Magnetic confinement method and self-demagnetization naval vessel

A technology of magnetic confinement and self-demagnetization, applied to ships, magnetic objects, ship weapons, etc., can solve the problems of time-consuming, labor-intensive and difficult modeling, and achieve the effect of convenient control and good magnetic confinement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a magnetic confinement method, specifically a method for magnetically confining a hollow magnet, including the following steps:

[0056] S1 prepares magnetically permeable structural parts;

[0057] S2 arranges the magnetically conductive structure inside the body to be degaussed, and provides a magnetic field line loop inside the body to be degaussed for the external magnetic field of the body to be degaussed, wherein the body to be degaussed is a hollow magnet.

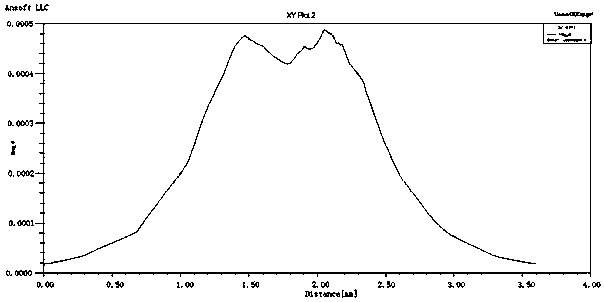

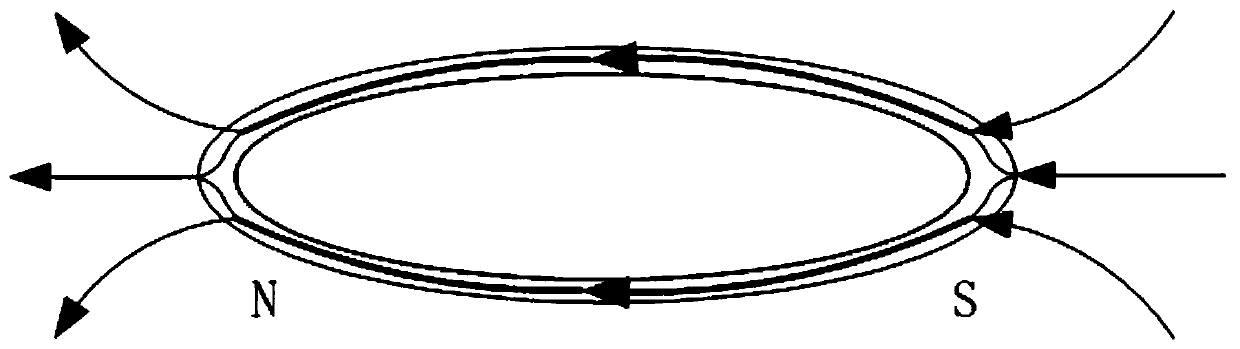

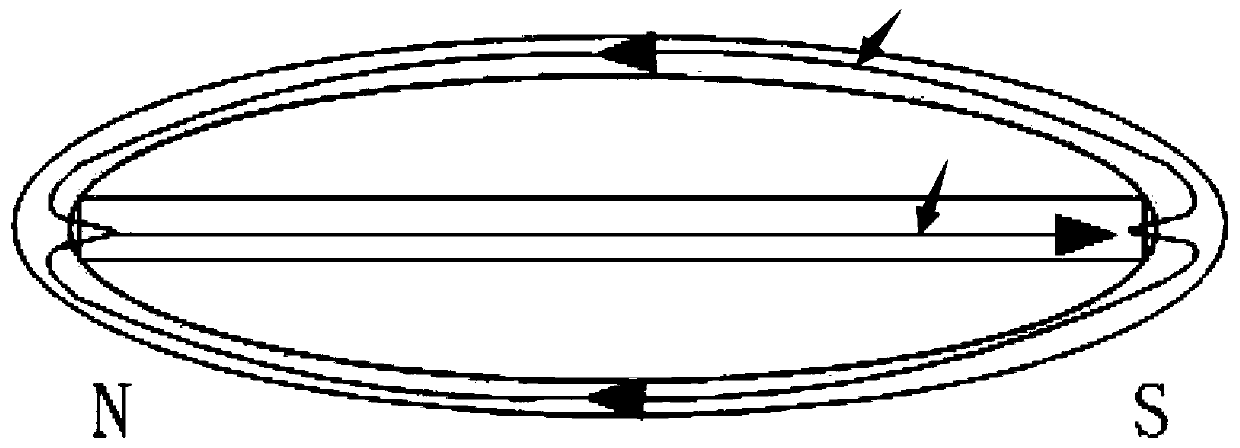

[0058] The principle of the above-mentioned magnetic confinement method is as follows: Figure 1-2 As shown, when no magnetic permeable structure is added, such as figure 1 As shown, the magnetic field lines of the main body to be degaussed are closed outside the main body to be degaussed, and the external magnetic field strength of the main body to be degaussed is high; after adding the magnetic conductive structure, as figure 2 As shown, the magnetically conductive structure prov...

Embodiment 2

[0073] This embodiment provides a self-degaussing ship, including: a ship main body with an internal cavity; a magnetically conductive structural member arranged inside the internal cavity of the ship main body, providing the external magnetic field lines of the ship main body in the A loop of magnetic field lines inside the ship's main body.

[0074] Compared with the existing ships, the self-degaussing ship of this embodiment is equipped with a magnetically permeable structural member, which can change the magnetic field lines of the permanent magnetism and the induced magnetism of the ship from forming a magnetic circuit outside the ship to forming a magnetic circuit inside the ship , so as to achieve the purpose of "degaussing"; compared with the prior art, the self-degaussing ship of this embodiment has changed the original thinking of "degaussing", and the magnetism is constrained inside the ship, without the need to regularly go to the degaussing station or use the degau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com