A device for demagnetization by soaking in antirust solution

A rust-proof liquid and demagnetization technology, applied in magnetic objects, electrical components, circuits, etc., can solve the problems of bumping and demagnetization of demagnetized workpieces, and achieve the effect of reducing bumps, completely demagnetizing, and solving quality problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

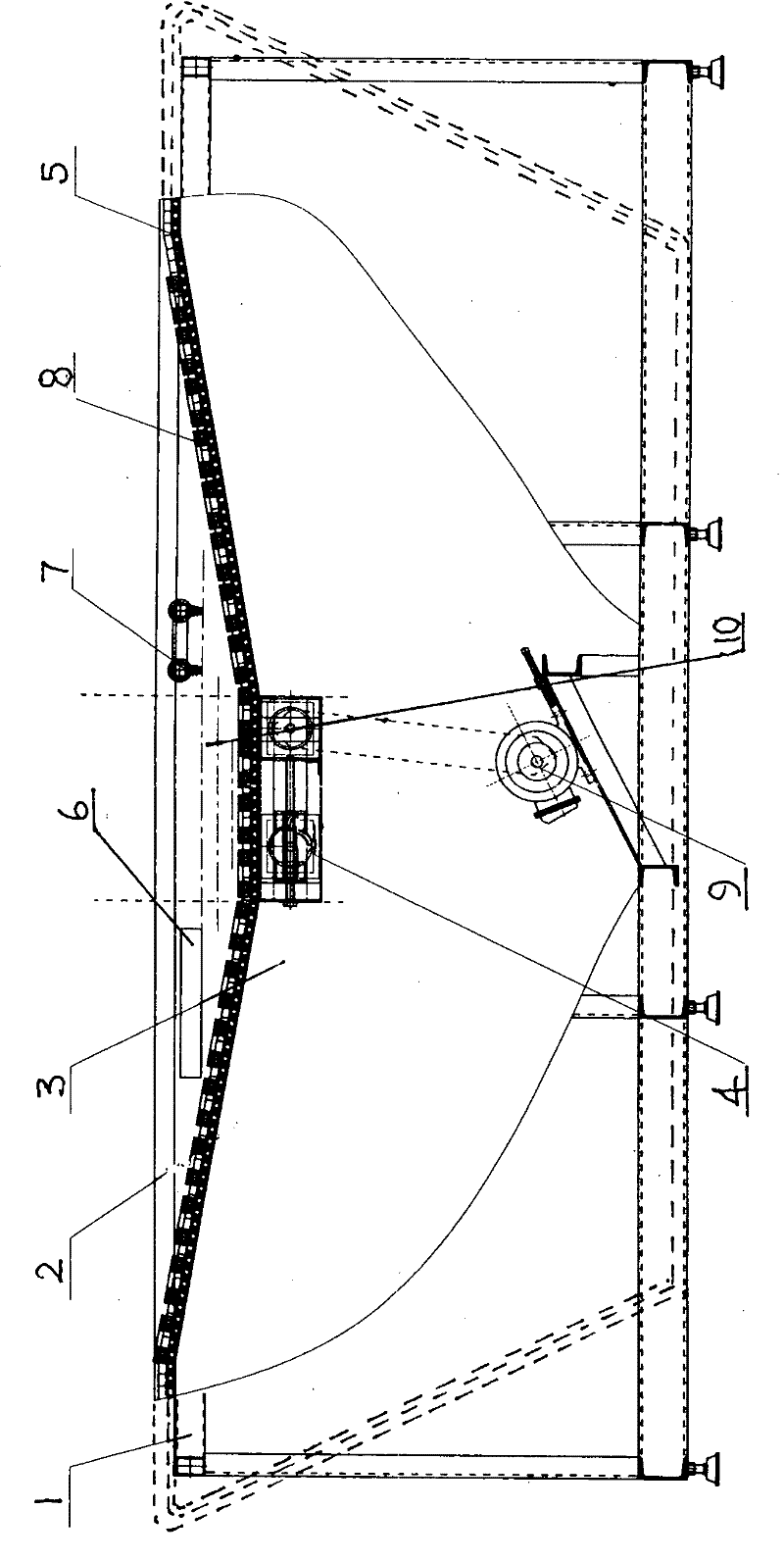

[0017] There is a frame 1, a tank body 2 is arranged in the middle of the frame body, the tank body is filled with anti-rust liquid 3, the center of the tank body is equipped with a demagnetizer 4 that cooperates with a demagnetization motor 9, and an overflow port is provided at the upper end of the tank body 6 and the shower head 7, the upper end of the demagnetizer is provided with a conveyor belt 5, the workpiece 8 is placed on the upper end of the conveyor belt, and the dotted line between the workpiece and the demagnetizer is the demagnetization zone 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com