Acoustic-magnetic label demagnetizer and demagnetization method

A degausser and label technology, applied to magnetic objects, electrical components, circuits, etc., can solve problems such as principle defects, achieve optimal design, increase degaussing distance, and improve power supply parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

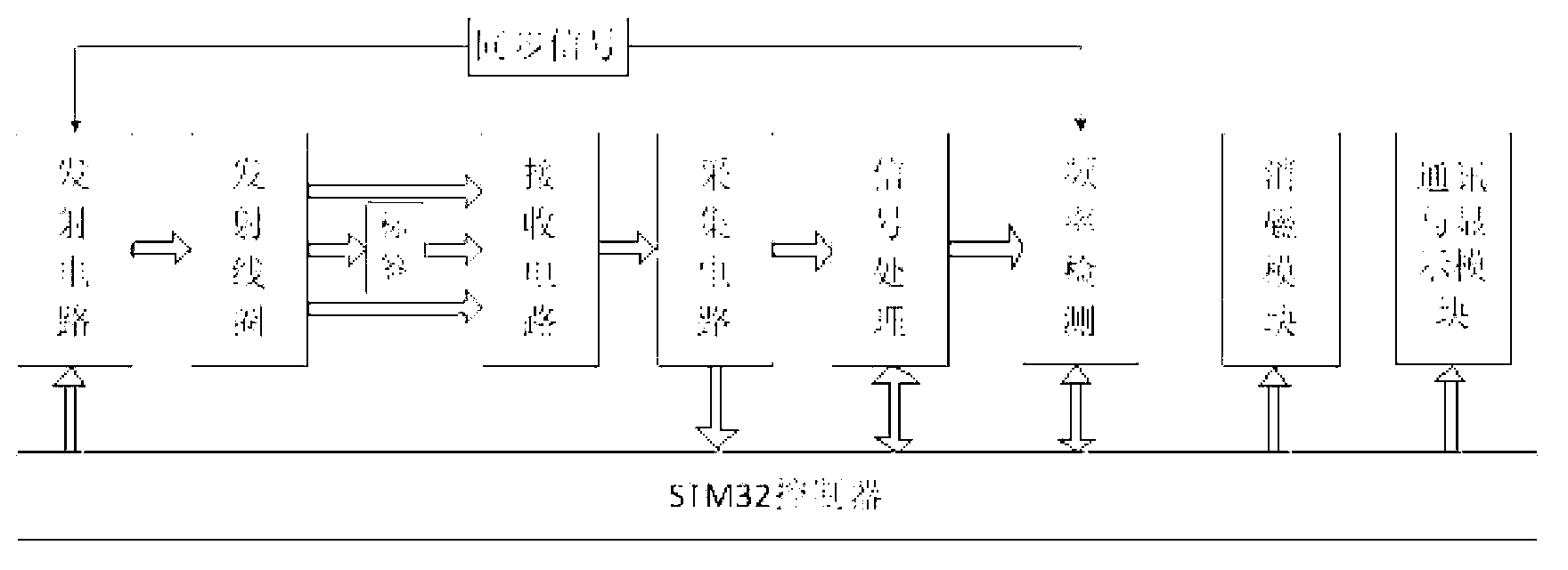

[0013] figure 1 Shown is an acoustic magnetic label degausser, including a synchronous signal circuit, a transmitting circuit, a receiving circuit, an acquisition circuit, a signal processing module, a frequency detection module, a degaussing module, a communication and display module and a main control module; the synchronous signal circuit The output ends are respectively connected to the input ends of the transmitting circuit and the frequency detection module; the output ends of the transmitting circuit are connected to the input ends of the receiving circuit, the output ends of the receiving circuit are connected to the input ends of the acquisition circuit, and the output ends of the acquisition circuit are respectively connected to signal The processing module and the main control module, the output end of the signal processing module is connected with the input end of the frequency detection module; The frequency detection module communicates bidirectionally with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com