Construction method of underground prestressed supporting structure

A construction method and technology for supporting structures, which are applied in basic structure engineering, excavation, sheet pile walls, etc., can solve the problems of reducing the strength of prestressed supporting piles, affecting the tension of anchor cables, and deviating from the predetermined position, so as to ensure Earth excavation and construction of underground structures, reducing construction costs and improving the effectiveness of working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

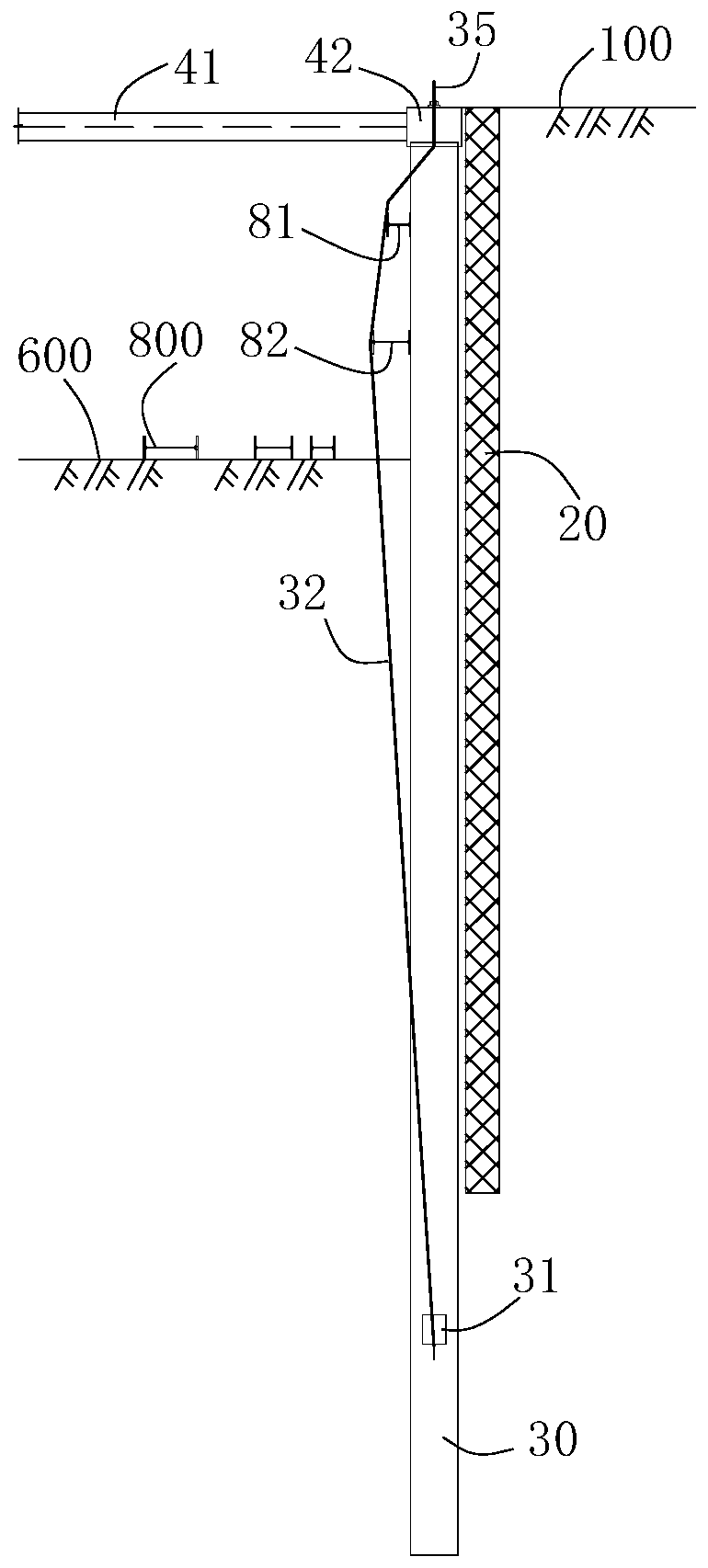

[0057] In this embodiment, five purlins are arranged in the foundation pit, from top to bottom are the first purlin 81, the second purlin 82, the third purlin 83, the fourth purlin 84 and the fourth purlin. Five purlins 85, wherein the first purlin 81 and the second purlin 82 are located within the set depth range of the initial excavation of the foundation pit, ie N=2, M=5.

[0058] The underground structure is provided with four roofs, from top to bottom are the first roof 51, the second roof 52, the third roof 53 and the fourth roof 54, that is, K=4 in this embodiment. In this application, the K-th roof is the lowest roof. Corresponding to the second top plate 52 , the third top plate 53 and the fourth top plate 54 , there are respectively provided a second support block 62 , a third support block 63 and a fourth support block 64 .

[0059] In this embodiment, the purlins are assembled from purlins, and the purlins are prefabricated on the ground.

[0060] In the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com