Demagnetizer and demagnetization method thereof

A demagnetization and magnetic field technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve problems such as unsatisfactory demagnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

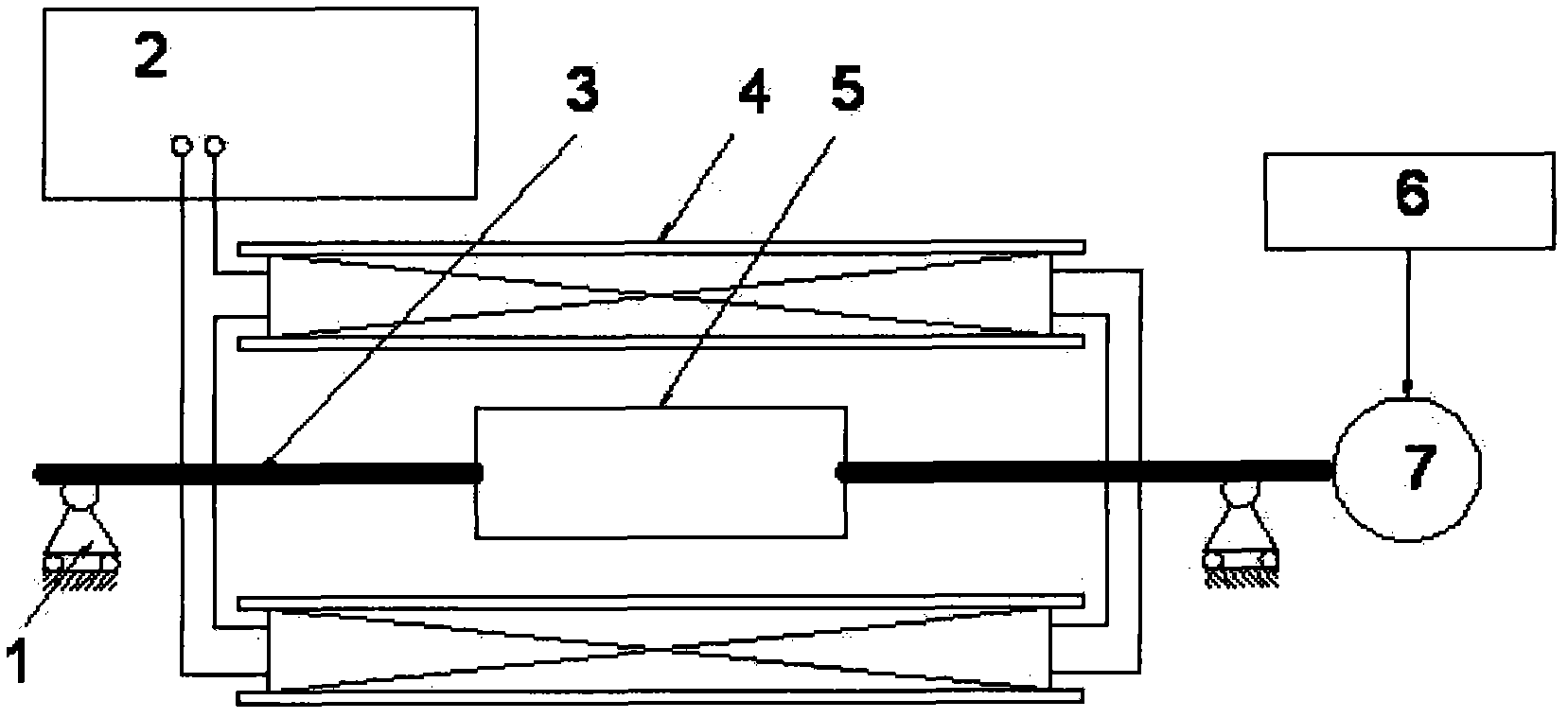

[0016] see figure 1 , which is a schematic structural view of a preferred embodiment of the demagnetization device of the present invention. As shown in the figure: it consists of a magnetizing power supply 2, a coil group 4, a high-speed motor 7, a frequency conversion controller 6, a bearing pair 1, a transmission shaft 3, and a material box 5; the coil group 4 is two corresponding The coils are connected together in series or in parallel, and then connected to the output end of the magnetizing power supply 2; a material box 5 is placed in the center of the coil group 4, and the two ends of the material box 5 are respectively connected to the transmission shaft 3, and the two ends of the transmission shaft 3 Each end is supported by a bearing pair 1, and one end of a transmission shaft 3 is connected to a high-speed motor 7, and the frequency conversion controller 6 performs frequency modulation operation control on the high-speed motor 7.

[0017] The demagnetization metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com