Chip collecting device for milling and turning combined machine tool

A technology of collecting device and compound machine tool, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. Practical value, avoid chip accumulation, avoid scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

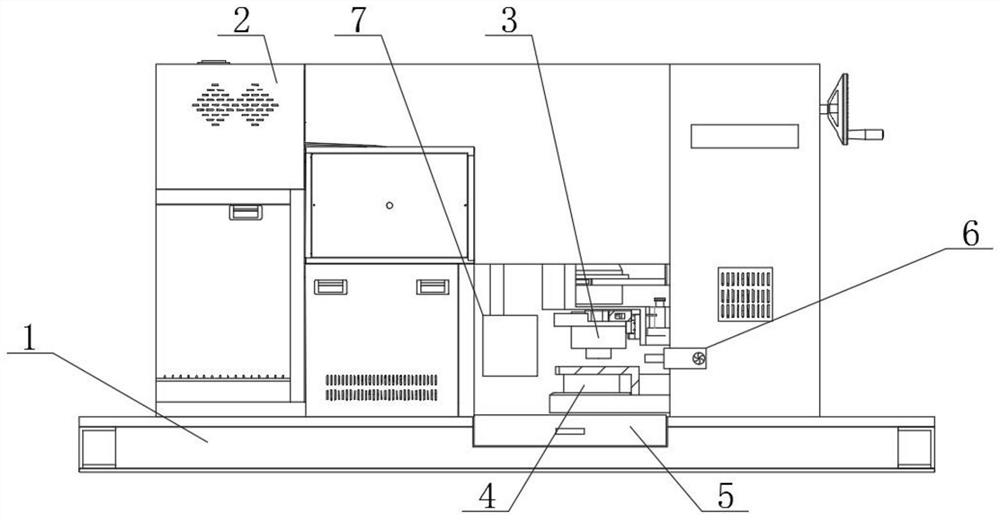

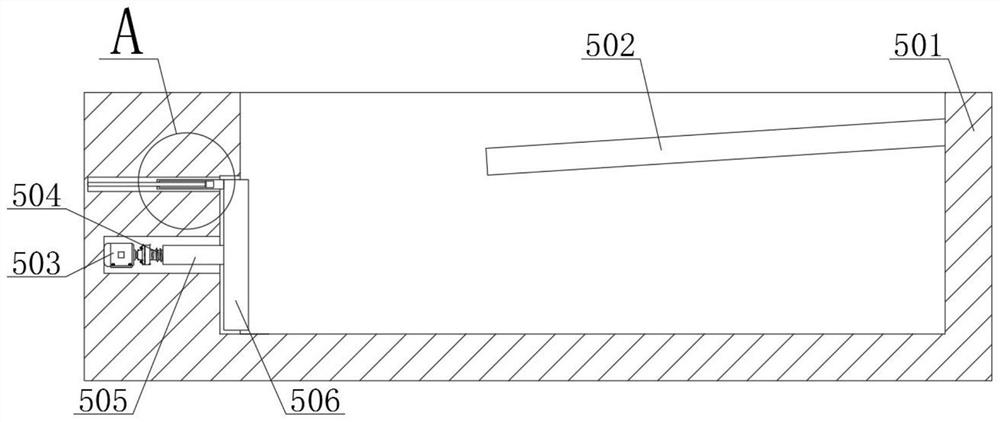

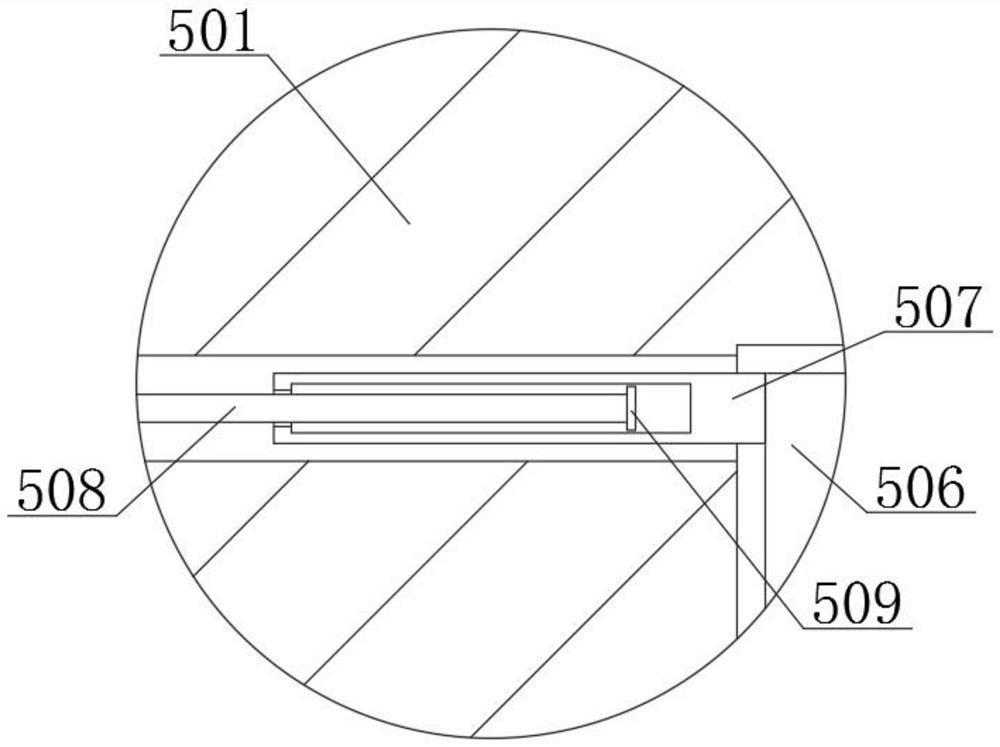

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , the present invention provides a technical solution:

[0028]A chip collection device for a milling-turning compound machine tool, comprising a base 1 and a milling machine 2, the upper end of the base 1 is fixedly connected to the milling machine 2, the inside of the milling machine 2 is fixedly connected to a milling cutter 3, and a fixed table 4 is provided below the milling cutter 3, and the fixed table 4. The right side is fixedly connected with the milling machine 2. The right side of the milling cutter 3 is provided with a blowing mechanism 6. The blowing mechanism 6 includes a fixed box 601 and a fan 602. The outside of the fixed box 601 is fixedly connected with the milling machine 2. The inside of the fixed box 601 is fixedly connected with Fan 602, the fan 602 provides wind power to make the chips blow to the left, the left side of the fan 602 is fixedly connected wi...

Embodiment 2

[0031] In Embodiment 2, the same parts as in Embodiment 1 will not be described again. The difference is that the setting of the inclined net 502 ensures that the chips falling from the fixed table 4 enter the sliding frame 501, and prevent the chips pushed to the right from falling out of the sliding frame. 501 overflows to ensure that the chips can be compressed and expand its capacity. When it needs to process the chips, slide the sliding frame 501 at this time, and then the chips can be processed centrally, saving a lot of time and improving cleaning efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com