Patents

Literature

42results about How to "Good degaussing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Workpiece demagnetizing method and workpiece demagnetizing device

InactiveCN101593604ANo human controlGood degaussing effectMagnetic bodiesDemagnetizing deviceSquare waveform

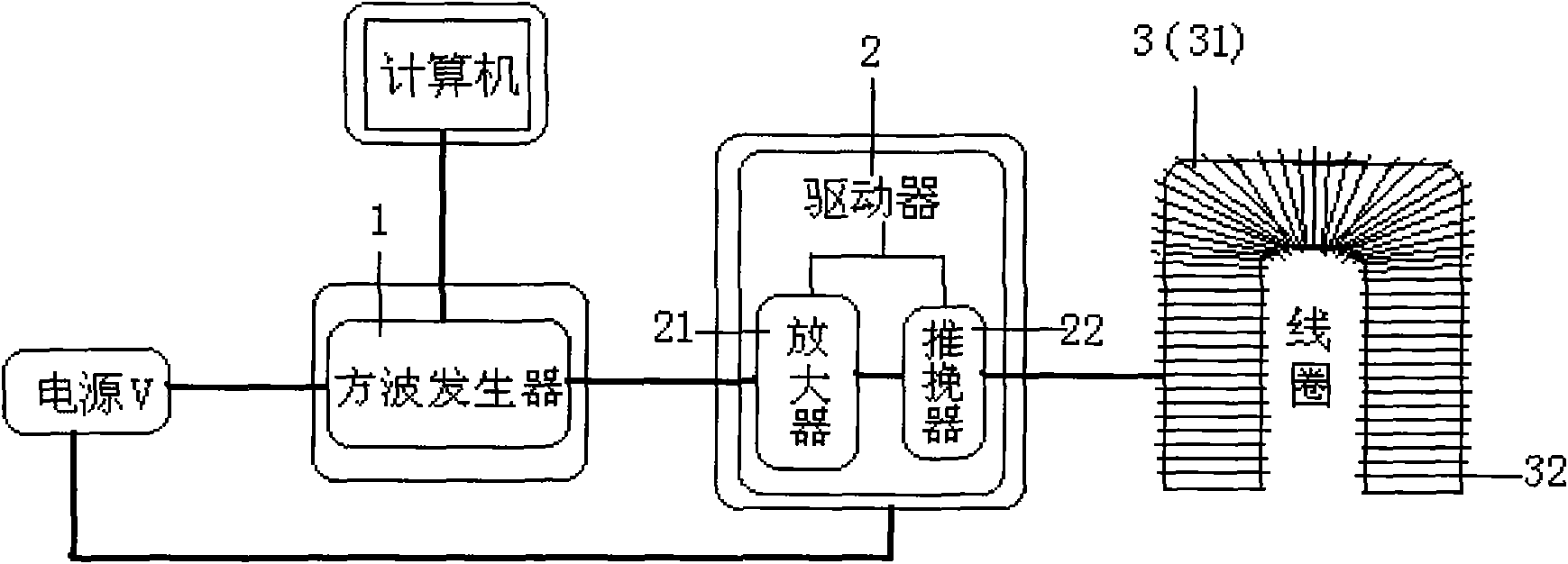

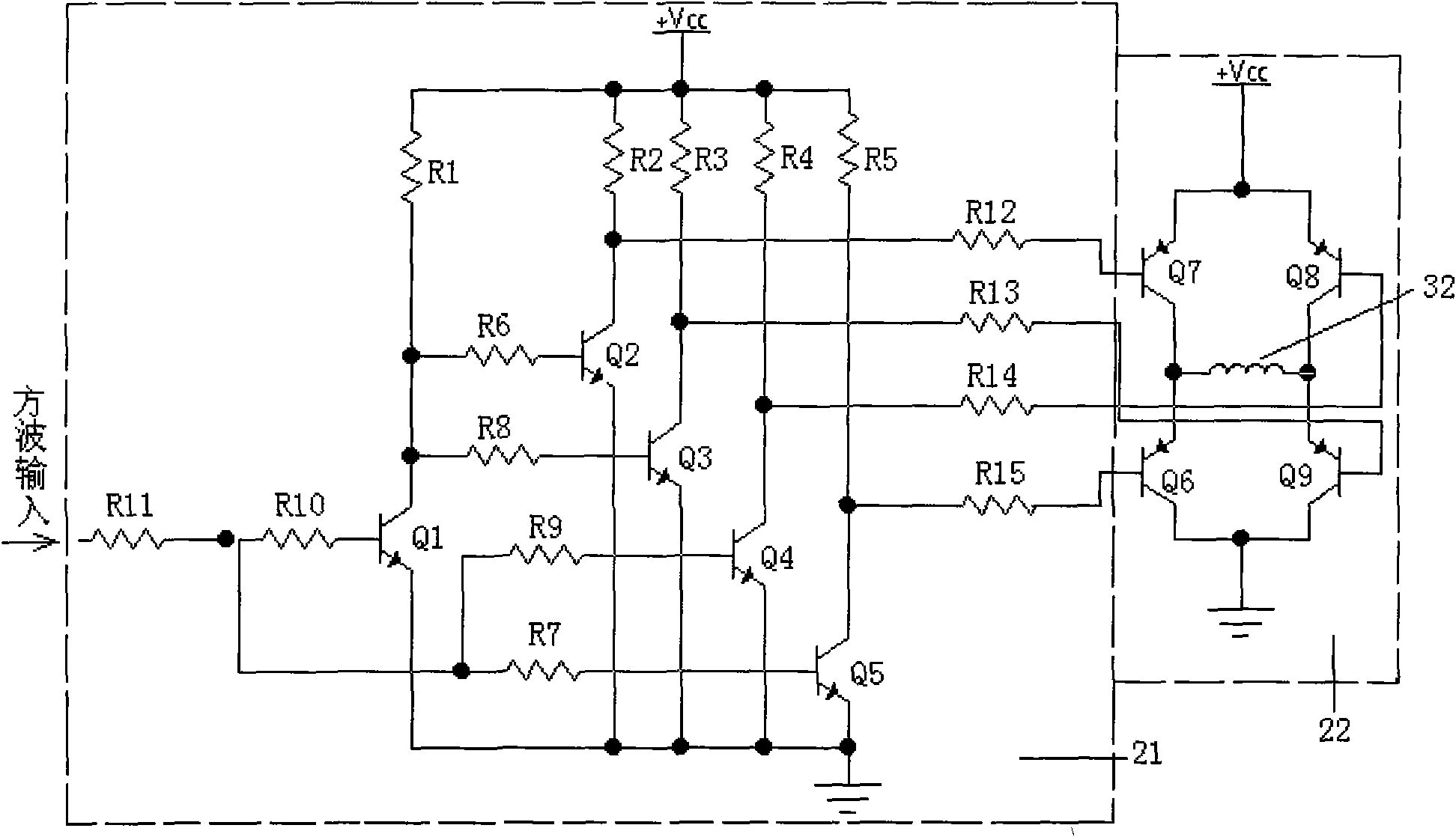

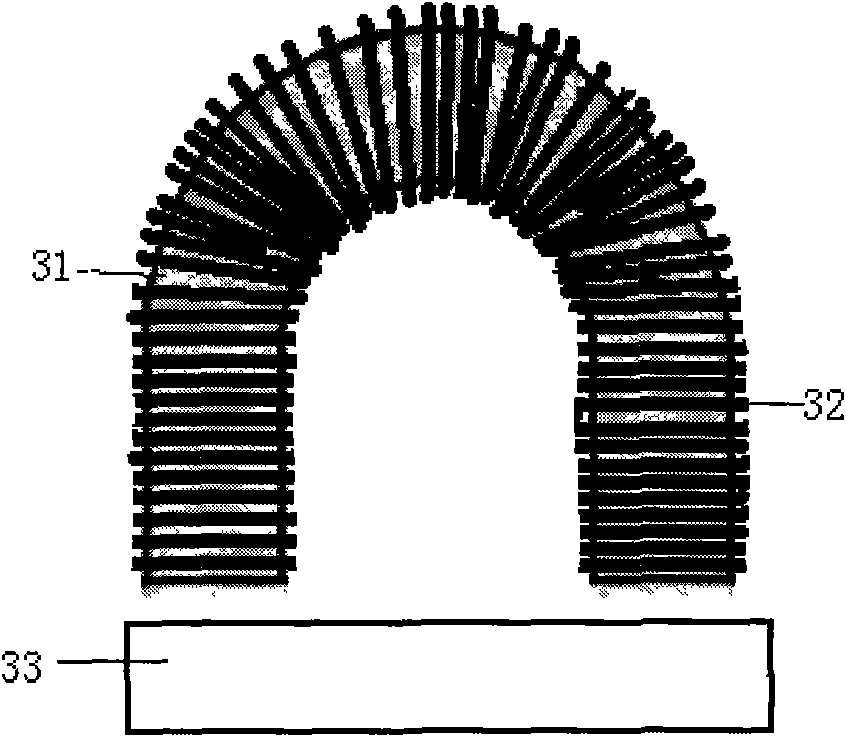

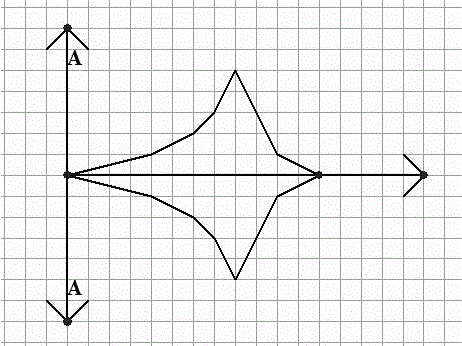

The invention relates to a workpiece demagnetizing method and a workpiece demagnetizing device. The method selects a square wave signal with unchanged frequency and amplitude; an amplifying circuit and a push-pull circuit are connected into a drive circuit; and the drive circuit is connected with a coil. Corresponding to the method, the demagnetizing device mainly comprises a power supply, a signal generator, a driver and a coil. An unfading alternating magnetic field generated by the method and the device can not only demagnetize a static workpiece but also can carry out continuous demagnetization on a dynamic workpiece and have wide application range; a ferrite is adopted as a magnetic core; demagnetizing current with high frequency and unchanged amplitude is conducted to the coil; the alternating magnetic field generated by the coil can disturb the residual magnetic domain of the workpiece; the demagnetizing effect is good; and the method is simple and feasible and the device has a compact structure so as to solve the difficult problem of demagnetization in the field and have practical value.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

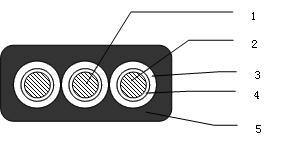

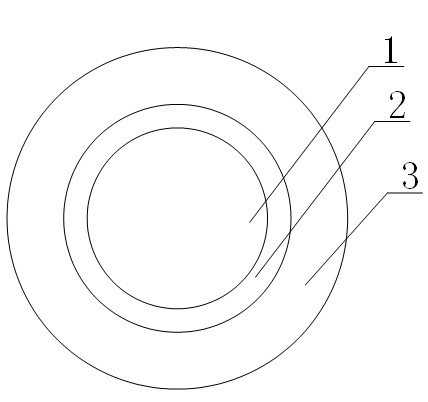

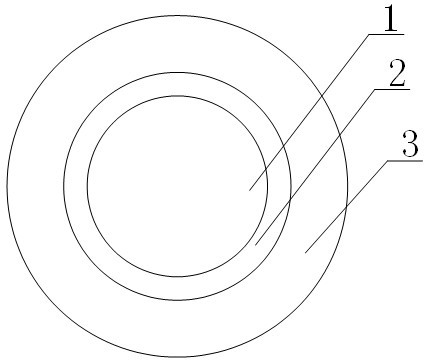

Longitudinal water-sealing degaussing cable and manufacturing process for same

InactiveCN102509582AReduce distractionsImprove water absorptionClimate change adaptationFlat/ribbon cablesLow smoke zero halogenElectrical conductor

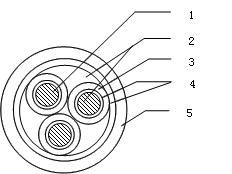

The invention discloses a longitudinal water-sealing degaussing cable. The longitudinal water-sealing degaussing cable is characterized by comprising three cores which are arranged in a delta shape or linearly. A plurality of tin plated copper wires are twisted to form a conductor in the center of each core of the cable by an electric wire and cable twisting machine. A waterproof adhesive is filled in gaps between every two of the plurality of tin plated copper wires. A first layer of wrapped waterproof tape is arranged on the periphery of the conductor. An insulating layer made of an insulating material ethylene propylene rubber is arranged on the periphery of the first layer of wrapped waterproof tape. A second layer of wrapped waterproof tape is arranged on the periphery of the insulating layer. A sheath is arranged on the periphery of the second layer of wrapped waterproof tape. The waterproof adhesive is filled in gaps between every two of the three cores which are arranged in the delta shape. The longitudinal water-sealing degaussing cable has the advantages that: by a multi-core structure, troubles in the multi-turn winding laying of the conventional single-core structure are avoided, and the longitudinal water-sealing degaussing cable is convenient to mount and lay; the longitudinal water-sealing degaussing cable can be used for compensating for own induced magnetic field of a naval ship, and is small in interference and good in degaussing effect, and a generated magnetic field is regular and easy to control; and the longitudinal water-sealing degaussing cable is low-smoke, halogen-free and low-toxicity.

Owner:NANJING QUANXIN CABLE TECH

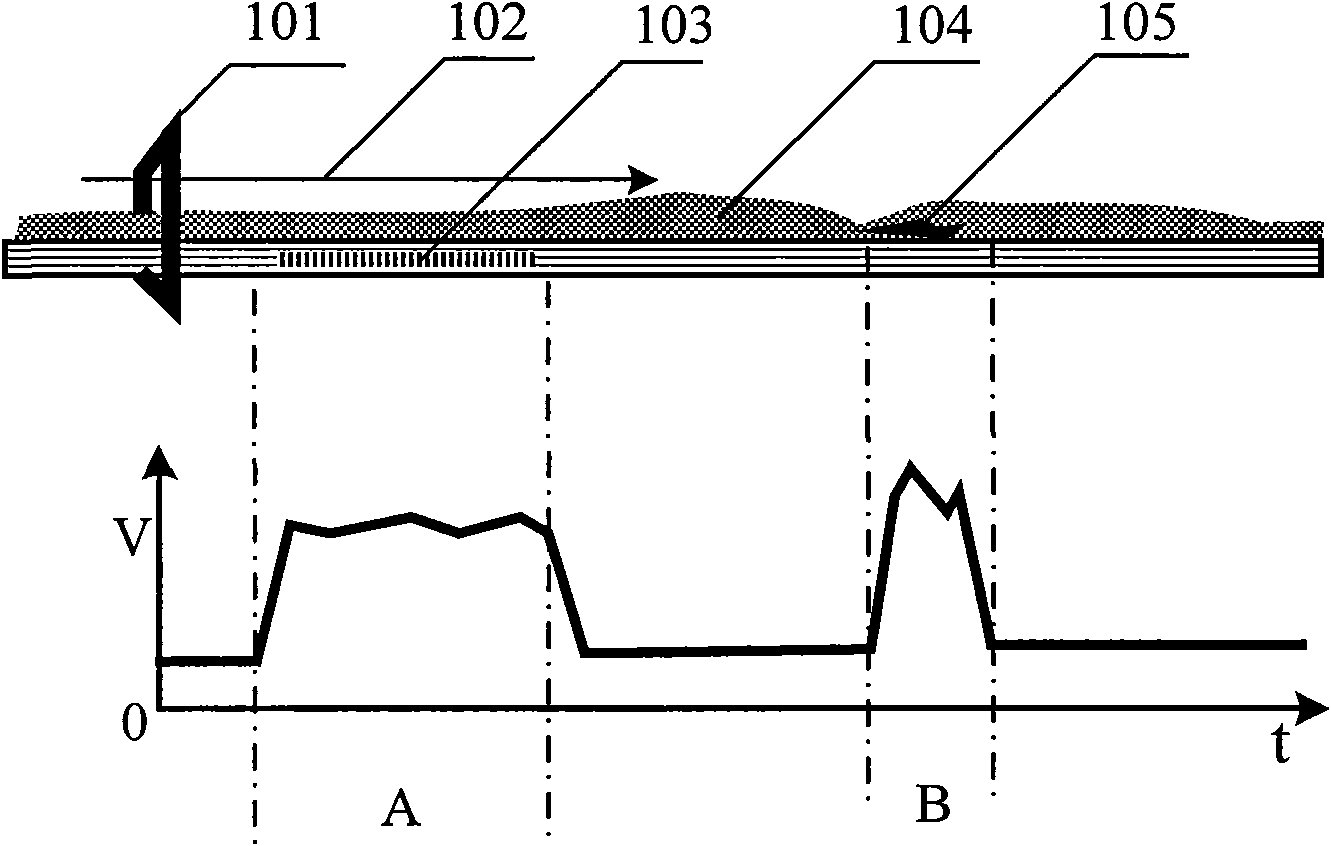

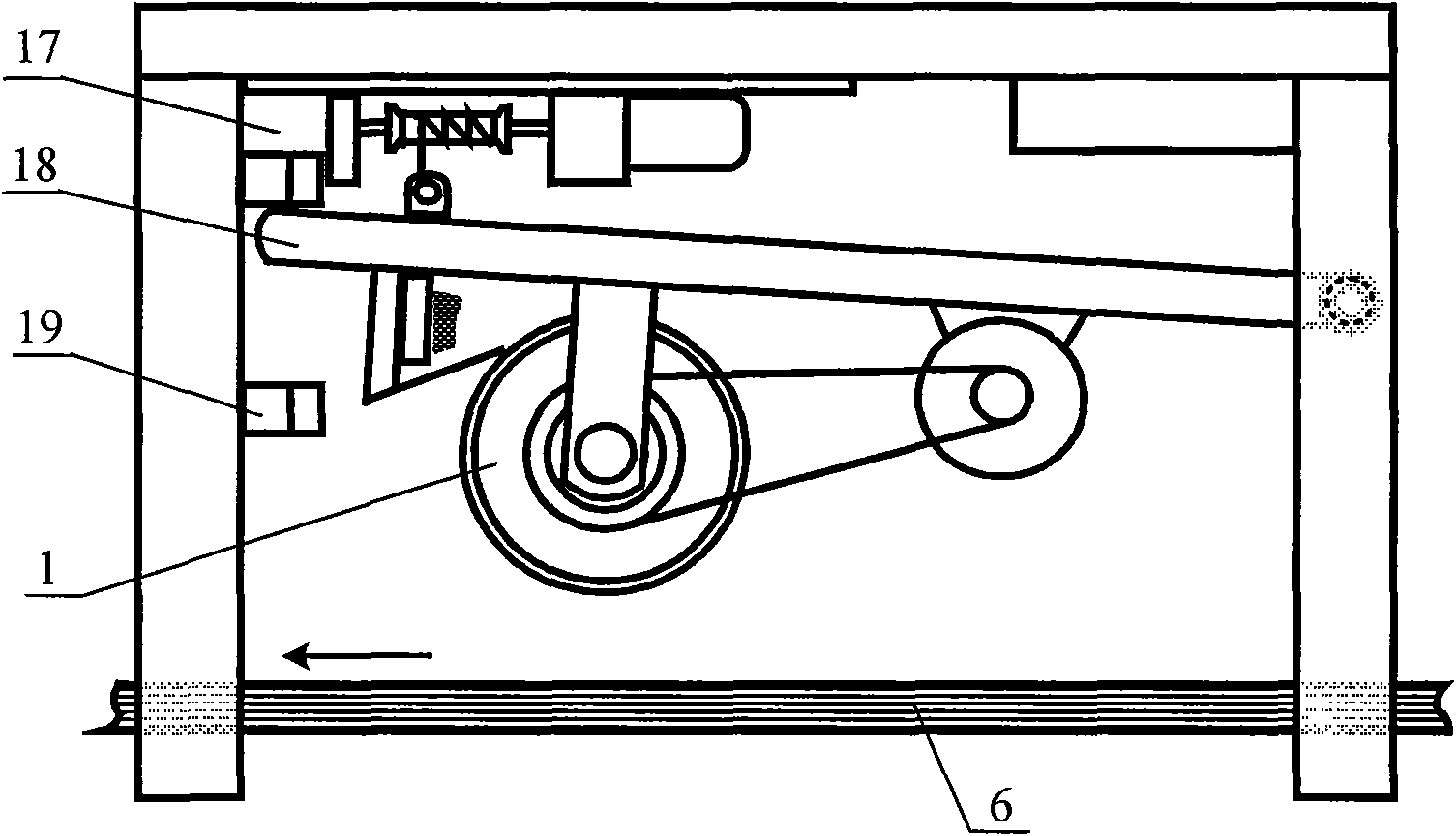

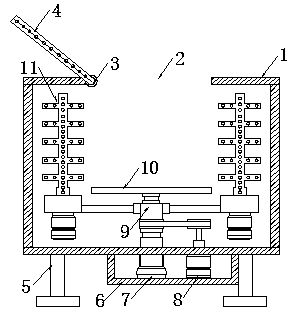

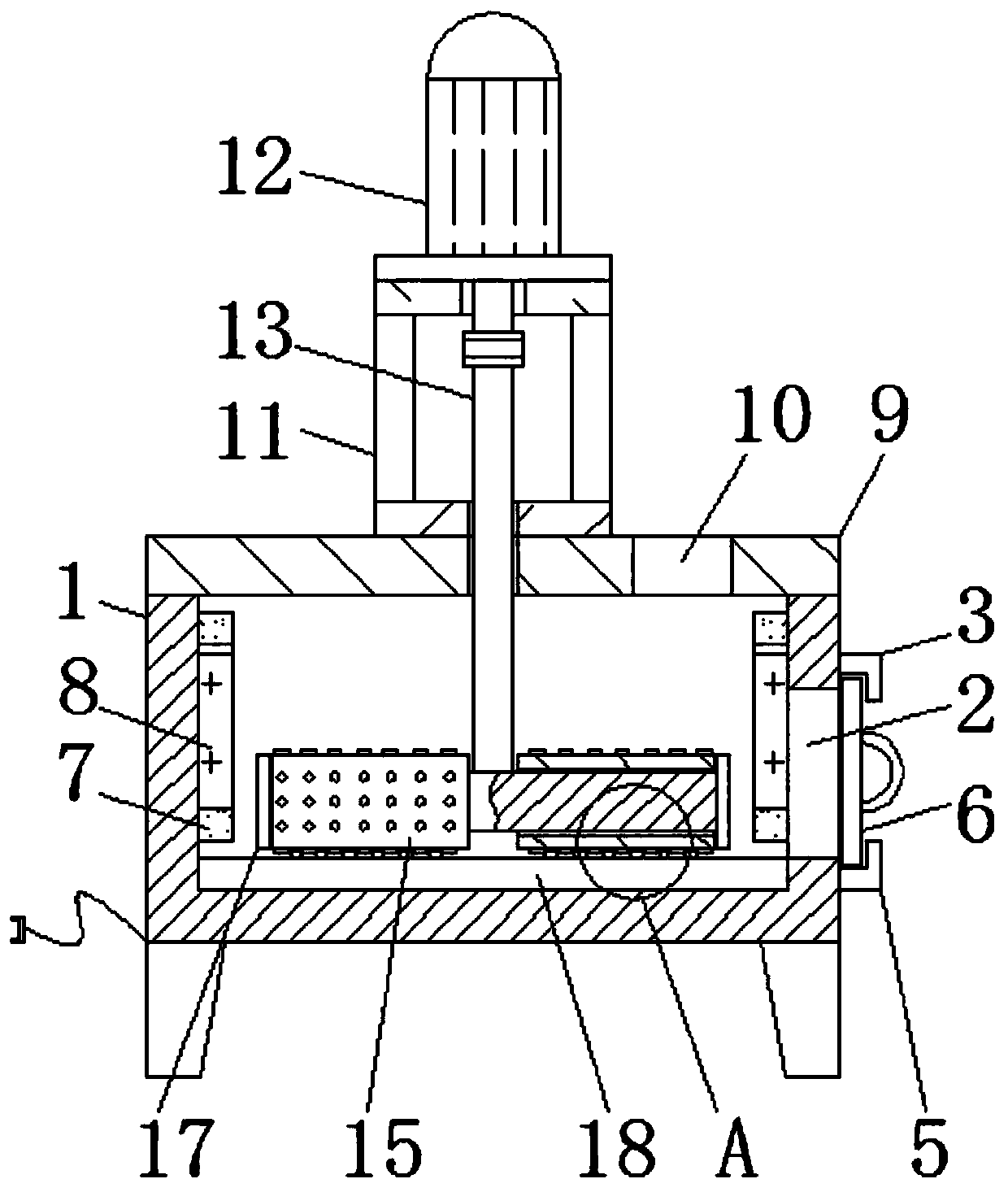

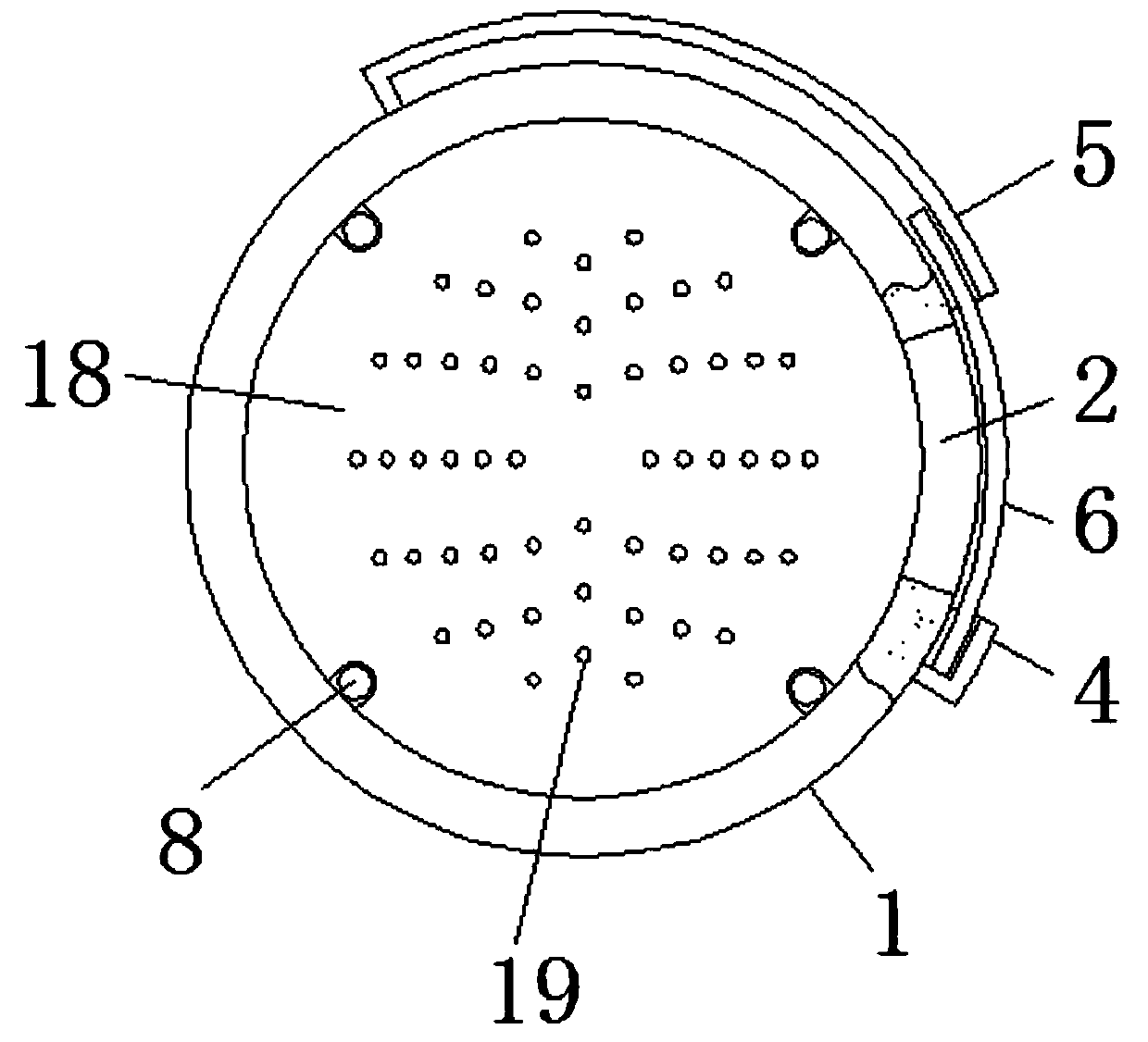

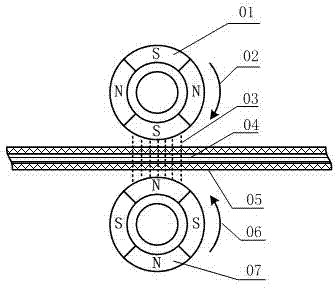

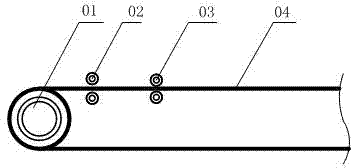

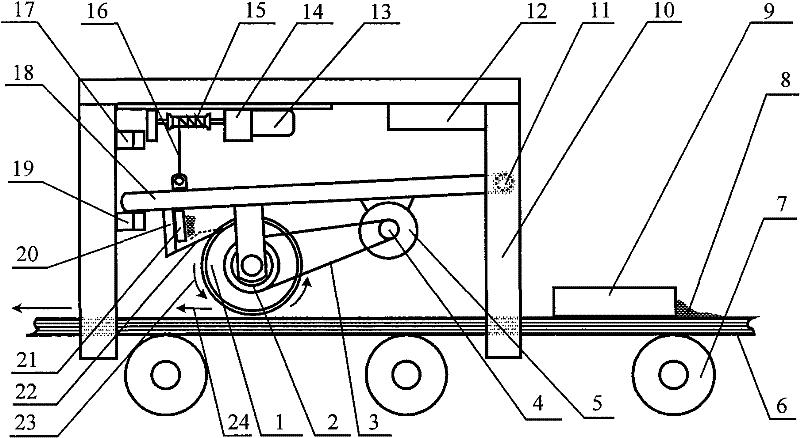

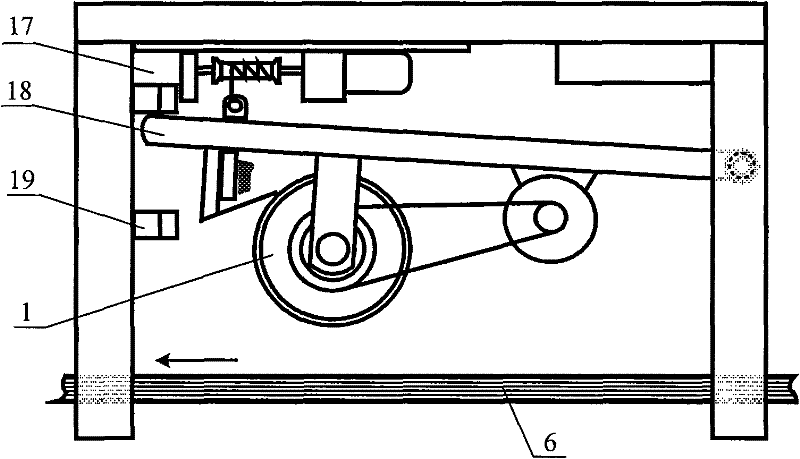

Conveyer belt multi-pole magnetic roller asynchronous demagnetizing device

ActiveCN101930822AIncrease the magnetic field strengthSolve problems interfering with metal detectorsMagnetic bodiesDemagnetizing deviceVertical bar

The invention discloses a conveyer belt multi-pole magnetic roller asynchronous demagnetizing device, which comprises a multi-pole magnetic roller (1), a magnetic roller drive motor (5), a magnetic roller framework (18), a structural frame (10), a lifting device and a controller (12), wherein the multi-pole magnetic roller is hang on the magnetic roller framework through a magnetic roller shaft, the magnetic roller drive motor drives a magnetic roller shaft transmission belt wheel (2) to rotate through a power belt wheel (4) and a transmission belt (3) so as to drive the multi-pole magnetic roller to rotate, and the multi-pole magnetic roller is positioned above a conveyer belt (6); the structural frame is positioned above a conveyer belt return plane, and a vertical bar of the structural frame is fixed on the ground; and one end of the magnetic roller framework is connected on the vertical bar of the structural frame through a rotating shaft (11), the other end of the magnetic roller framework is provided with the hoisting device, an upper stop point (17) and a lower stop point (1) with travel switches are formed on the vertical bar at the other end of the structural frame, the output of the travel switches is connected with a controller (12), and the controller controls the magnetic roller drive motor and the hoisting device. The demagnetizing device has the advantages of simple structure, low energy consumption and good demagnetizing effect.

Owner:BAOSHAN IRON & STEEL CO LTD +1

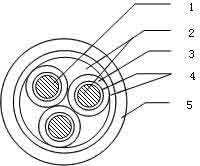

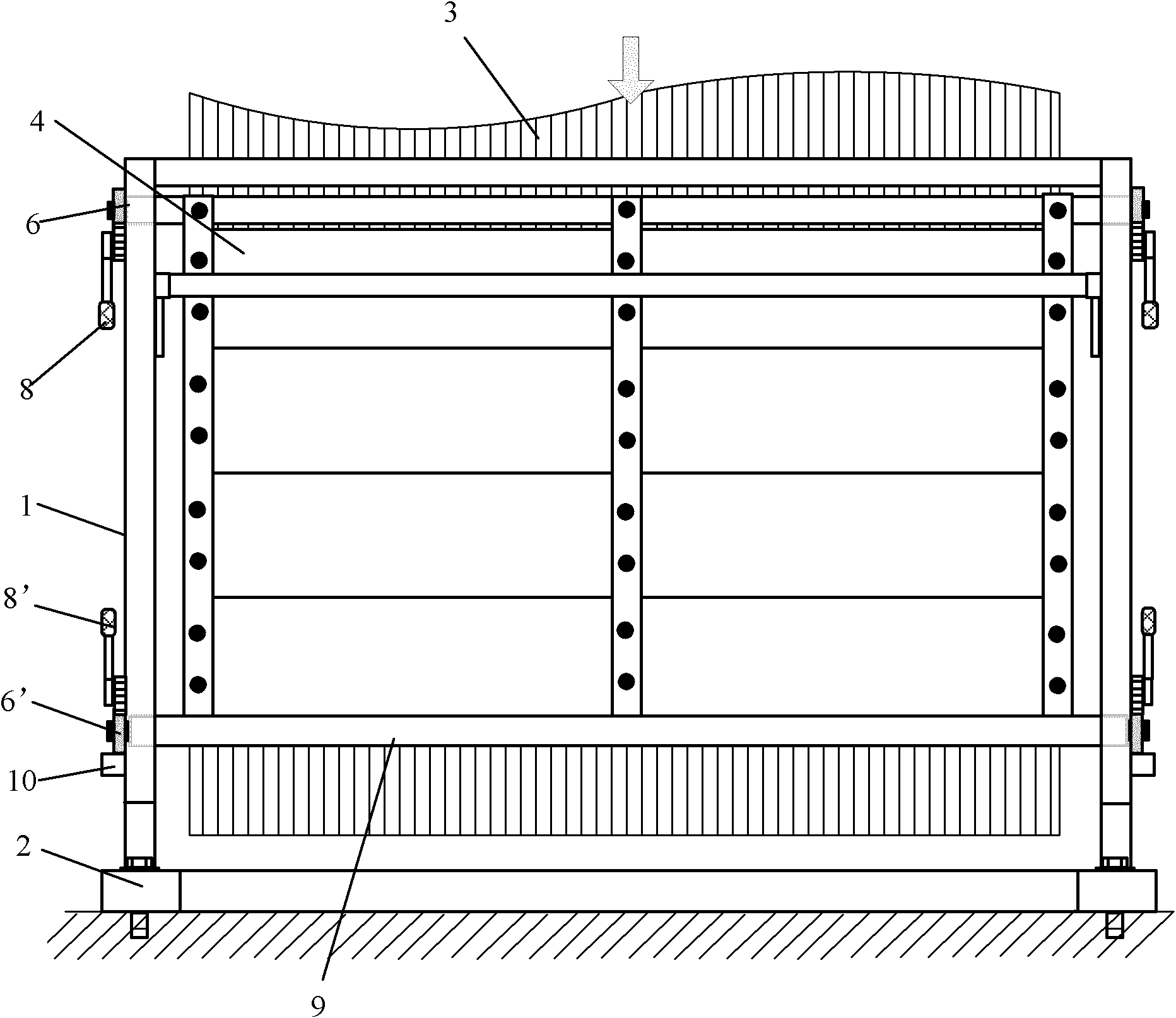

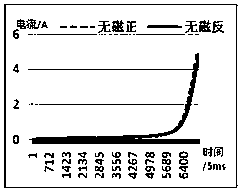

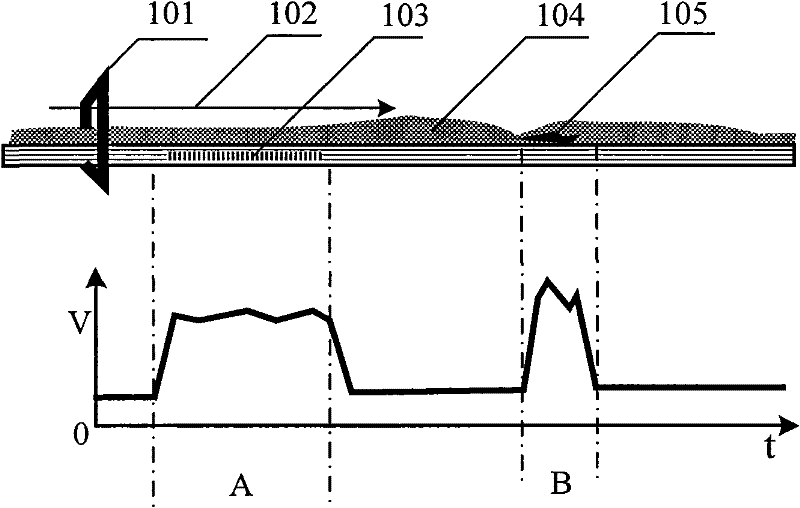

Method and device for demagnetizing steel wire conveying belt without energy consumption

ActiveCN102646496AGood degaussing effectInnovative design ideasConveyorsMagnetic bodiesPeak valueEngineering

The invention discloses a method and a device for demagnetizing a steel wire conveying belt without energy consumption. The method comprises the following steps of: a) allowing the moving direction of the steel wire conveying belt to get into an alternating magnetic field formed by a demagnetizing plate, wherein the distance between the demagnetizing plate and the steel wire conveying belt can be adjusted; b) adjusting the distance between the demagnetizing plate and the steel wire conveying belt, and measuring the magnetic field intensity on the back surface of the steel wire conveying belt, if the measured value of the magnetic field intensity is more than 200 Gs, the distance is qualified; c) adjusting the distance that the steel wire conveying belt departs from the demagnetizing plate, acquiring a detection signal through a metal detector, inputting the detection signal into an oscillometer, and observing whether interference pulse exists or not and the peak value of interference pulse wave, if a waveform curve is flat, demagnetization is qualified, and when the waveform curve is abnormal, adjusting the current distance until the detection signal is qualified; and d) after adjusting the current distance until the detection signal is qualified, starting a steel wire conveying belt machine set to perform demagnetizing operation, wherein in the process, the metal detector extracts the detection signal to analyze the whole periphery of the conveying belt to judge a demagnetizing effect. The problem about demagnetizing the steel wire conveying belt is solved by the method and the device, and the method and the device have the characteristics of no maintenance, energy conservation and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

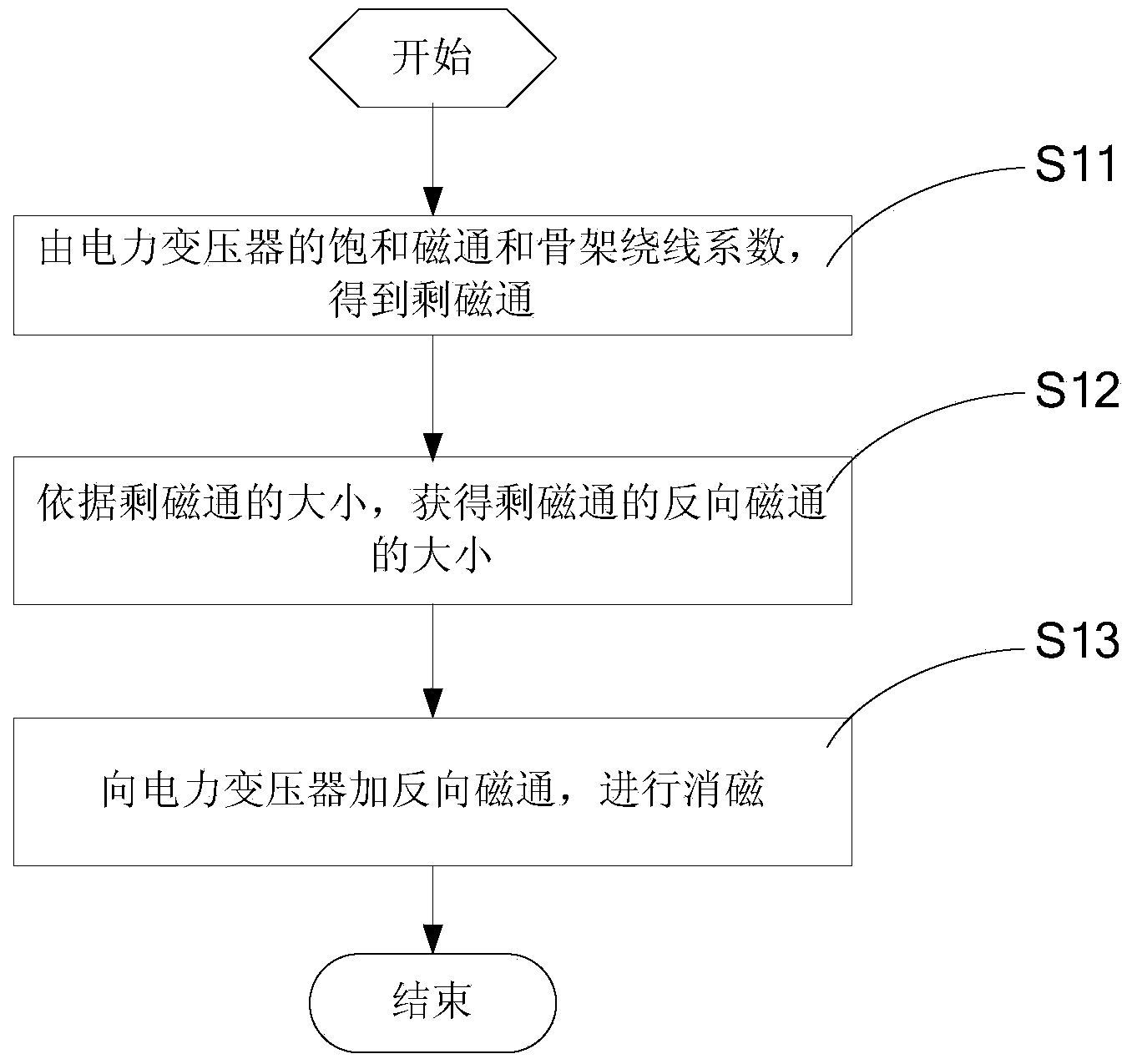

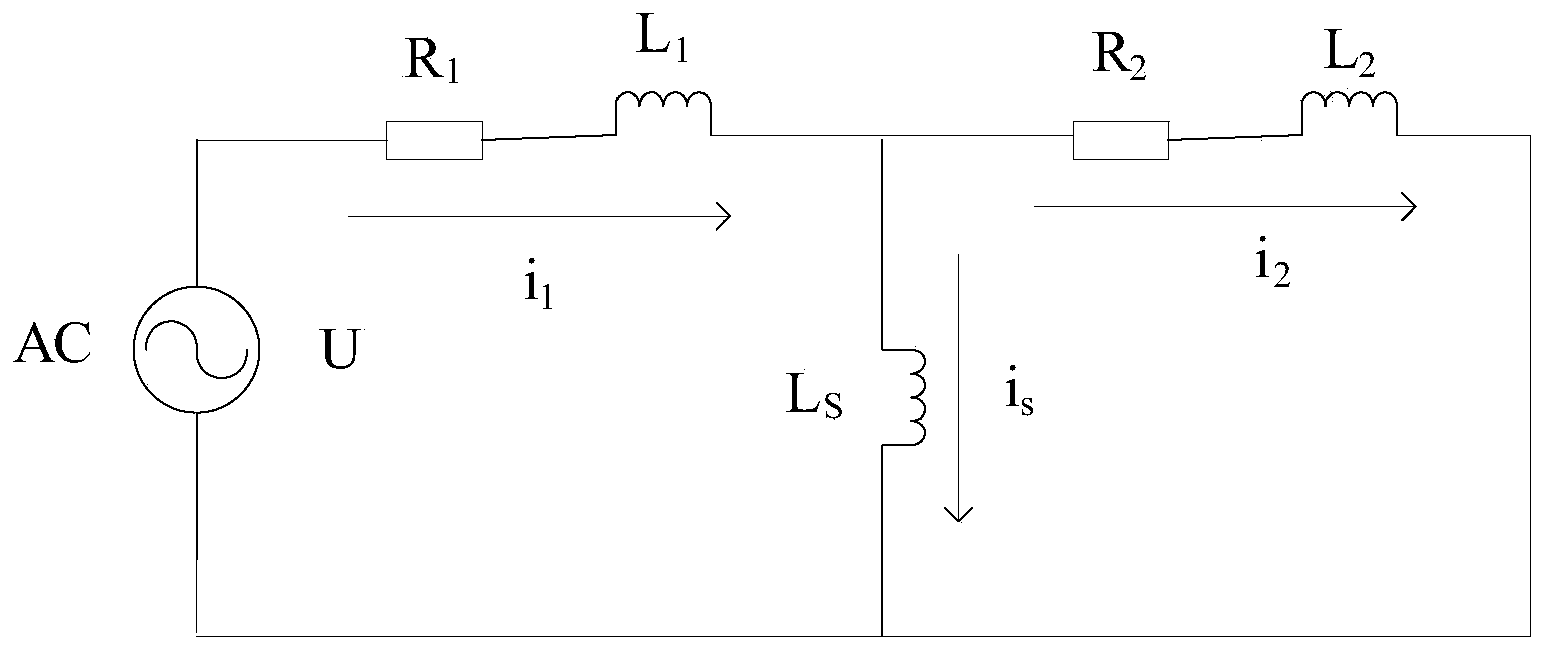

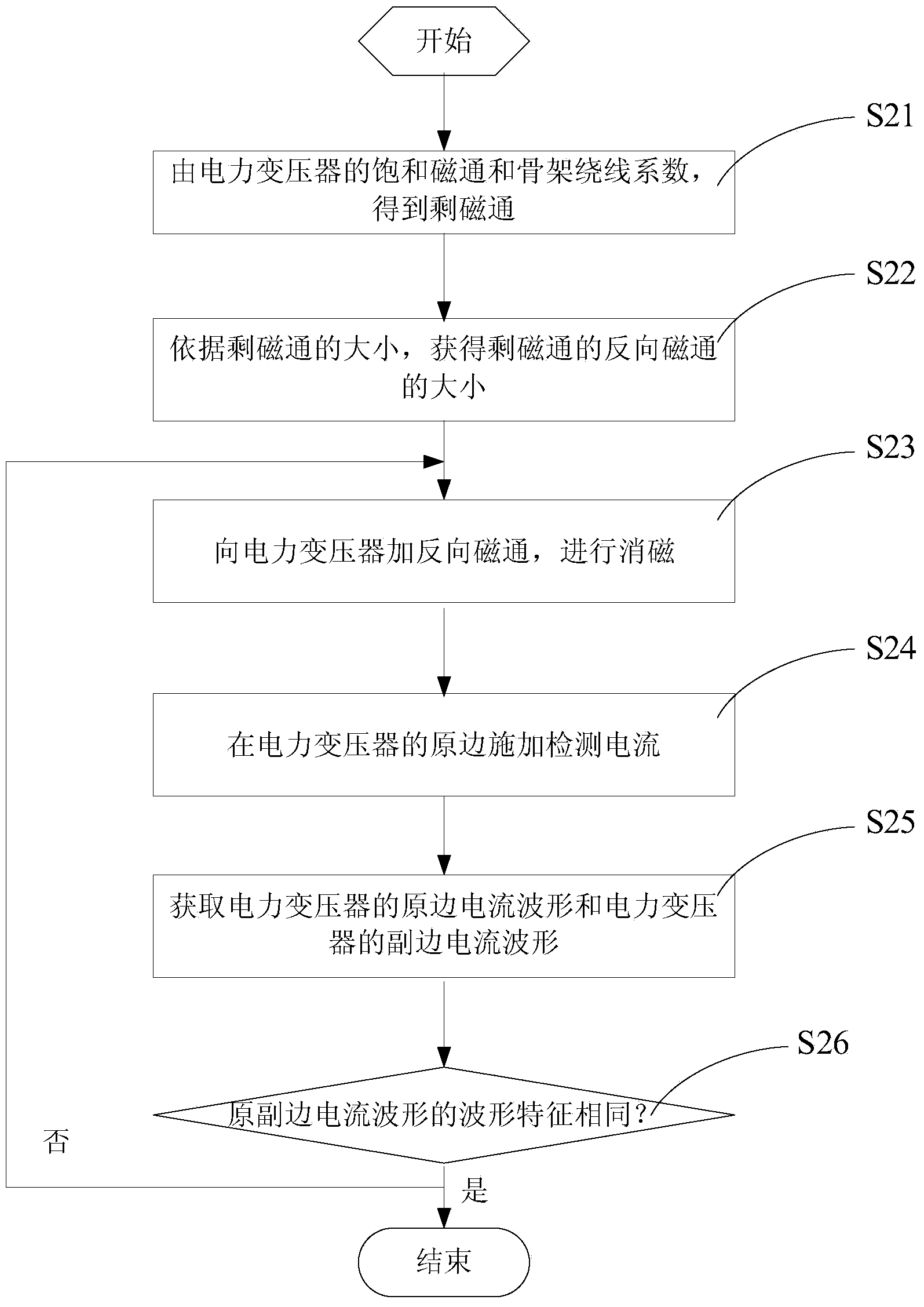

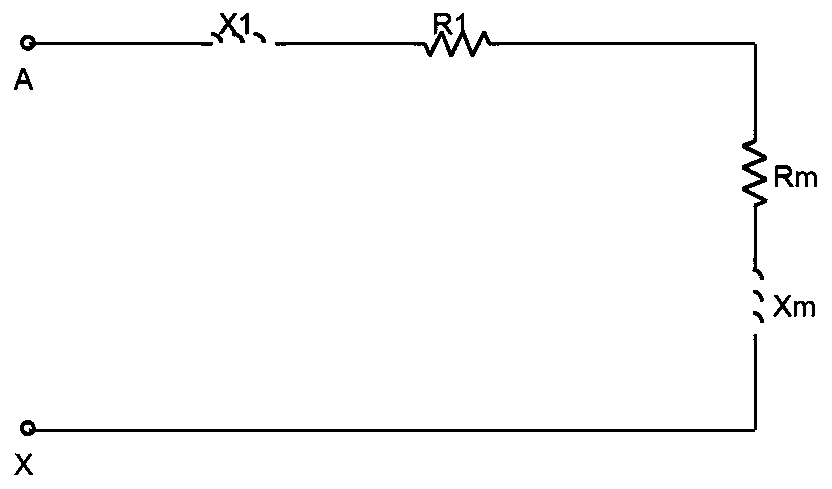

Method and system for degaussing power transformer

The invention provides a method and a system for degaussing a power transformer. According to the method, after direct resistance of the power transformer is tested, a residual magnetic flux of the power transformer is obtained by a saturated magnetic flux and framework wire wrapping coefficients of the power transformer; a counter magnetic flux of the residual magnetic flux is obtained according to the magnitude and the polarity of the residual magnetic flux; the counter magnetic flux is added to the power transformer, and the aim of degaussing the residual magnetic flux is realized by the property that the direction of a transient state magnetic flux in the counter magnetic flux is opposite to that of the residual magnetic flux. According to the method and the system for degaussing the power transformer, the magnitude and the polarity of the residual magnetic flux in the power transformer are firstly estimated, and a counter magnetic flux technological means is added to realize effective degaussing of the residual magnetic flux; the degaussing effect is obvious, and the problems in the prior art are solved.

Owner:STATE GRID CORP OF CHINA +4

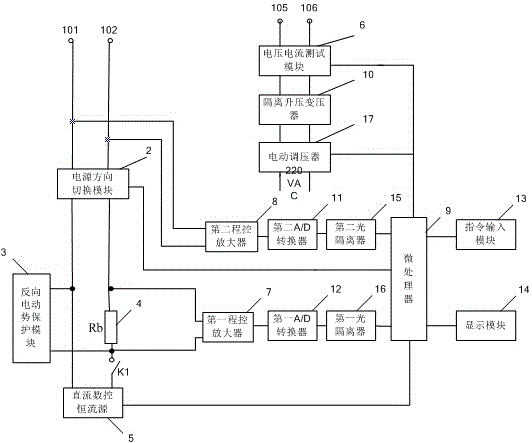

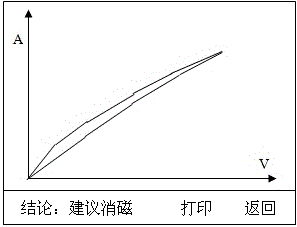

Transformer demagnetization analyzer

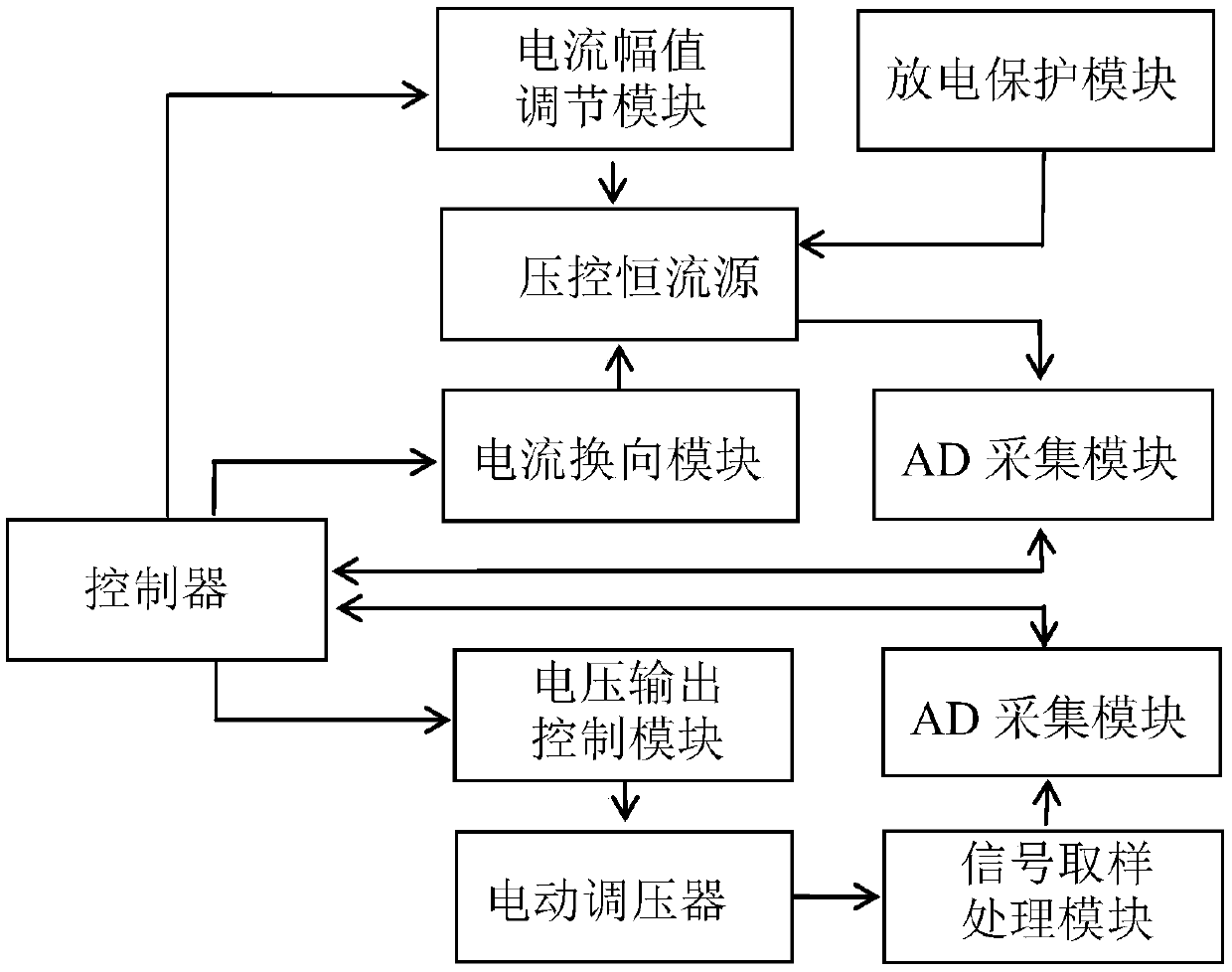

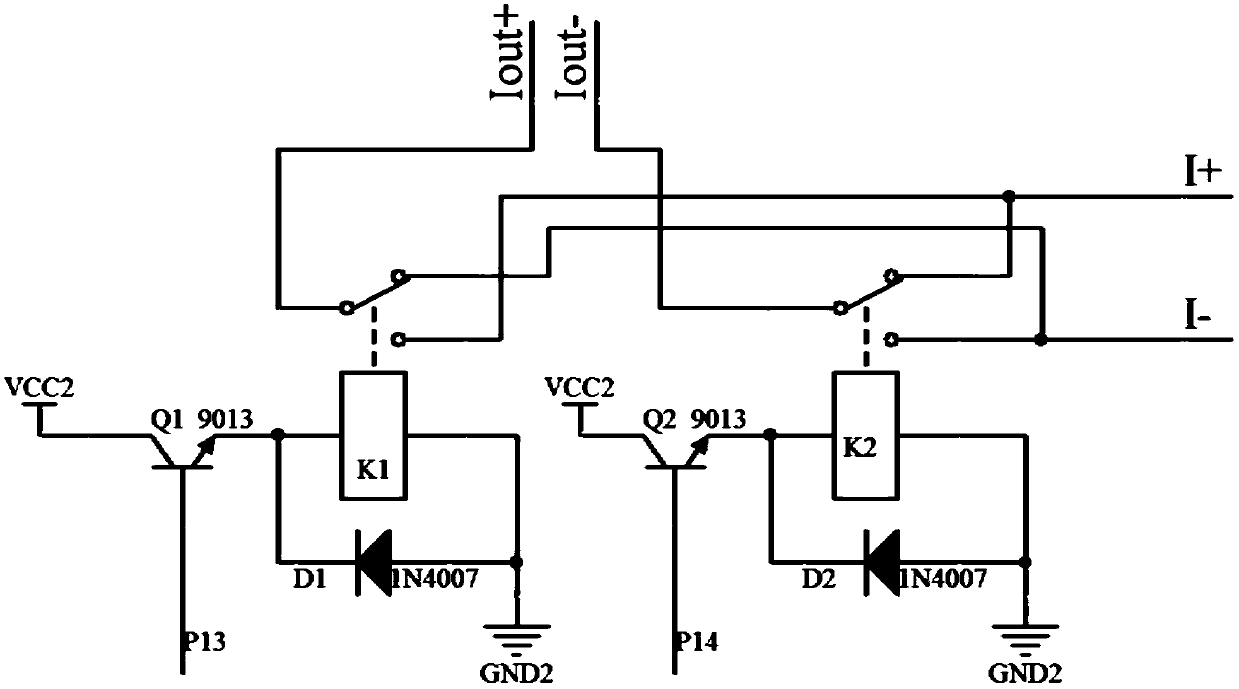

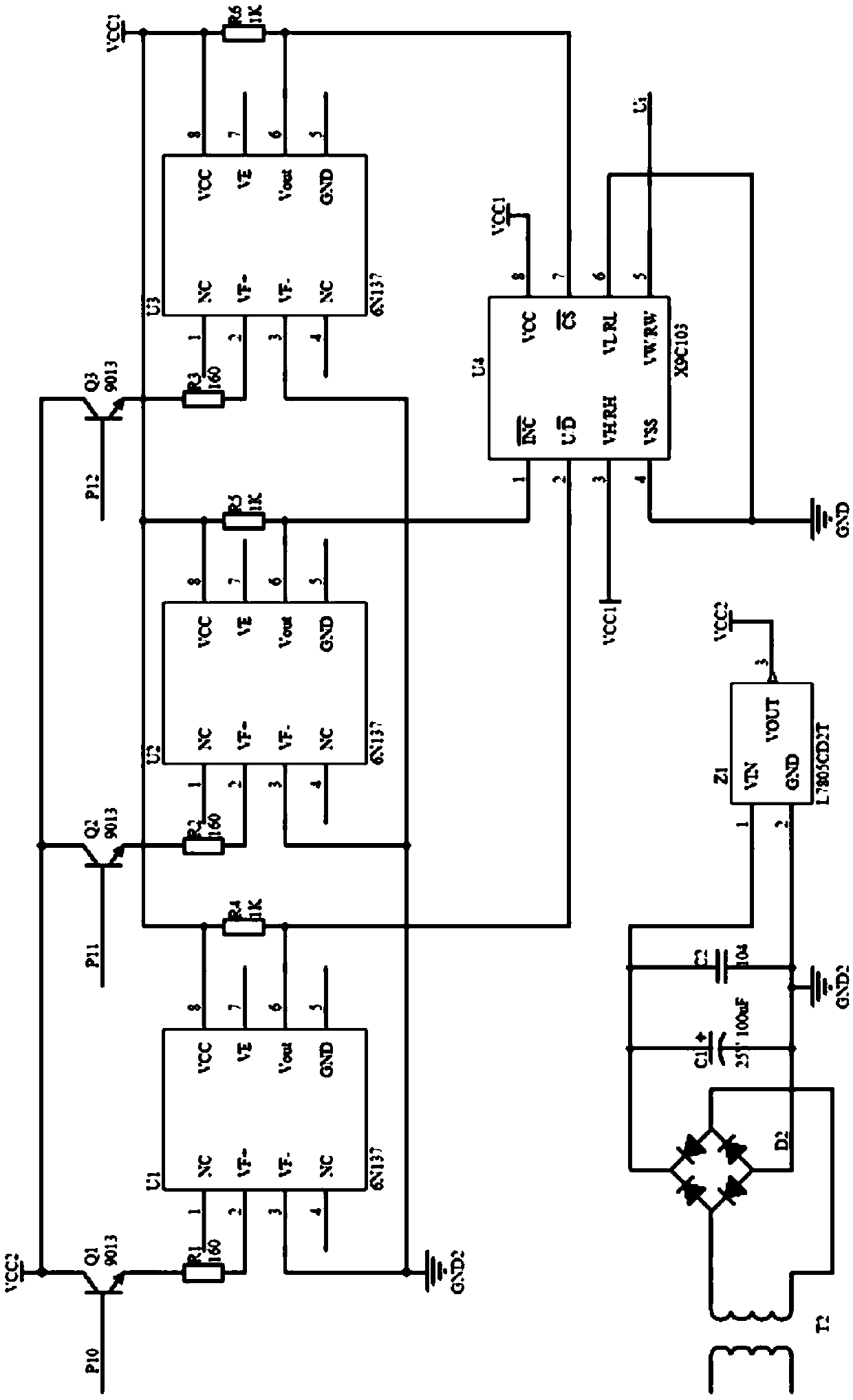

InactiveCN104833929AGood degaussing effectImprove degaussing efficiencyMagnetic property measurementsNumerical controlTransformer

The invention discloses a transformer demagnetization analyzer. The transformer demagnetization analyzer comprises a first direct-current residual magnetism analysis demagnetization output terminal, a second direct-current residual magnetism analysis demagnetization output terminal, a power supply direction switching module, a direct-current numerical control constant current source, a first optical isolator acquisition resistor Rb, a switch K1, a microprocessor, a reverse electromotive force protection module, a first program-controlled amplifier, a first A / D converter, a first optical isolator connection, a second program-controlled amplifier, a second A / D converter, a second optical isolator, an instruction input module, a display module, an alternating-current residual magnetism analysis output terminal, a voltage and current test module, an isolated boost transformer and an electric voltage regulator. The transformer demagnetization analyzer realizes the technical effects that the transformer demagnetization analyzer is capable of carrying out demagnetization and also can detect the residual magnetism amount of the transformer, the demagnetization effect is good, and the demagnetization efficiency is relatively high.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +2

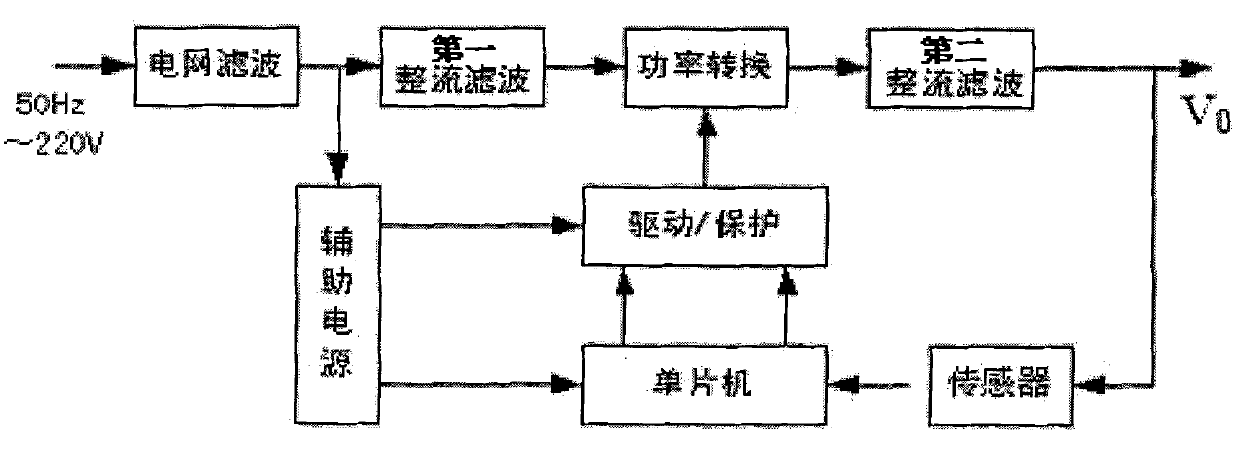

Conjugated pipeline demagnetizer

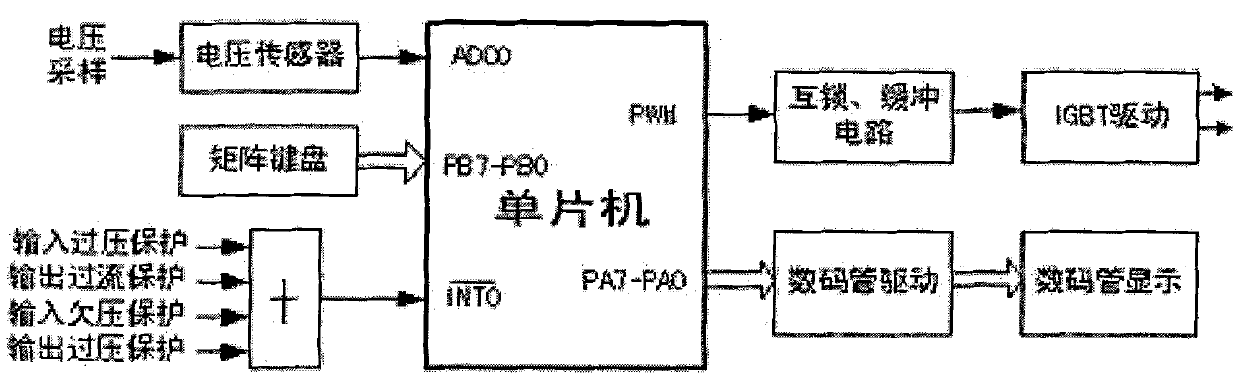

ActiveCN102024547AReduce magnetic field strengthGood degaussing effectMagnetic bodiesMicrocontrollerPower switching

The invention discloses a conjugated pipeline demagnetizer. The conjugated pipeline demagnetizer comprises a switching circuit, a control circuit, a drive circuit and a demagnetizing coil. The switching circuit provides direct current for pipeline demagnetization for the demagnetizing coil. A singlechip is arranged in the control circuit. The drive circuit drives a power switching device in the switching circuit. The switching circuit is formed by sequentially connecting a power grid filter circuit, a first rectification filter circuit, a power conversion circuit, and a second rectification filter circuit. The demagnetizing coil is made from flexible wire and an explosion-proof aviation plug is adopted for connection. The conjugated pipeline demagnetizer has the advantages of high demagnetization and self-shielded characteristic, good adaptability of terminal, and energy conversation and security.

Owner:国家管网集团北京管道有限公司

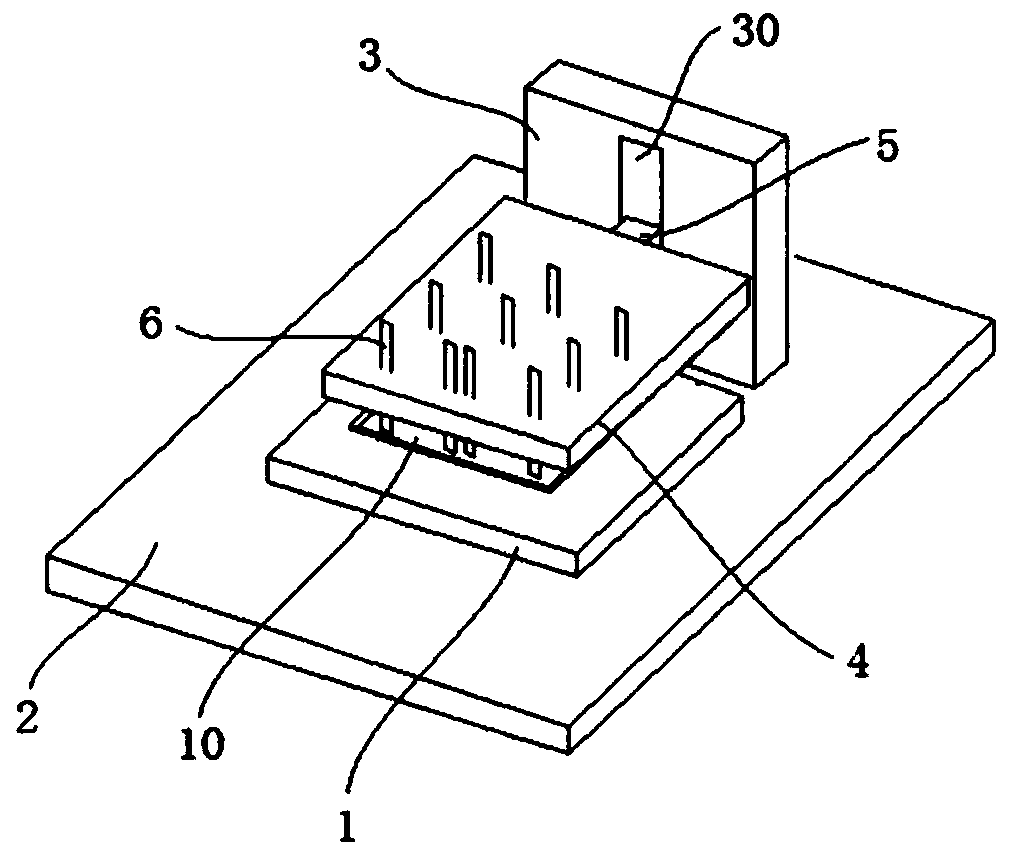

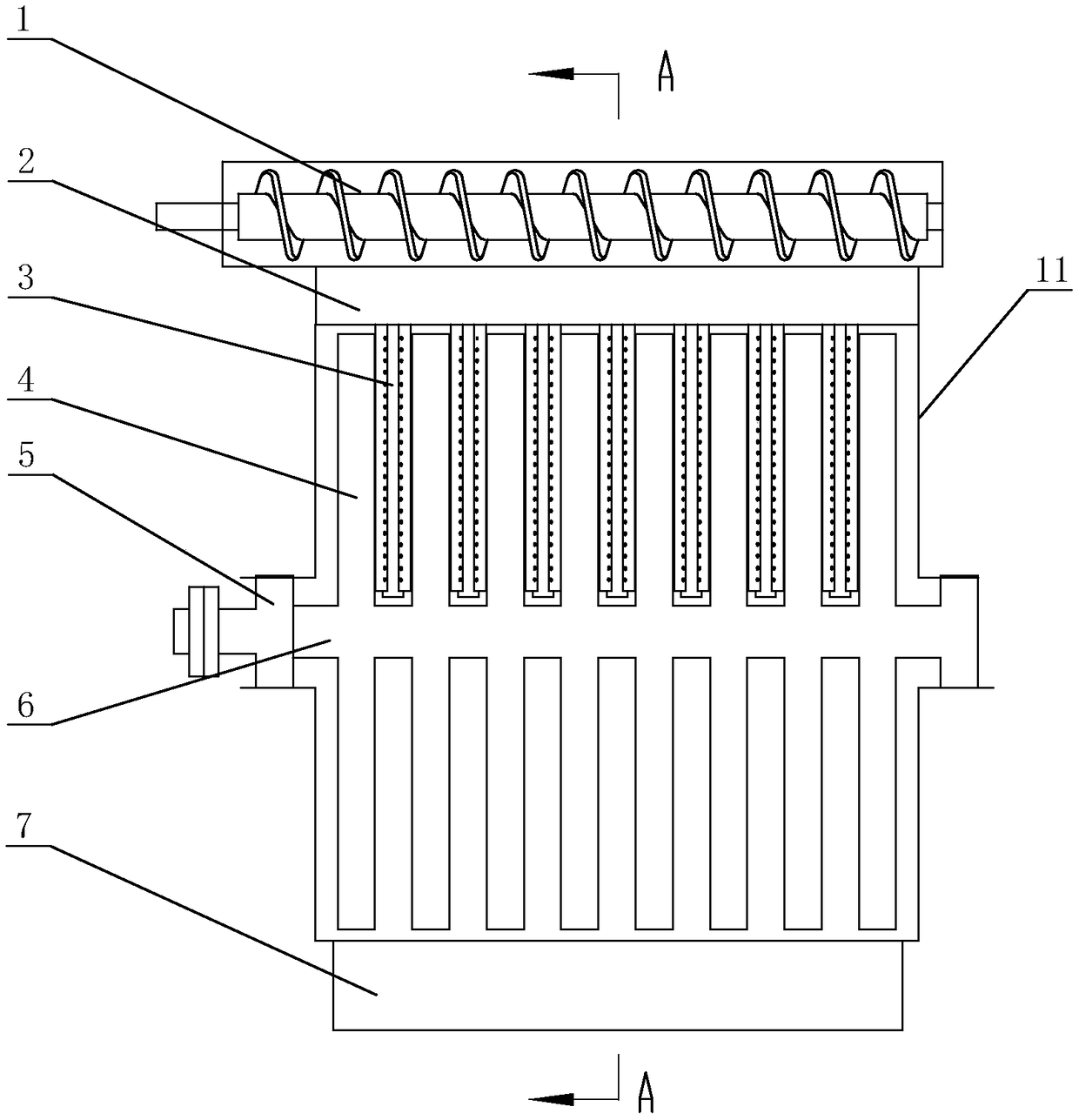

Assistant cooling structure of water-cooled platform

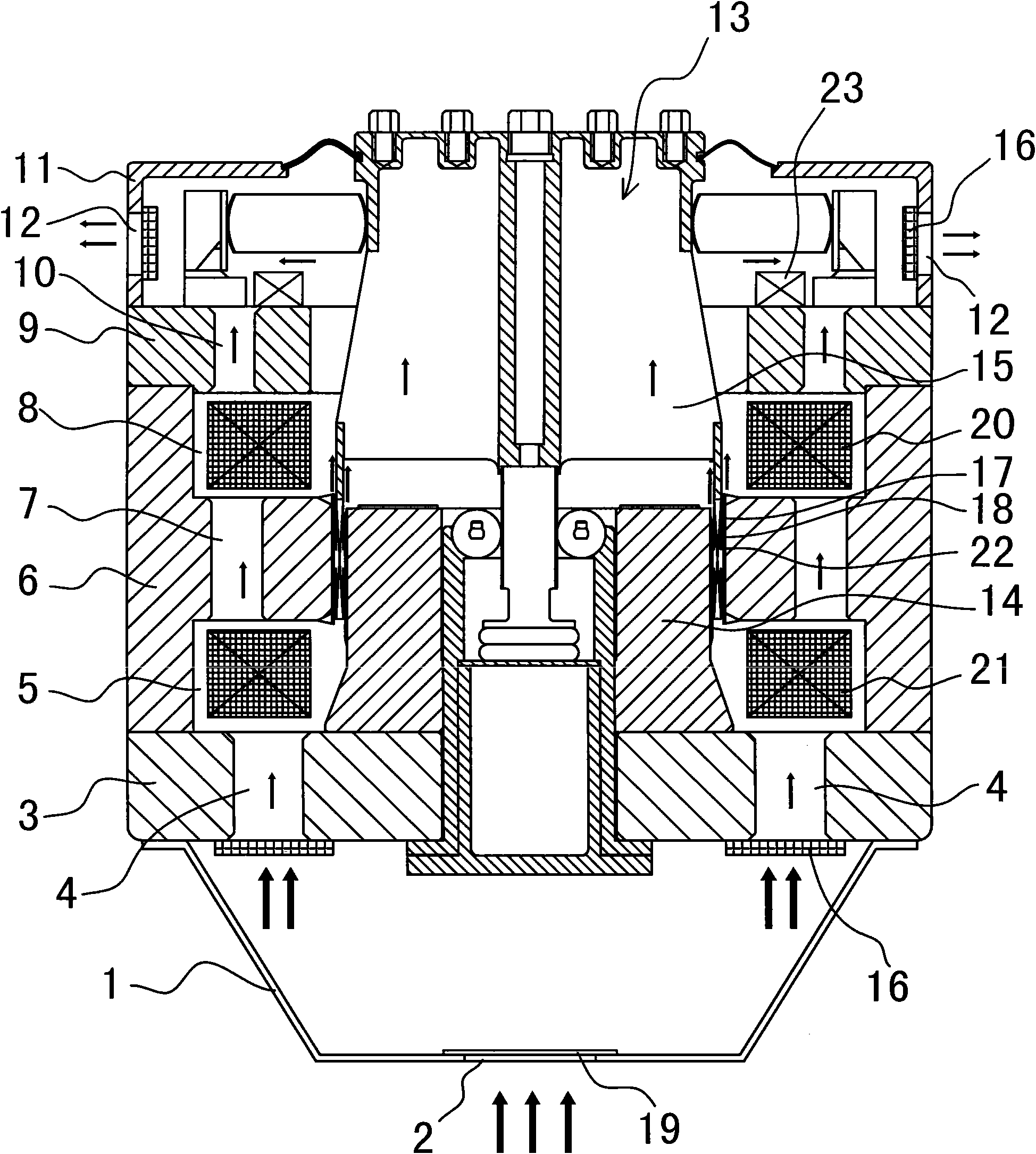

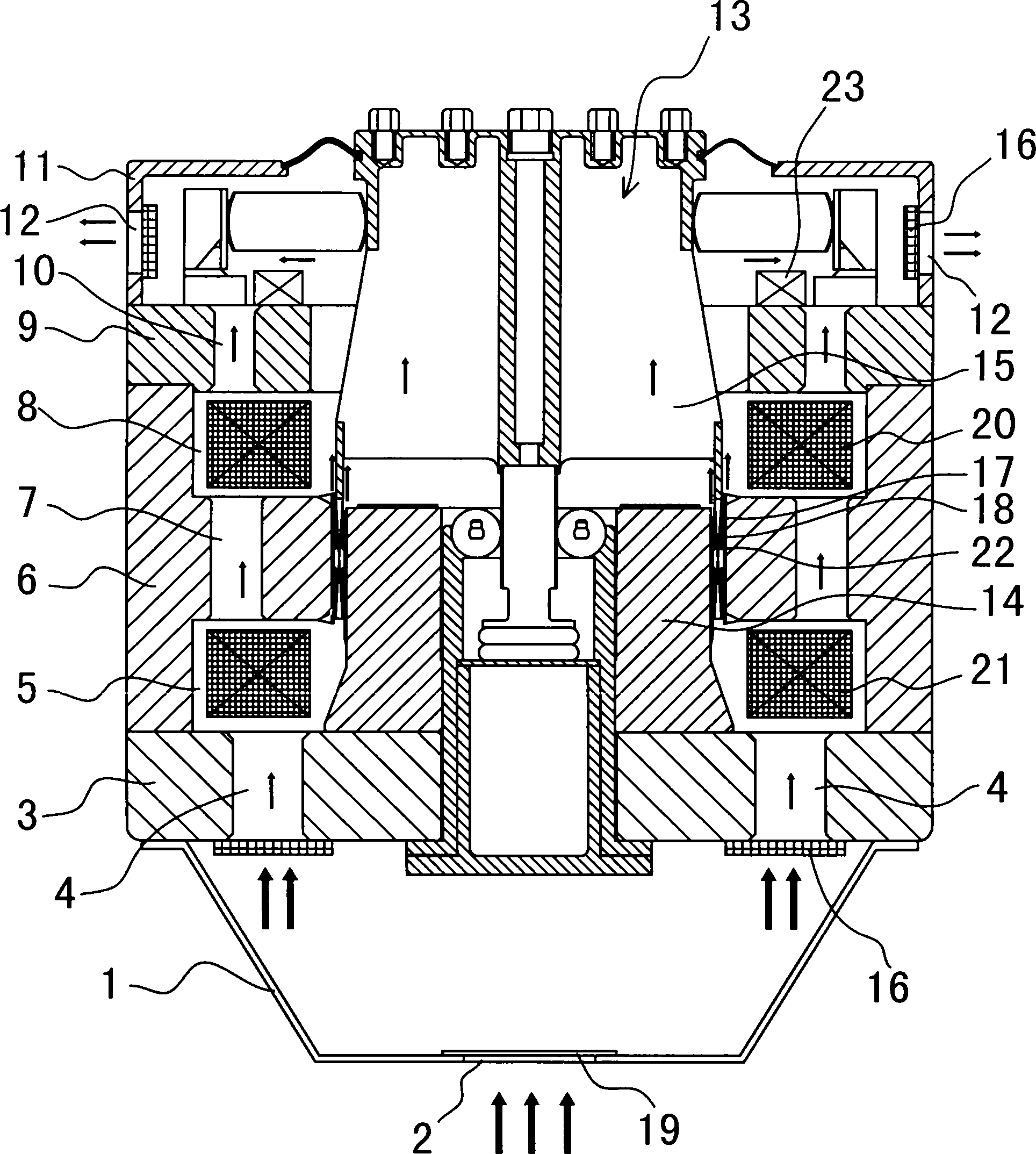

ActiveCN101793589ASolve the problem of high temperature riseIncrease powerVibration testingMagnetic polesEngineering

The invention relates to an assistant cooling structure of a water-cooled platform. The invention is characterized in that a lower cover casing below the water-cooled platform body is provided with an air inlet, and an upper cover casing of the water-cooled platform body is provided with an air outlet; inlet air from the air inlet orderly passes through a first ventilation opening and the arrangement space of a lower excitation coil and is divided into three paths, wherein the first path flows through a second ventilation opening, the second path flows through the clearance between the outer side of a moving coil and a magnetic cylinder ring, the third path flows through the clearance between the inner side of the moving coil and a central magnetic pole, and then the three paths converge in the communicated space of the arrangement space of an upper excitation coil, the upper space of the moving coil and a third ventilation opening and finally reach the air outlet, thereby forming a ventilation and heat radiation duct from bottom to top. The invention can dissipate heat generated by the magnetic cylinder due to the iron loss, solves the problem that the existing water-cooled platform has high temperature rise in the platform body under the condition of large-magnitude and long-time operation, and has the advantages of simple structure, low manufacture cost and easy implementation.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

Remanence evaluating and demagnetizing device of power transformer and remanence evaluation and demagnetizing control methods

ActiveCN109254253AAccurate and fast degaussingDegaussing is fast and thoroughMagnetisation measurementsMagnetic bodiesDemagnetizing deviceRemanence

The invention discloses a remanence evaluating and demagnetizing device of a power transformer. In a main circuit, two ends of a switch power are respectively connected with a filter capacitor and a resistor R0 in parallel, a forward end of the switch power is connected with a main switch T5 in serial, a switch T6 and a resistor R1 serial branch, a switch 1 and a switch 2 serial branch, a switch 3and a switch 4 serial branch are connected at the rear end of the main switch T5 in parallel, a drive circuit is connected with drive ends of the main switch T5, the switch T6, the switch 1, the switch 2, the switch 3 and the switch 4, and a control circuit is connected with the drive circuit and is used for sending an instruction to the drive circuit. The device provides reference for rapid, accurate demagnetization, is more intelligent, can demagnetize rapidly and thoroughly, and greatly shortens field demagnetization time and improves demagnetization effect.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +5

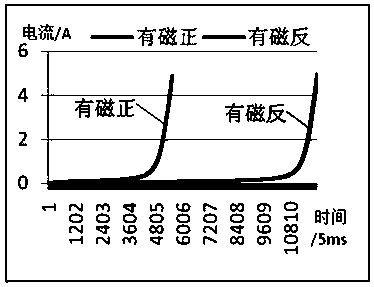

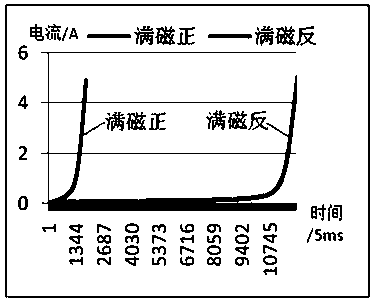

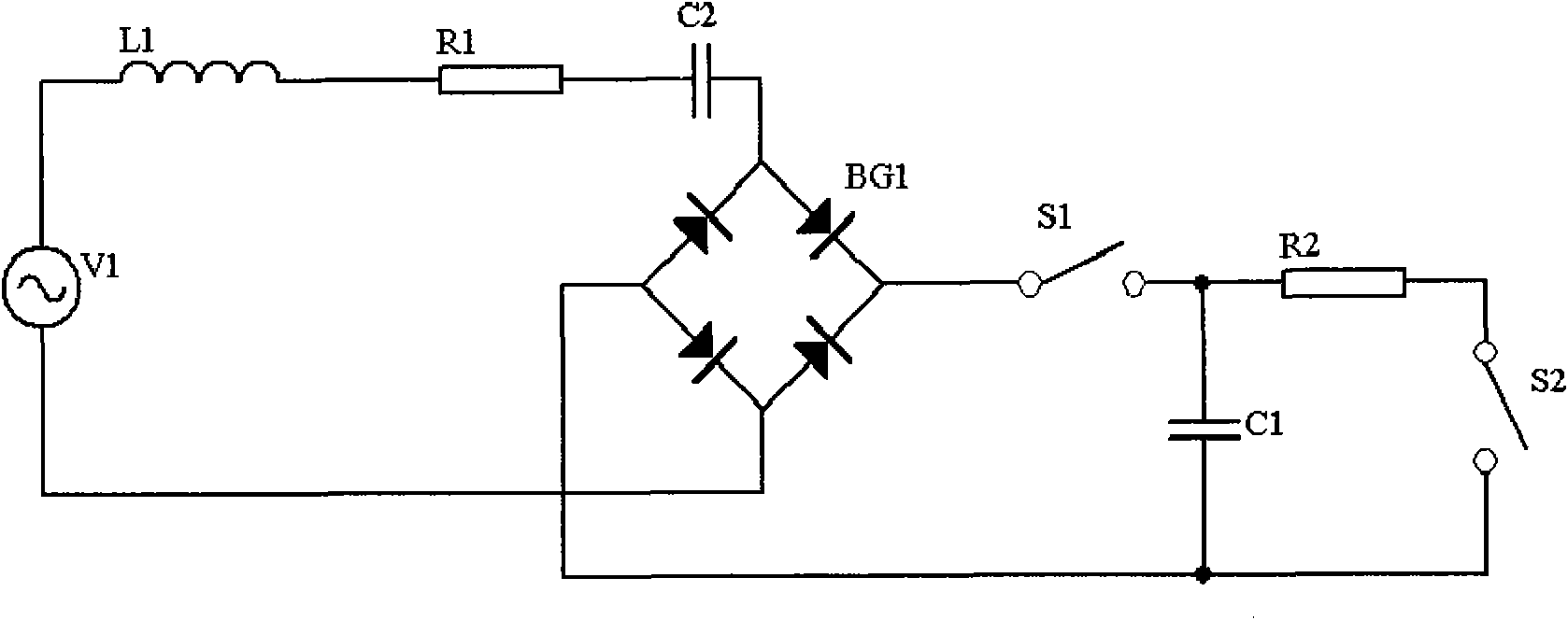

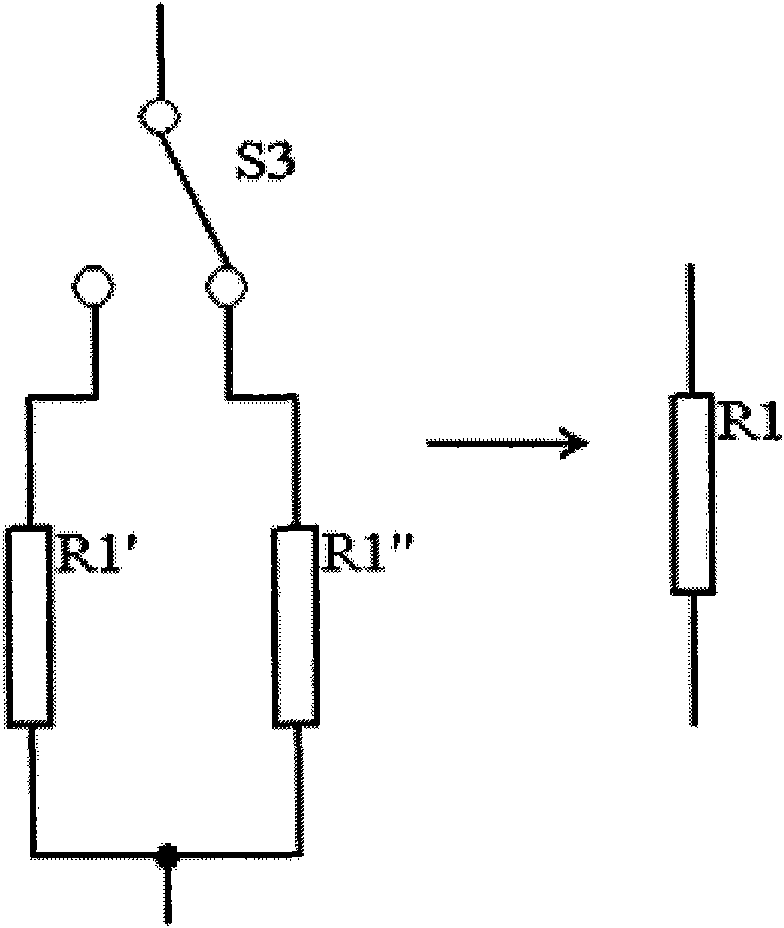

Demagnetization method and demagnetization circuit

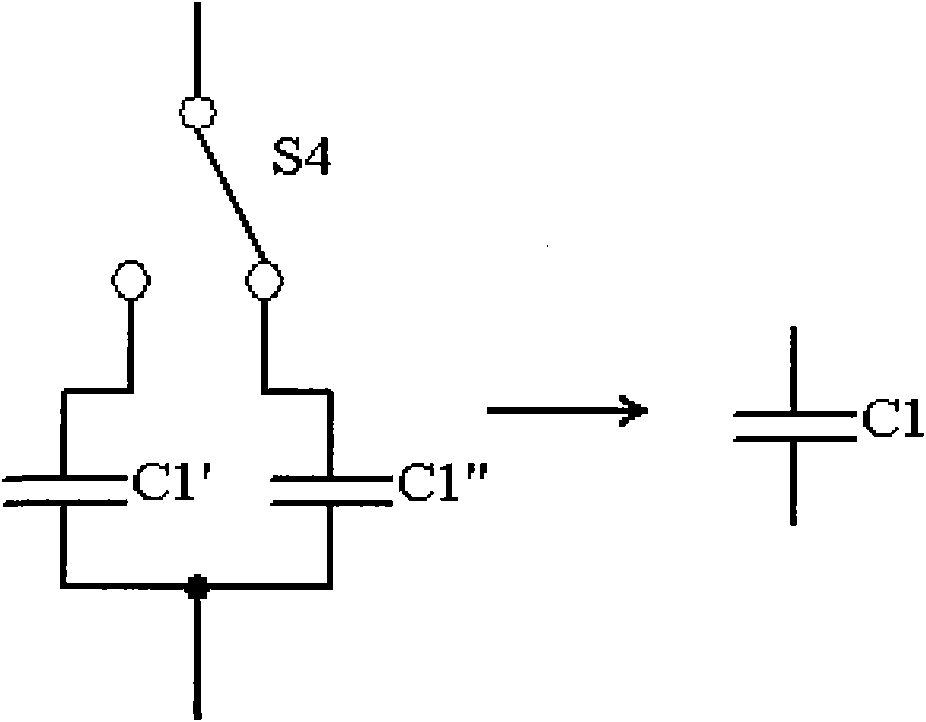

InactiveCN101819850AIngenious structureThe principle is simpleMagnetic bodiesDiode bridge rectifierCapacitance

The invention discloses a demagnetization method and a demagnetization circuit. The change rule that charge current slowly decreases along with time and finally decreases to zero when a rectifying circuit charges a capacitor is used as the current change rule required for demagnetization in a magnetic field coil to achieve the purpose of demagnetizing magnetic materials. The demagnetization circuit comprises an AC main loop, a DC charge loop and a discharge loop, wherein the AC main loop is formed by connecting an AC power source, a magnetic field coil, a current limiting resistor, a resonant capacitor and an AC terminal of a diode bridge rectifier stack in series; the DC charge loop is formed by connecting a DC terminal of the diode bridge rectifier stack, two switches, a capacitor and a resistor; and one switch is used for controlling the DC charge loop, and the other switch is used for controlling the discharge loop. The invention has the advantages of novel method, skillful circuit structure, simple realization and good demagnetization effect, can achieve the purpose of repeated demagnetization, and can freely and flexibly regulate the demagnetization degree and the demagnetization time.

Owner:湖南省联众科技有限公司

Demagnetization and residual magnetism measurement device for power transformer

ActiveCN110828101AEfficient measurementRemanence measurement is validMagnetic bodiesMagnetic property measurementsRemanenceTransformer

The invention relates to a demagnetization and residual magnetism measurement device for a power transformer. The device comprises a demagnetization structure for performing demagnetization in a direct-current attenuation reversing mode, a residual magnetism measuring structure used for quantizing residual magnetism by collecting second harmonics in the exciting current, and a controller connectedwith the demagnetization structure and the residual magnetism measuring structure. The demagnetization and residual magnetism measurement device is advantaged in that on one hand, residual magnetismof the power transformer can be reduced or even eliminated, on the other hand, the residual magnetism amount of an iron core of the power transformer can be effectively measured before, during and after demagnetization, and the residual magnetism amount can be accurately reflected, the device has further has properties of simple operation, high demagnetization speed, obvious demagnetization effect, accurate and rapid residual magnetism amount test and the like.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Degaussing cable trough, laying device for ship cable and cable laying method

ActiveCN107425488AEasy laying workReduced Scratch DamageApparatus for laying cablesVertical barEngineering

The invention provides a degaussing cable trough, a laying device for a ship cable and a cable laying method and relates to the technical field of cable laying. The degaussing cable trough comprises a cable trough body, a cover board and a cable fastening hook for fixing the cable, wherein the section of the cable trough body is rectangular and an opening is formed in the top; the cover board covers the opening in the top of the cable trough body; the cable fastening hook is internally arranged in the cable trough body and comprises a U-shaped bracket and two opposite and parallel lifting rods; the U-shaped bracket is formed by two vertical bars and a bottom bar; two grooves are formed in the inner side of each lifting rod and are correspondingly limited in the outer ends of the two vertical bars; and the two lifting rods are connected through a fastener. The laying device for the ship cable is formed by connecting a plurality of degaussing cable troughs and two adjacent degaussing cable troughs are connected through one sleeve. The cable laying method is implemented by adopting the laying device for the ship cable. The cable laying work of a constructor can be greatly facilitated through laying the cable in each cable trough body, and a scratched injury to the cable is reduced.

Owner:宝应帆洋船舶电器配件制造有限公司

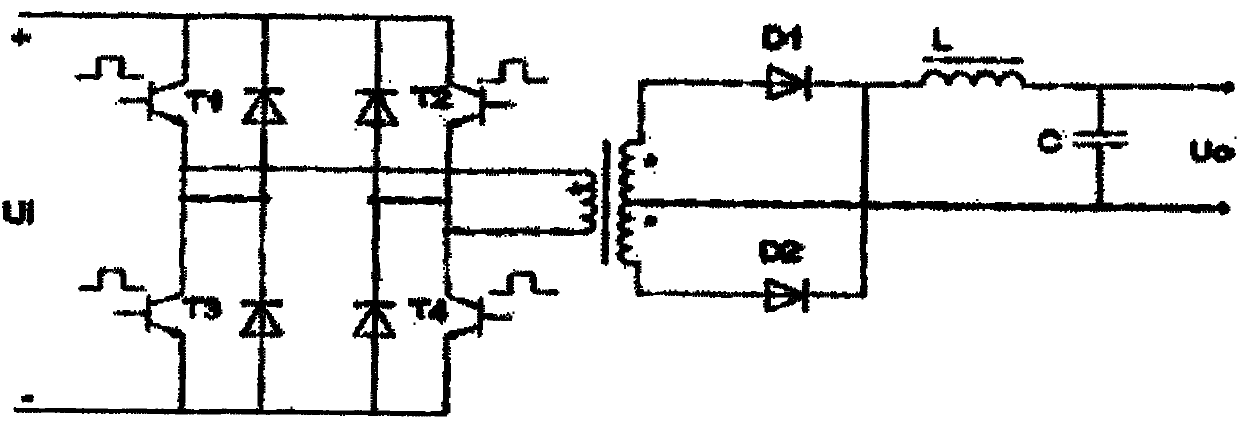

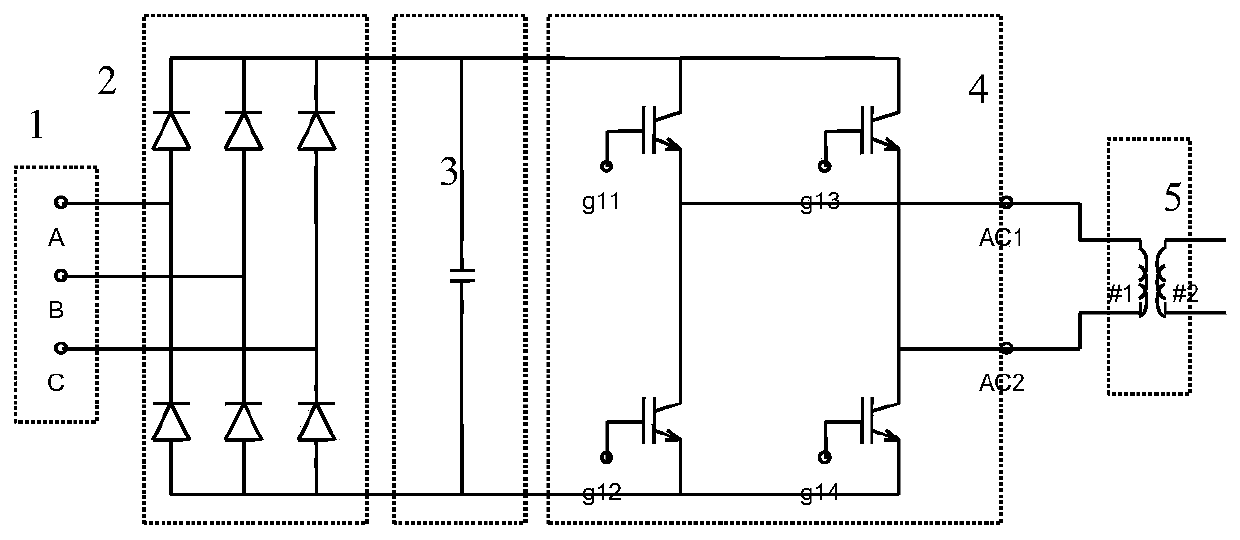

Low frequency degaussing power supply for power transformer

InactiveCN109889055AReduce volumeEfficient degaussingMagnetic bodiesAc-ac conversionTransformerThree-phase

The invention relates to a low frequency degaussing power supply. The low frequency degaussing power supply is characterized by comprising a three-phase alternating current power supply, a three-phasebridge rectifier circuit, a filter circuit, a bridge low frequency inverter circuit. The three-phase alternating current power supply is connected with an input end of the three-phase bridge rectifier circuit. An output end of the three-phase bridge rectifier circuit is connected with an input end of the filter circuit. The output end of the filter circuit is connected with the input end of the bridge low frequency inverter circuit. The output end of the bridge low frequency inverter circuit is connected with a primary side of a transformer. According to the low frequency degaussing power supply, degaussing is carried out through adoption of the low frequency power supply. Compared with power frequency degaussing, the power supply has the advantage that a size is greatly reduced. A degaussing effect reaches a level of alternating current degaussing. The degaussing effect is good. An equipment size is small. Efficient degaussing of a large-scale power transformer can be realized.

Owner:SUZHOU INDAL PARK HAIWO TECH

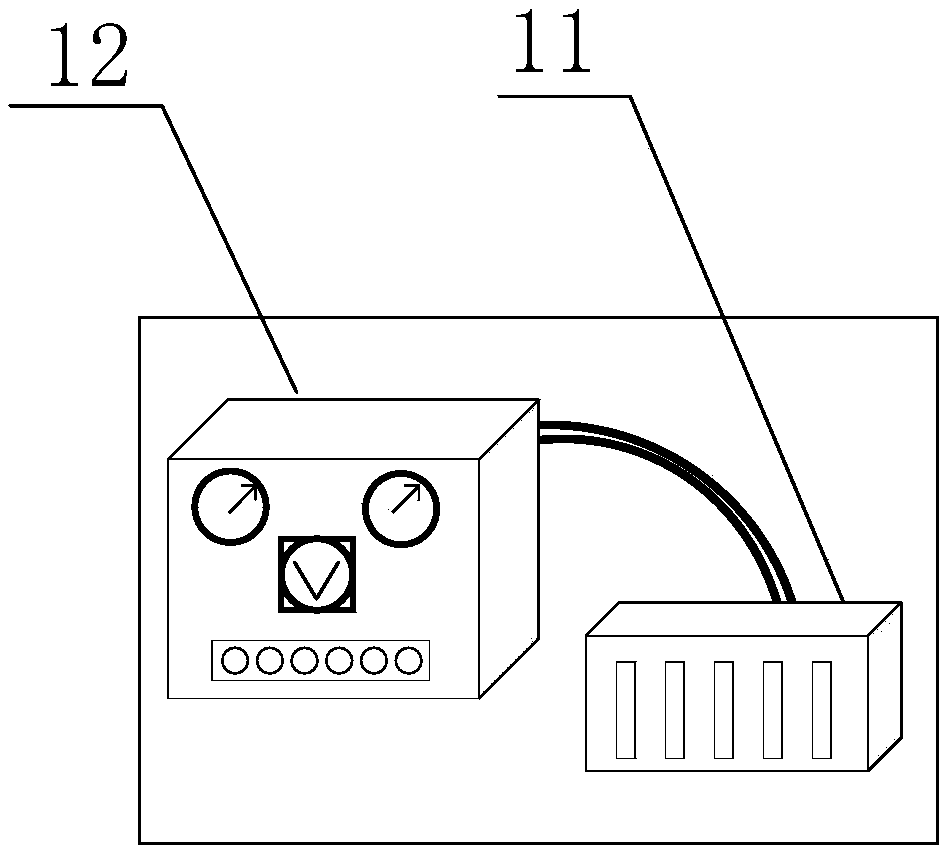

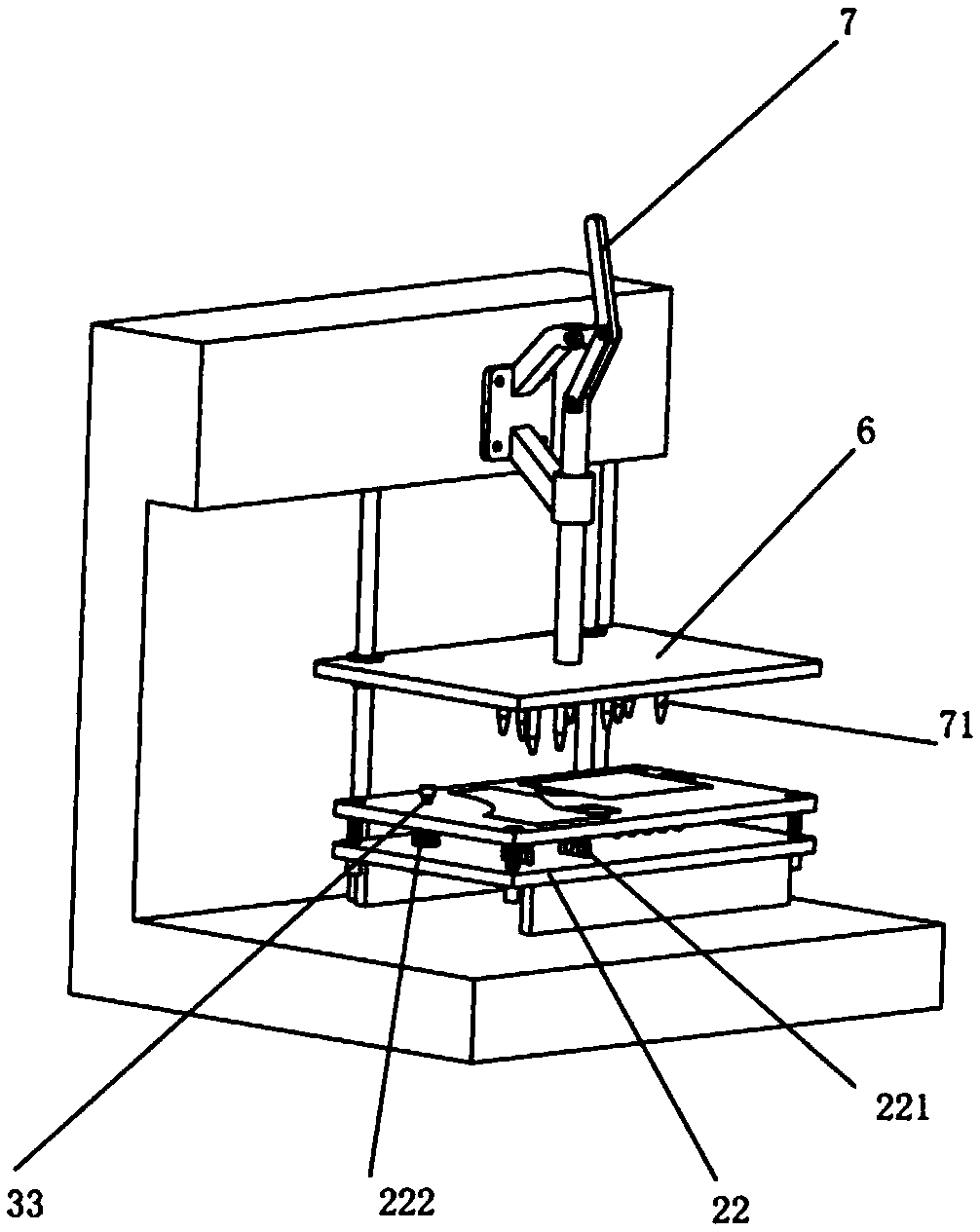

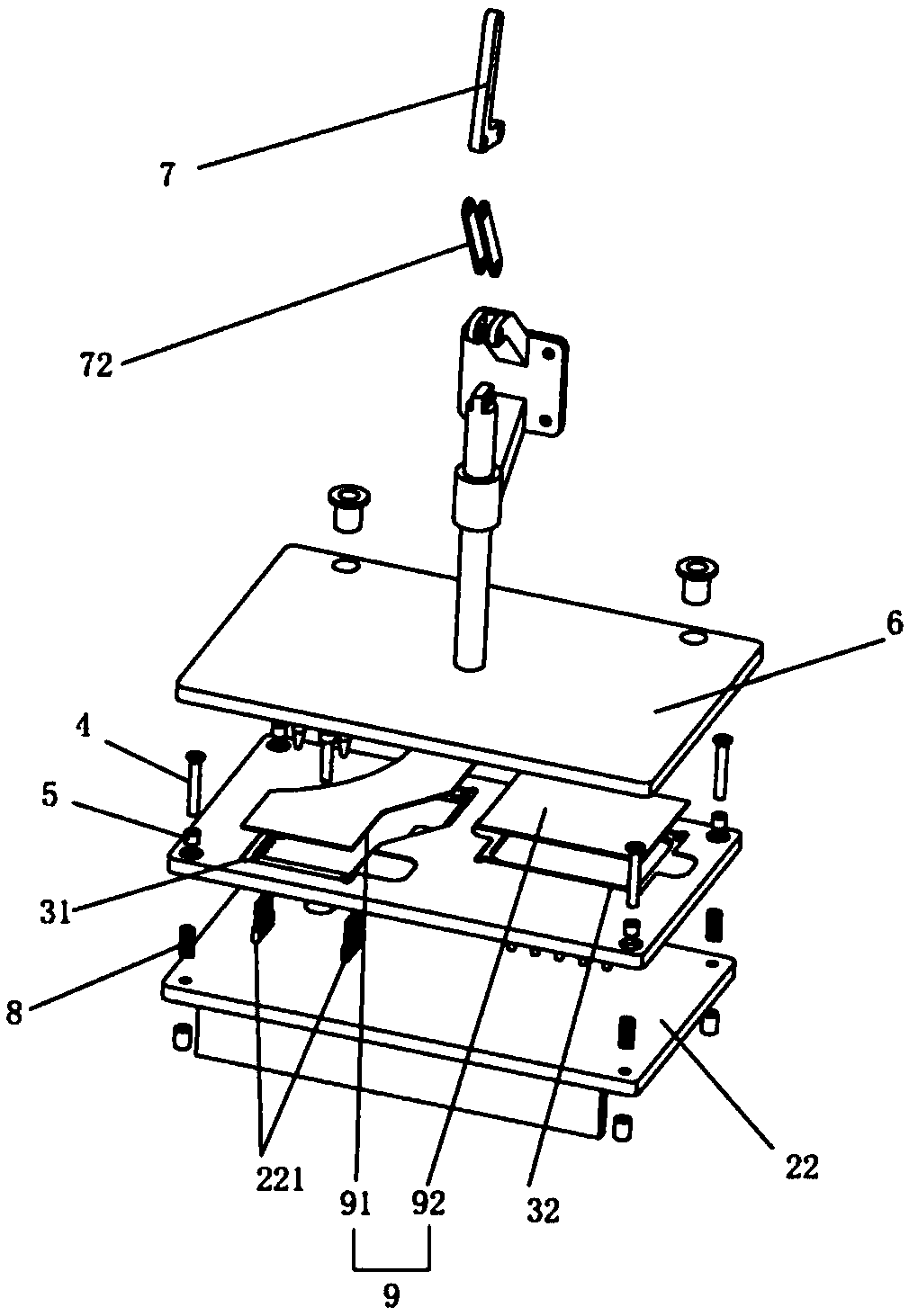

Circuit board testing tool

InactiveCN109541436ASimple structureEasy to operatePrinted circuit testingMeasurement instrument housingEngineeringMagnet

The invention discloses a circuit board testing tool which comprises the components of a workpiece placing part that is provided with at least one placing trough of which the size and the shape correspond with the size and the shape of a to-be-tested circuit board; a supporting fixing board which is vertically arranged on a worktable, wherein a sliding trough is arranged on the supporting fixing board in a height direction, and the sliding trough extends to bottom of the supporting fixing board; and a probe mounting board which is provided with a slide block that slides in the sliding trough at one end. The probe mounting board is pressured and is provided with a plurality of detecting probes. The probes of the plurality of detecting probes are arranged correspondingly with a plurality ofcontacts on the to-be-tested circuit board. The probe mounting board is internally provided with a demagnetizer, and a magnet conducting board which is arranged at bottom of the probe mounting board and abuts against the demagnetizer. The circuit board testing tool has advantages of simple structure and convenient operation. Accurate alignment of the detecting probes and the contacts on the circuit board can be realized and the plurality of contacts on the circuit board can be tested, thereby saving tedious operation in manual testing and improving testing accuracy and efficiency.

Owner:鹤山市泰利诺电子有限公司

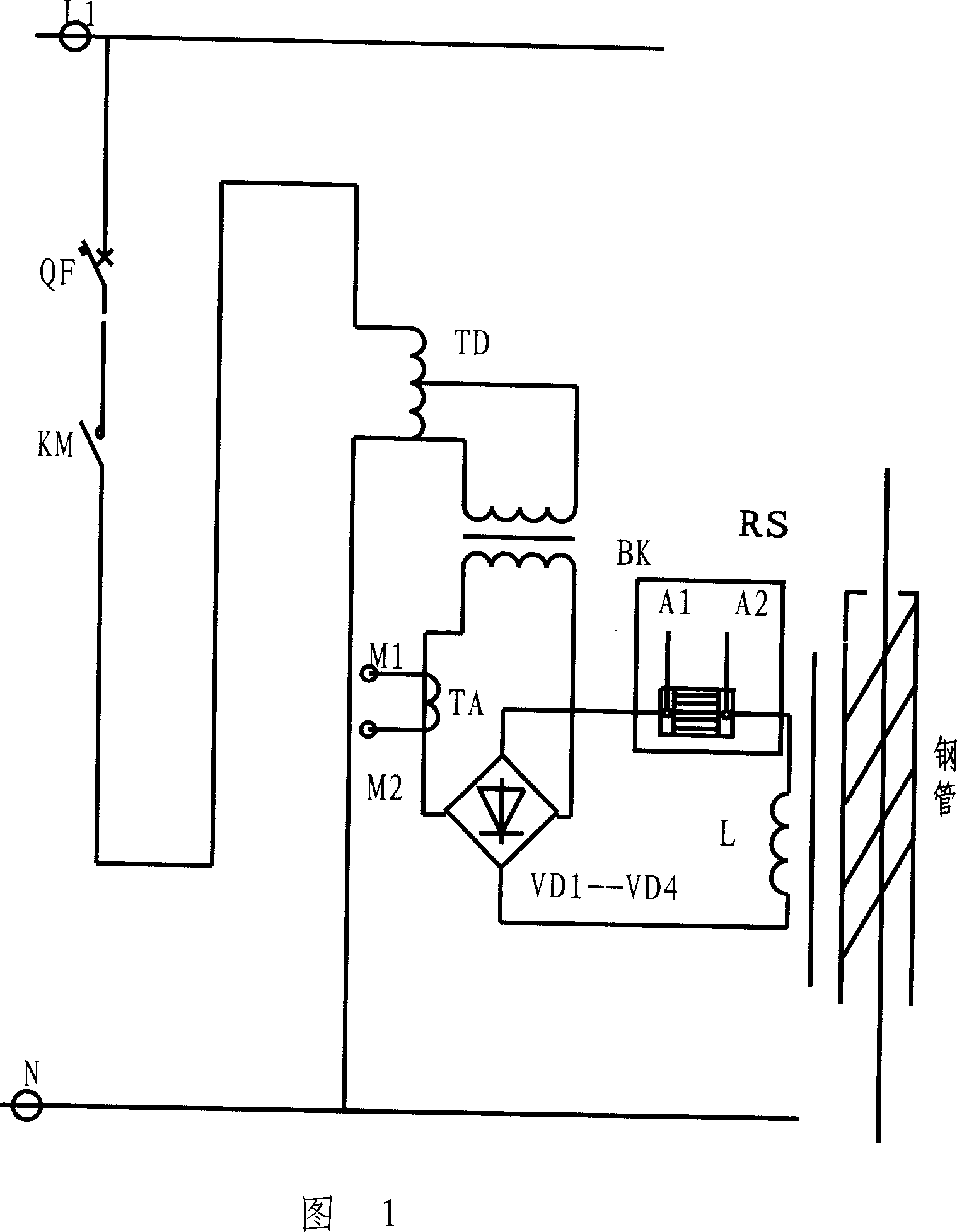

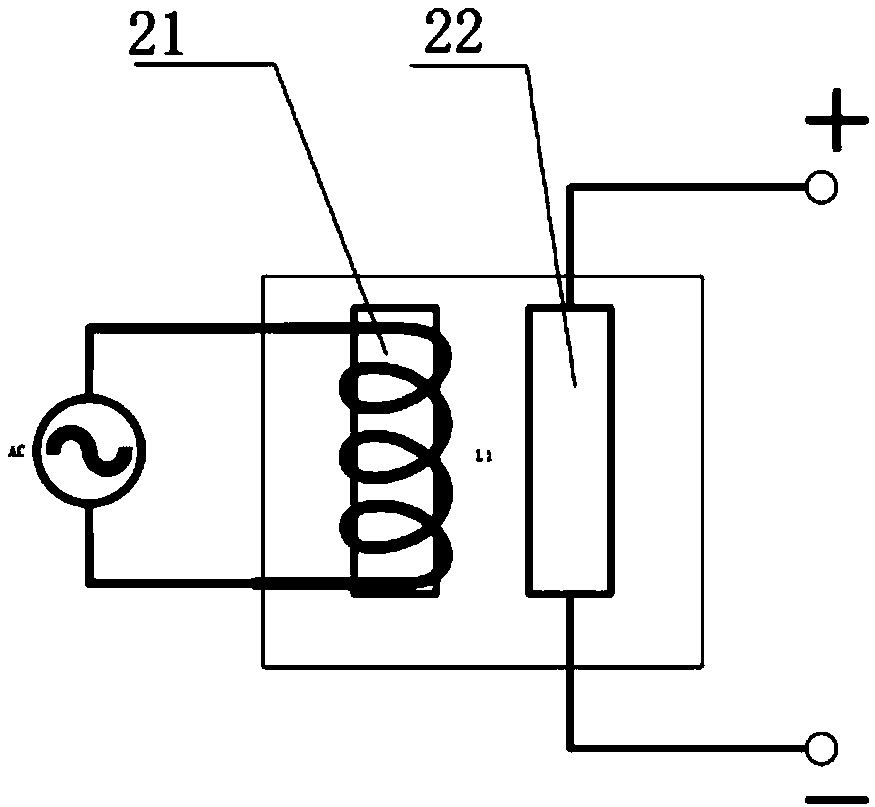

Demagnetizing method and device of the spring welding pipe

InactiveCN101017725ASimple structureGood degaussing effectMagnetic bodiesSocial benefitsManufacturing technology

The related degaussing method for spiral weld pipe mainly applies magnetic field with reverse direction to magnetic field generating welding current to take coarse degaussing and fine degaussing. Besides, the relative equipment comprises a degaussing transformer, a contact voltage regulator, a bridge rectifier, and a coil. The residual magnetic field is less 10Gs. This invention has well both economic and social benefits.

Owner:JIANGSU TONGYU STEEL PIPE GRP

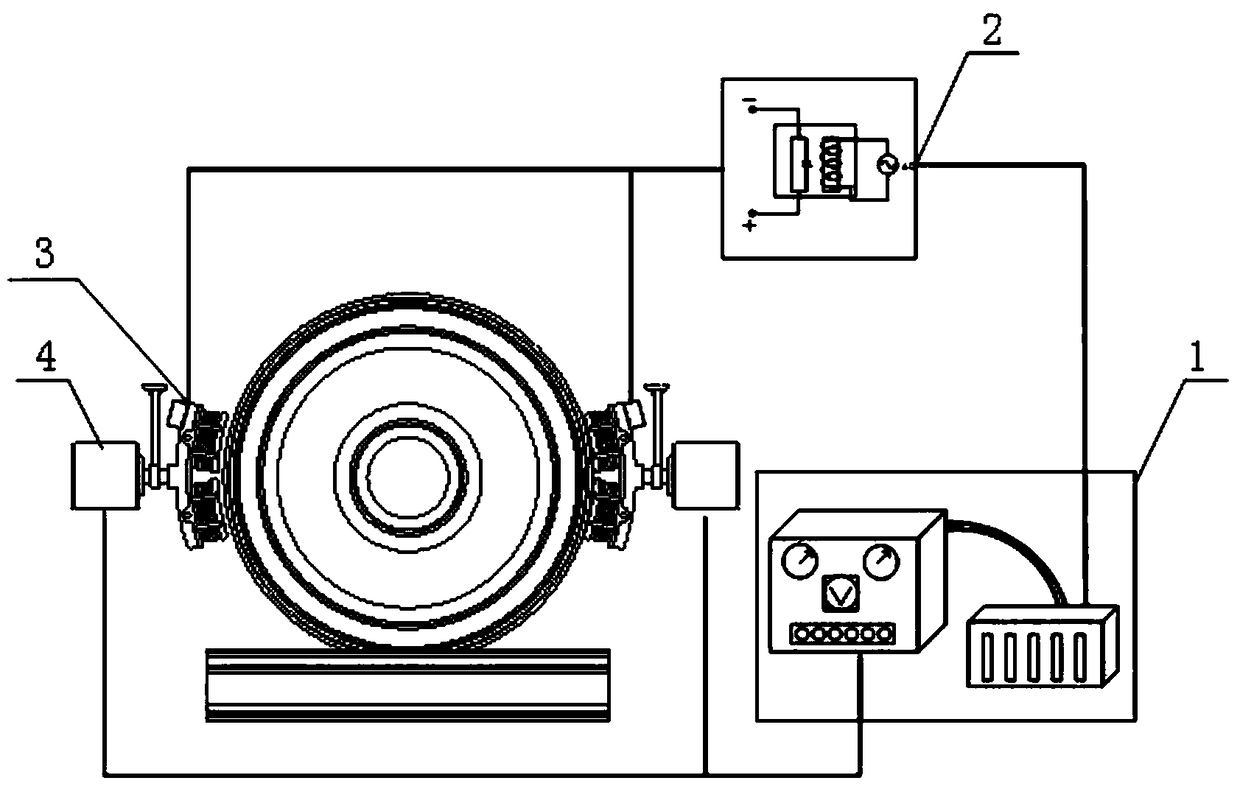

System for improving adhesion force of train wheel rail

ActiveCN109501817AEasy to operateSolve the problem of insufficient adhesionLocomotivesAdhesion forceAdhesion coefficient

The invention relates to a system for improving the adhesion force of a train wheel rail. The system comprises a control device (1), an excitation power supply (2), a wheel tread electromagnetic device (3) and a pneumatic pushing device (4); when a train is subjected to traction or braking, the control device (1) controls pressure air to be input into the pneumatic pushing device (4) and the wheeltread electromagnetic device (3) is pushed to get close to a wheel tread; meanwhile, an instruction is sent to the excitation power supply (2) and needed excitation current is output to the wheel tread electromagnetic device (3) to form a magnetic field nearby the rotary train wheel tread; an eddy flow is generated on the tread and an adsorption force on a steel rail is generated; meanwhile, thesurface of the train wheel tread is magnetized; meanwhile, the adsorption force on the steel rail tread is increased through the train wheel tread; the effect of increasing the adsorption force on a train wheel is realized under the condition of an adhesion coefficient between the wheel rails. Compared with the prior art, the system provided by the invention has the advantages that the system is convenient to mount, the adhesion force of the wheel rail is remarkably improved, damages to the steel rail and the wheel are not caused and the like.

Owner:TONGJI UNIV

Circuit board detection device

InactiveCN109507567AImprove adaptabilityImprove work efficiencyElectronic circuit testingMeasurement instrument housingEngineeringManufacturing line

Owner:鹤山市泰利诺电子有限公司

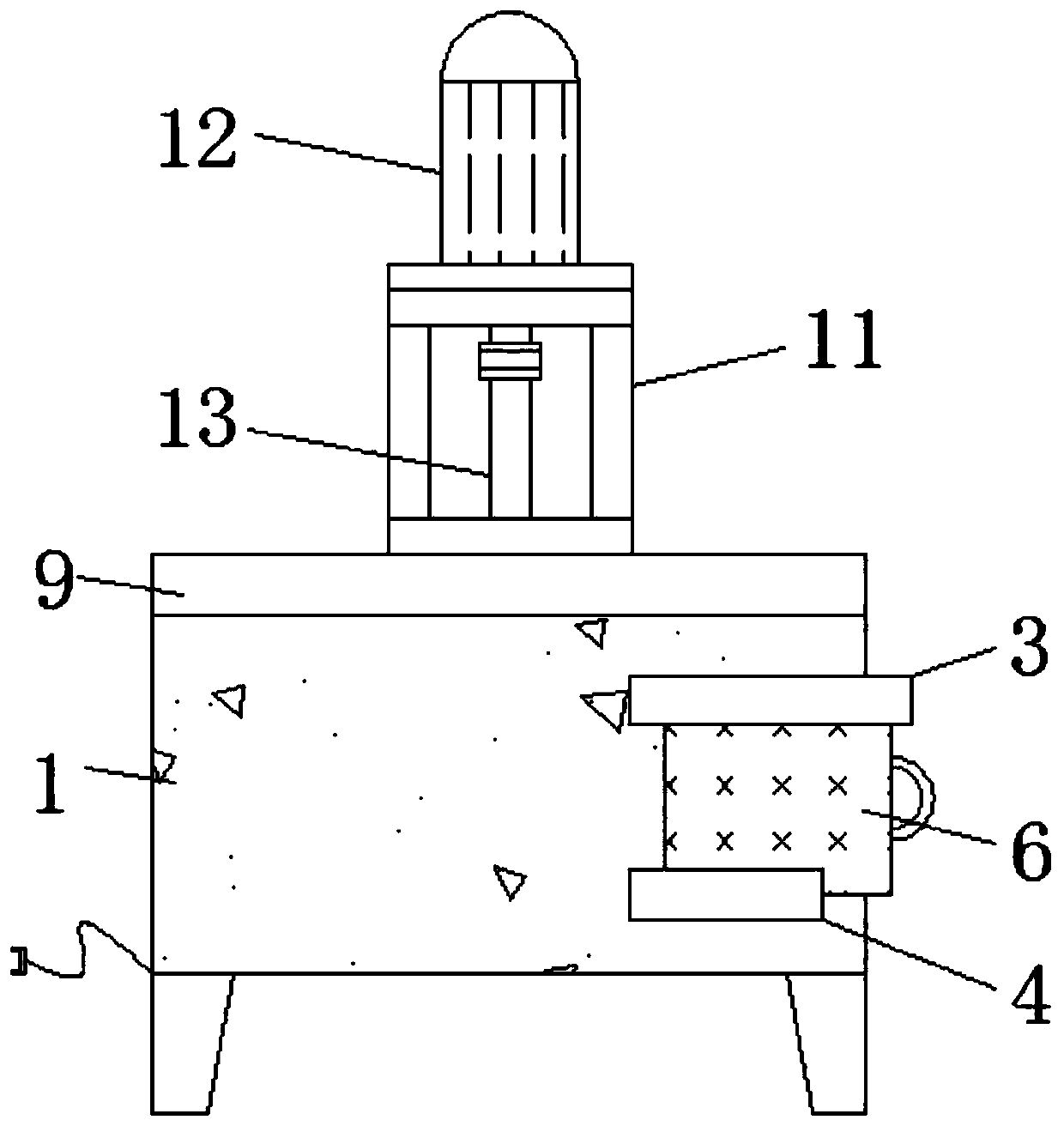

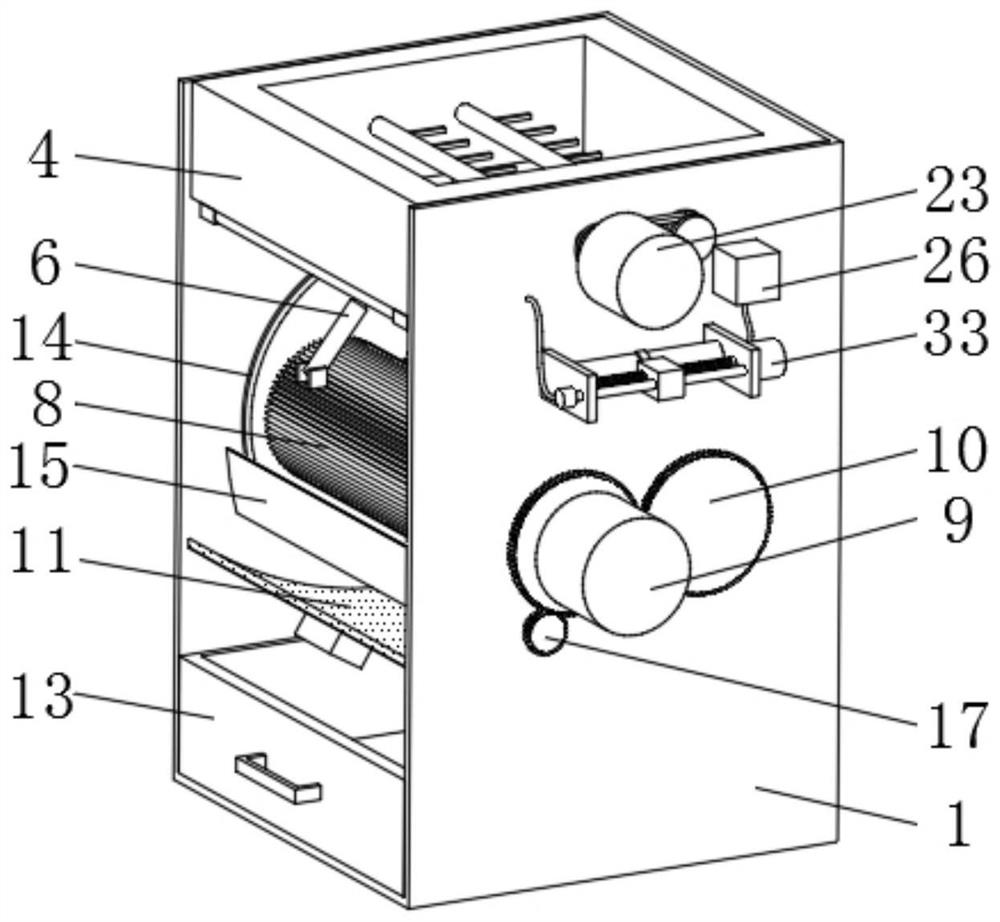

Full demagnetization equipment for electronic information equipment

ActiveCN108711438ARealize the degaussing operationRealize multi-angle degaussing operationErasing methodRecord information storageHydraulic cylinderTransmission belt

The invention discloses full demagnetization equipment for electronic information equipment. The full demagnetization equipment comprises a body, a feeding hole, a hinge, a closing cover, supporting legs, a driving groove, a hydraulic cylinder, a driving motor, a shaft sleeve, an objective table, demagnetization rods, demagnetization coils, mounting frames, a rotating motor, connecting rods, a lifting column, a movable connecting piece, a transmission wheel and a transmission belt. The objective table is lifted through the hydraulic cylinder, and then the electronic information equipment can be taken and placed in the body, so that the operation is simple and convenient; the body is sealed through the closing cover, so that the demagnetization operation of the electronic information equipment in a sealed space is realized; meanwhile, the two demagnetization rods arranged correspondingly are used for continuously moving and rotating at the peripheral end of the equipment, and the demagnetization coils are mounted in the closing cover at the upper and lower ends and the objective table, so that the multi-direction and multi-angle demagnetization operation of the electronic information equipment is realized, the demagnetization effect of the electronic information equipment is further improved, and various use requirements under the actual condition are met.

Owner:XUZHOU SANHE AUTOMATIC CONTROL EQUIP

Non-magnetic cast iron

The invention relates to power cast iron production, namely, non-magnetic cast iron. The non-magnetic cast iron comprises the following chemical components in percentage by mass: 66% of pig iron, 12% of ferro-manganese, 3% of silicon iron, 16% of copper and 3% of nickel. According to the scheme, the non-magnetic cast iron is prepared by adding different raw materials at different temperatures and finally performing quenching treatment. The cast iron is free of magnetism and can be used in power fittings, particularly used in insulators, and has a better use effect. In the production process, different raw materials are added at different temperatures, the melting effect is good, the demagnetization effect is good, and qualified non-magnetic cast iron can be obtained.

Owner:通化名成电瓷电器有限公司

Degaussing device capable of achieving degaussing effect for computer information storage equipment

ActiveCN110379585AGuaranteed degaussing effectEfficient crushingMagnetic bodiesGrain treatmentsSurface statesInformation storage

The invention discloses a degaussing device capable of achieving the degaussing effect for computer information storage equipment. The device includes a main casing, an end cap, a motor and shaft baffle plates, wherein a right side of the main casing is provided with a bin outlet, a second lower sliding rail is arranged at the rear of a first lower sliding rail, the main casing is internally welded with a mounting block, the mounting block is internally equipped with an electromagnetic rod, left and right end surfaces of a rotation rod are respectively equipped with the shaft baffle plates through bolts, an inner lower bolt of the main casing is equipped with a permanent magnetic chassis, and an upper surface of the permanent magnetic chassis is provided with a second convex block. The device is advantaged in that an electromagnetic rod is set, in the use process, the current is connected with a coil in the electromagnetic rod, the coil is made to generate a magnetic field, a third magnetic field is generated in the main casing, the magnetic fields are in a side surface state, the internal magnetic fields are quite confused, and degaussing performance is further enhanced.

Owner:HUNAN UNIV OF ARTS & SCI

Method and device for demagnetizing steel wire conveying belt without energy consumption

ActiveCN102646496BGood degaussing effectInnovative design ideasConveyorsMagnetic bodiesWave shapePeak value

The invention discloses a method and a device for demagnetizing a steel wire conveying belt without energy consumption. The method comprises the following steps of: a) allowing the moving direction of the steel wire conveying belt to get into an alternating magnetic field formed by a demagnetizing plate, wherein the distance between the demagnetizing plate and the steel wire conveying belt can be adjusted; b) adjusting the distance between the demagnetizing plate and the steel wire conveying belt, and measuring the magnetic field intensity on the back surface of the steel wire conveying belt, if the measured value of the magnetic field intensity is more than 200 Gs, the distance is qualified; c) adjusting the distance that the steel wire conveying belt departs from the demagnetizing plate, acquiring a detection signal through a metal detector, inputting the detection signal into an oscillometer, and observing whether interference pulse exists or not and the peak value of interference pulse wave, if a waveform curve is flat, demagnetization is qualified, and when the waveform curve is abnormal, adjusting the current distance until the detection signal is qualified; and d) after adjusting the current distance until the detection signal is qualified, starting a steel wire conveying belt machine set to perform demagnetizing operation, wherein in the process, the metal detector extracts the detection signal to analyze the whole periphery of the conveying belt to judge a demagnetizing effect. The problem about demagnetizing the steel wire conveying belt is solved by the method and the device, and the method and the device have the characteristics of no maintenance, energy conservation and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

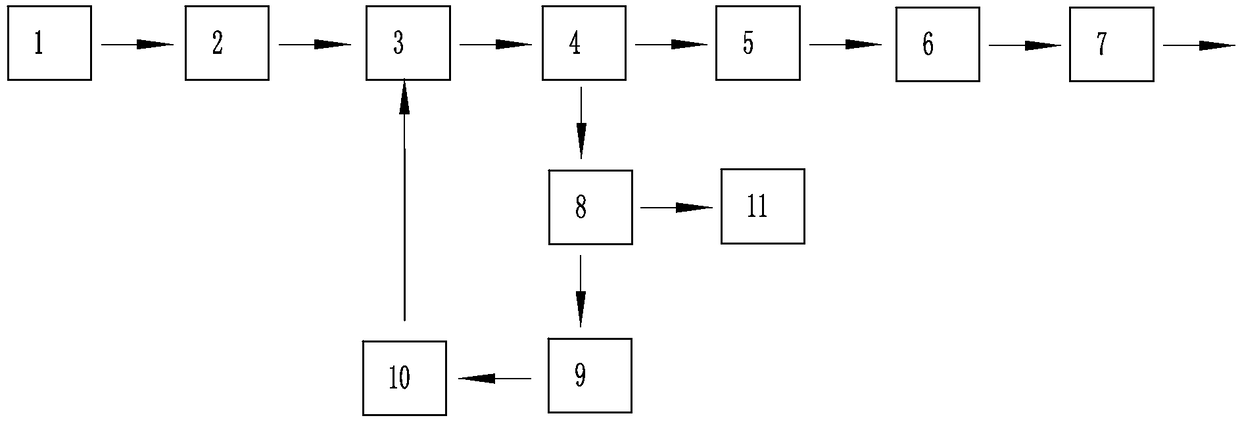

Super magnetic sewage purifying system and process

InactiveCN109231701AShort stayImprove processing efficiencyWater treatment parameter controlSludge treatment by de-watering/drying/thickeningActive carbonSmall footprint

The invention relates to a super magnetic sewage purifying system and process, and belongs to the field of sewage treatment. The super magnetic sewage purifying system comprises a coarse-fine screen 1, a primary settling tank 2, a stirring-mixing reactor 3, a super magnetic purifier 4, an MBR (Membrane Bioreactor) membrane filter 5, an active carbon abdsorber 6, a clean water pond 7, a dispersionreducer 8, a residual magnetism eliminator 9, a superparamagnetic doser 10 and a concentrated dehydrator 11. The super magnetic sewage purifying system has the advantages of simple process, high treatment efficiency, low investment, quick response, no constraint on geographic position, small influences of environment factors, ready availability of raw materials, small floor area and convenience inpractical application.

Owner:王腾

Degaussing cable for naval vessel

InactiveCN102623094AIncrease ampacityIncrease temperatureNon-insulated conductorsInsulated cablesCopper conductorMasking tape

The invention discloses a degaussing cable for a naval vessel. The degaussing cable comprises a conductor in the middle of the cable, wherein an aluminum foil mask tape is wrapped outside the conductor; and a low-smoke halogen-free and flame-retardant insulating layer is extruded outside the aluminum foil mask tape. According to the degaussing cable, the degaussing effect can be enhanced effectively, the outer diameter and weight of a product are reduced, and convenience is brought to pavement of the product; the insulating layer is made of a low-smoke halogen-free and flame-retardant crosslinking material, so that the cable carrying capacity, working temperature level and physical and mechanical properties are enhanced greatly, and the running power of the cable is raised remarkably; meanwhile, compared with an ordinary degaussing cable, the cable disclosed by the invention has the advantages that: only a small amount of low-smoke and nontoxic gas is produced during combustion, and the cable belongs to an environmentally-friendly product; and meanwhile, a thin copper soft wire with a high-electric-conductivity clad layer is adopted, so that the corrosion resistance and oxidation resistance of a copper conductor are enhanced.

Owner:无锡市群星线缆有限公司

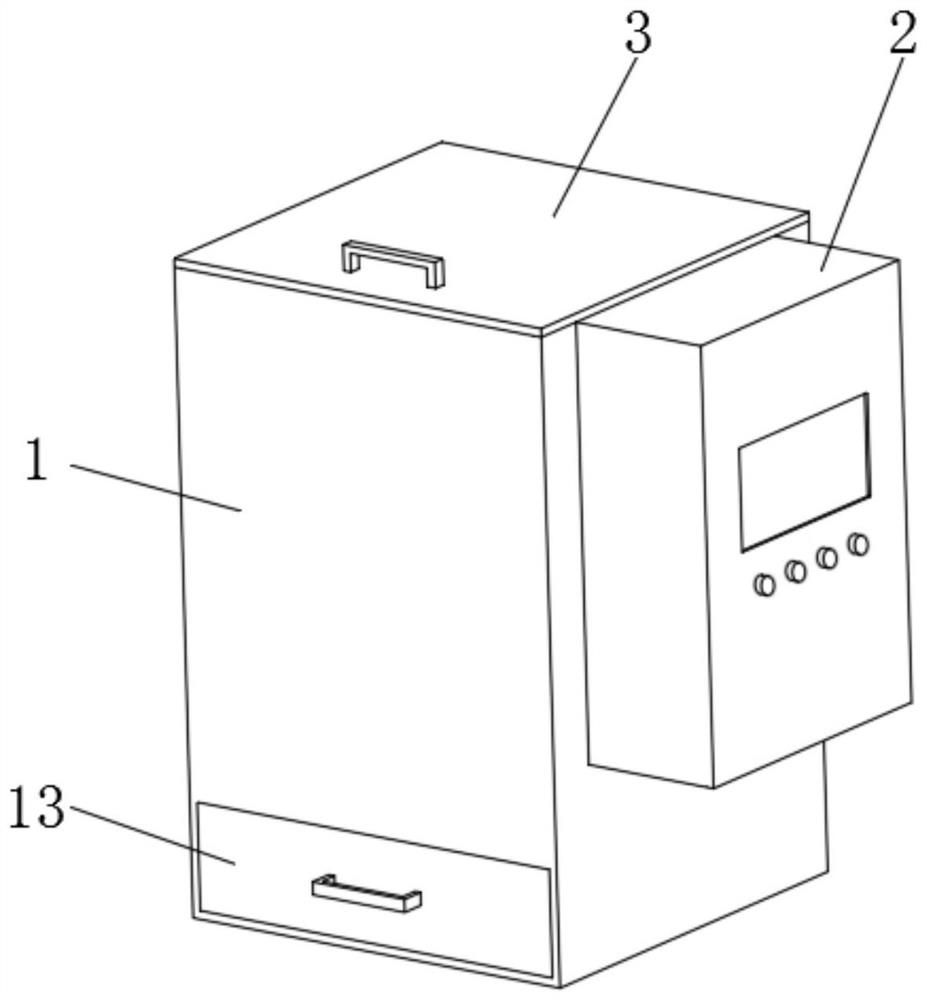

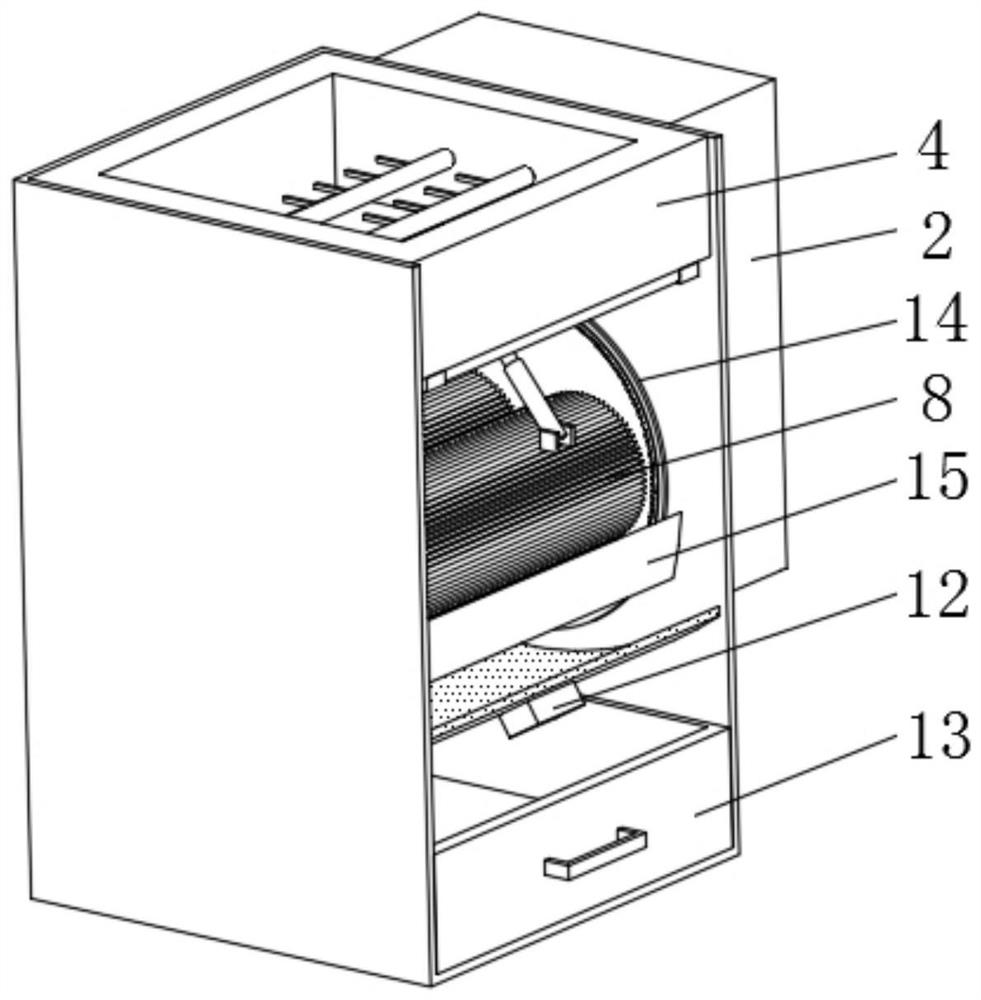

Turnover degaussing device for computer hard disk

PendingCN113231444AReasonable structureGood degaussing effectSolid waste disposalErasing methodMechanical engineeringSoftware engineering

The invention discloses a turnover degaussing device for a computer hard disk, and relates to the field of computer hard disk degaussing. The turnover degaussing device comprises a processing box, a control box is fixedly mounted on the side of the processing box, a box cover is rotatably mounted on the top of the processing box, a degaussing box with a built-in degaussing coil is fixedly mounted in the processing box, baffles are rotationally installed on the inner walls of the two sides, away from each other, of the processing box, the two baffles are located under the degaussing box and matched with each other, and the same electric push rod is rotationally installed on the inner walls of the two sides, away from each other, of the processing box and the bottoms of the two baffles. According to the turnover degaussing device for the computer hard disk, through the arrangement of a degaussing part, full degaussing processing can be carried out on different types of computer hard disks, the degaussing effect is good, the application range is wide, through the arrangement of a smashing part, the degaussed computer hard disks can be thoroughly smashed, the phenomenon that hard disk information is possibly recovered is avoided, and the practicability of the device is improved.

Owner:彭伟

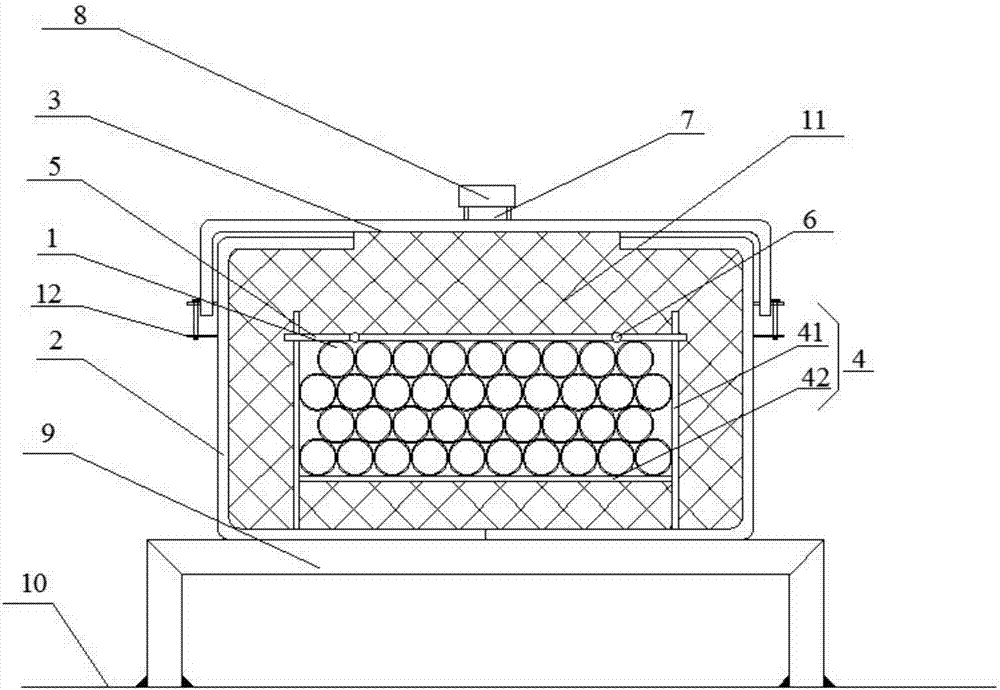

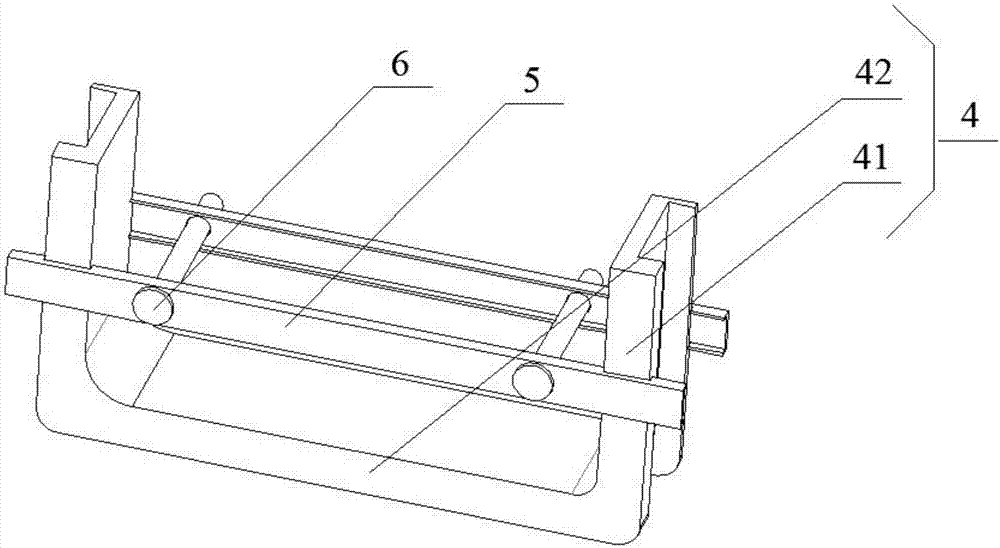

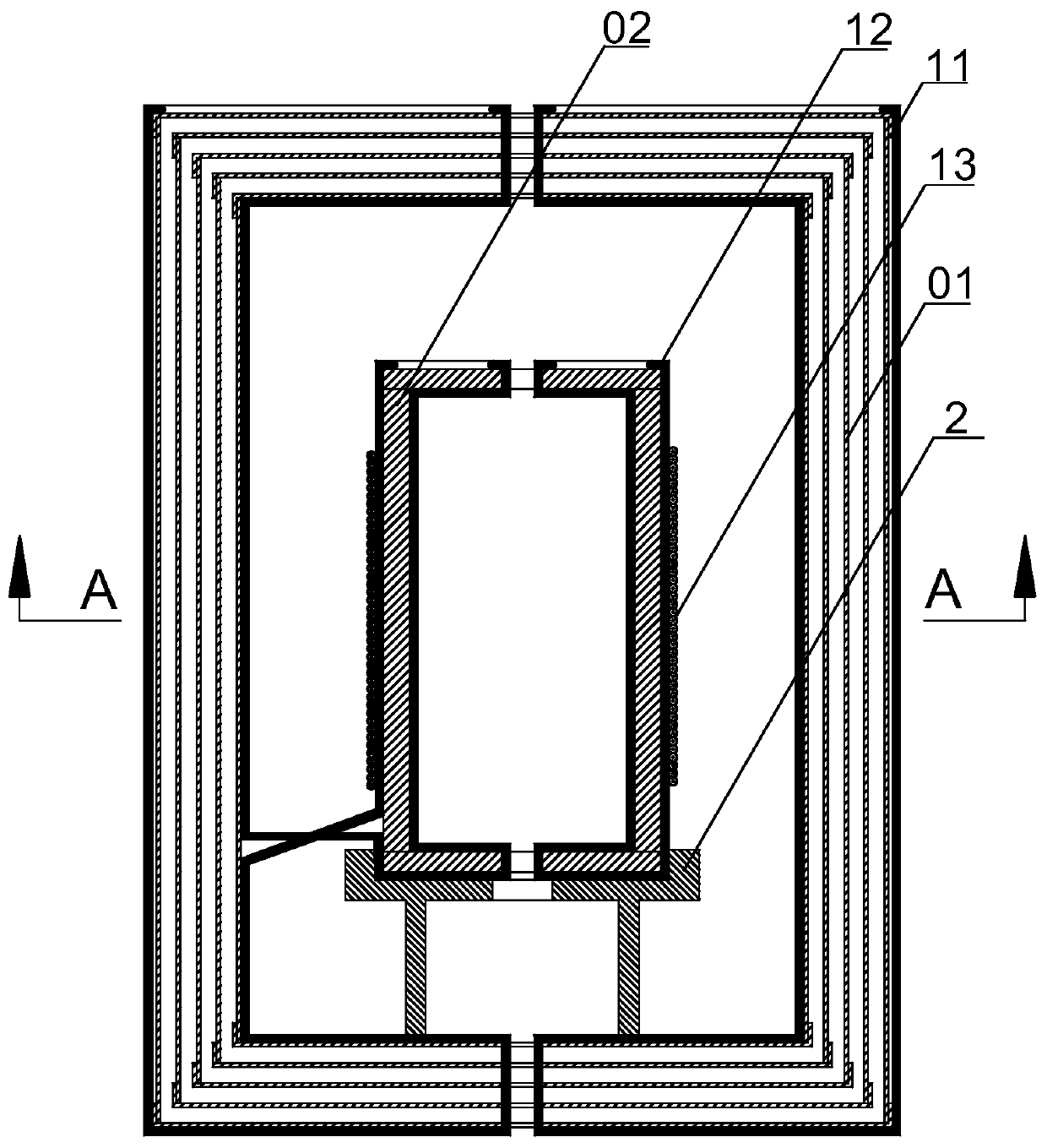

A degaussing coil device for ferrite-permalloy composite magnetic shielding barrel

ActiveCN109003777BGood degaussing effectEnsure consistencyMagnetic bodiesMagnetic field gradientLow noise

Owner:BEIHANG UNIV

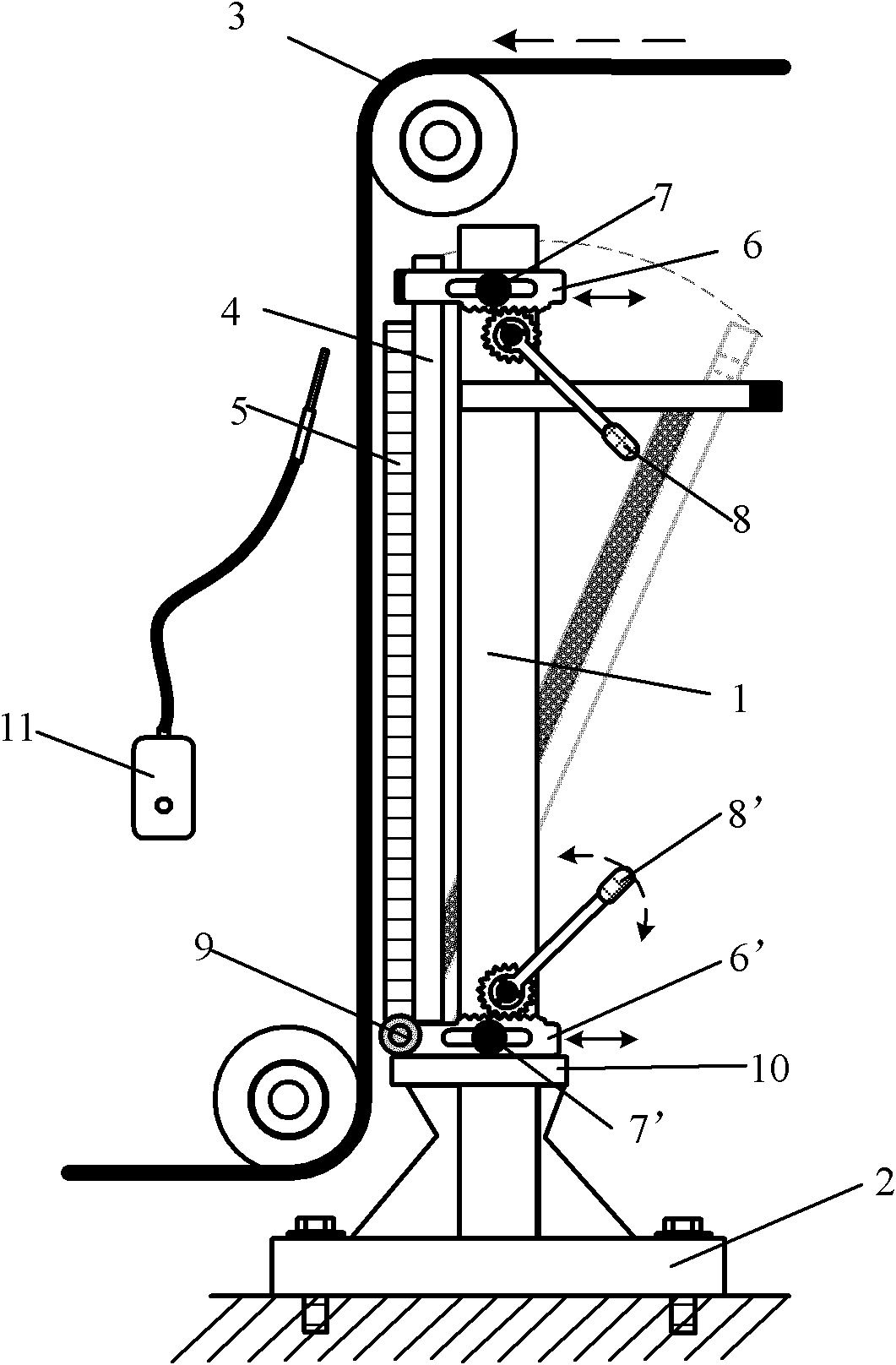

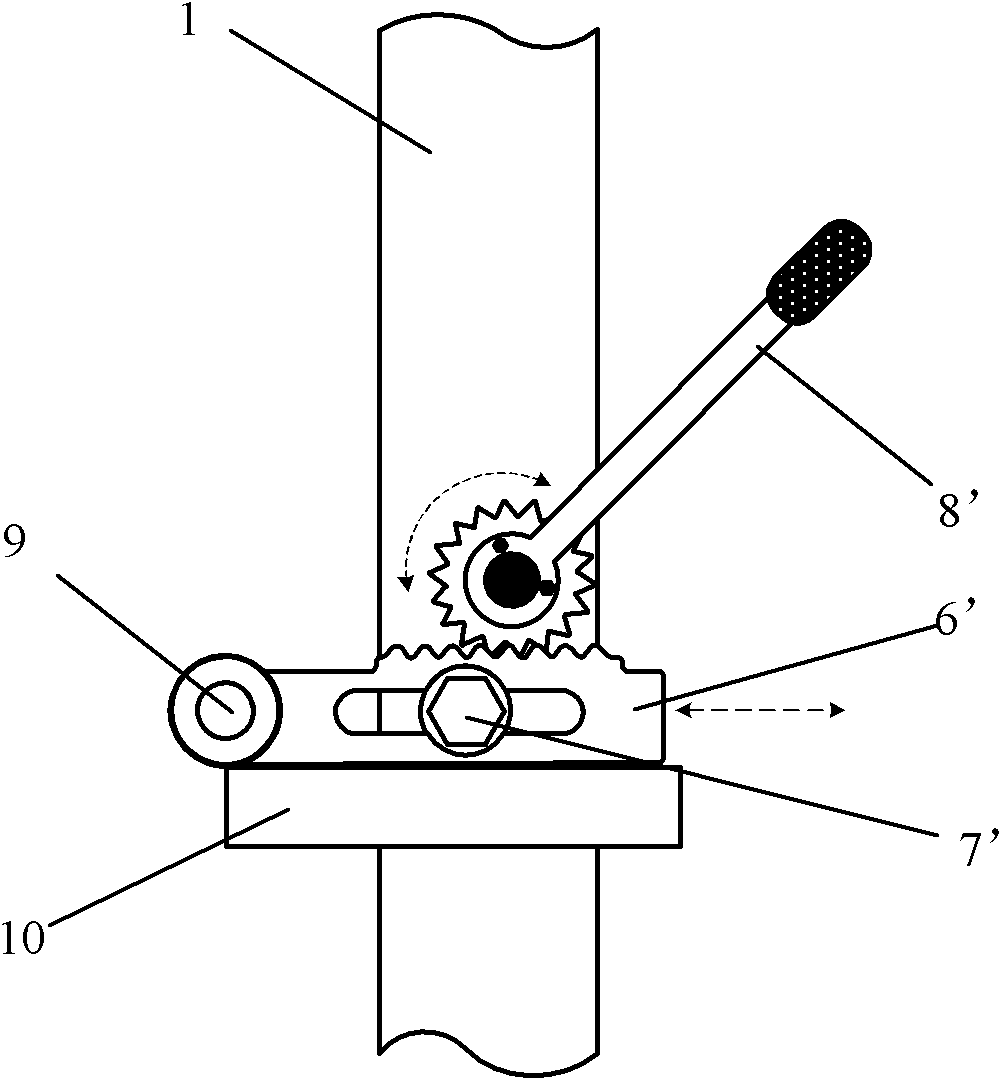

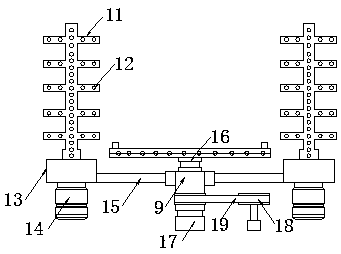

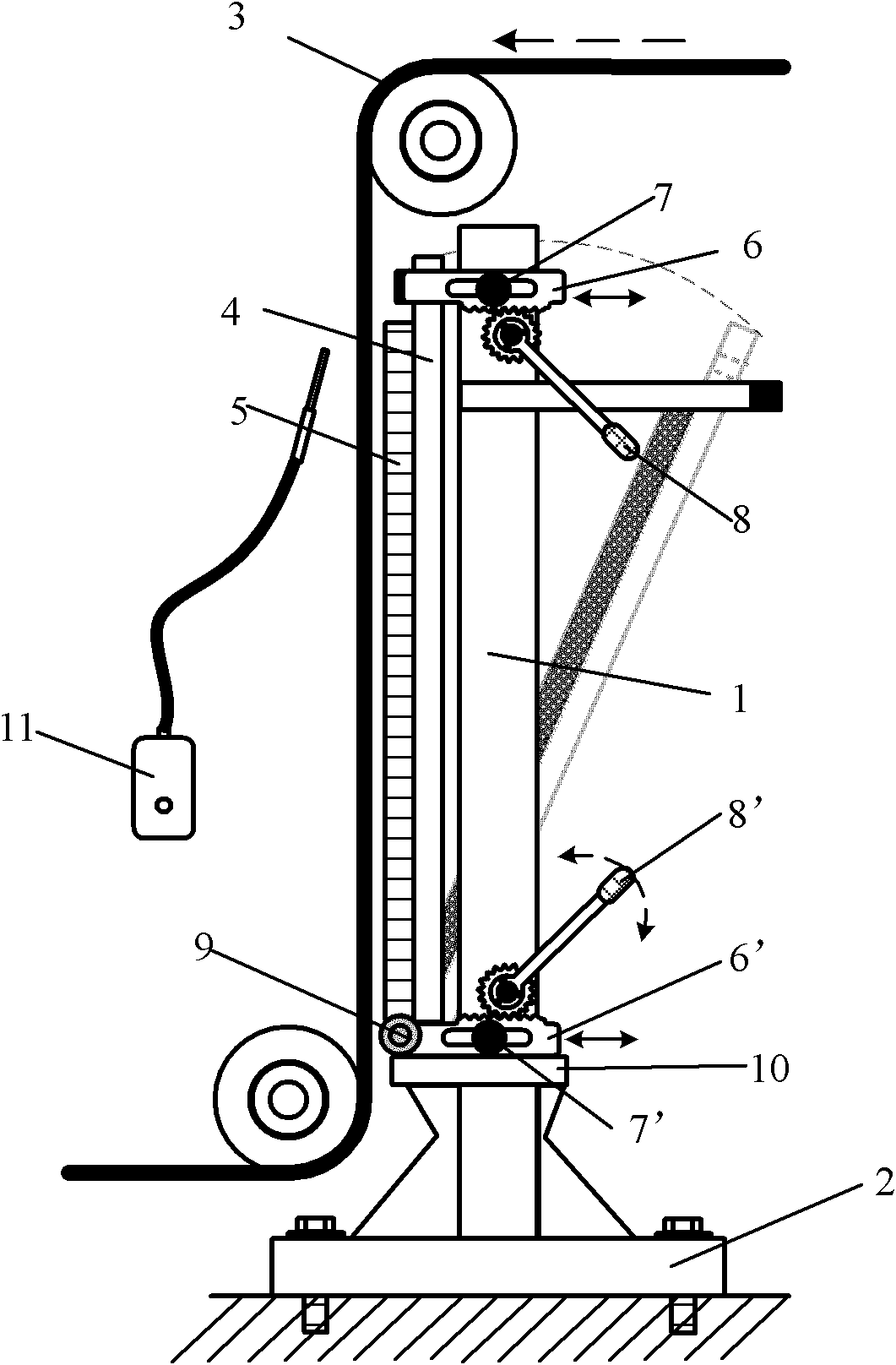

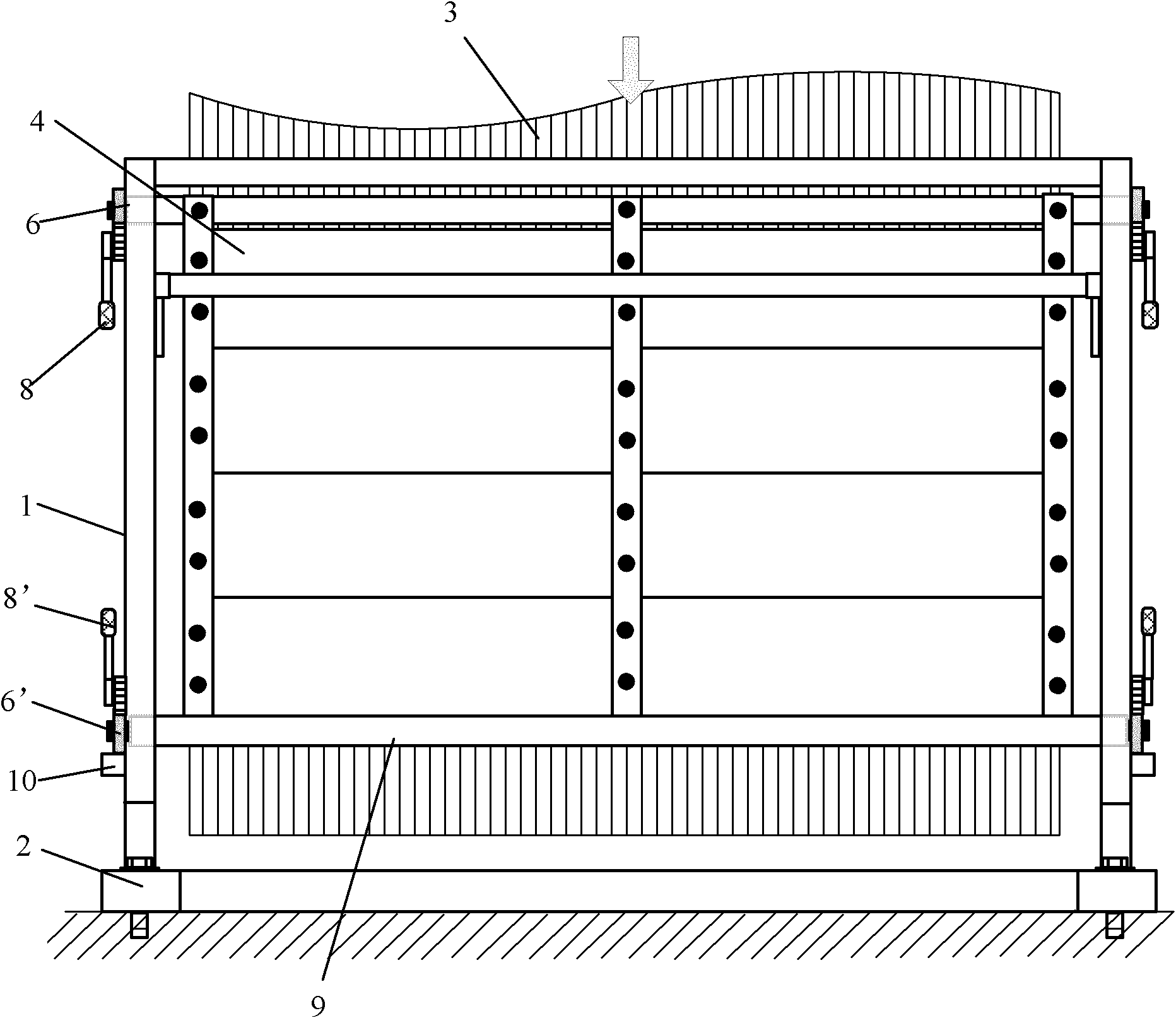

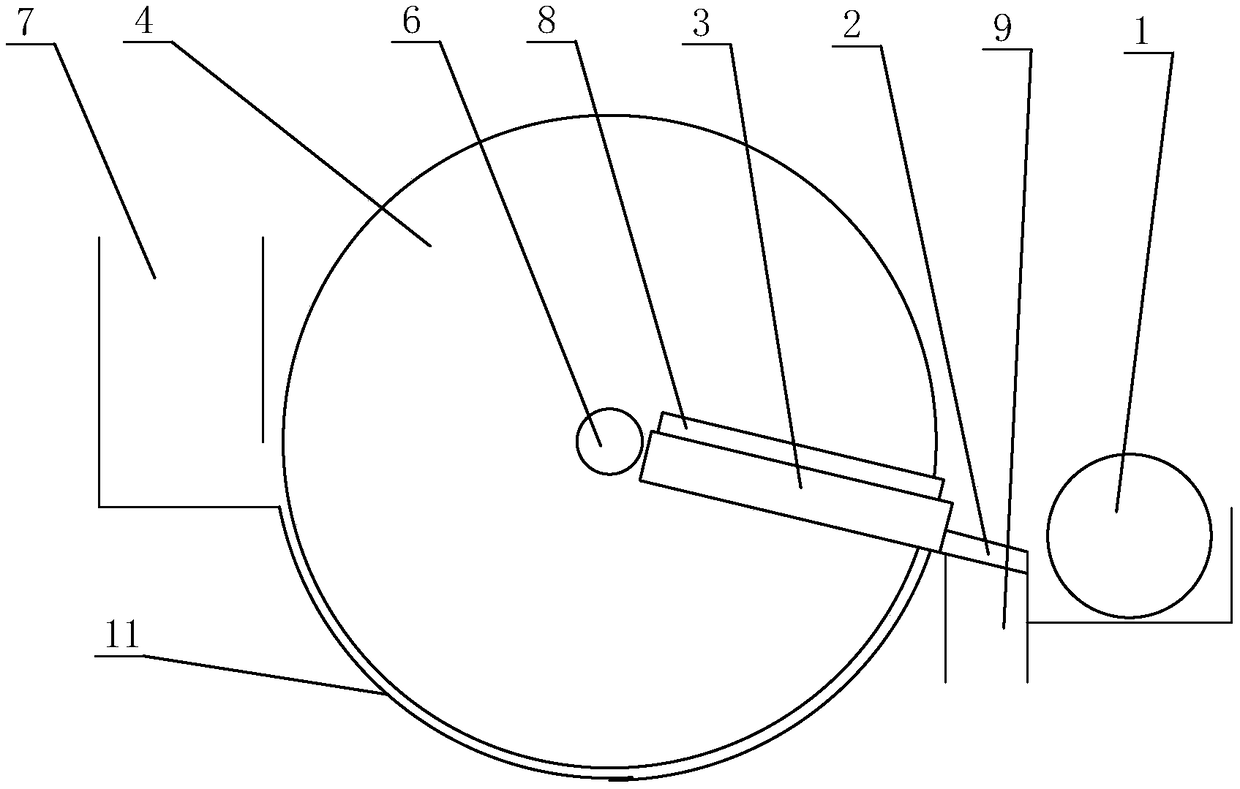

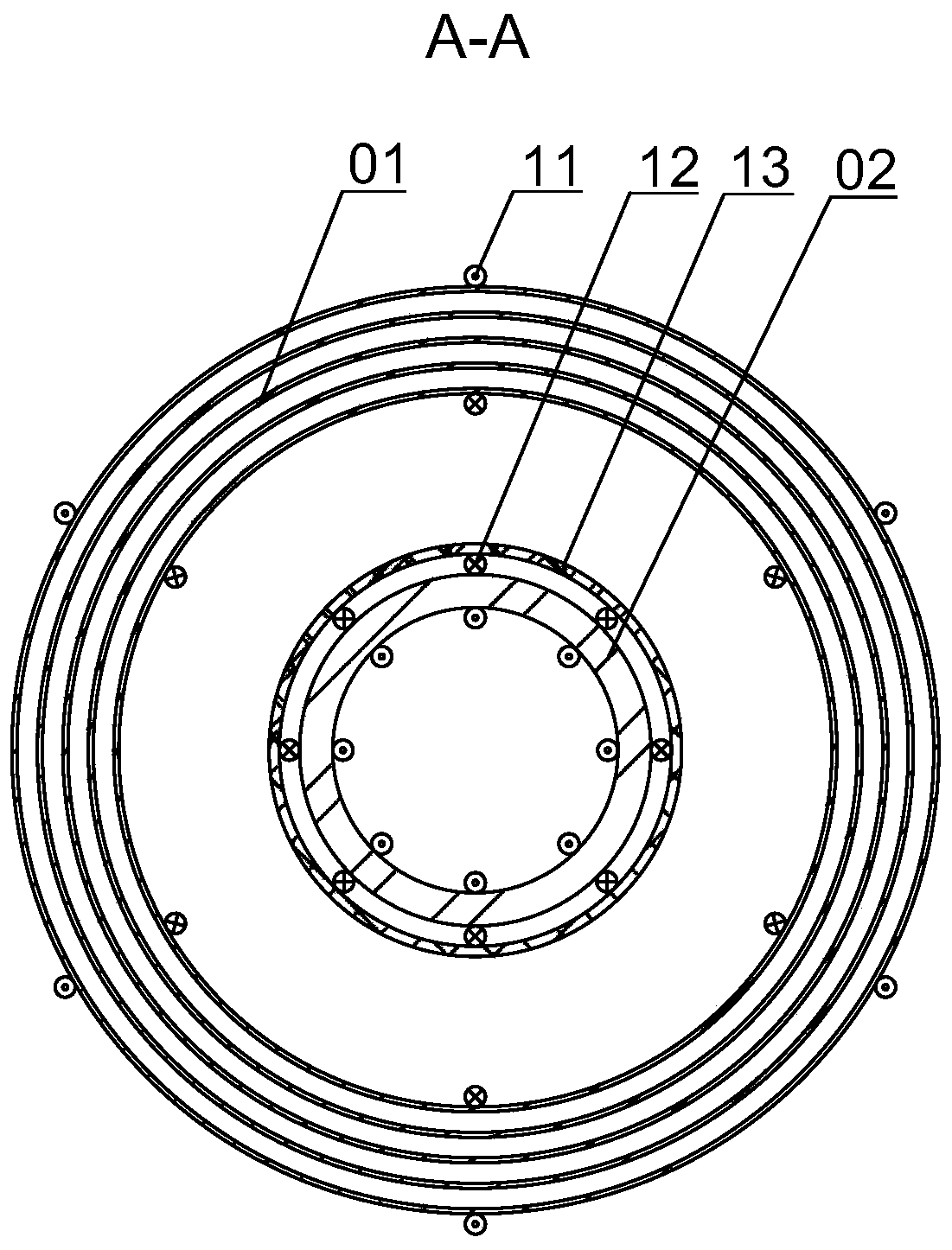

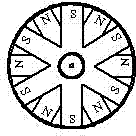

Demagnetizing method and device for steel wire lining conveyer belt by double magnetic rollers

ActiveCN102956340BTo achieve the purpose of degaussingConditions for Realizing the Alternating and Decreasing Magnetic FieldConveyorsMagnetic bodiesDemagnetizing deviceMagnetic poles

The invention relates to a demagnetizing method and device, and in particular relates to a demagnetizing method and device for a steel wire lining conveyer belt by double magnetic rollers. The demagnetizing method for the steel wire lining conveyer belt by double magnetic rollers comprises the steps of: placing two demagnetizing rollers (1 and 7) respectively above and below the steel wire lining conveyer belt (5), wherein the demagnetizing rollers are multiple-magnetic-pole magnetic rollers with adjacent heterospoles, and the diameters of the demagnetizing rollers are the same, the numbers of the magnetic poles are equal, and the magnetic densities are the same. The two demagnetizing rollers are synchronous at the same speed and rotate in opposite directions (2 and 6), and the heterospoles of the two demagnetizing rollers which rotate synchronously are opposite to each other; and the steel wire (4) lining conveyer belt moves. According to the demagnetizing method and device for the steel wire lining conveyer belt by the double magnetic rollers provided by the invention, the demagnetizing magnetic field is an alternating magnetic field which penetrates through the conveyer belt. The demagnetizing device provided by the invention is simple and compact in structure and easy to implement. Through field conduct and use, the lining steel wire of the demagnetized steel wire lining conveyer belt can be penetrated through more than 10mm, so that a demagnetizing effect is remarkable.

Owner:BAOSHAN IRON & STEEL CO LTD

Conveyer belt multi-pole magnetic roller asynchronous demagnetizing device

ActiveCN101930822BIncrease the magnetic field strengthSolve problems interfering with metal detectorsMagnetic bodiesPower beltDemagnetizing device

The invention discloses a conveyer belt multi-pole magnetic roller asynchronous demagnetizing device, which comprises a multi-pole magnetic roller (1), a magnetic roller drive motor (5), a magnetic roller framework (18), a structural frame (10), a lifting device and a controller (12), wherein the multi-pole magnetic roller is hang on the magnetic roller framework through a magnetic roller shaft, the magnetic roller drive motor drives a magnetic roller shaft transmission belt wheel (2) to rotate through a power belt wheel (4) and a transmission belt (3) so as to drive the multi-pole magnetic roller to rotate, and the multi-pole magnetic roller is positioned above a conveyer belt (6); the structural frame is positioned above a conveyer belt return plane, and a vertical bar of the structuralframe is fixed on the ground; and one end of the magnetic roller framework is connected on the vertical bar of the structural frame through a rotating shaft (11), the other end of the magnetic rollerframework is provided with the hoisting device, an upper stop point (17) and a lower stop point (1) with travel switches are formed on the vertical bar at the other end of the structural frame, the output of the travel switches is connected with a controller (12), and the controller controls the magnetic roller drive motor and the hoisting device. The demagnetizing device has the advantages of simple structure, low energy consumption and good demagnetizing effect.

Owner:BAOSHAN IRON & STEEL CO LTD +1

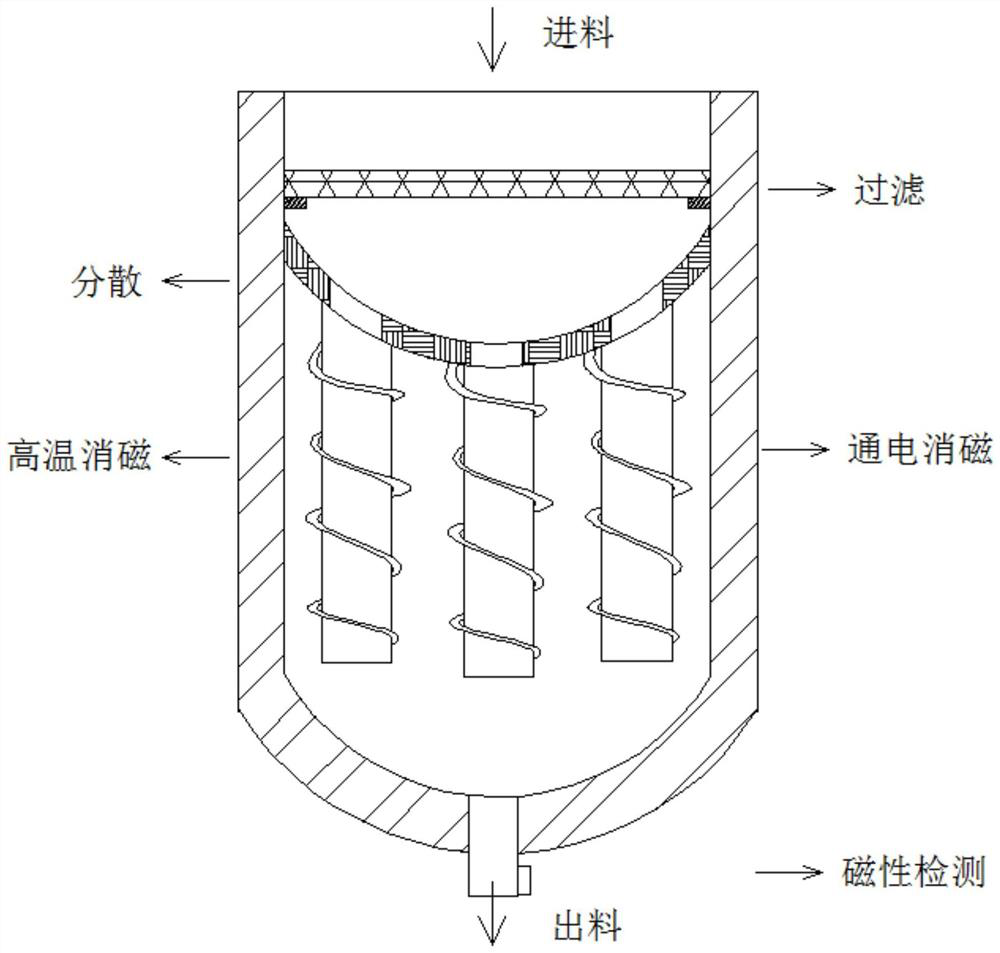

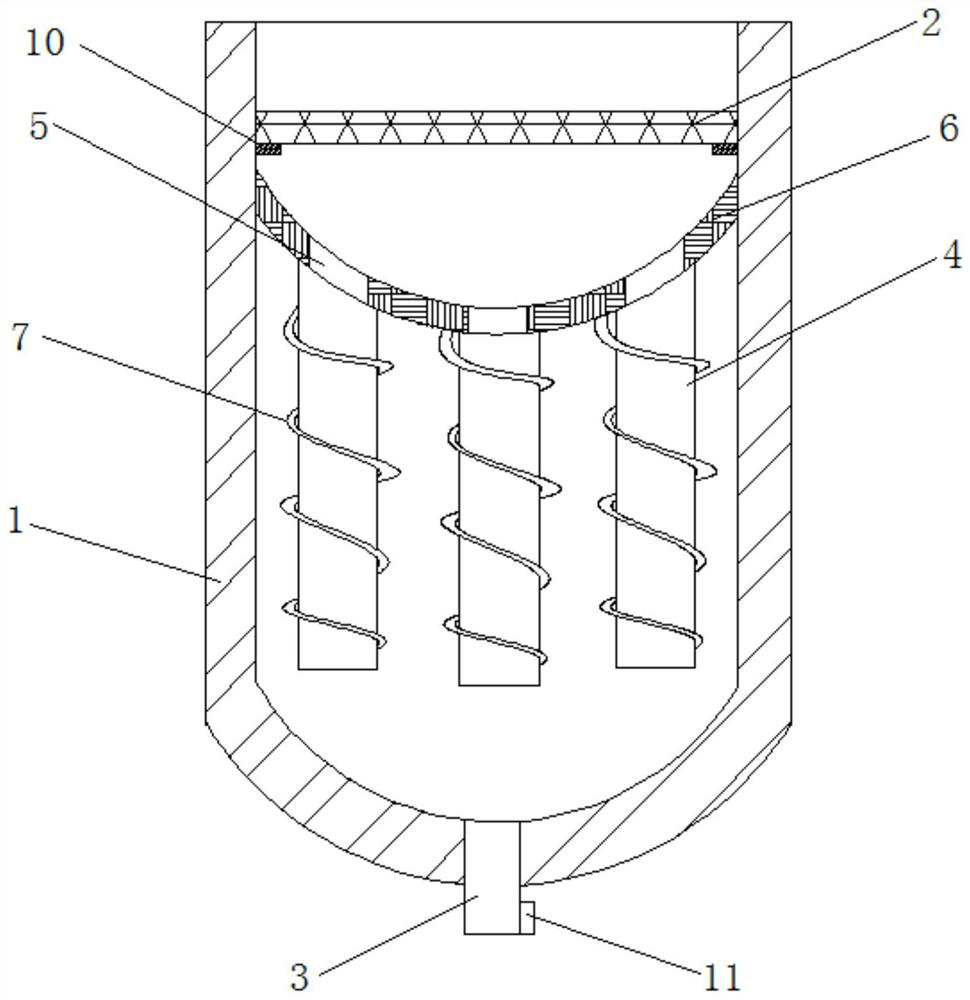

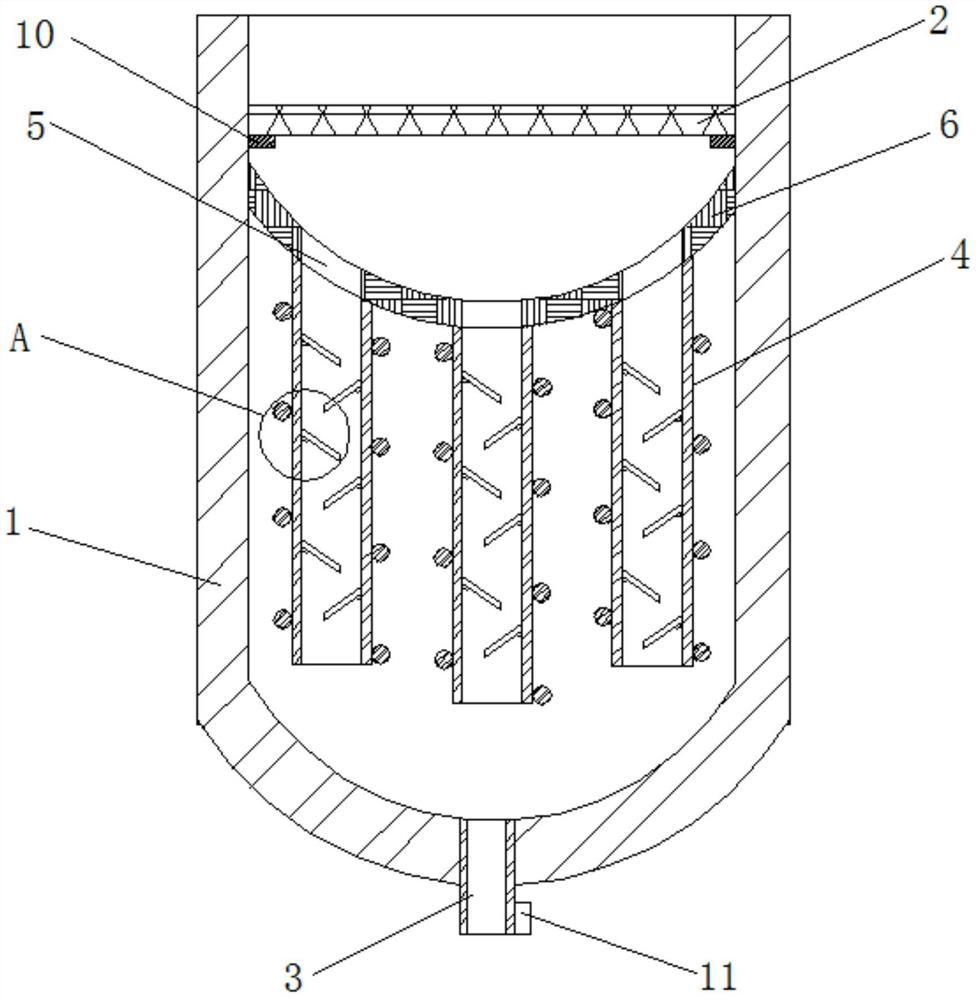

A kind of preparation method of skutterudite preheating cement

ActiveCN109721263BLow magnetic substanceReduce the content of magnetic substancesMagnetic bodiesSkutteruditeMining engineering

The invention discloses a method for preparing skutterudite preheated cement, which belongs to the technical field of cement preparation. A method for preparing skutterudite preheated cement utilizes double degaussing components in a powerful degaussing cylinder to demagnetize cement at high temperature and demagnetize cement, namely The high-temperature heat storage heat conduction tube and the serpentine conductive column perform high-temperature autoclaving and "ionization" on the falling cement raw materials respectively, and demagnetize the magnetic substances in the cement raw materials, and the high-temperature degaussing and power-on degaussing are carried out at the same time to achieve double enhanced demagnetization. Purpose: When the degaussed cement raw material falls to the lower end of the powerful degaussing cylinder, use the miniature magnetic detector installed at the side end of the leaking material connection pipe to detect the content of magnetic substances inside, so as to ensure that the content of magnetic substances in the cement raw material is reduced to the minimum. Prepare qualified cement raw materials into cement, basically eliminate the influence of magnetic substances on cement quality, significantly improve the stability of cement buildings, and improve the safety factor of high-rise buildings.

Owner:肇庆市金岗水泥有限公司

non-magnetic cast iron

The invention relates to power cast iron production, namely, non-magnetic cast iron. The non-magnetic cast iron comprises the following chemical components in percentage by mass: 66% of pig iron, 12% of ferro-manganese, 3% of silicon iron, 16% of copper and 3% of nickel. According to the scheme, the non-magnetic cast iron is prepared by adding different raw materials at different temperatures and finally performing quenching treatment. The cast iron is free of magnetism and can be used in power fittings, particularly used in insulators, and has a better use effect. In the production process, different raw materials are added at different temperatures, the melting effect is good, the demagnetization effect is good, and qualified non-magnetic cast iron can be obtained.

Owner:通化名成电瓷电器有限公司

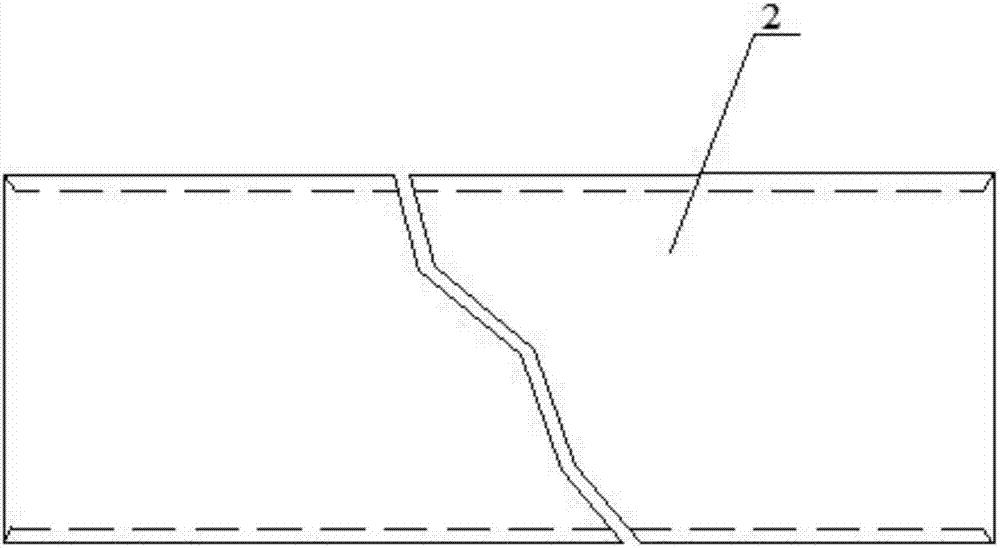

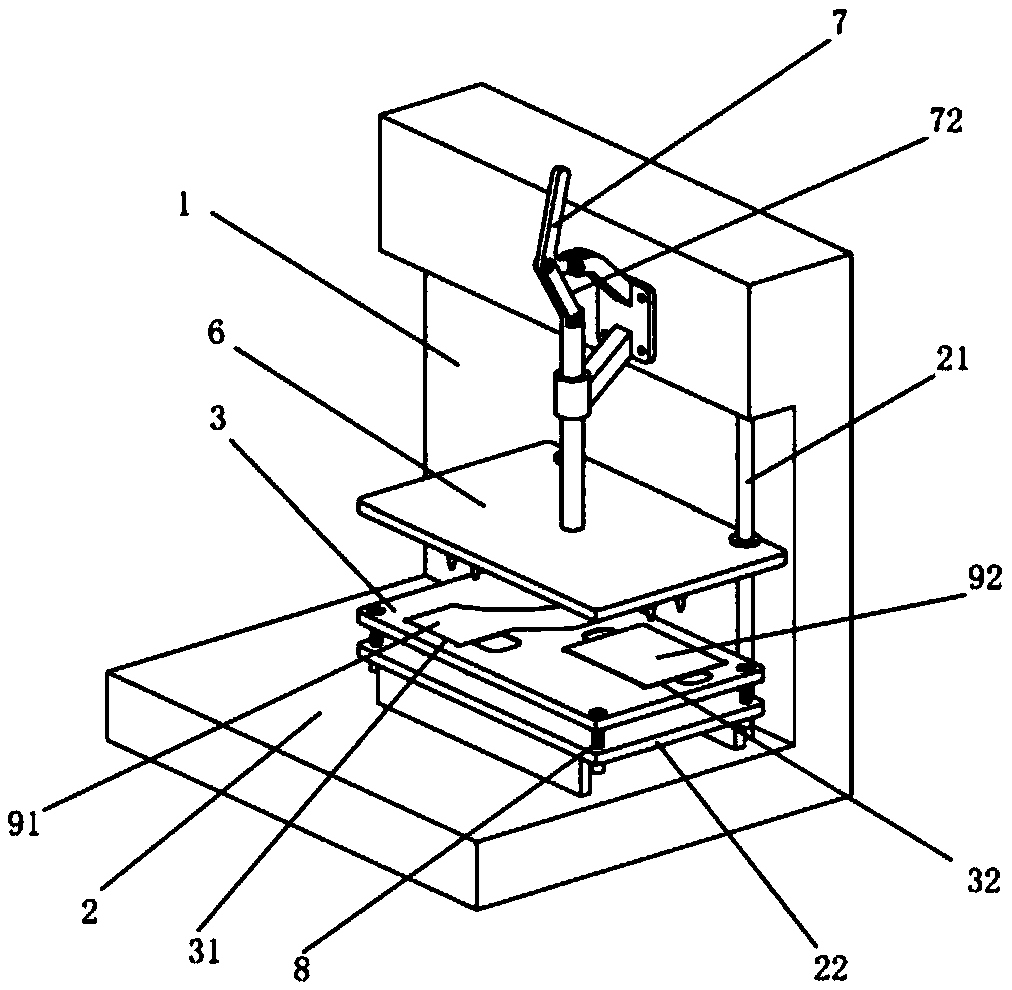

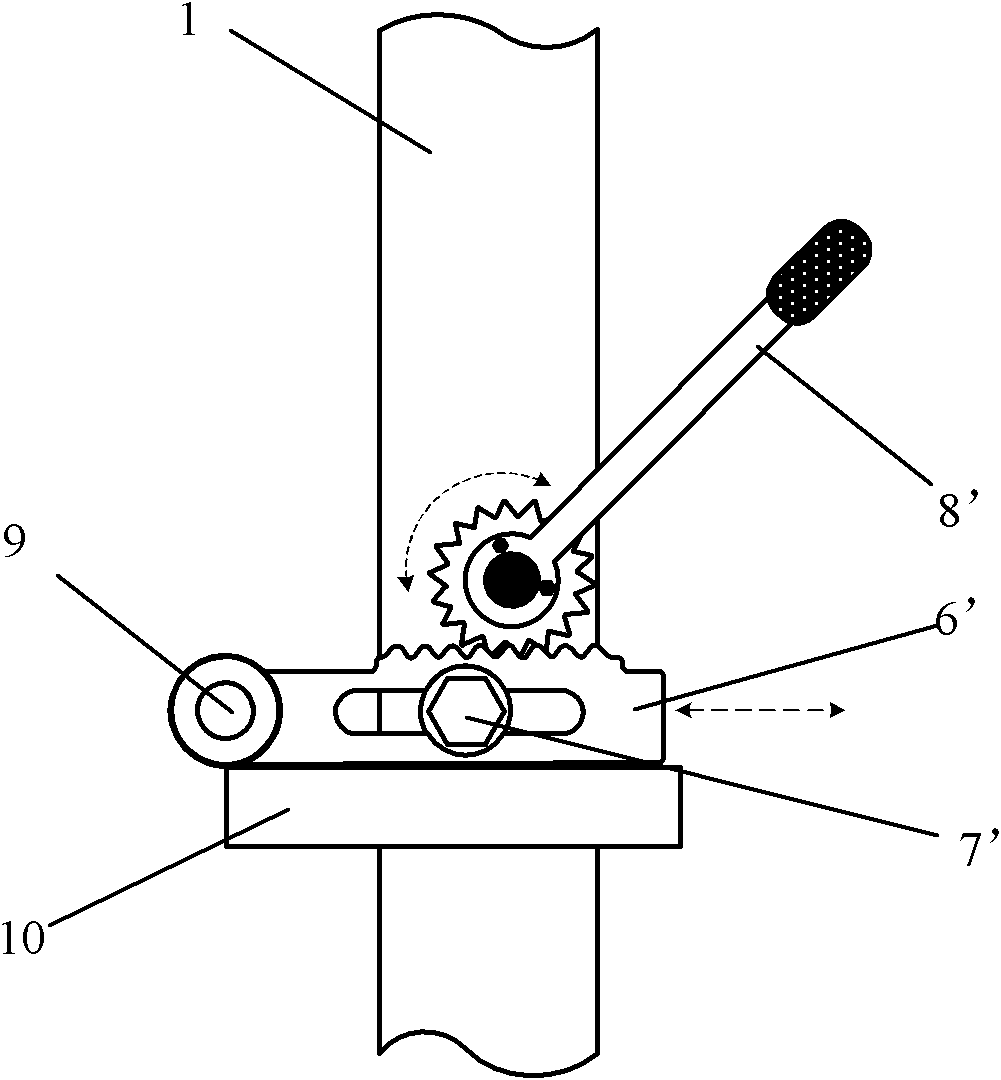

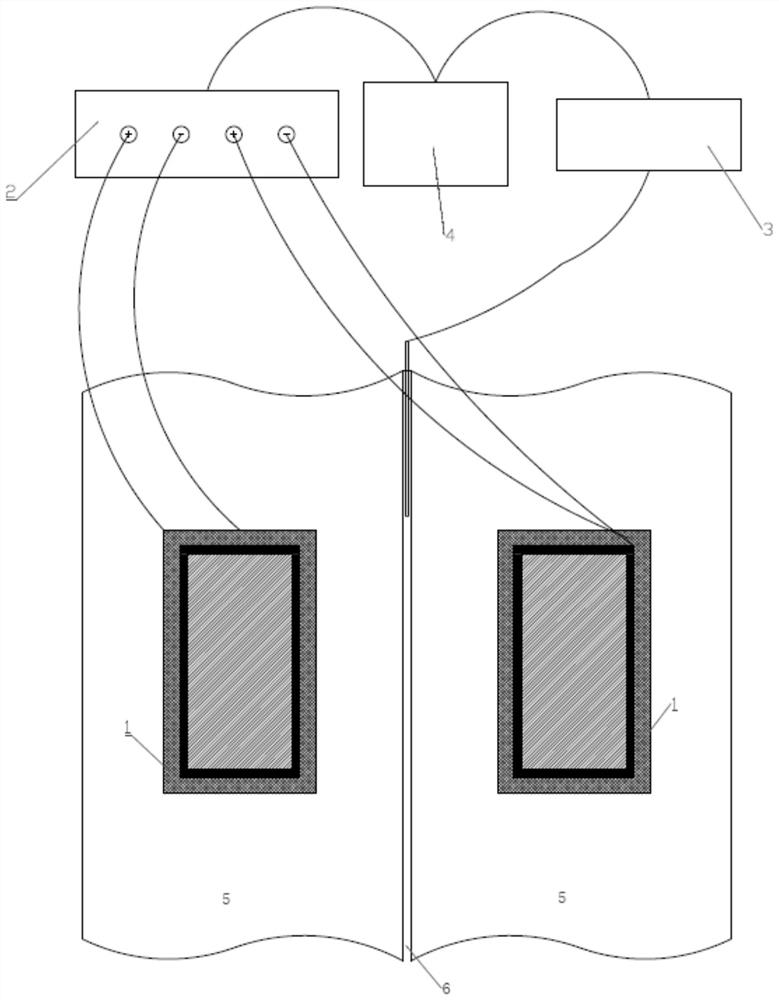

Automatically controlled direct current degaussing device and method

PendingCN113921223AGood degaussing effectEasy to operateMagnetic bodiesDemagnetizing deviceButt welding

The invention belongs to the technical field of degaussing, and relates to an automatically controlled direct current degaussing device and method for eliminating a welding seam magnetic field in the butt welding process of large steel plates in the industrial production. In the degaussing device, a pair of degaussing heads (1) are movably arranged at the front end of a welding machine, are symmetrically arranged at the two sides of a to-be-welded edge seam, and are connected with a positive electrode and a negative electrode of a programmable power supply (2), and the programmable power supply (2) supplies power through commercial power, so that a direct-current strong magnetic field is generated between the two demagnetizing heads (1). A Gauss meter (3) is connected with a PLC (4) through a serial port and is used for collecting the magnetic field data of the to-be-welded edge seam and transmitting the magnetic field data to the PLC (4), the PLC (4) controls the programmable power supply (2) to output a current through the program operation to enable the demagnetizing heads (1) to generate a needed demagnetizing magnetic field, the magnetic field of the welding seam (6) of a steel plate (5) is counteracted before welding, and therefore it is guaranteed that the magnetic field at the welding seam of the large steel plate meets the set requirement. The degaussing device is easy to operate and is suitable for the automatic control over the magnetic field in the large steel plate butt welding process.

Owner:CENT IRON & STEEL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com