Thin sheets pre-tighten positioning clamping device

A positioning clamping and thin plate technology, which is applied in automobile manufacturing and mechanical fields, can solve the problem that the thin plate sample cannot limit the rotation of the sample, and achieve the effect of simple structure, accurate positioning and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

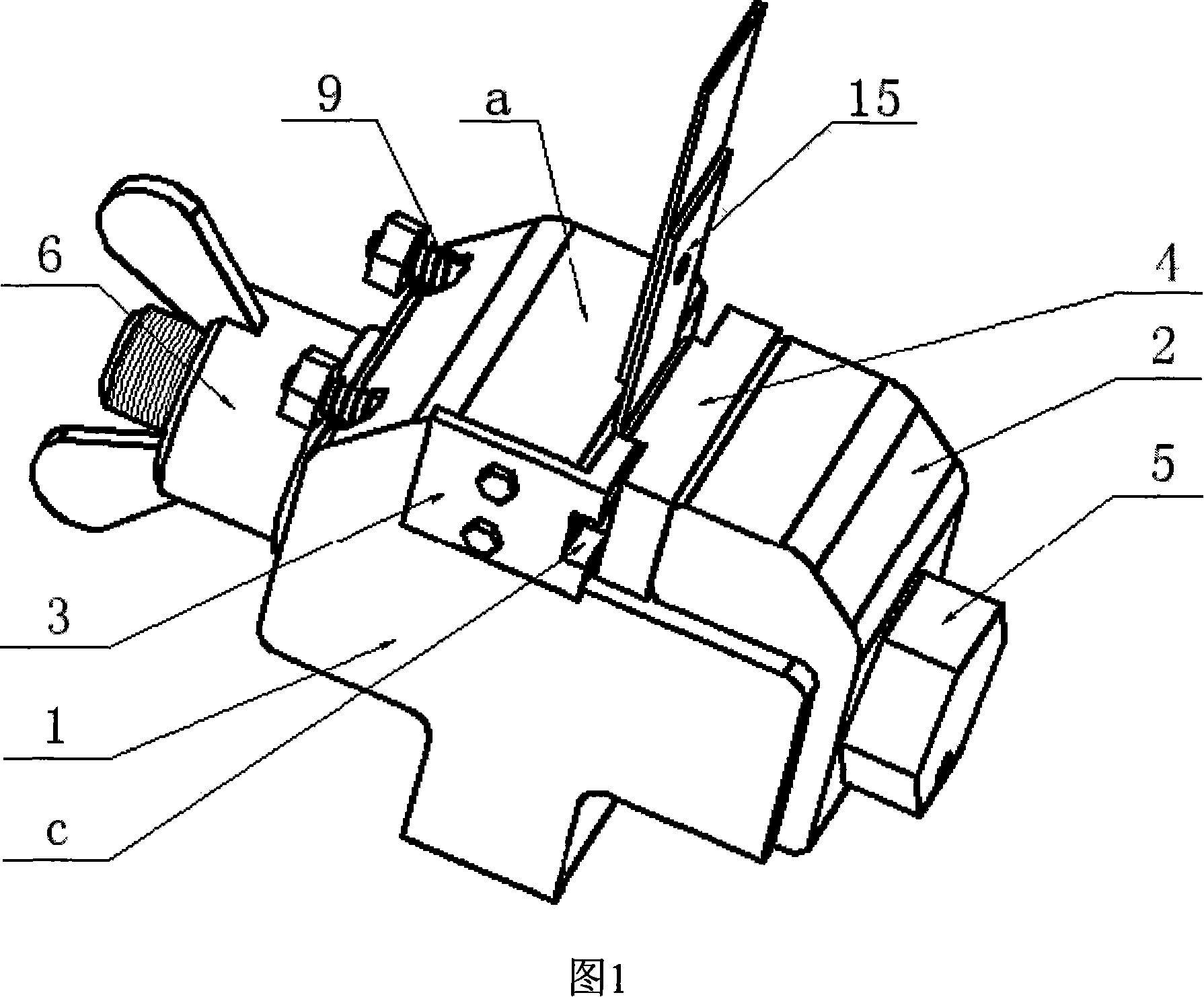

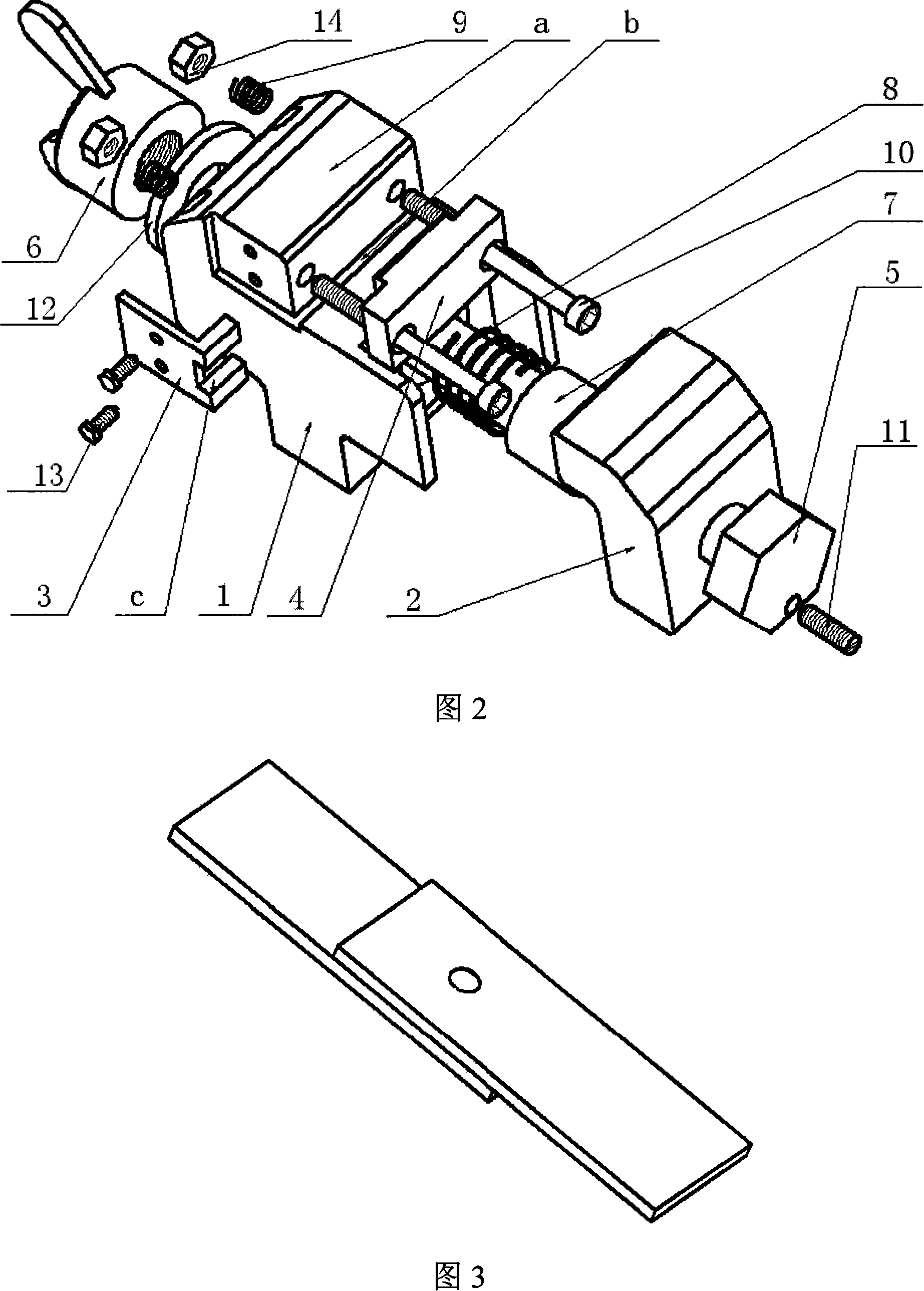

[0019] Embodiments of the present invention will be specifically described below with reference to FIGS. 1 to 3 .

[0020] As shown in FIG. 1 , this embodiment mainly includes a base 1 , a clamping block 2 , an "L"-shaped positioning block 3 , a pre-tightening slider 4 , fastening bolts 5 and fastening nuts 6 . Wherein, the upper surface of the base 1 is provided with a fixed chuck a integrated with the base 1, and a pre-tightening slider 4 is arranged on the right side of the fixed chuck a, and the pre-tightening screw 10 is arranged in a direction from right to left. The direction passes through the pre-tightening slider 4 and the fixed chuck a in turn and enables the pre-tightening slider 4 to slide left and right along the outer surface of the pre-tightening screw 10, and the pre-tightening screw 10 can pass through the nut 14 arranged at the left end of the pre-tightening screw 10 Make the left end surface of the pre-tightening slider 4 contact with the right end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com