Conveyer belt multi-pole magnetic roller asynchronous demagnetizing device

A degaussing device and multi-pole magnetization technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of no-load and other problems, achieve low energy consumption, good degaussing effect, and ensure the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

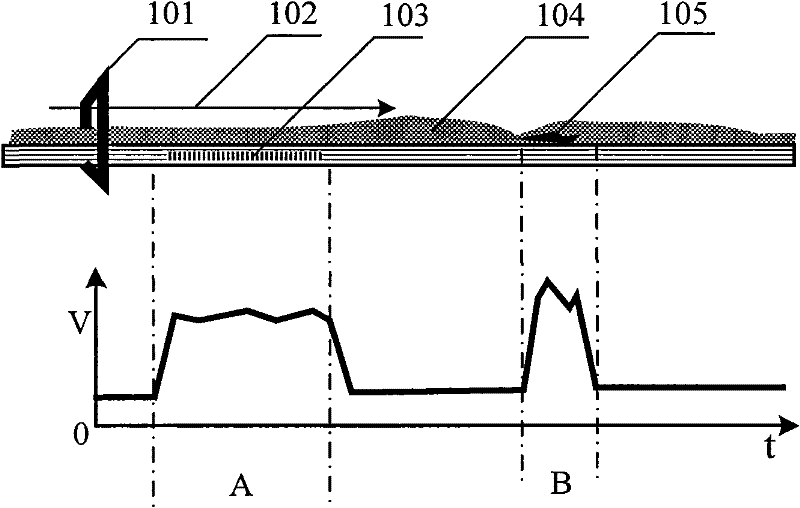

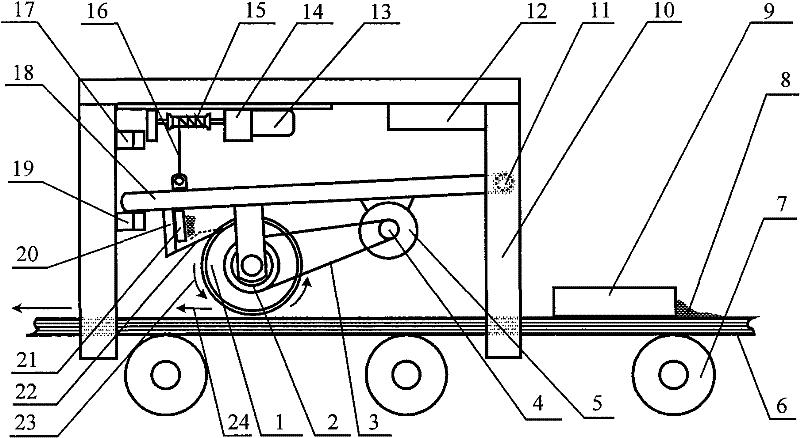

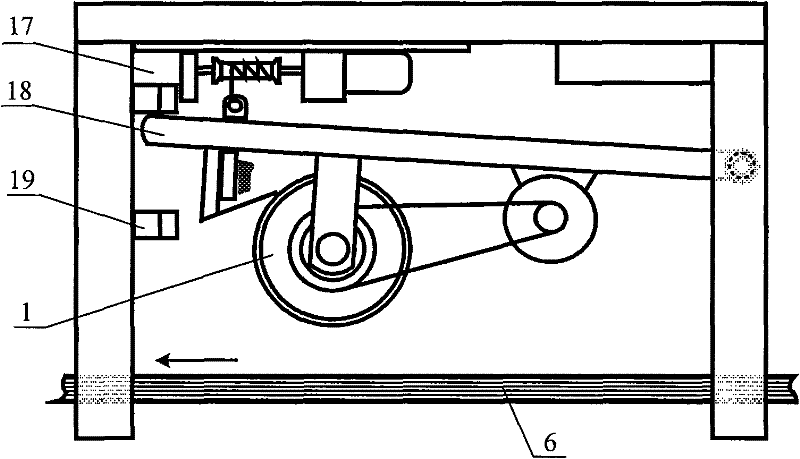

[0023] see figure 2 , an asynchronous degaussing device for multi-pole magnetic rollers on a conveyor belt, comprising a multi-pole magnetic roller 1 , a magnetic roller drive motor 5 , a magnetic roller frame 18 , a structural frame 10 , a lifting device and a controller 12 . The multi-pole magnetic roller 1 is suspended and installed on the magnetic roller frame 18 through the magnetic roller shaft, and the magnetic roller driving motor 5 is installed on the magnetic roller frame 18, and the magnetic roller driving motor 5 drives the magnetic roller shaft through the power pulley 4 and the transmission belt 3 The transmission pulley 2 drives the multi-pole magnetic roller 1 to rotate, and the multi-pole magnetic roller 1 is located above the conveyor belt 6 . The structural frame 10 is a box-shaped frame structure, the structural frame 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com