Automatic double-sided deburring and cleaning-drying production line

A deburring and production line technology, applied in drying, drying machine, drying gas layout, etc., can solve the problems of inability to realize intelligent assembly line mass production, low efficiency, no cleaning and drying function, etc., and achieve complete functions , Yield and quality improvement, the effect of cleaning and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

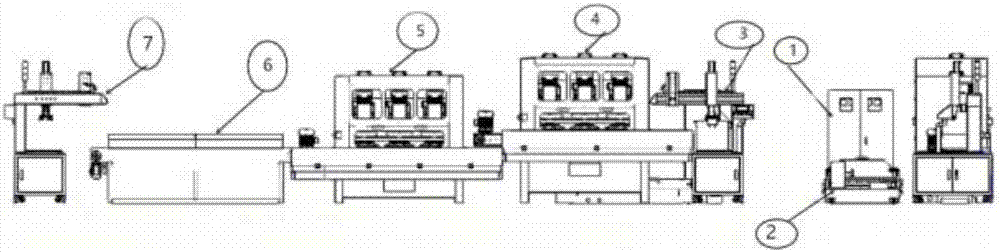

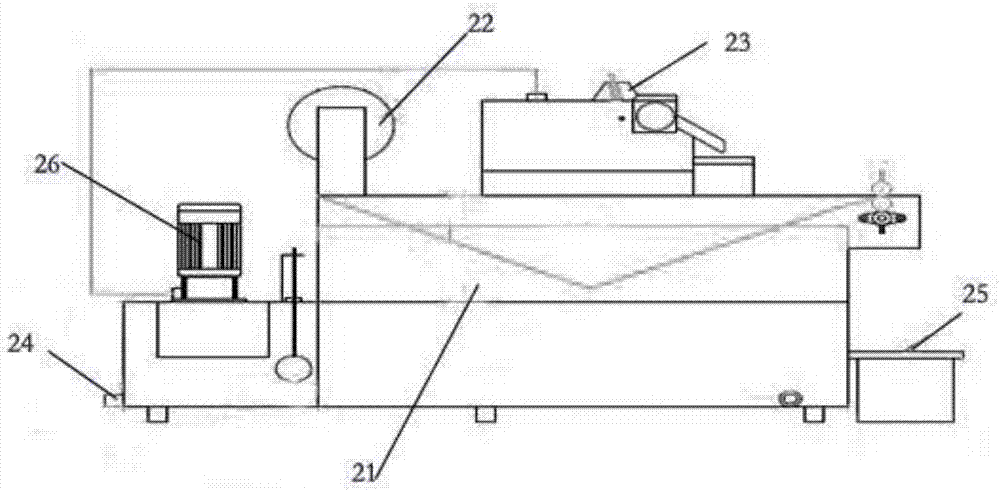

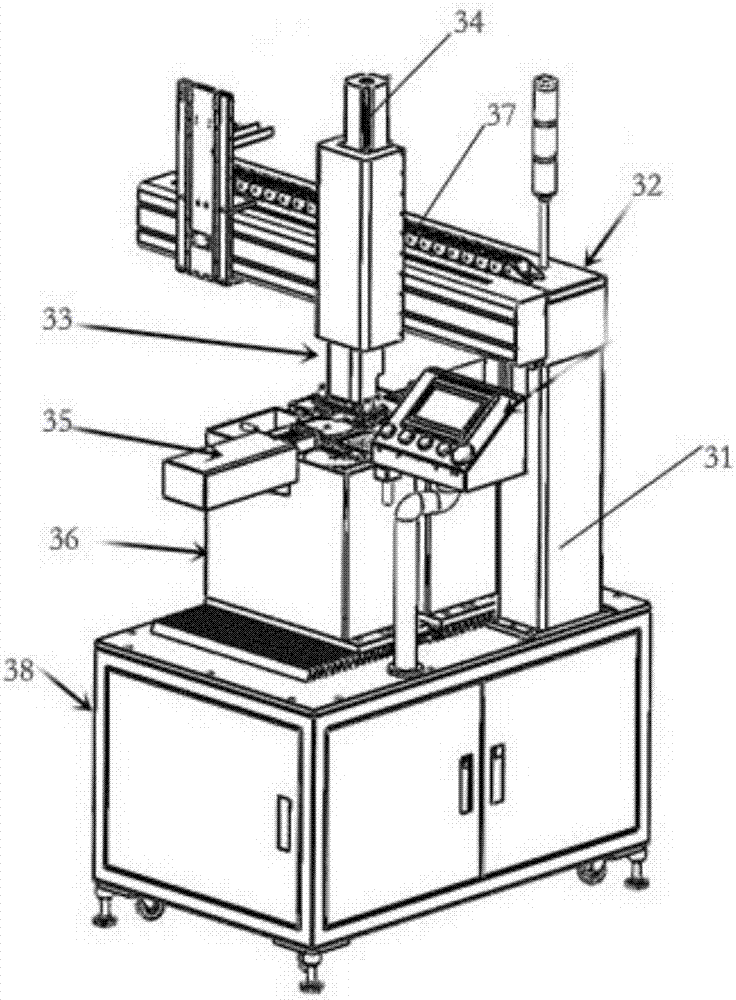

[0021] See Figure 1 to Figure 5 As shown, an automatic double-sided deburring cleaning and drying production line includes an electrical cabinet 1 that controls the operation of the entire system, a feeding manipulator 3, a first deburring machine 4, a second deburring machine 5, and an integrated cleaning and drying machine 6 And the feeding manipulator 7, the feeding manipulator 3 is arranged directly above the input end of the first deburring machine 4, and the workpiece is transported to the first deburring machine 4 through the magnetic chuck 33 of the feeding manipulator 3 On the forward track, the workpiece enters the input port of the second deburring machine 5 through the magnetic turning roller of the first deburring machine 4, and the first deburring machine 4 and the second deburring machine 5 are respectively connected with the paper bag Type water circulation filtration system 2 is connected to form a circulation system. The paper bag type water circulation filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com