Automatically controlled direct current degaussing device and method

A technology of DC degaussing and degaussing method, applied in the field of degaussing, which can solve the problems of inconvenient carrying and transportation, difficulty in meeting steel plate welding requirements, inability to degauss large flat plates, etc., and achieve good degaussing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

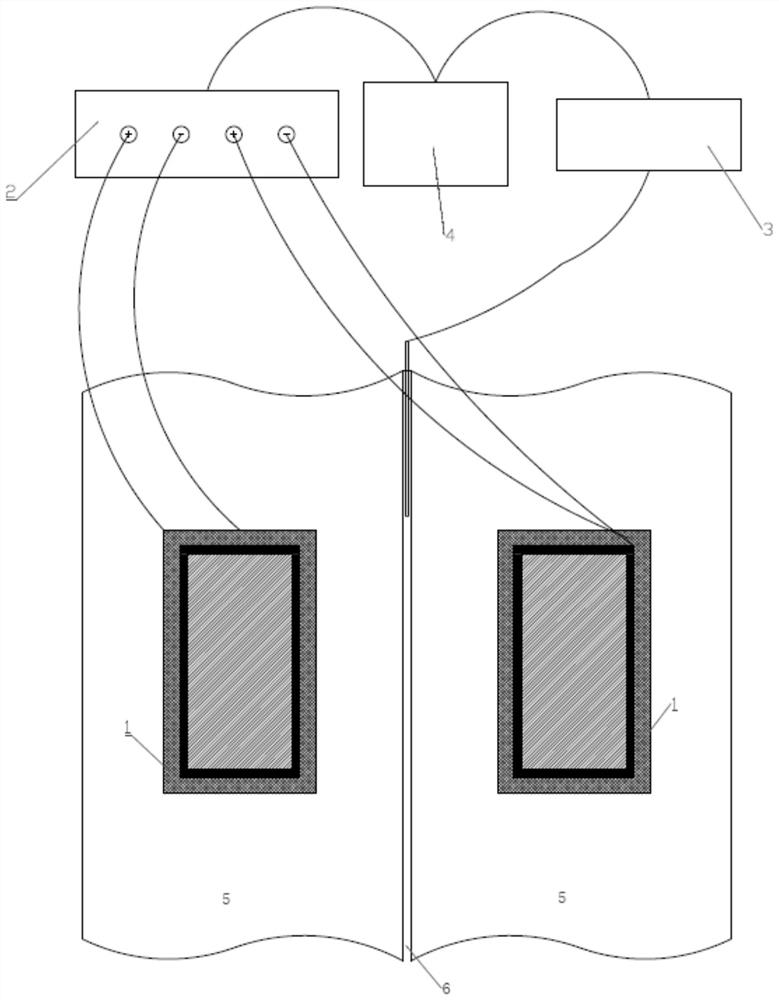

[0029] The present invention is an automatic control DC degaussing device, which comprises a degaussing head 1 , a program-controlled power supply 2 , a Gauss meter 3 and a PLC controller 4 . The degaussing heads 1 are generally two in a pair, used at the same time, placed on both sides of the weld 6 of the large steel plate 5 to be welded, used to generate a DC strong magnetic field to offset the magnetic field at the weld of the large steel plate, the degaussing head 1 and the program-controlled power supply 2 positive and negative connections. On the one hand, the program-controlled power supply is connected to the degaussing head, outputs DC current, and supplies power to the degaussing head to generate the required DC magnetic field; The PLC controller 4 is the control system of the device, which has a well-prepared setting program inside, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com