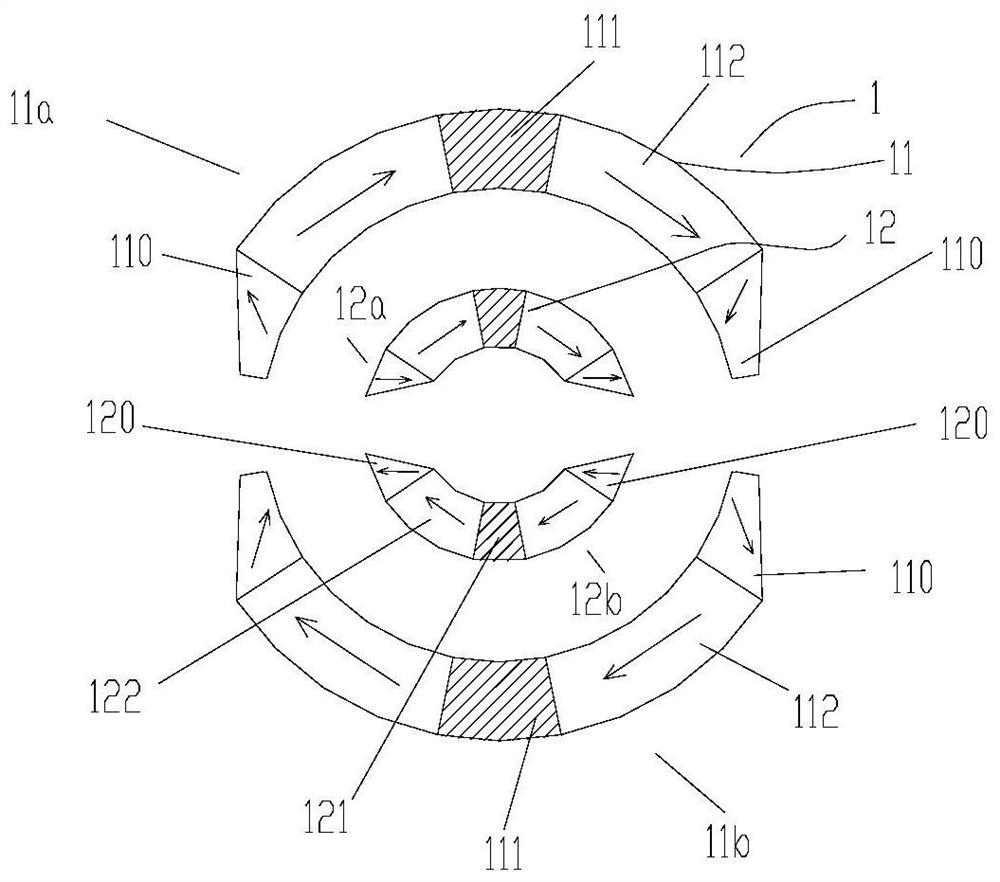

[0077] Such as Figure 1-7 As shown, the first embodiment is described. The magnet constituted by the first embodiment has four magnetic gaps (ie air gap space), and the basic principle of its magnetic circuit can be referred to Figure 14 shown.

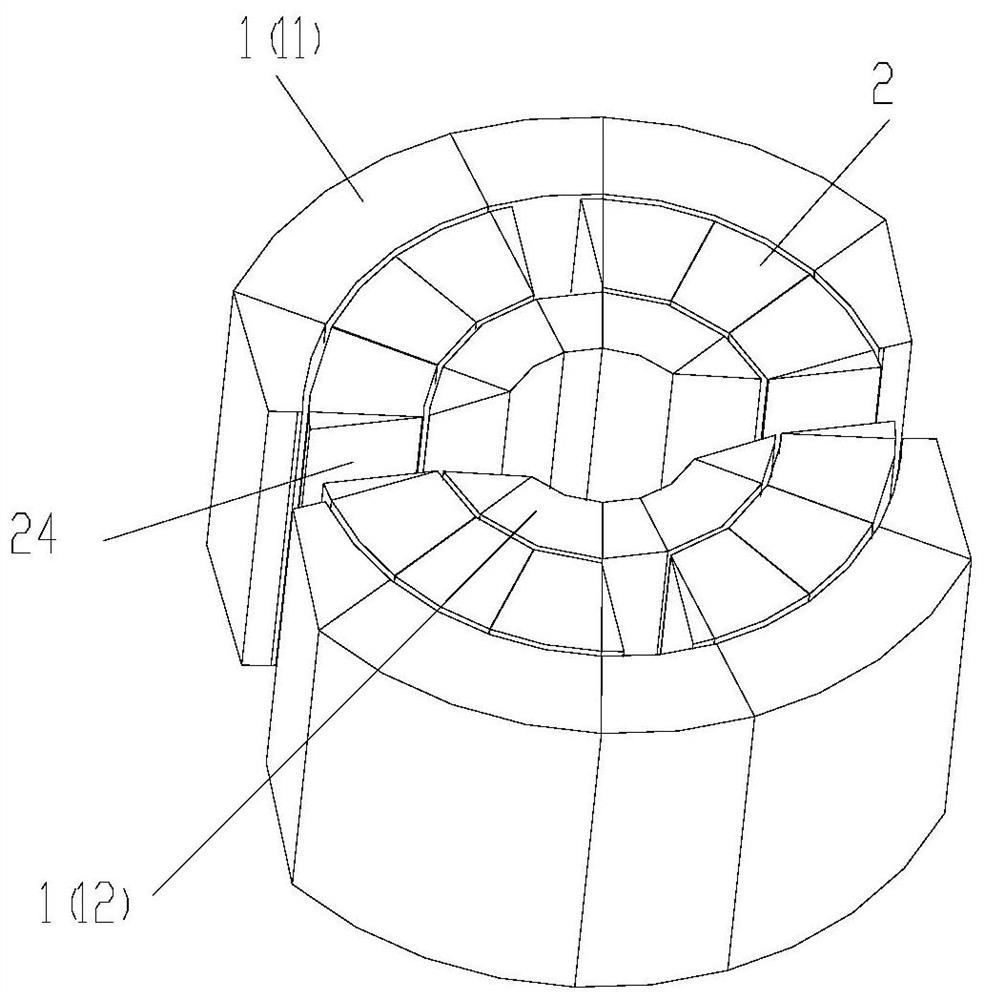

[0078] Such as figure 1 As shown, the magnetic field system is composed of two magnet assemblies, the first assembly 1 and the second assembly 2; the first assembly 1 is composed of 2 first magnet assembly units, and the 2 first magnet assembly units are preferably 360° uniform arrangement; figure 2 As shown, it is a three-dimensional schematic diagram of the first embodiment, and it can be seen that there are four magnetic gaps for placing the magnetic working medium bed 24 .

[0079] Preferably,

[0080] The magnetic force lines of the second magnet assembly are connected in series to form a closed loop. The closed magnetic circuit formed by the second magnet assembly connected in series can effectively increase the magnetic...

no. 2 approach

[0121] Such as Figure 8-9 A second embodiment is shown, which differs from the first embodiment in the first magnet assembly. Such as Figure 8 Shown is a second embodiment.

[0122] A schematic diagram of the first magnet assembly in the second embodiment is shown in Figure 9 As shown, the first magnet assembly in the first embodiment is as image 3 shown; image 3 and Figure 9 The difference is that Figure 9 A non-magnetic inner connector 124 and a non-magnetic outer connector 114 are added;

no. 3 approach

[0124] Figure 10-11 Used to describe the third embodiment, Figure 10 The third embodiment represented by and figure 1 The first embodiment shown differs in the second magnet assembly.

[0125] Figure 11 represents a third embodiment of the second magnet assembly and Figure 4 The second magnet assembly of the first embodiment shown differs in that: Figure 11 Each second magnet assembly unit is composed of two second soft magnets 22, a second permanent magnet 21 in the middle, and pole pieces 23 at both ends; the entire second magnet assembly uses four second permanent magnets in total. 21, while Figure 4 Used eight second permanent magnets 21 in. The use of soft magnets instead of permanent magnets can reduce the cost of the magnet system. In addition, the use of soft magnetic materials on both sides of the magnetic working fluid bed is conducive to the aggregation of magnetic circuits and is also conducive to Figure 10-11 The better magnetic shielding effect of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com