Demagnetizing method and device for steel wire lining conveyer belt by double magnetic rollers

A technology of degaussing device and degaussing method, which is applied to conveyors, transportation and packaging, magnetic objects, etc., can solve the problems of insufficient penetration force, high density of steel wires in conveyor belts, failure to achieve degaussing effect, etc. Easy implementation and clear degaussing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

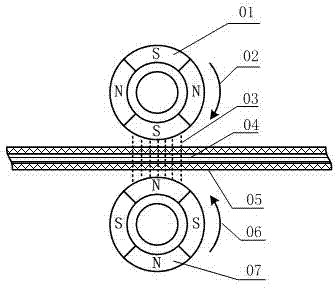

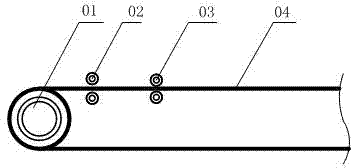

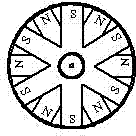

[0040] see Figure 4 , Figure 5 , a steel wire lined conveyor belt double-roller degaussing device, comprising an upper degaussing roller 39, a lower degaussing roller 41, an upper degaussing roller drive pulley 24, a lower degaussing roller drive pulley 27, an upper degaussing roller rotating shaft bearing seat 25, a lower degaussing roller Roller shaft bearing seat 36, fixed bracket 30, motor power output pulley 22, belt guide pulley 26;

[0041] The upper degaussing roller rotating shaft 38 is set inside the upper degaussing roller 39, and the upper degaussing roller rotating shaft 38 is installed in the bearing housings 25 of the upper degaussing roller rotating shaft on both sides, and the bearing housings 25 are installed on the upper fixing bracket 30 through bolts 35. The fixed bracket 30 is installed on the frame 29 slotted hole 31 through the fixed bolt 32, and one end of the upper degaussing roller rotating shaft 38 is equipped with the upper degaussing roller dri...

Embodiment 2

[0051] see Figure 6 , Figure 7 , a steel wire lined conveyor belt double-roller degaussing device, comprising an upper degaussing roller 57, a lower degaussing roller 60, an upper degaussing roller transmission gear 53, a lower degaussing roller transmission gear 54, an upper degaussing roller rotating shaft bearing seat 55, a lower degaussing roller Roller shaft bearing housing 58, motor power output gear 52;

[0052] The upper degaussing roller rotating shaft 56 is set in the upper degaussing roller 57, and the upper degaussing roller rotating shaft 56 is installed in the degaussing roller rotating shaft bearing housing 55 on both sides, and the bearing housing 55 is fixedly installed on the frame, and the upper degaussing roller rotating shaft One end of 56 is equipped with upper degaussing roller transmission gear 53;

[0053] The lower degaussing roller rotation shaft 59 is set inside the lower degaussing roller 60, and the lower degaussing roller rotation shaft 59 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com