Patents

Literature

102results about How to "Cost-effective advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

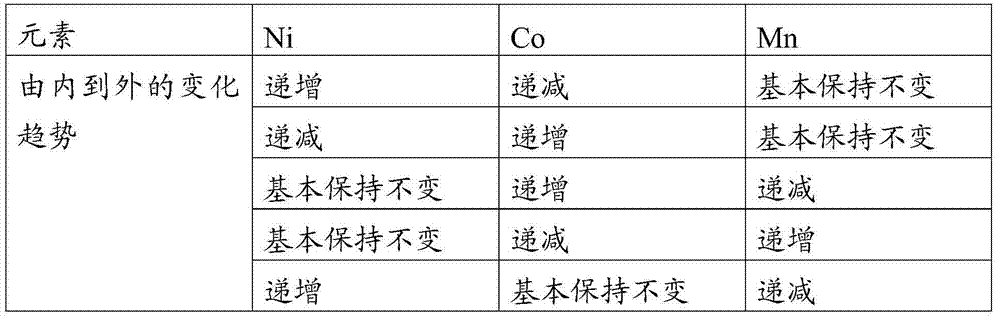

Gradient distribution multivariate composite material precursor as well as preparation method and application thereof

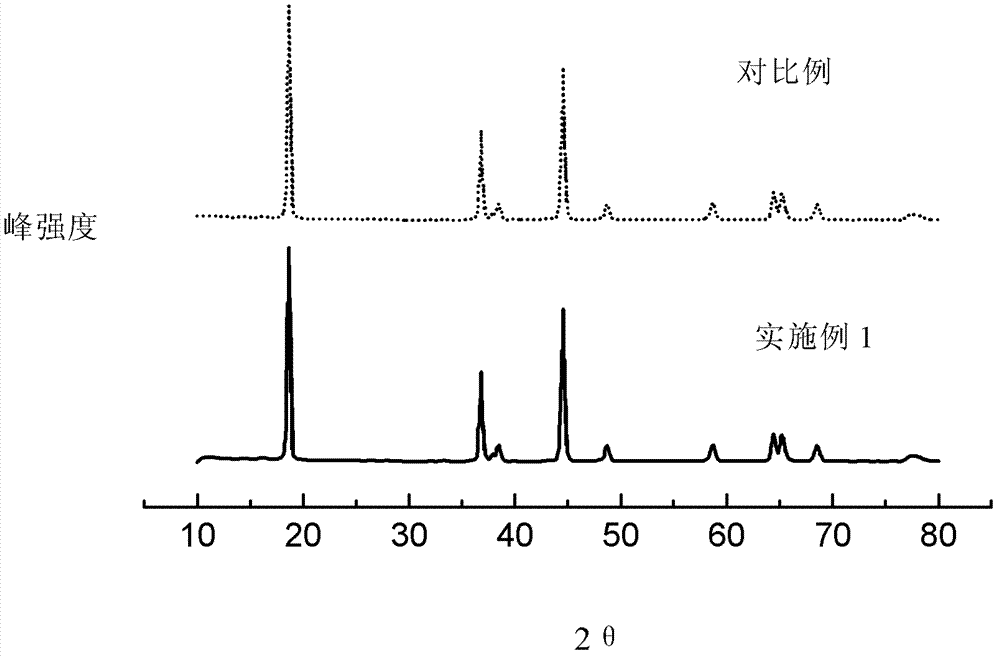

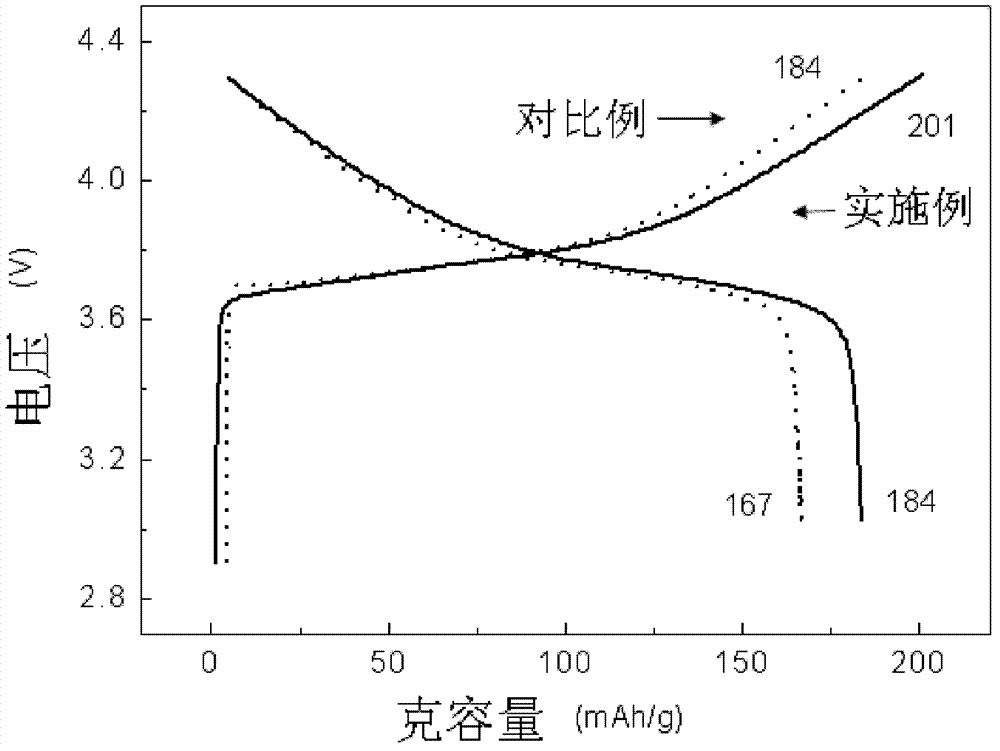

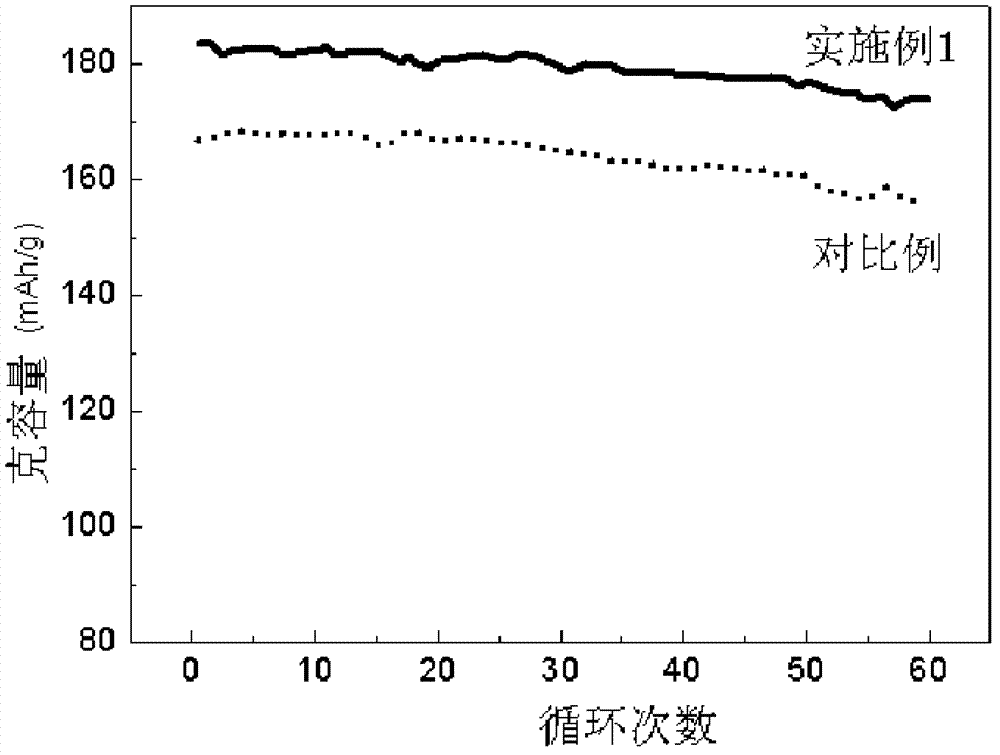

ActiveCN103367704AImproved thermal stability and safety performanceHigh discharge specific capacityCell electrodesIonTemperature cycling

The invention relates to a gradient distribution multivariate composite material precursor as well as a preparation method of the gradient distribution multivariate composite material precursor and an application in preparation of a lithium ion battery anode material. The precursor is prepared from the following molecular formula: NixCoyMnzM1-x-y-z(OH)2, wherein x is more than 0.2 and less than 0.8, y is more than 0.1 and less than 0.5, z is more than 0 and less than 0.6, and M is a doped metal ion and comprises one or more of Mg, Ca, Zn, Al, Cr, Zr and Ti; the precursor comprises a core part and an outer layer shell part in which multiple layers are sequentially covered in the core; a molecular formula composition of the core part is NikConMnmM1-k-n-m(OH)2, wherein k is more than 0.5 and less than 1, n is more than 0.05 and less than 0.5, and m is more than 0 and less than 0.6; and the outer layer shell part is used for controlling the proportion of the raw material components and a preparation process to ensure that the material composition of the outer layer shell part is distributed in a gradient mode. Compared with a ternary material with a uniform internal structure, the lithium ion battery anode material has the advantages that the high specific discharge capacity is developed; and meanwhile, the cycling stability, the high-temperature cycling stability and the rate capability of the materials also can be greatly improved.

Owner:SUZHOU GCL ENERGY TECH DEV CO LTD

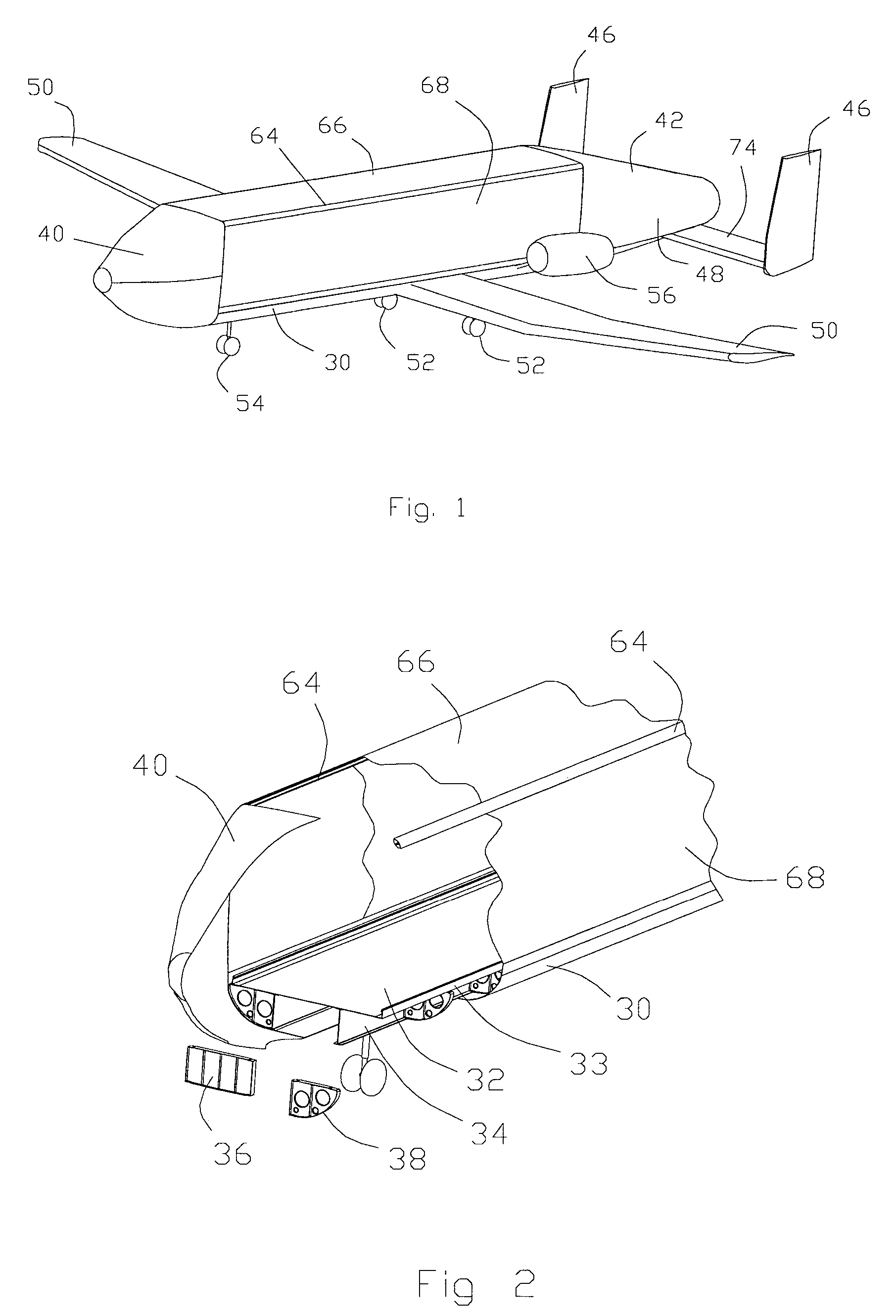

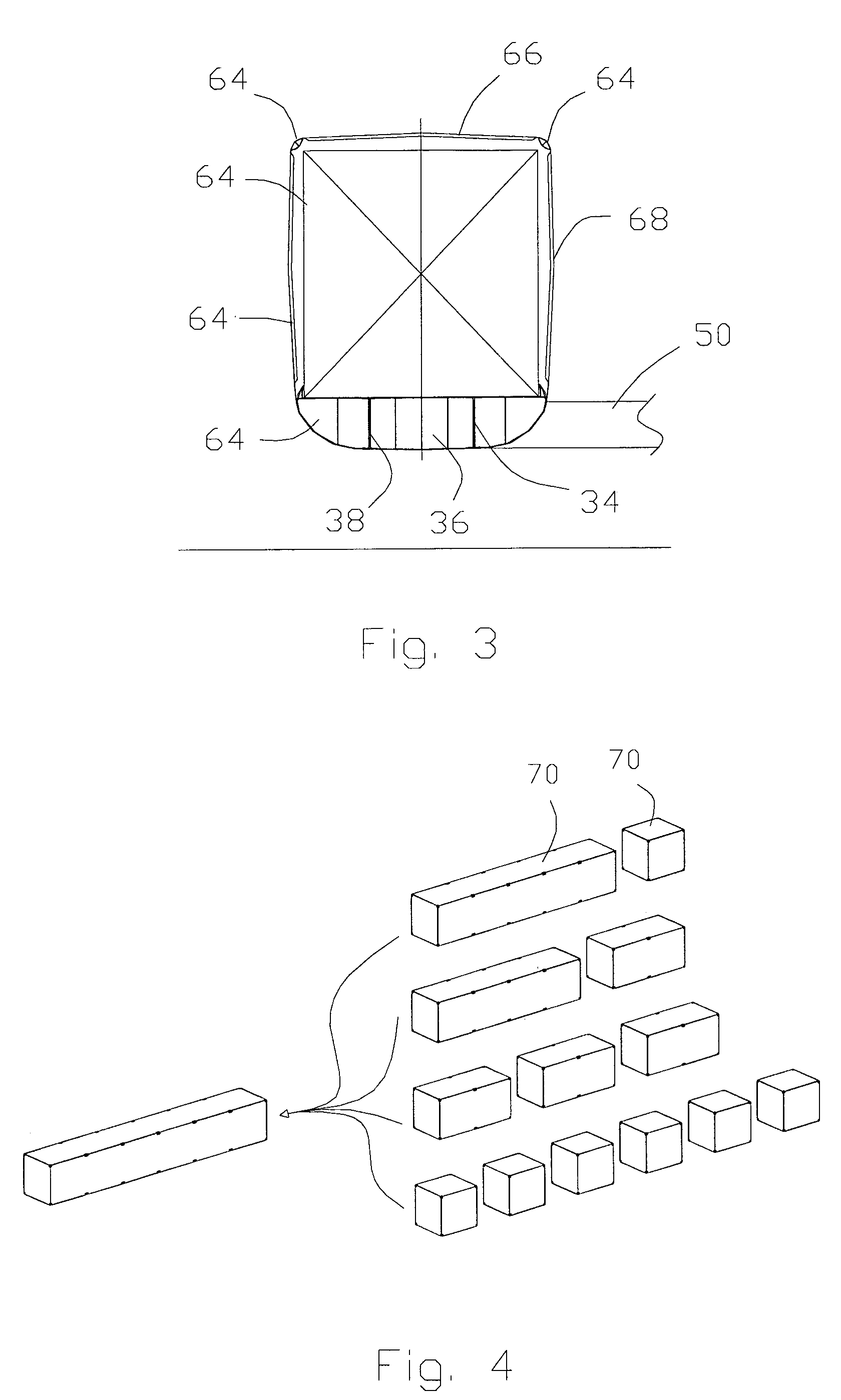

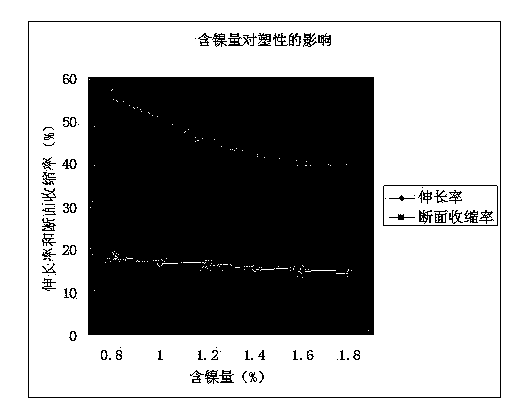

Cargo aircraft

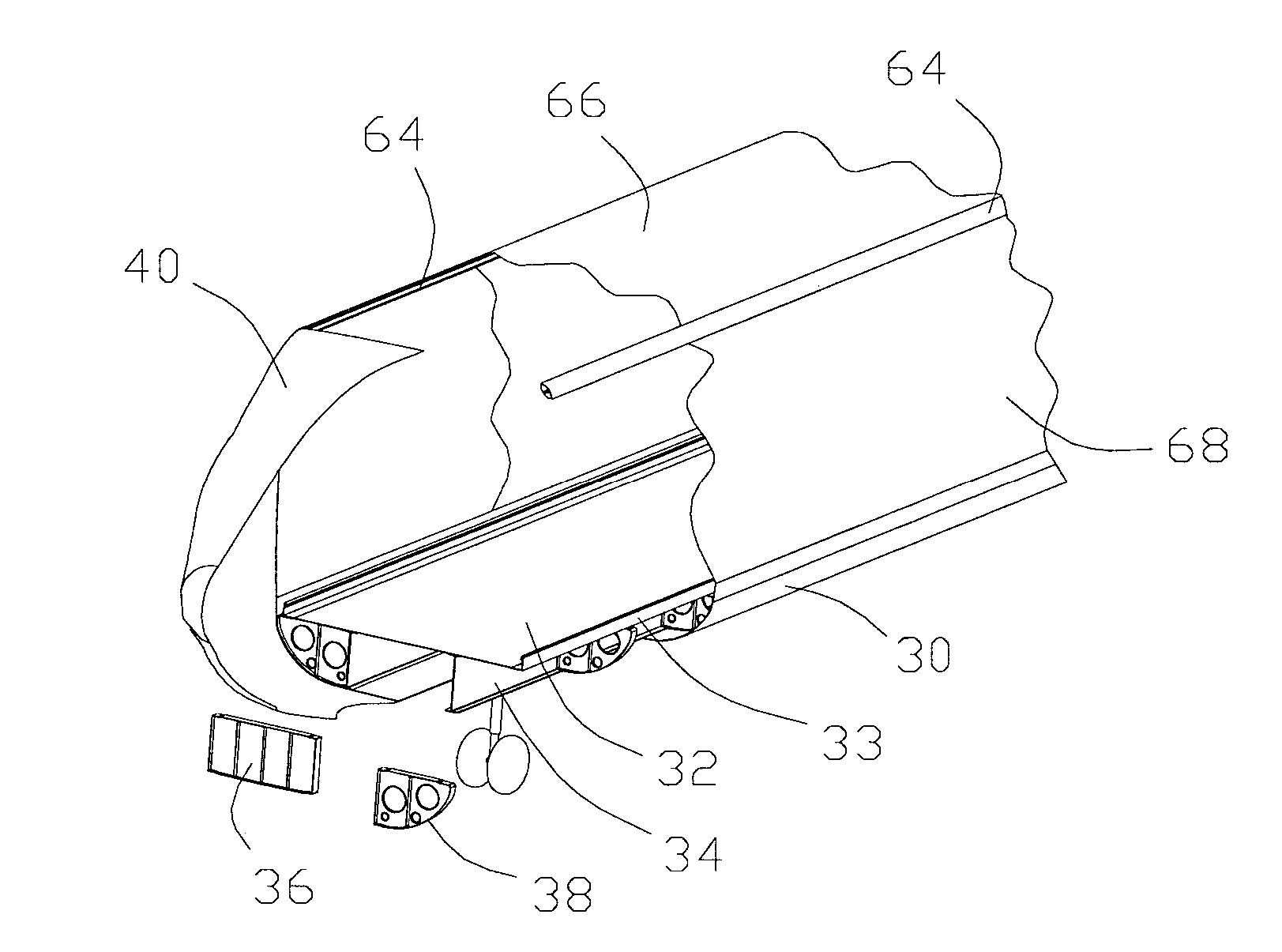

ActiveUS7261257B2Provide structural rigiditySpeed efficientUnmanned aerial vehiclesEfficient propulsion technologiesEngineeringCargo container

An aircraft for carrying at least one rigid cargo container includes a beam structure with a forward fuselage attached to the forward end of the beam structure and an empennage attached to the rearward end of the beam structure. Wings and engines are mounted relative to the beam structure and a fairing creates a cargo bay able to receive standard sized intermodal cargo containers. Intermodal cargo containers of light construction and rigid structure are positioned within the cargo bay and securely mounted therein. The beam structure is designed to support flight, takeoffs and landings when the aircraft is empty but requires the added strength of the containers securely mounted to the beam structure when the aircraft is loaded. The aircraft is contemplated to be a drone.

Owner:BIOSPHERE AEROSPACE

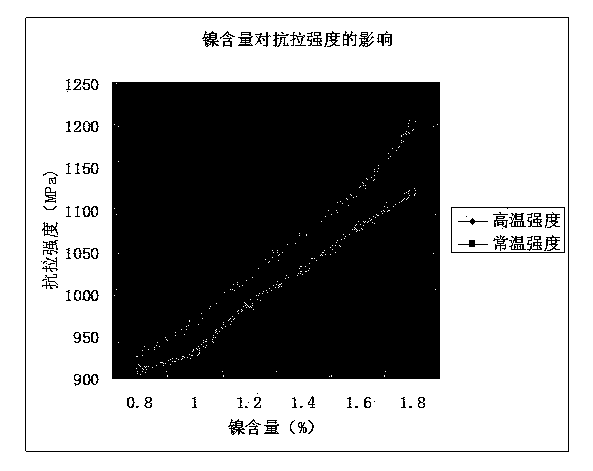

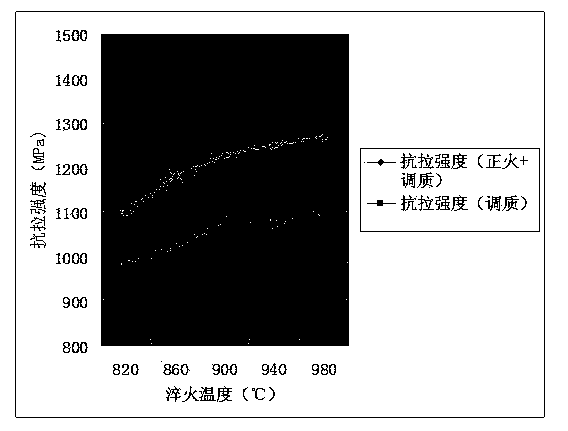

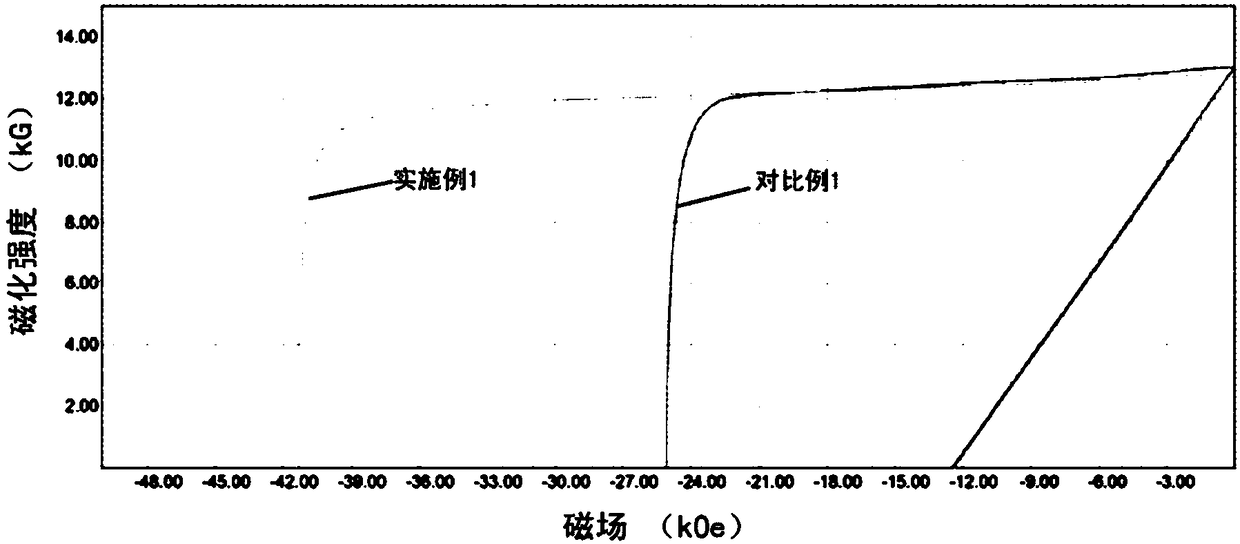

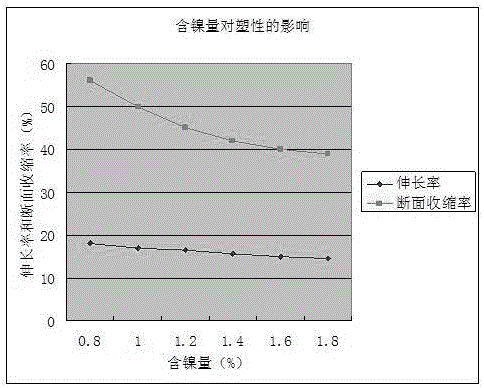

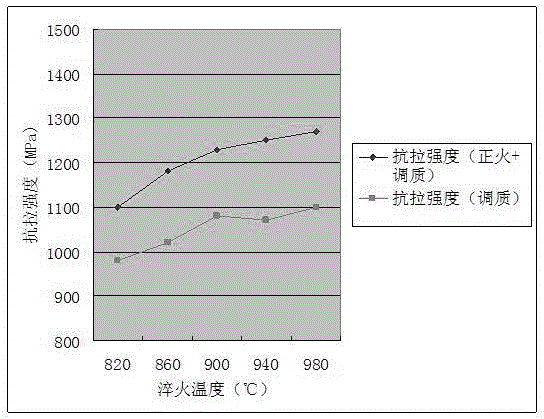

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Lithium-ion-battery gradient cathode-material precursor and preparation method thereof

The invention relates to a preparation method for a lithium-ion-battery gradient cathode-material precursor, and belongs to the technical field of preparation of lithium ion batteries cathode materials. The concrete steps of the method comprise; preparing a solution A and a solution B with different molar ratios from a nickel salt, a cobalt salt and a manganese salt, and controlling the volume of the solution A and the solution B to be same; employing a metering pump to gradually adding the solution A into the solution B, then adding the uniformly-mixed solution into a reaction kettle, and also adding an alkali solution and a complexing agent solution into the reaction kettle, and stabilizing synthesis technology parameters during reaction, stopping reaction once the solution A and the solution B are completely consumed, finally centrifuging, washing and drying, so as to prepare the spherical cathode material precursor with different-concentration gradient-distributed elements. The disclosed preparation method helps to improve the processing performance and the tap density of the cathode material, and overcome the disadvantages about capacity and stability of the material, and by controlling the morphology and the particle size of the cathode material, the physicochemical performances of the cathode material are controlled and the material stability is improved.

Owner:HUBEI RONGBAI LITHIUM BATTERY MATERIAL CO LTD

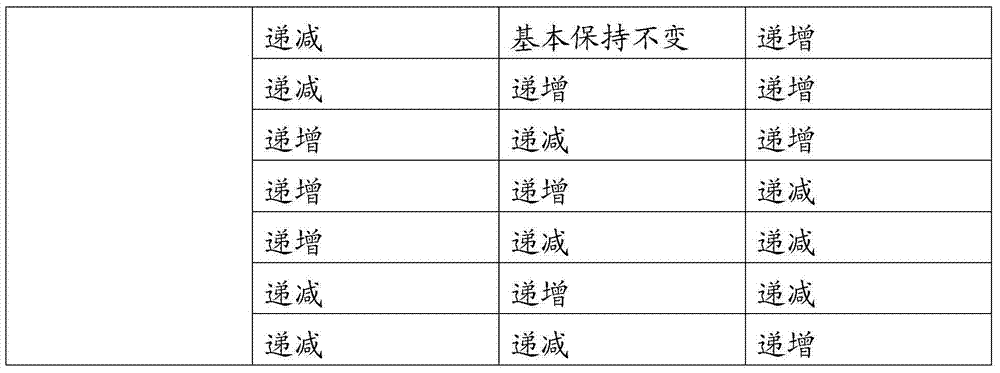

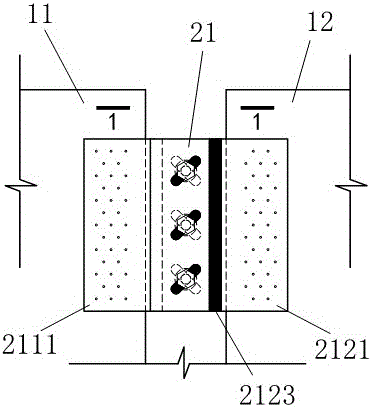

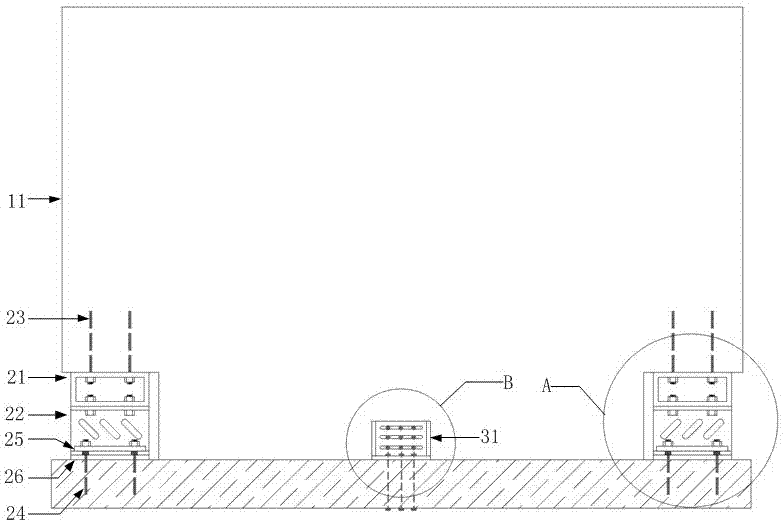

Cross laminated timber (CLT) double-board seismic wall with swinging energy-dissipation function

ActiveCN106639030AImprove deformationImprove energy consumptionWallsProtective buildings/sheltersLap jointEngineering

The invention relates to a cross laminated timber (CLT) double-board seismic wall with a swinging energy-dissipation function. The CLT double-board seismic wall is composed of two CLT shear walls, a friction-type vertical connecting piece and a friction-type pulling-resistant anchoring piece. The two CLT shear walls are spliced together through the friction-type vertical connecting piece, and a wall body is connected with a floor or a foundation through the friction-type pulling-resistant anchoring piece. Under the effect of an earthquake, the CLT shear walls rotate in the wall board plane, the friction-type vertical connecting piece is in shear, and lap joint friction surfaces of the friction-type vertical connecting piece slide relatively to dissipate energy; and meanwhile, the specially-designed pulling-resistant anchoring piece is matched with rotation of the CLT shear walls, and friction surfaces in the pulling-resistant anchoring piece also slide relatively to dissipate energy. The CLT shear walls are hardly damaged after the earthquake, friction sheets in the vertical connecting piece and the pulling-resistant anchoring piece are not damaged and do not need to be replaced after the earthquake, and the ideal anti-seismic property that the structure is stable under small earthquakes, the seismic wall swings but is not damaged under large earthquakes, and no post-earthquake maintenance or only a small amount of post-earthquake maintenance is needed is achieved.

Owner:TONGJI UNIV

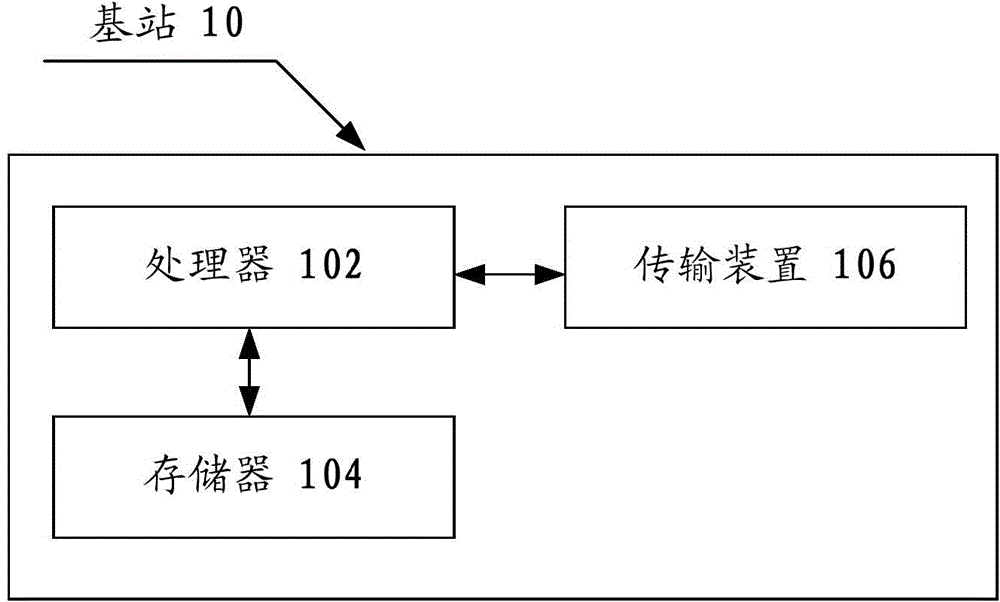

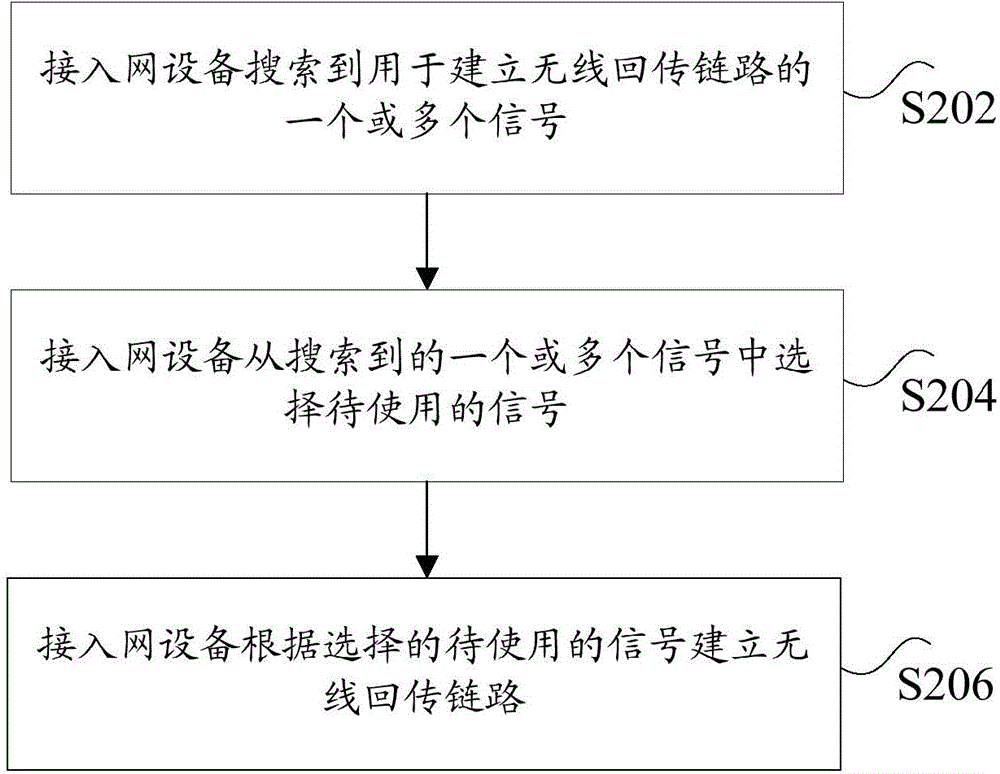

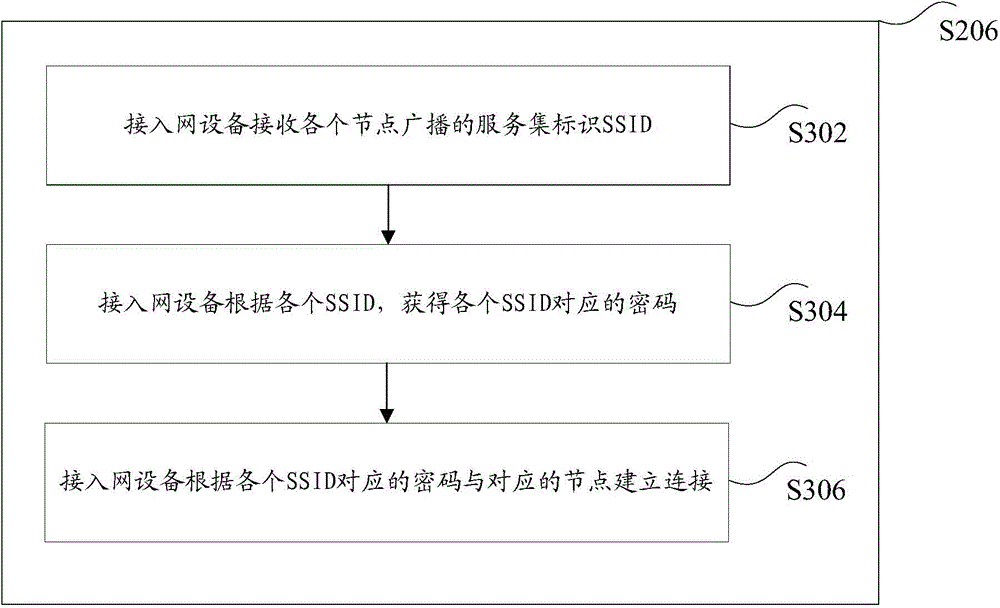

Method and apparatus for establishing wireless backhaul link and communication system

InactiveCN106162817AIncrease flexibilityLow costAssess restrictionConnection managementAccess networkWireless backhaul

The invention discloses a method and an apparatus for establishing a wireless backhaul link and a communication system. The method comprises the steps that an access network device searches one or more signals for establishing the wireless backhaul link; the access network device selects a to-be-used signal from the searched one or more signals; and the access network device establishes the wireless backhaul link according to the selected to-be-used signal. According to the method and the apparatus disclosed by the invention, the technical problem of relatively complex deployment resulting from the use of wired connection in the backhaul link in the prior art is solved.

Owner:BAICELLS TECH CO LTD

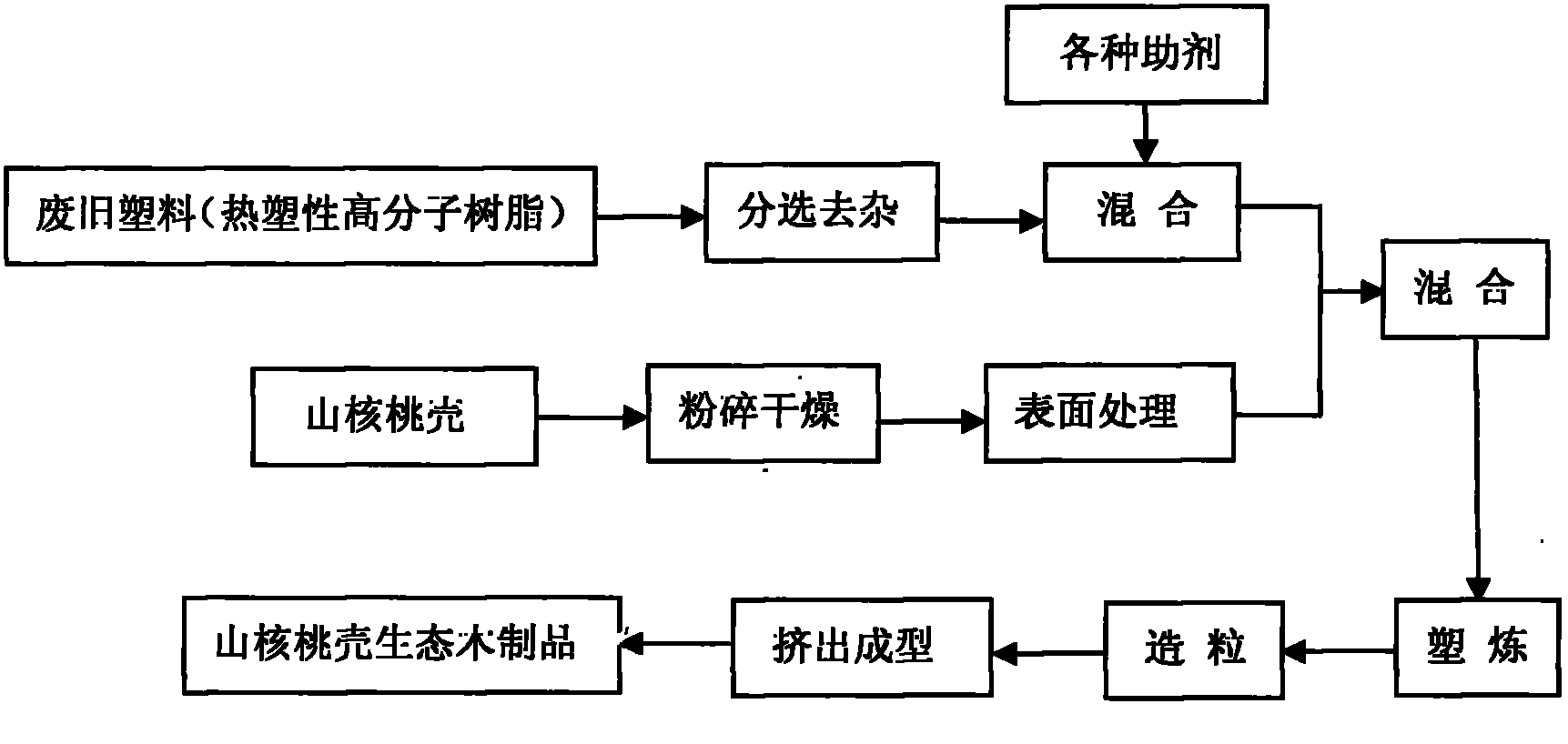

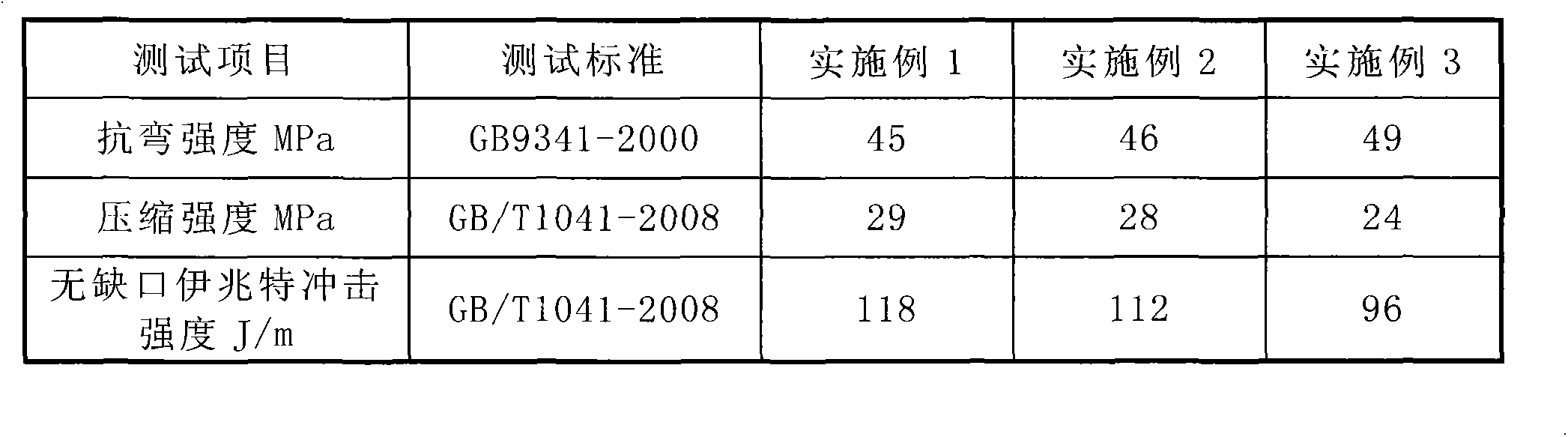

Hickory nut shell ecologic wood composite material and preparation method thereof

The invention relates to a plastic-wood composite material and provides a hickory nut shell ecologic wood composite material and a preparation method thereof. The hickory nut shell ecologic wood composite material is prepared from following components including, by weight, 50-60 parts of a thermoplastic high-molecular resin, 40-50 parts, or 30-40 parts, of hickory nut shell powder, 10-20 parts of wood powder, 8-10 parts of light calcium carbonate, 10-14 parts of a compatilizer, 2-4 parts of a thermal stabilizer, 2-4 parts of a lubricant, 2-3 parts of a plasticizer, and 1-3 parts of an antioxidant and an ultraviolet stabilizer. A comprehensive technology comprising deep process of raw materials and extrusion moulding and the like is employed. Deep process waste of wild hickories and waste plastic resources are employed. The composite material in the invention has dual-characteristics, which exist in common plastic-wood, of wood and plastic, is better in mechanical performances and is more rigid, durable, wear-resistant and weather-resistant. The method is simple and convenient, is low in manufacturing cost, can be recovered and recycled, can save energy resources and can protects environment.

Owner:LIAONING CHANGBAIXIANZI BIOTECH

Preparation method of carbon/ceramic composite material

The invention discloses a preparation method of a carbon / ceramic composite material and aims at solving the problems that a traditional preparation method of the carbon / ceramic composite material is long in production cycle, high in cost and the like. The preparation method of a carbon / ceramic composite material comprises four steps of preparing ceramic slurry, grouting, carrying out dehumidification, performing recrystallization and sintering, and the sintering is carried out according to a temperature curve, and compact ceramic matrix coating layers are formed on the surfaces of carbon fibers to prepare the carbon / ceramic composite material. The preparation method of the carbon / ceramic composite material disclosed by the invention can be quickly sintered and is short in preparation cycle, and the bending strength of the prepared carbon / ceramic composite material reaches 130-150 Mpa.

Owner:HUNAN JIUHUA CARBON HI TECH

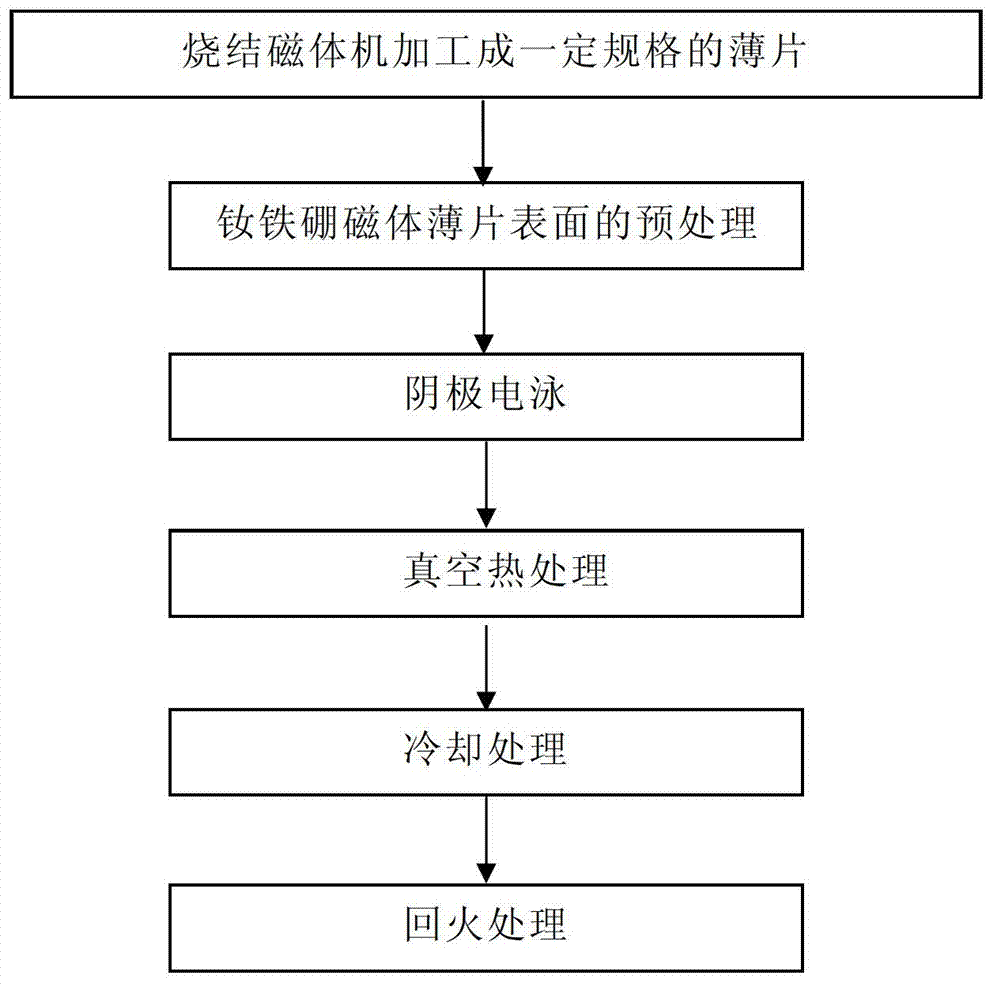

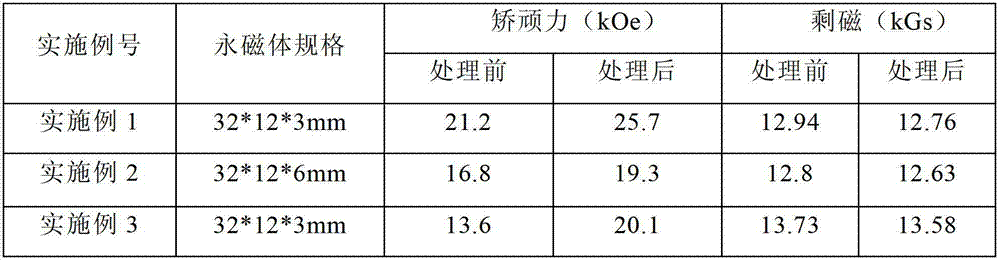

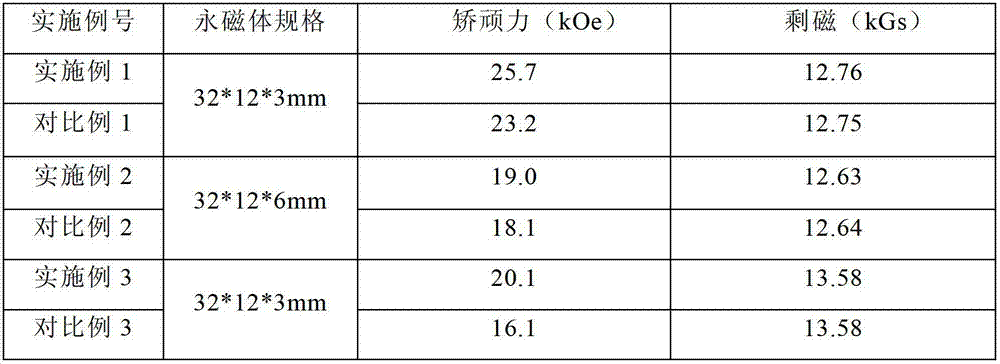

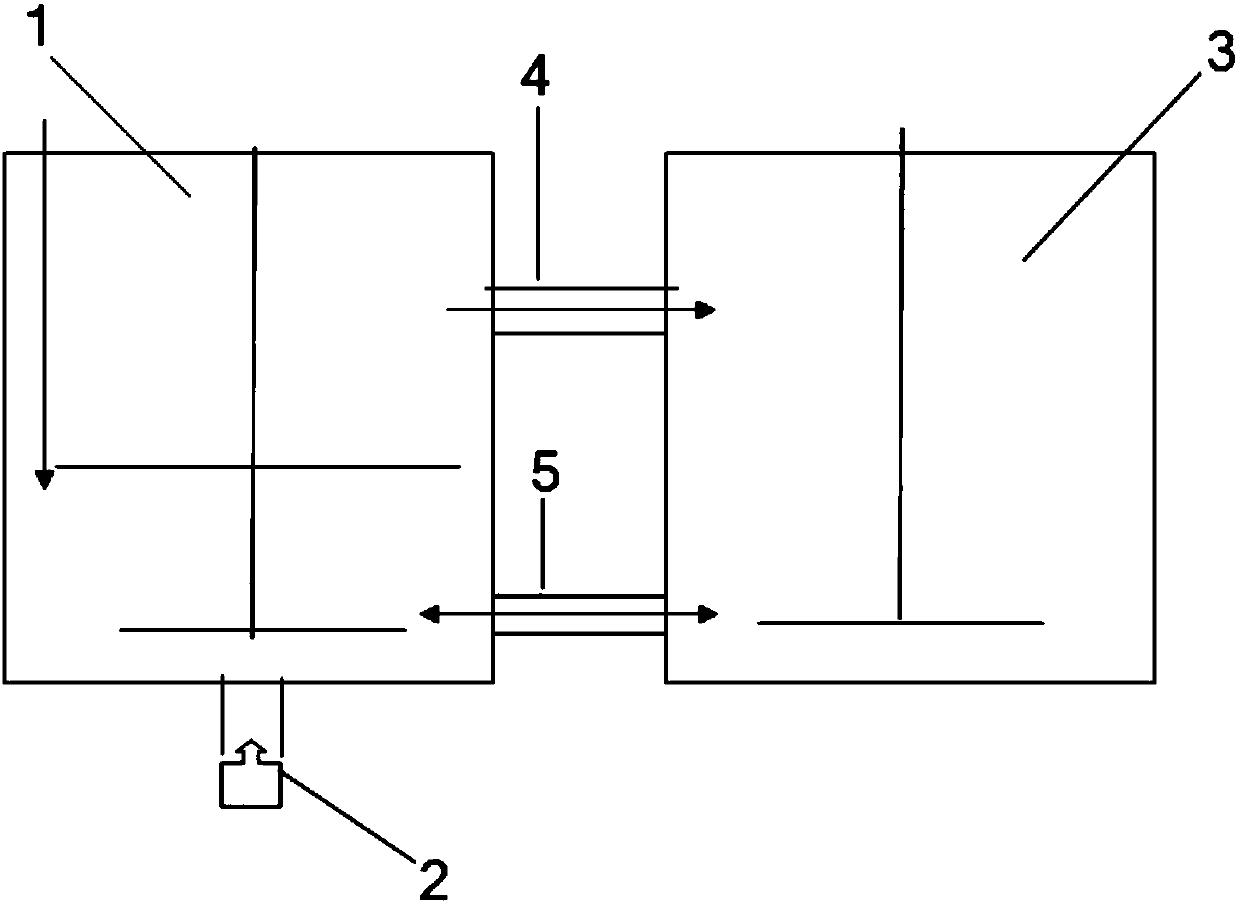

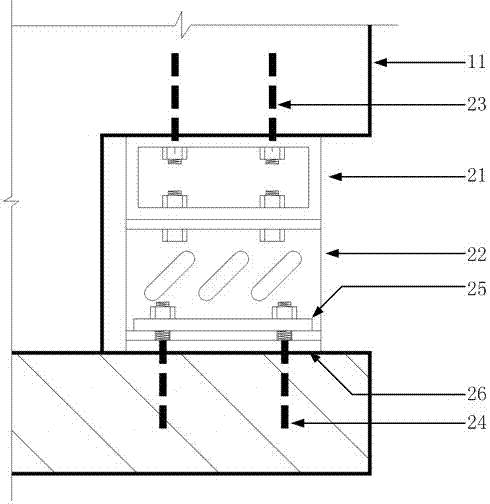

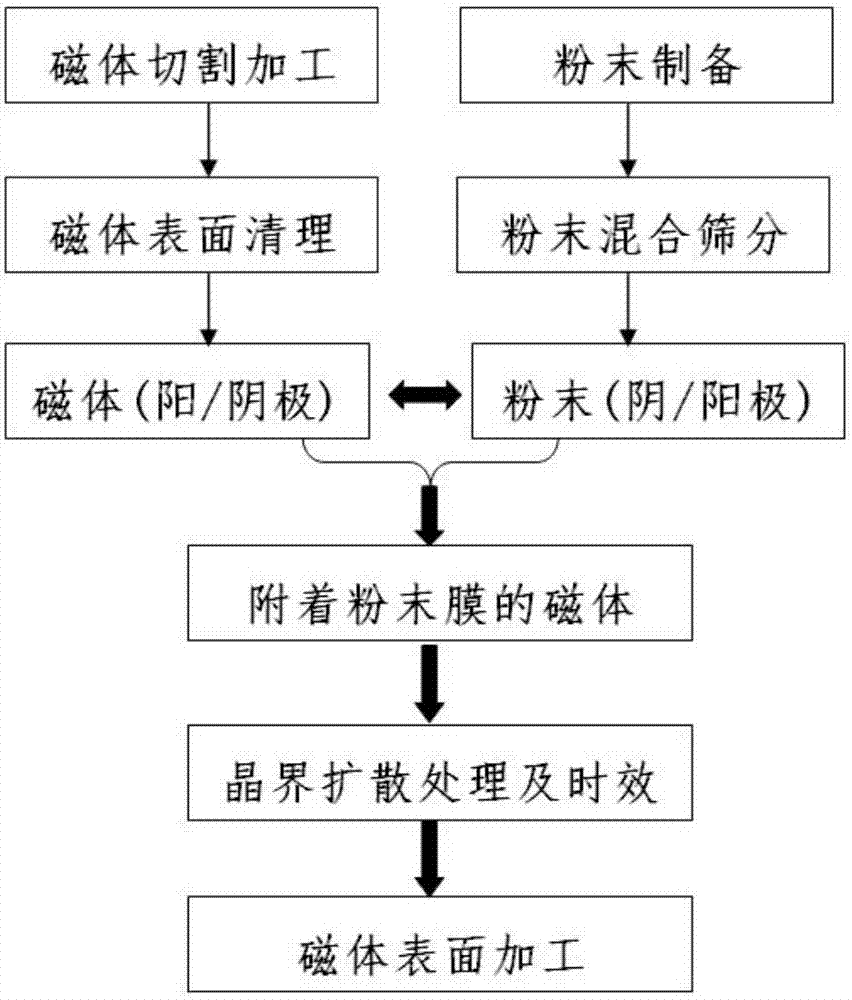

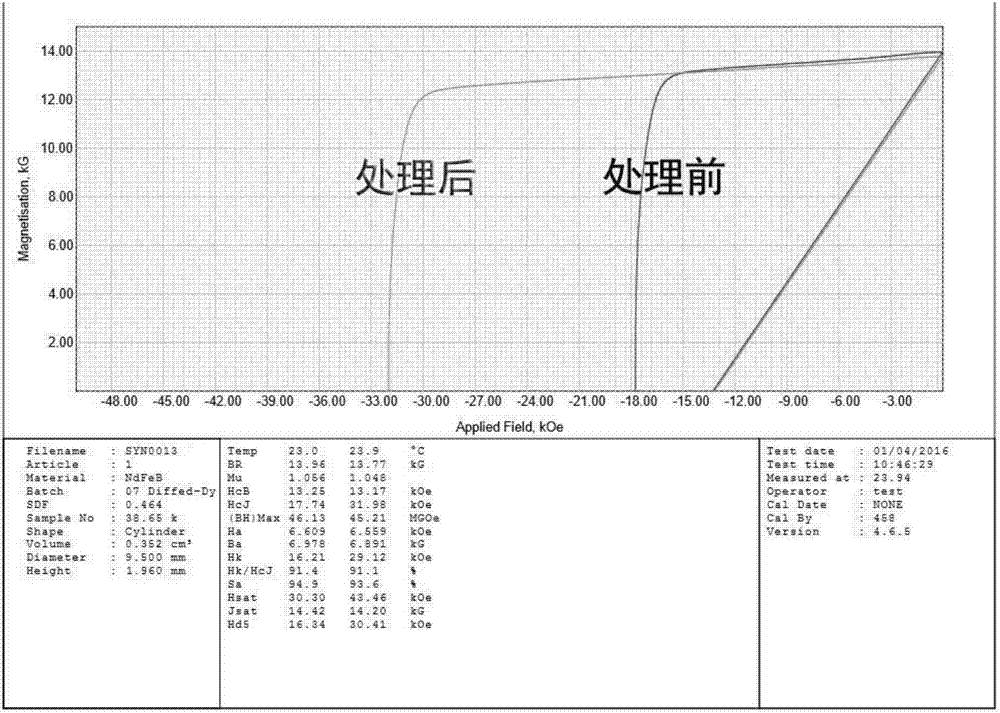

Method for preparing rare earth permanent magnetic material

ActiveCN102776547AImprove bindingAvoid wastingElectrophoretic coatingsInductances/transformers/magnets manufactureRare-earth elementElectrophoresis

The invention provides a method for preparing a rare earth permanent magnetic material, which belongs to the technical field of rare earth permanent magnetic materials. The method takes the colloidal solution of LRHs powder as a cathode electrophoretic solution, an NdFeB permanent magnet which is undergone surface pretreatment is subjected to cathode electrophoresis, and through controlling the electrophoretic voltage and the electrophoretic time, an attachement film which has the preset thickness and is rich in heavy rare earth elements is obtained on the surface of the NdFeB permanent magnet; and then, the NdFeB permanent magnet which is adhered with the attachement film is subjected to vacuum heat treatment, cooling treatment and tempering sequentially, and thus the NdFeB rare earth permanent magnetic material with improved performance is obtained. The coercive force of the NdFeB rare earth permanent magnetic material which is obtained by the method is obviously improved, and can be improved by 2000-7000Oe before the treatment; compared with non-treatment, the coercive force of the treated sintered NdFeB permanent magnetic material can be improved by 10-50%, and meanwhile, the residual magnetism is basically not reduced obviously, and is only lowered by 1-2%; and in addition, the usage of the heavy rear earth is greatly reduced.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Preparation method of gradient precursor of cathode material for lithium ion batteries

InactiveCN107785543AUniform gradientControl the Co-precipitation Reaction ProcessCell electrodesSecondary cellsAluminium-ion batteryGradient material

The invention relates to a preparation method of a gradient precursor of a cathode material for lithium ion batteries, belonging to the technical field of preparation of the cathode material for the lithium ion batteries. The gradient precursor has a chemical formula of NixCoyMn1-x-y(OH)2 or NixCoyAl1-x-y(OH)2, wherein the content of Ni is more than 0.4 and less than 0.98, the content of Co is more than 0.1 and less than 0.8, and the content of Mn / Al is more than 0.01 and less than 0.7; the metallic elements are enabled to react according to an increasing proportion or a decreasing proportion,and a spherical gradient material is obtained by crystallizing. The gradient precursor of the cathode material for the lithium ion batteries is high in ramming density, good in degree of sphericility, uniform in particle size distribution, and the like, and can avoid the defects caused by the fact that the elements provide different properties.

Owner:HENAN KELONG NEW ENERGY CO LTD

Method for repairing and treating quality defect of cast-in-place pile

ActiveCN103541359ASimple methodShort construction periodBulkheads/pilesStructural engineeringCement slurry

The invention discloses a method for repairing and treating a quality defect of a cast-in-place pile. The method is characterized by comprising the following steps that 1) the defect position of the pile is dynamically measured through low strain; 2) the top of the pile is drilled into for core taking, the depth of the core taking exceeds the defect position, and the exceeding depth is 1-2 times of the diameter of a pile body; 3) high-pressure hole flushing is carried out, and mud blocks, fine sand and other filler in the defect position are removed; 4) high-pressure hole cleaning is carried out, dregs in a core hole are returned out of a core hole opening, and no dreg sediment exists in the core hole until water is clear and the dregs are removed completely; 5) the hole is punched and filled with high-pressure cement slurry, and fine cracks and fissures of the defect position are filled with the cement slurry; 6) pipe insertion is carried out, and a grouting pipe and a slurry discharge pipe are inserted; 7) the hole is sealed; 8) high-pressure grouting is carried out, and the core hole is filled with the mixed cement slurry. Dynamic testing and retesting can both be restored and reach the standard through the low strain after the defected pile is repaired and treated. The method is simple and easy to implement, the working period for repairing and treating the quality defect of the cast-in-place pile is short, repairing construction cost is low, original project design is changed slightly, and the repaired pile is reliable in quality.

Owner:浙江省岩土基础有限公司

Steel and wood hybrid earthquake resistant wall with post-earthquake self reset function

ActiveCN105756217AImprove deformationImprove energy consumptionWallsShock proofingResidual deformationPre stress

The invention relates to a steel and wood hybrid earthquake resistant wall with a post-earthquake self reset function. The steel and wood hybrid earthquake resistant wall is formed by steel beams, steel columns, wood shear walls, post-tensioned unbounded prestressed tendons and friction type dampers, wherein the post-tensioned unbounded prestressed tendons penetrate through the steel beams longitudinally, penetrate through the upper ends of the steel columns and are fixed to the outer sides of the steel columns by using anchors; the friction type dampers are positioned at the upper parts of the wood shear walls and are connected with raising plates of the wood shear walls by adopting bolts. Under small earthquakes, a steel framework and the wood shear walls work together, so that the structure is enabled to have higher lateral stiffness; under middle earthquakes or big earthquakes, a shear force applied to the friction type dampers is greater than a slip shear force of the friction type dampers, friction surfaces of the friction type dampers start to slip to consume energy, and the damage to the wood shear walls can be reduced to a large extent; the post-tensioned unbounded prestressed tendons are always in an elastic tension state, beam column nodes after an earthquake return to an initial state under the action of the post-tensioned unbounded prestressed tendons, the steel beams and the steel columns are basically not damaged, residual deformation of the structure is very small, and the friction type dampers are not damaged under the action of the earthquake and has no need to be replaced after the earthquake.

Owner:TONGJI UNIV

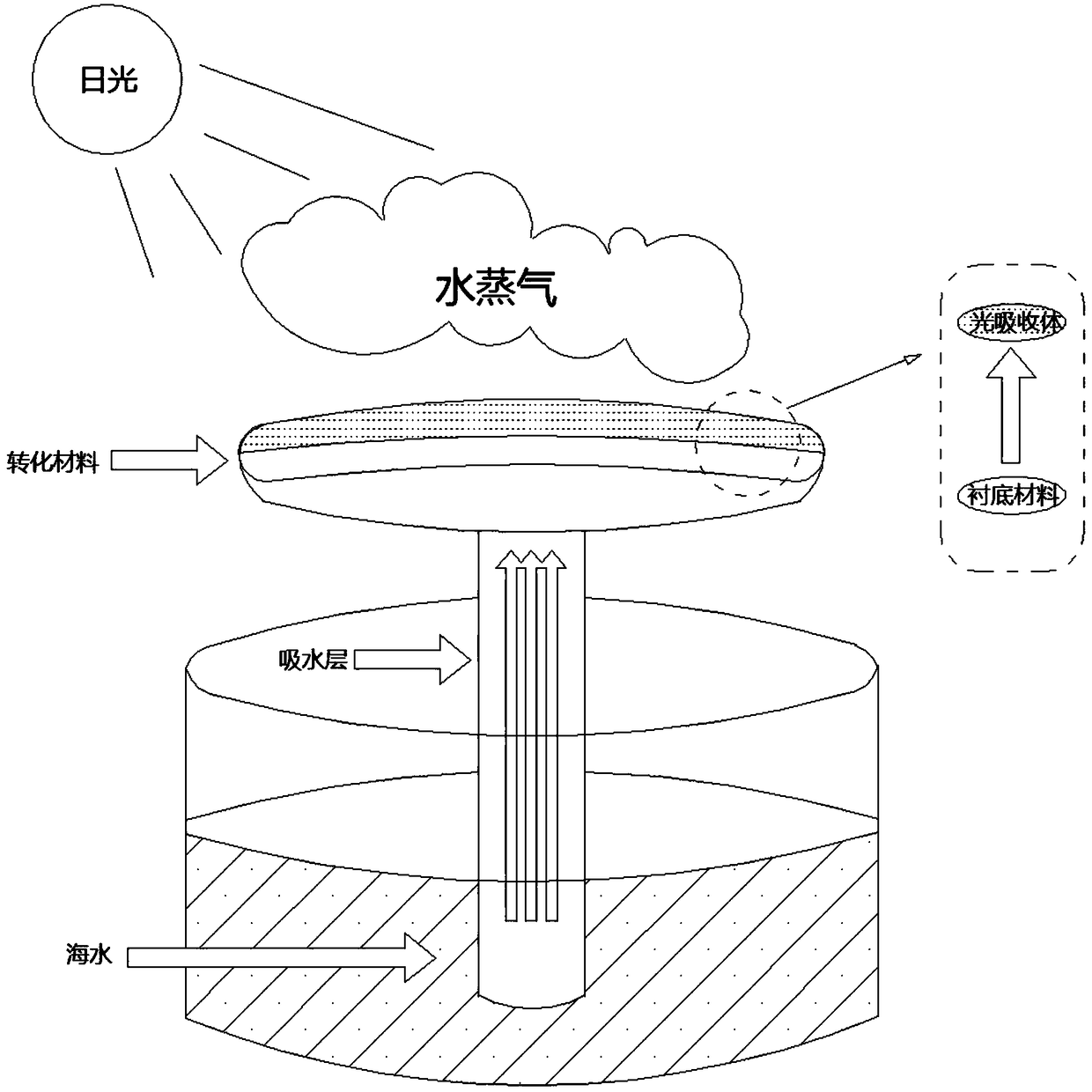

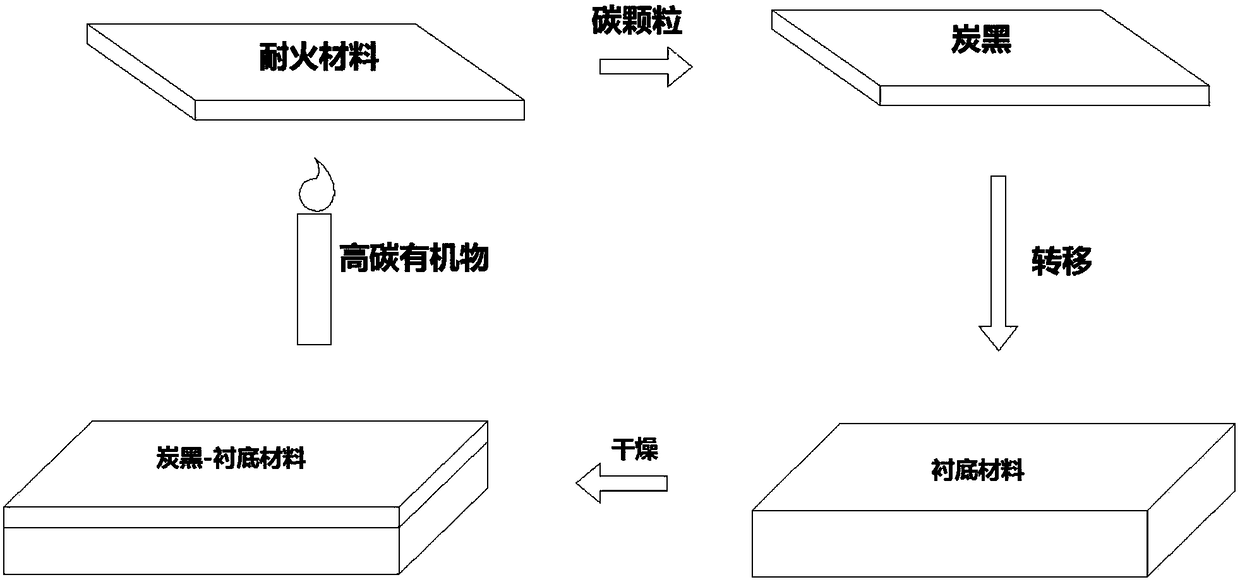

Light-heat-steam conversion material and preparation method thereof

ActiveCN108408813AStrong water absorptionWide variety of sourcesGeneral water supply conservationSeawater treatmentCoated surfaceDesalination

A light-heat-steam conversion material and a preparation method thereof, and the preparation method comprises the following steps: selecting a water-absorbing material, to be more specific, selectinga porous, highly water-absorbent and light-weight substrate material, cleaning the substrate material for standby use; preparing carbon black of a carbon black light-heat conversion coating, to be more specific, burning a high carbon organic matter, horizontally placing a refractory material above the high carbon organic matter to collect carbon black particles generated by the burning, and cooling the refractory material after collection of the carbon black particles; transferring the carbon black particles, to be more specific, wiping the surface with a carbon black coating of the refractorymaterial to transfer the carbon black particles to the surface of the water absorbing material until the surface of the water absorbing material is completely covered by the carbon black particles. Asimple desalination system of seawater or other wastewater prepared by the light-heat-steam conversion material is simple in operation, the material is cheap and easy to take, no electric energy is consumed, and the simple desalination system has good stability, and is suitable for large-area low-cost preparation.

Owner:SOUTH CHINA NORMAL UNIVERSITY

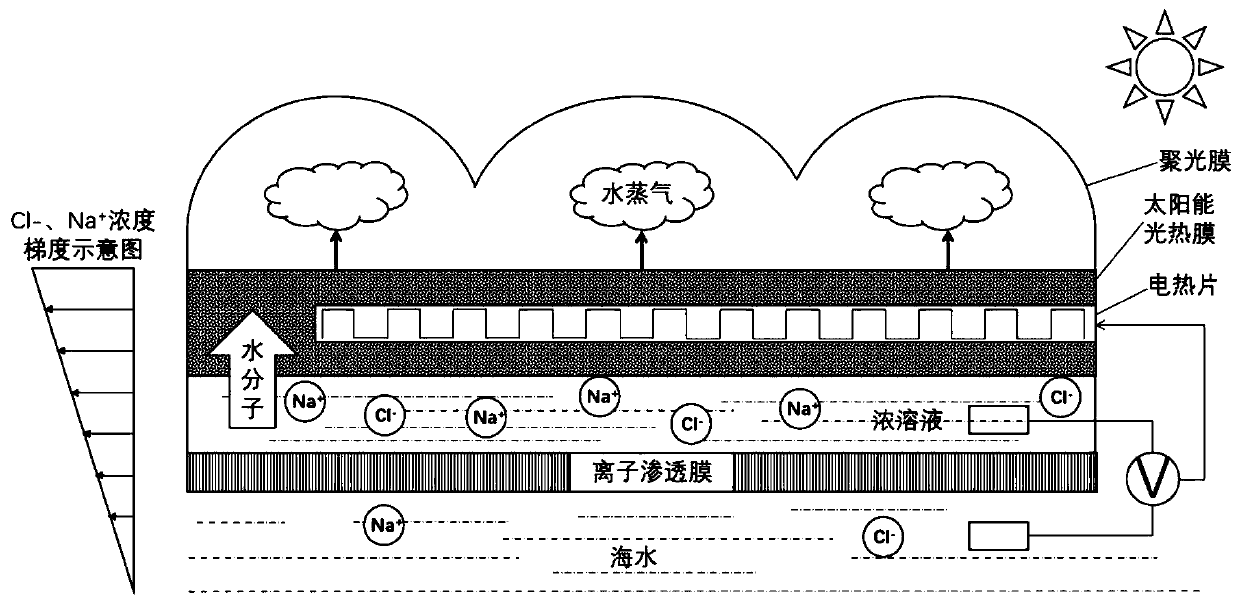

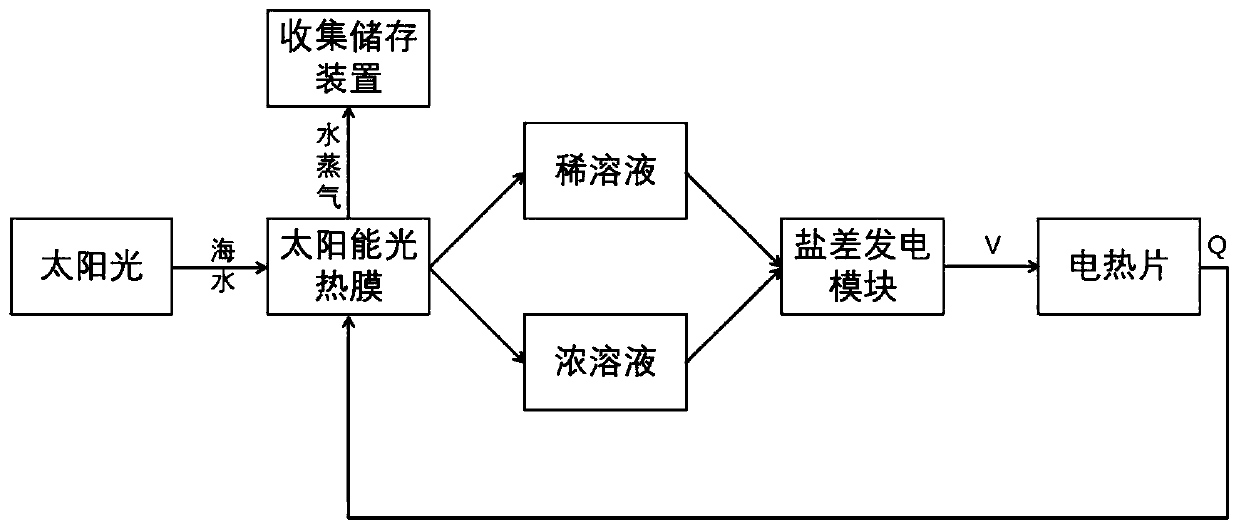

Solar-driven photo-thermal-salinity gradient power generation coupling synergistic interface evaporation system

InactiveCN111268754AImprove evaporation efficiencyThe principle is simpleGeneral water supply conservationSeawater treatmentSeawaterElectric energy

The invention provides a solar-driven photo-thermal-salinity gradient power generation coupling synergistic interface evaporation system. The system comprises a light condensation film, a solar photo-thermal film, a salinity gradient power generation module and a collection and storage device, wherein the solar photo-thermal film is used for evaporating the seawater, so that the salt difference power generation module generates power by utilizing the concentration difference generated in the evaporation process and feeds back electric energy in situ to Joule to heat the solar photo-thermal film, and thereby the evaporation temperature of the solar photo-thermal film is increased, and the evaporation efficiency of the process is further improved; the storage device is used for collecting steam or condensate water generated by solar evaporation. Compared with the prior art, the solar photo-thermal conversion and utilization efficiency can be remarkably improved through the solar evaporation coupling salinity gradient power generation technology; the system is expected to be applied to the fields of sea water desalination, waste heat utilization, renewable energy power generation andthe like in a large scale.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

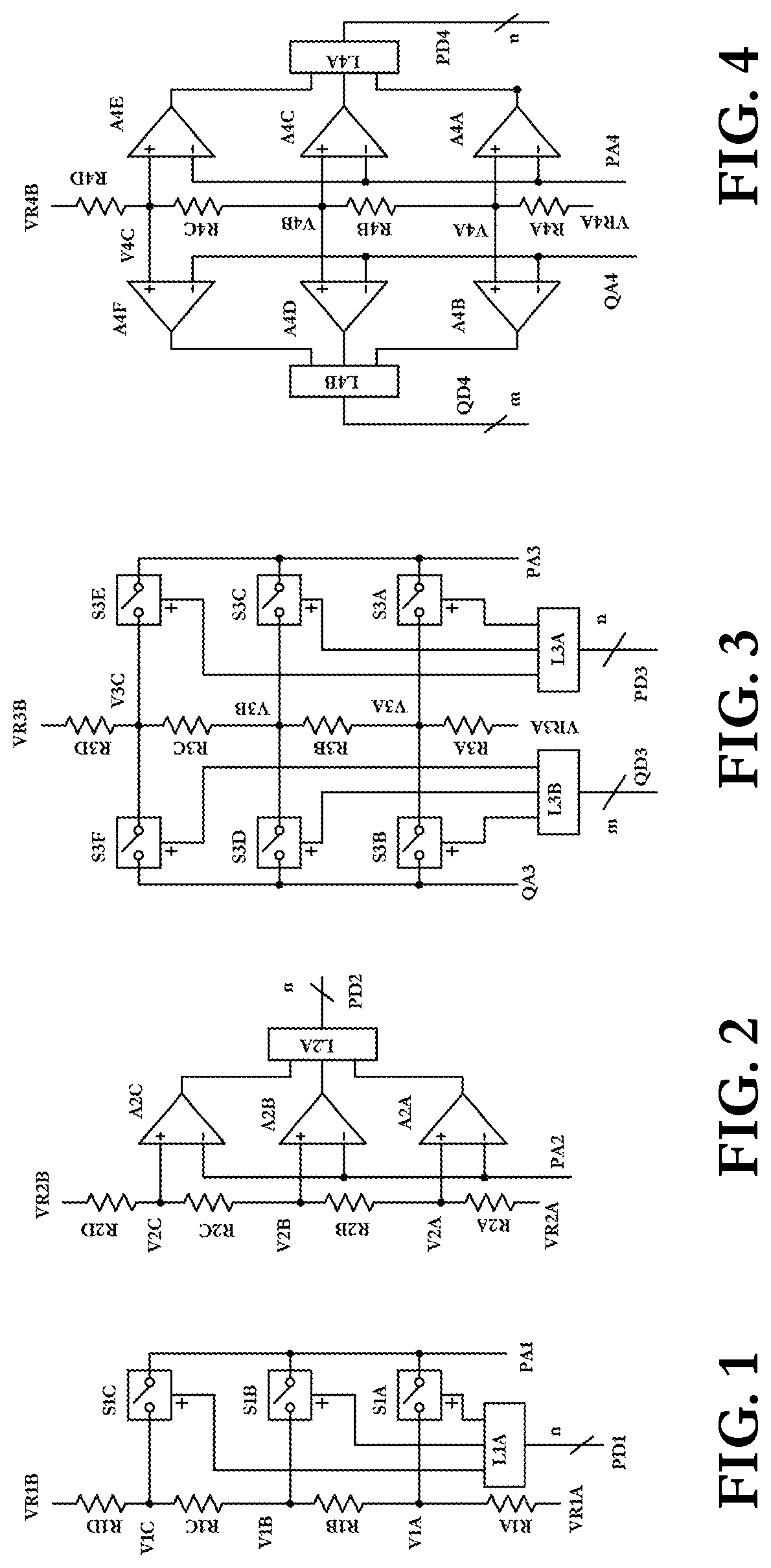

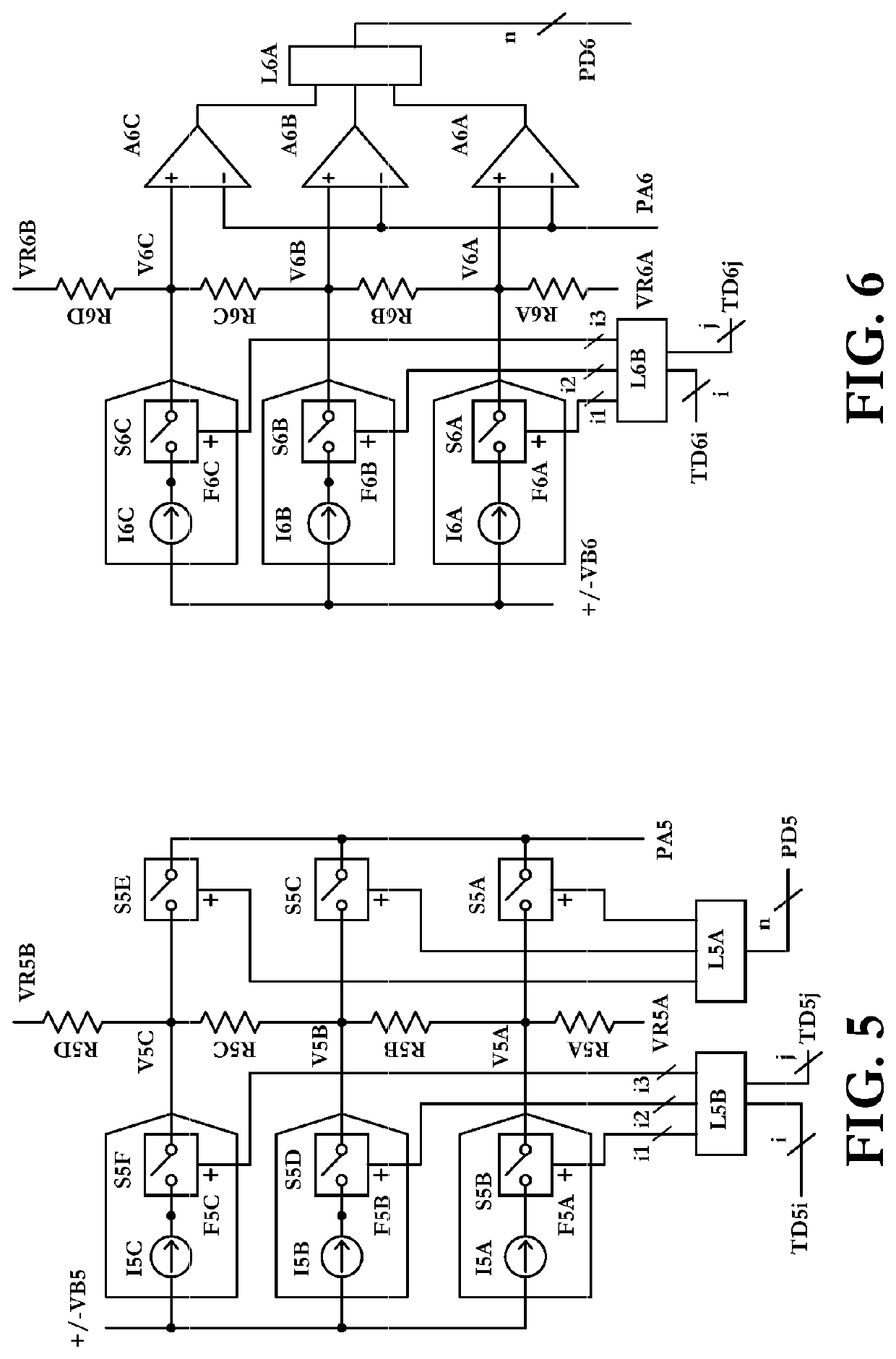

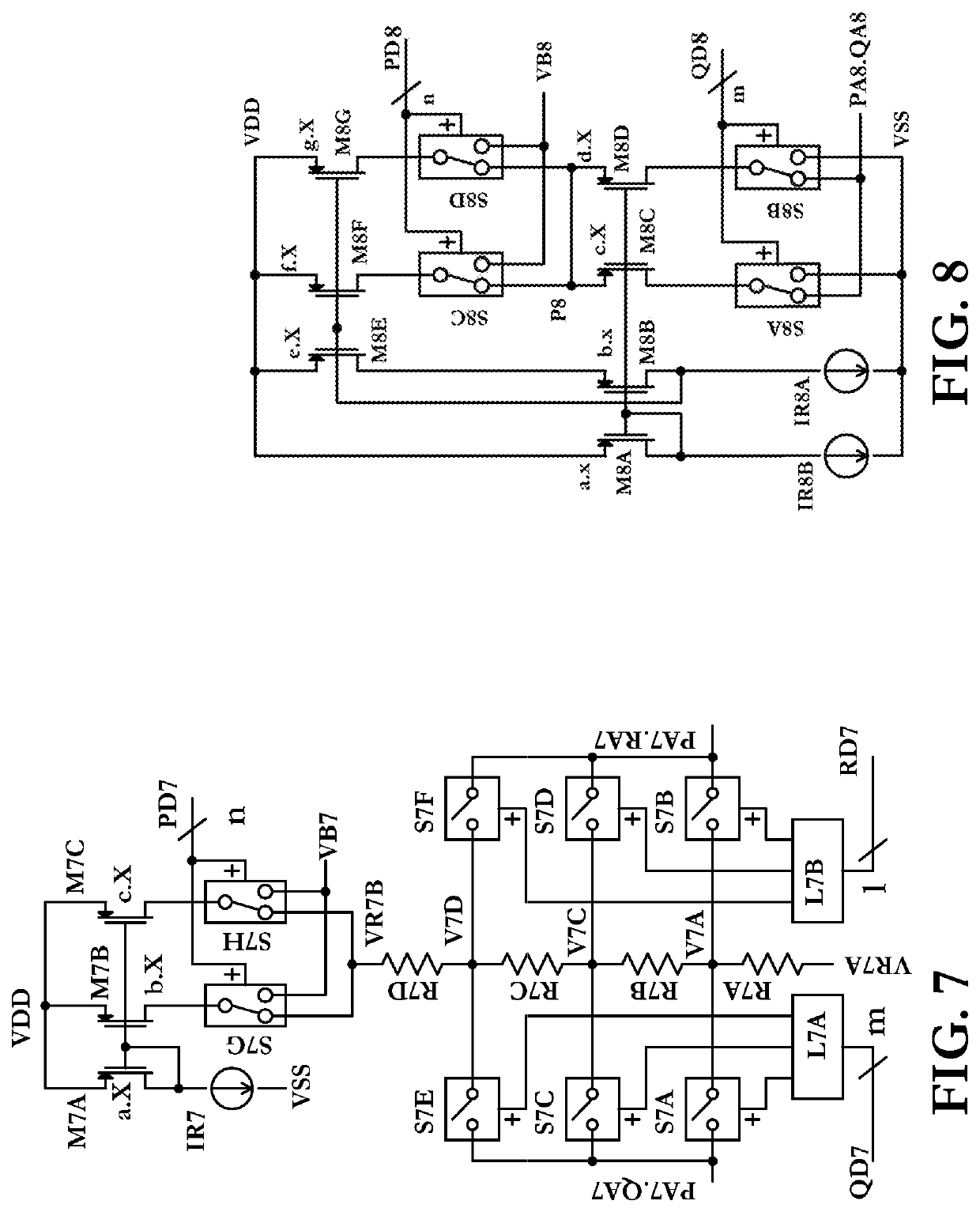

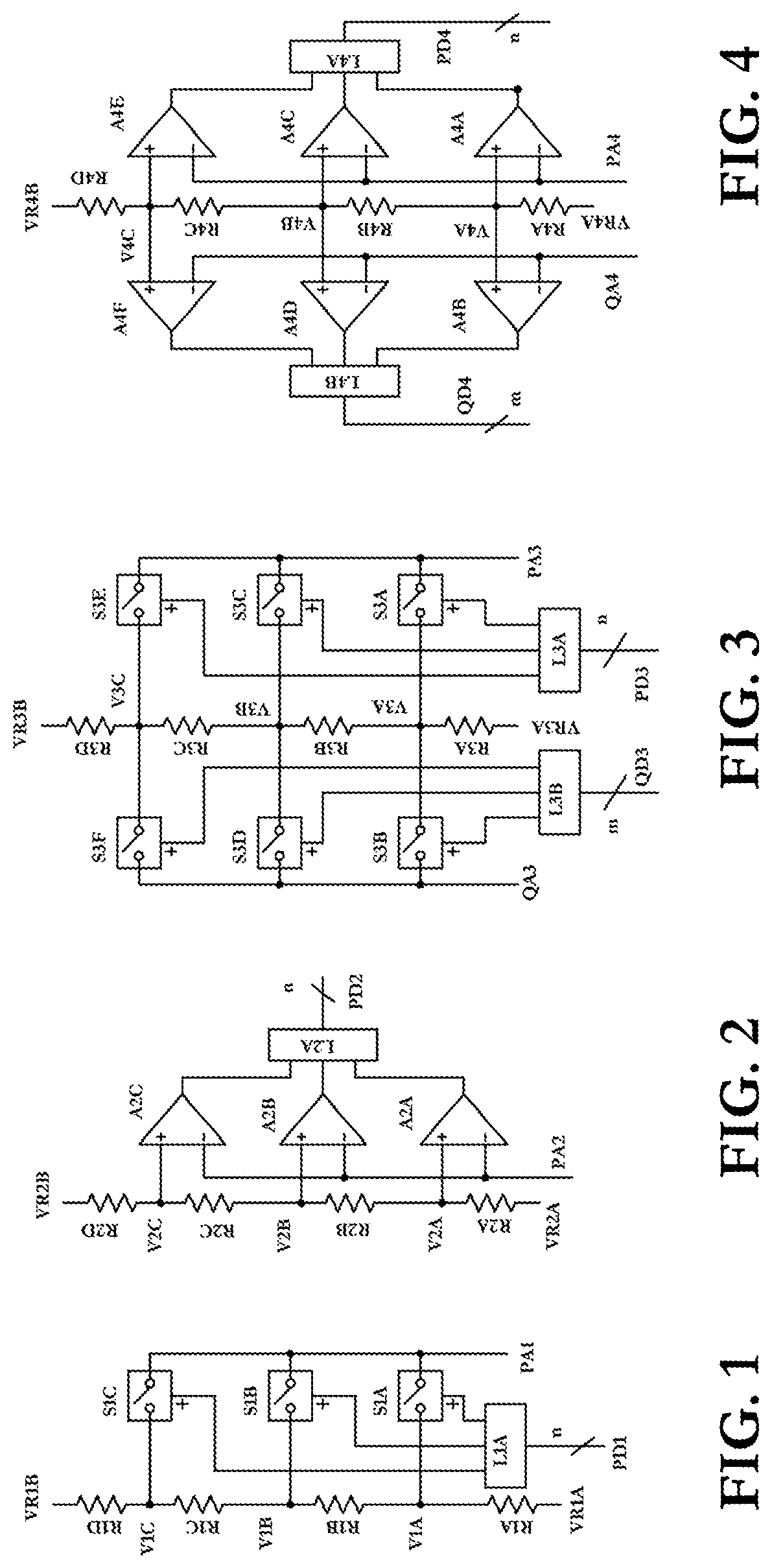

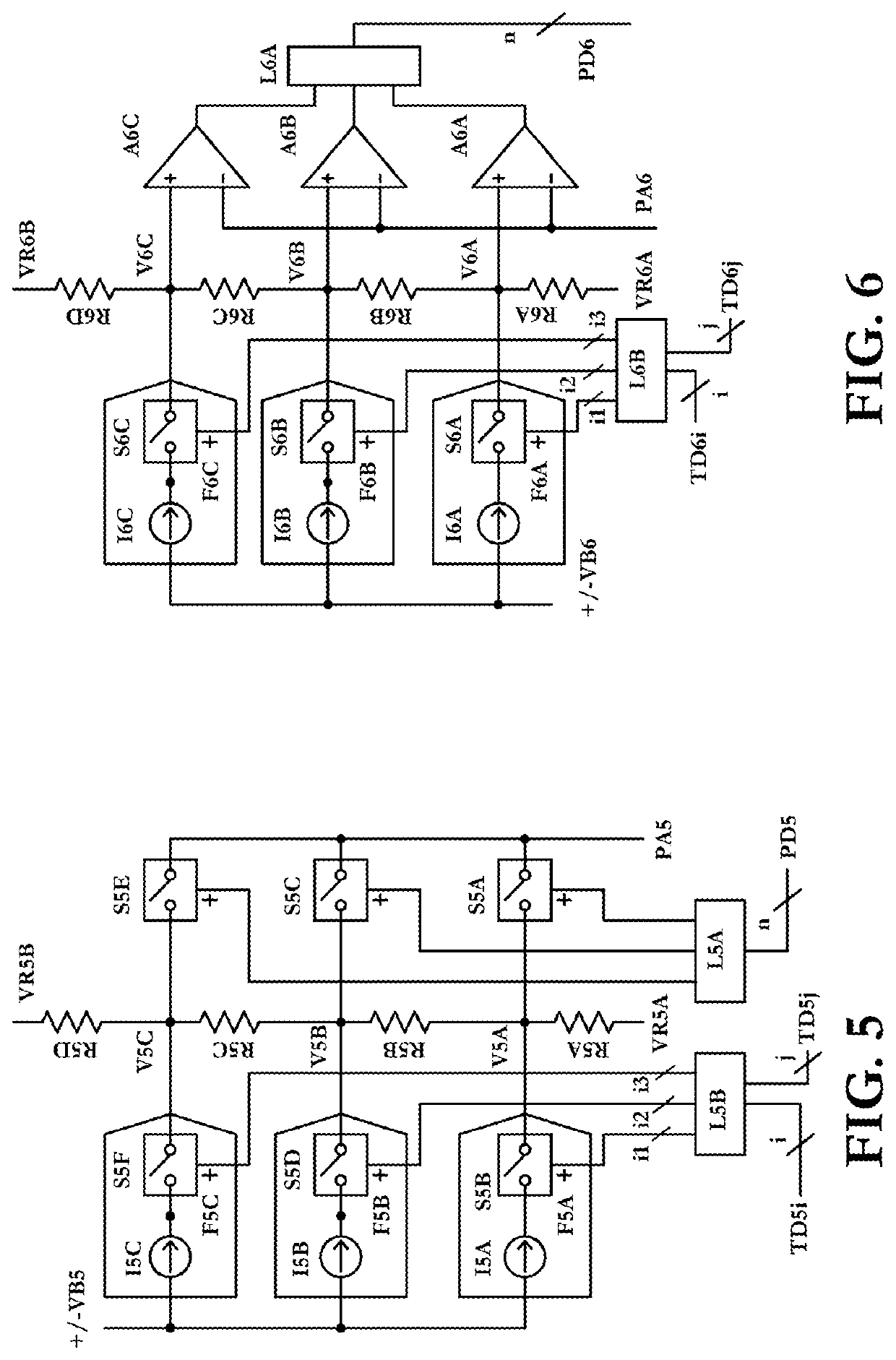

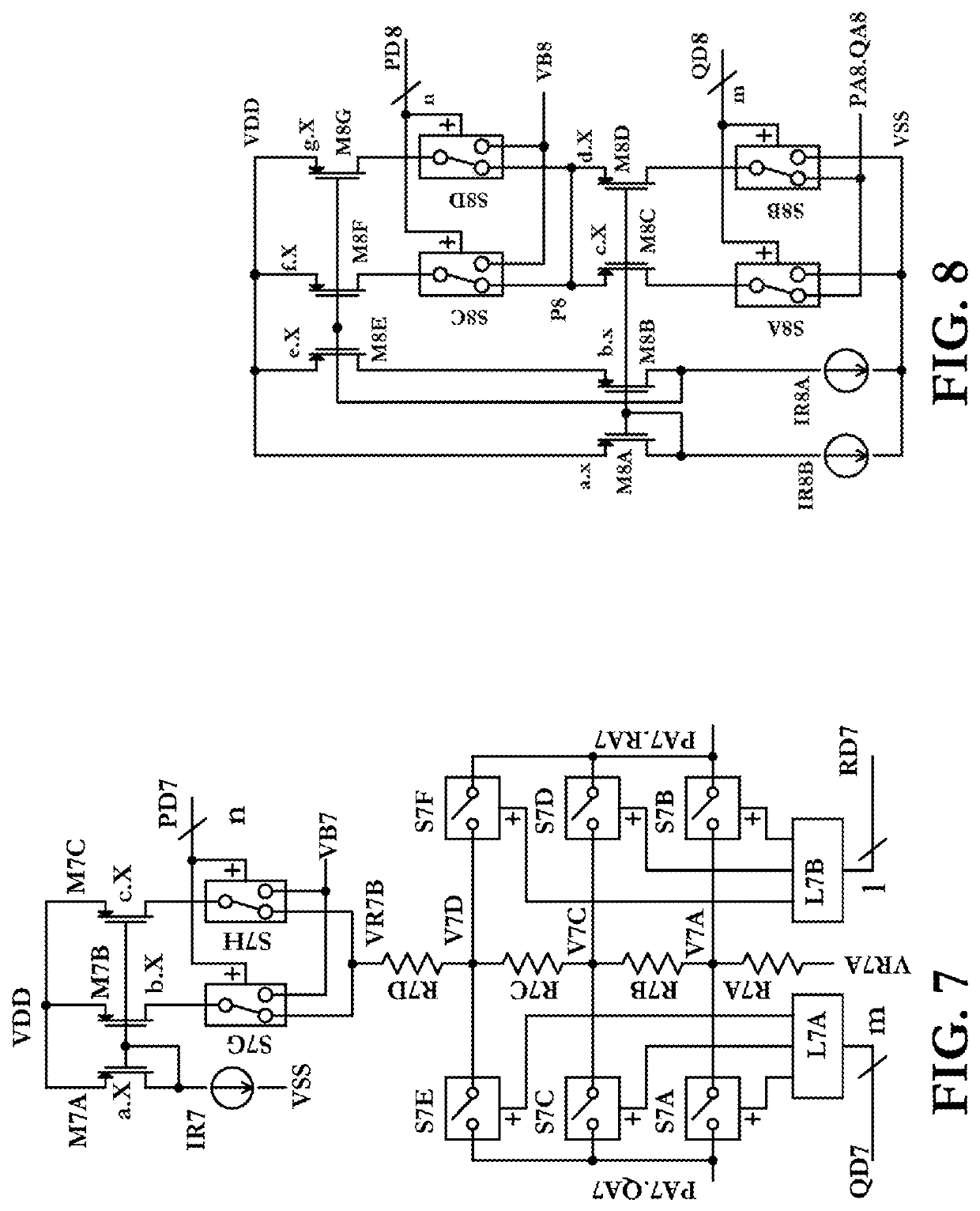

Mixed-mode multipliers for artificial intelligence

ActiveUS10594334B1Cost-effective advantageGreat degreeElectric signal transmission systemsComputing operations for logarithmic/exponential functionsData transformationAlgorithm

Multipliers are fundamental building blocks in signal processing, including in emerging applications such as machine learning (ML) and artificial intelligence (AI) that predominantly utilize digital-mode multipliers. Generally, digital multipliers can operate at high speed with high precision, and synchronously. As the precision and speed of digital multipliers increase, generally the dynamic power consumption and chip size of digital implementations increases substantially that makes solutions unsuitable for some ML and AI segments, including in portable, mobile, or near edge and near sensor applications. The present invention discloses embodiments of multipliers that arrange data-converters to perform the multiplication function, operating in mixed-mode (both digital and analog), and capable of low power consumptions and asynchronous operations, which makes them suitable for low power ML and AI applications.

Owner:FAR ALI TASDIGHI

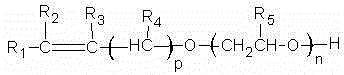

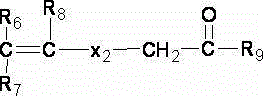

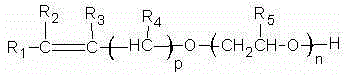

Polyether polycarboxylic acid water reducing agent and preparation method therefor

The present invention discloses a polyether polycarboxylic acid water reducing agent and a preparation method therefor. Macromonomers with relatively weak activity are used to replace part of macromonomers with better activities but with higher prices; unsaturated acid with lower cost is used to replace part of unsaturated acid with a higher price; a suitable redox initiation system is chosen; and by adjusting a proportion of an initiator, a molecular weight regulator, and a comonomer, polymerization is performed at the temperature of 25-30 DEG C, and a high performance polycarboxylic acid water reducing agent that is suitable for preparing low-grade concrete is prepared; and the method is low in material cost, simple in operation, and green and environmentally friendly; the water reducing performance of the water reducing agent can be equivalent to the performances of naphthalene-series and aliphatic water reducing agents, and the water reducing agent has an advantage of high cost performance.

Owner:CHINA BUILDING MATERIALS ACAD +1

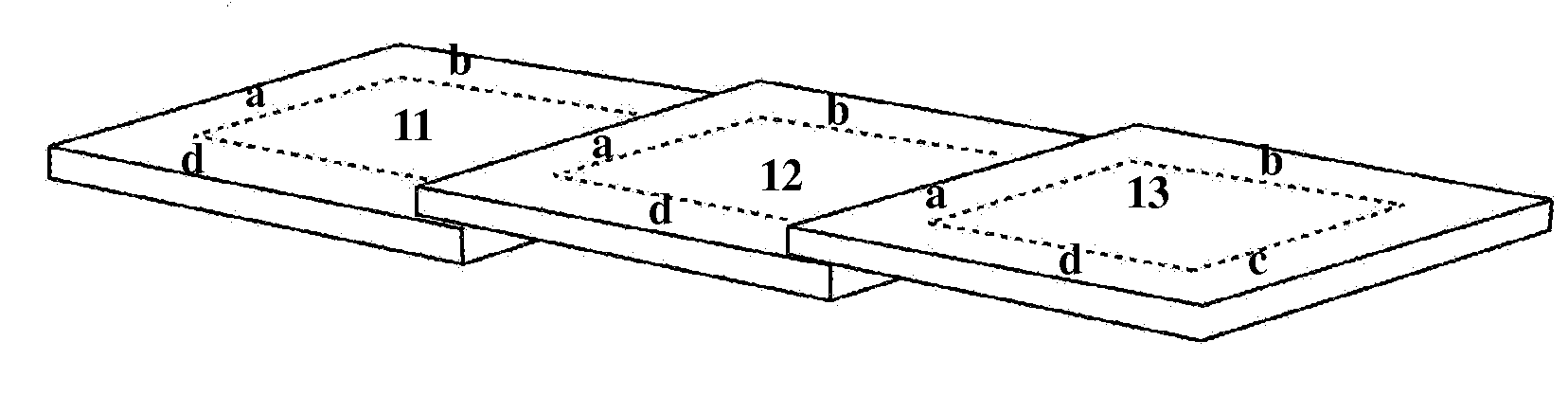

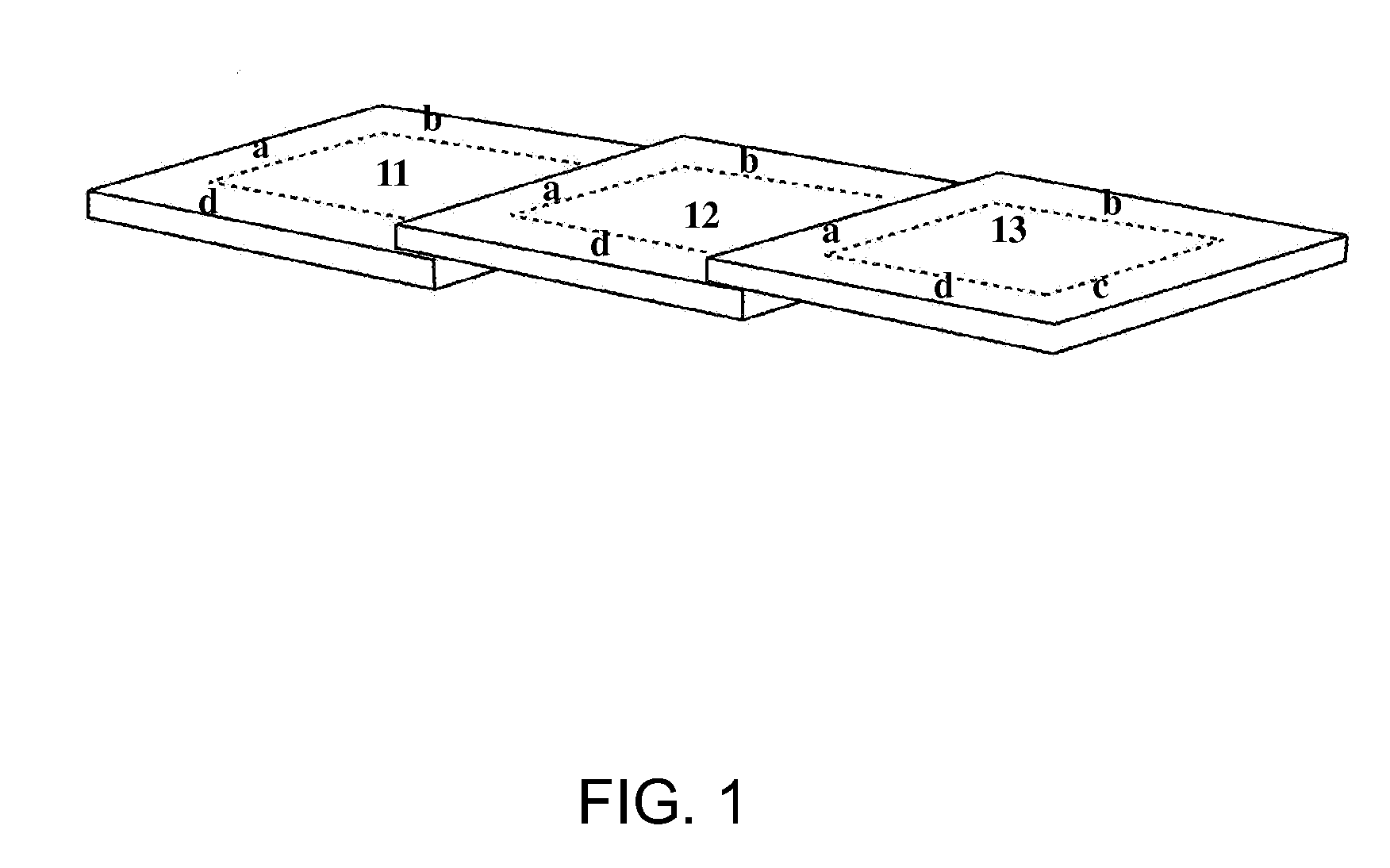

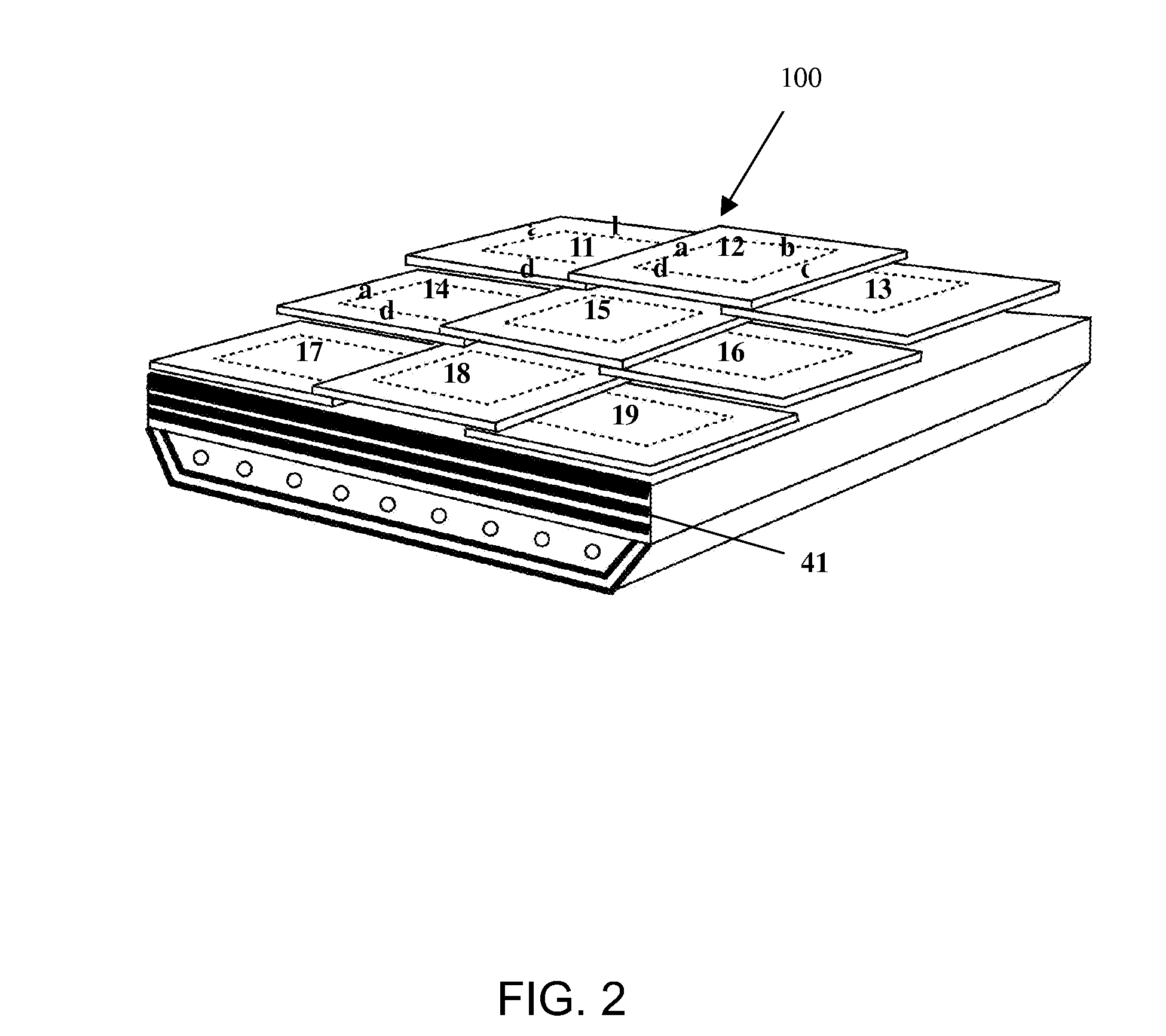

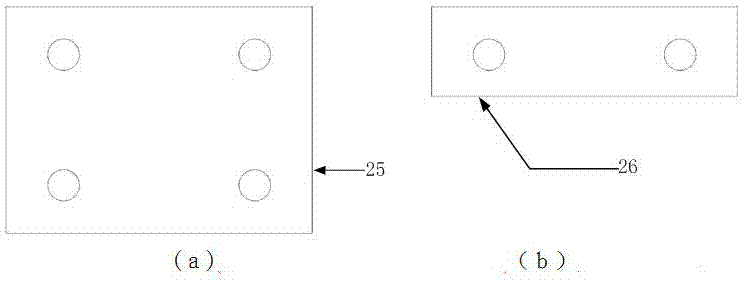

Liquid crystal display (LCD) panel assembling method

InactiveUS20080117161A1Increase display areaAvoid large gapsStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

Disclosed is a liquid crystal display (LCD) panel assembling method, comprising the following steps: preparing a plurality of unitary LCD panels; and aligning or overlapping any one side edge of a unitary LCD panel with any one side edge of another unitary LCD panel, as such forming a large assembled LCD panel having smaller gaps. Also, disclosed is an LCD display, comprising a plurality of unitary LCD panels; a plurality of pixel elements; and a backlight module. In the above-mentioned structure, the respective unitary LCD panel includes a display area and a non-display area composed of a plurality of side edges. Any one side edge of the unitary LCD panel is aligned or overlapped with any one side edge of another unitary LCD panel, thus forming an assembled LCD panel having larger display area and smaller gaps in-between. In addition, also disclosed is another method of assembling the LCD panel and a display for using the same, wherein side edge corners of a plurality of unitary LCD panels are chamfered before being assembled.

Owner:HU CHUNG MING

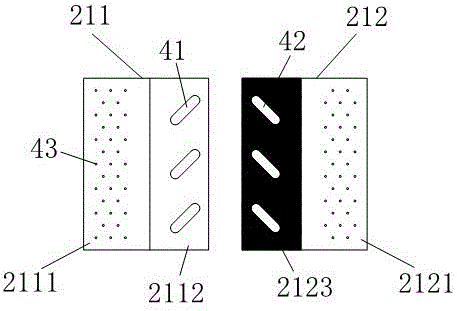

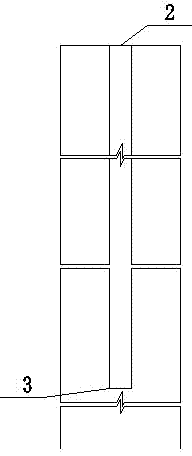

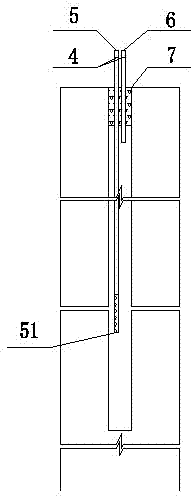

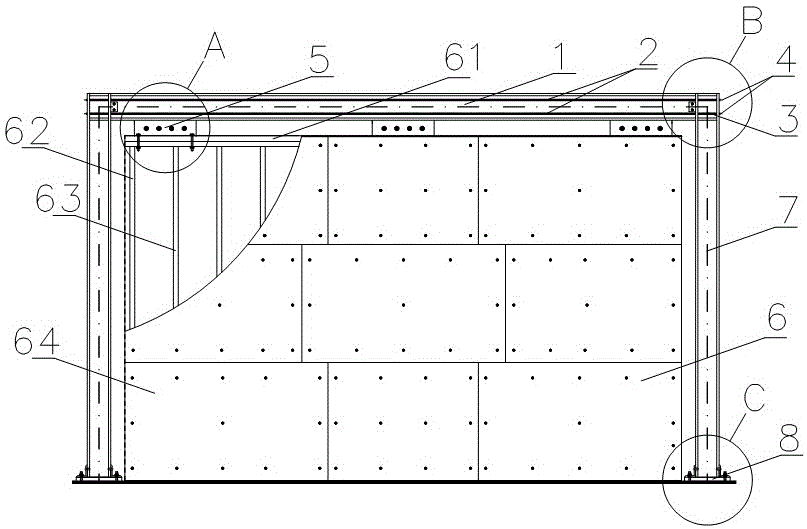

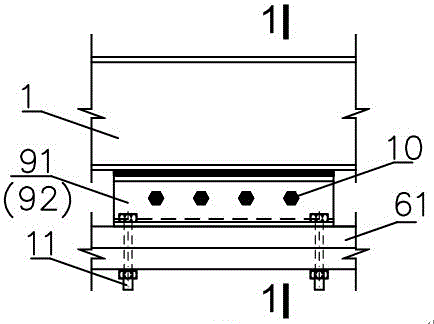

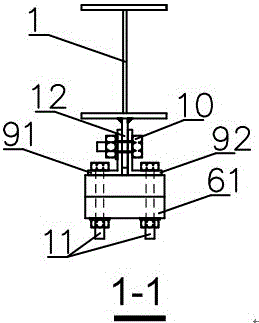

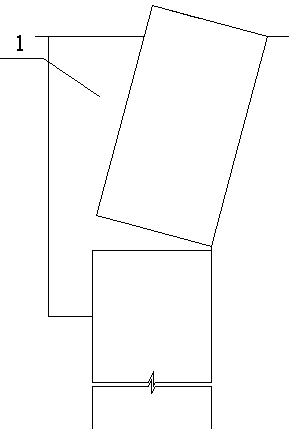

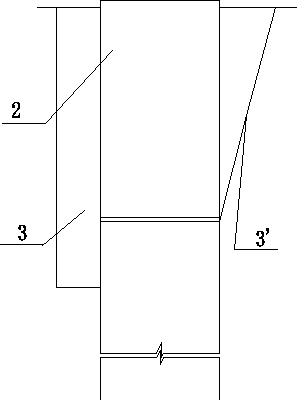

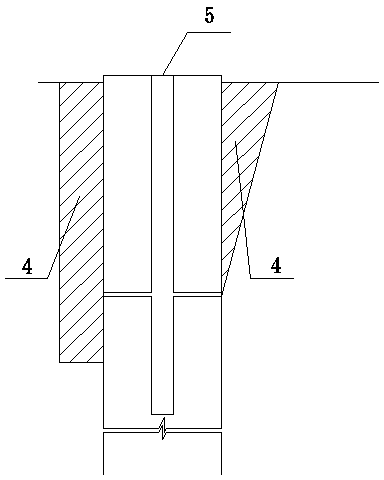

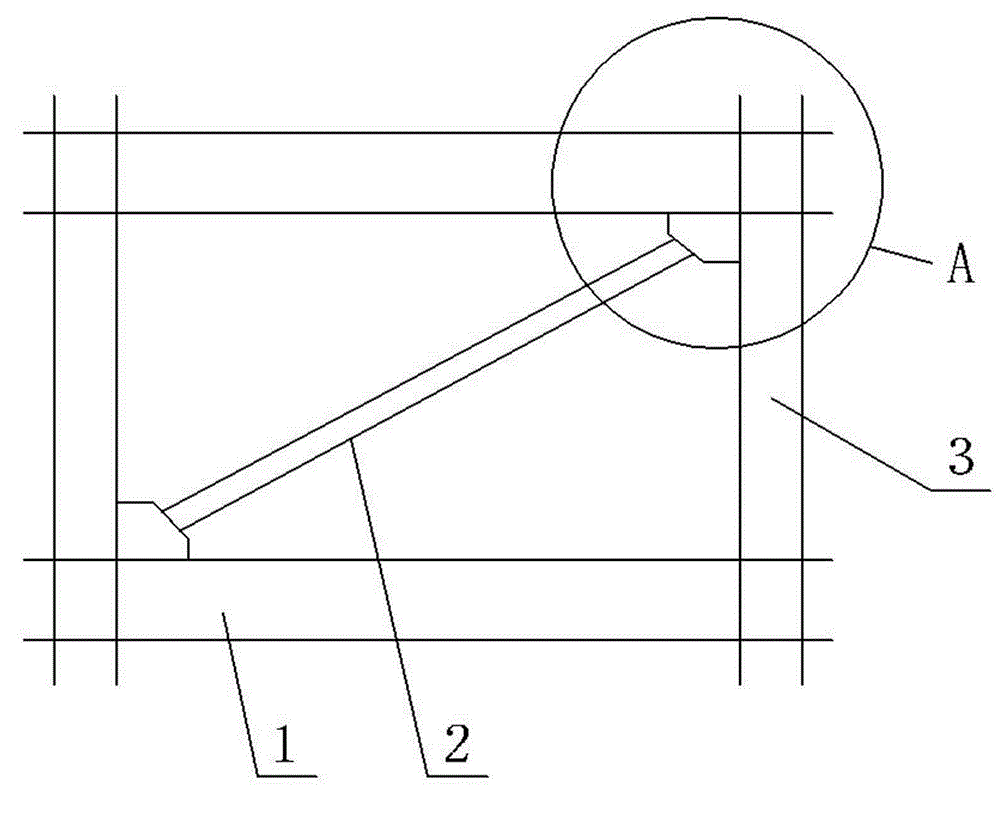

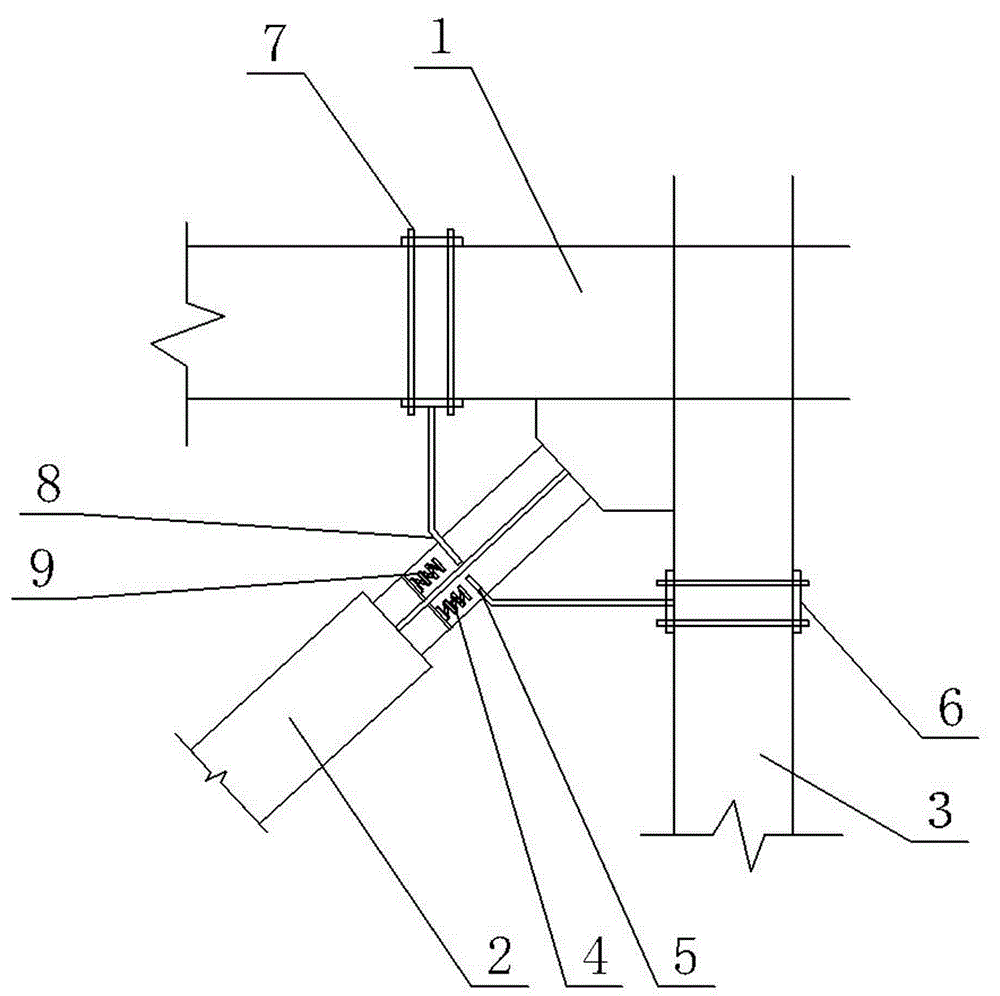

Orthogonal laminated wood shear wall with replaceable wall feet

InactiveCN107190879AIncrease lateral stiffnessAvoid damageWallsProtective buildings/sheltersEngineeringRebar

The invention relates to an orthogonal laminated wood shear wall with replaceable wall feet. The orthogonal laminated wood shear wall is composed of an orthogonal laminated wood shear wall body, box-type cushion tools, I-shaped flexible steel energy-dissipation members, steel cushion plates, embedded rebars and ribbed angle steel. Notches where members can be replaced are symmetrically reserved in the two feet of the orthogonal laminated wood shear wall body. The box-type cushion tools are firmly connected through the embedded rebars in the orthogonal laminated wood shear wall body. Upper flanges of the I-shaped flexible steel energy-dissipation members are firmly connected with the box-type cushion tools through bolts. Lower flanges of the I-shaped flexible steel energy-dissipation members are firmly connected through the embedded rebars in a foundation or a floor. In the middle of the bottom of the orthogonal laminated wood shear wall body, standard circular holes are formed in the face, making contact with the shear wall body, of the ribbed angle steel, and the angle steel is firmly connected with the orthogonal laminated wood shear wall body by nails or self-tapping screws via the circular holes. Long circular holes are formed in the other face of the angle steel, and the angle steel is connected with the floor or the foundation through high-strength bolts. The high-strength bolts apply pretension force, so that during a small earthquake, the shear resistance at the junction between the angle steel and the floor or between the angle steel and the foundation is sufficient, and during a medium earthquake or a severe earthquake, the high-strength bolts and the angle steel can slide relatively.

Owner:TONGJI UNIV

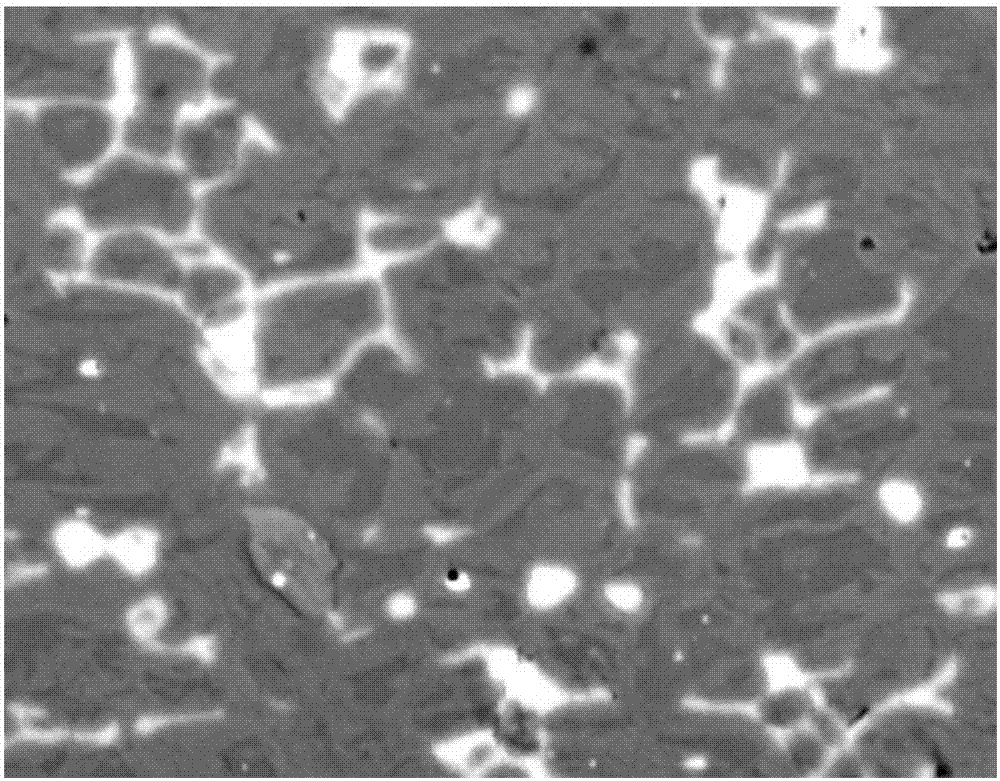

Rare earth permanent magnet material and preparation method thereof

ActiveCN108183021AReduce usageImprove performanceSolid state diffusion coatingInductances/transformers/magnets manufactureRare earthFluoride

The invention discloses a rare earth permanent magnet material and a preparation method thereof. The method comprises the steps of sintering treatment, diffusion heat treatment and tempering; during sintering treatment, composite powder for diffusion is laid on the surface of a neodymium-iron-boron magnetic powder layer and subjected to spark plasma sintering treatment, a neodymium-iron-boron magnetic body with a diffusion layer solidified on the surface is obtained, wherein the proportional expression of components of the composite powder for diffusion is H100-x-yMxQy, H is one or more of Dy,Tb, Ho and Gd metal powder, fluoride powder or oxide powder, M is Nd or Pr or Nd and Pr metal powder, and Q is one or more of Cu metal powder, Al metal powder, Zn metal powder and Sn metal powder; xis the atomic percent of the M component in the composite powder for diffusion, y is the atomic percent of the Q component in the composite powder for diffusion, x is within 0-20, and y is within 0-40. The preparation method is high in efficiency, good in diffusion effect and low in use amount of heavy rare earth.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Alloy cast steel used for high-speed train brake disc and high-speed train brake disc manufactured through alloy cast steel

The invention discloses alloy cast steel used for a high-speed train brake disc and the high-speed train brake disc manufactured through the alloy cast steel. The alloy cast steel in the claim 1 comprises, by weight percent, 0.18%-0.26% of carbon, 0.30%-0.50% of silicon, 0.68%-1.40% of manganese, smaller than or equal to 0.025% of phosphorus, smaller than or equal to 0.013% of sulfur, 1.10%-1.82% of chromium, 0.90%-1.50% of nickel, 0.65%-1.02% of molybdenum, 0.22%-0.34% of vanadium, smaller than or equal to 0.30% of the sum of the content of other components and the balance iron, wherein tungsten is smaller than 0.1%. The alloy cast steel has the main beneficial effects that grains are refined through reasonable matching and heat treatment of alloy elements such as manganese, nickel, chromium, molybdenum and vanadium and main components such as carbon and silicon in a cast steel material, hardenability and the thermal strength performance of the alloy cast steel material are improved, the constant-temperature strength and the high-temperature strength are greatly improved, and the good comprehensive mechanical property is achieved. The brake disc manufactured through the alloy cast steel can completely meet the technical requirement for use of high-speed trains under the working condition.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Preparation method for rare earth permanent magnet material

PendingCN107146670AReduce usageImprove performanceSolid state diffusion coatingInductances/transformers/magnets manufactureRare-earth elementSurface cleaning

The invention relates to a preparation method for a rare earth permanent magnet material. The preparation method comprises the steps of weighing powder of three kinds of raw materials of H, M and Q according to atomic percentage contents in a general formula of H<100-x-y>M<x>Q<y>, and performing mixing and screening processing in nitrogen or other oxygen-less environment to obtain composite powder; next, performing mechanical processing on a sintered NdFeB magnet to obtain specific shapes and dimensions, and performing surface cleaning and drying to obtain a to-be-processed NdFeB magnet; next, enabling the composite powder to be attached to the surface of the to-be-processed NdFeB magnet through static in an oxygen-less environment; and performing vacuum heat treatment and tempering treatment in sequence to obtain the rare earth permanent magnet material. By adoption of the method, high efficiency, high binding force between heavy rare earth element attachment and the base magnet, and convenience in residual powder recycling are realized; and the coercivity of the prepared NdFeB magnet can be improved by 4,000-14,000Oe, the residual magnetism is only reduced by 1-2%, and the heavy rare earth usage amount can be saved by 30% compared with that of the equivalent-performance magnet.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Lost foam casting technology of duplex metal composition hammer head

InactiveCN104550723AImprove bindingImprove yieldFoundry mouldsFoundry coresLiquid metalLost-foam casting

The invention discloses a lost foam casting technology of a duplex metal composition hammer head. By lost foam casting method, high-chromium cast iron (liquid) at the head part and carbon steel (a solid) at the handle part are effectively bonded into the duplex metal composition hammer head; the ratio of the liquid metal volume to the solid metal volume for duplex composition casting is 5 to 1, and the bonding form of the two kinds of metal is mechanical bonding; when the volume ratio is 8 to 1, the bonding is firm so as to form good bonding; when the volume ratio is 10 to 1, the bonding form belongs to metallurgical bonding, and the bonding surface is extremely firm; the volume ratio of the two kinds of metal is 8.7 to 1, and he requirement of firm bonding is met. The lost foam casting technology has the beneficial effects that the technological technique is simple, the production cost is low, the yield is high, and the economical and popularization value is obvious.

Owner:QINGDAO TIANHENG MACHINERY

Treatment method of deviation and fracture remediation of pile body of filling pile

The invention discloses a treatment method of deviation and fracture remediation of a pile body of a filling pile. The treatment method of the deviation and fracture remediation of the pile body of the filling pile is characterized by comprising the following steps: 1) dynamically determining the defect position of the pile under low stress; 2) rectifying the deviation of the pile body; 3) drilling and coring the top of the pile, wherein the coring length exceeds the defect position, and is 1-2 times of the diameter of the pile body; 4) flushing holes with high pressure, namely clearing filled materials of mud and the like in the defect position; 5) clearing the holes, namely returning sink residue in core holes out of the core holes; 6) filling the holes by high-pressure cement paste, namely filling cracks in the defect position; 7) inserting pipes, namely inserting slurry filling pipes, special accelerator pipes and paste discharge pipes; 8) sealing the holes, namely sealing the top parts of the core holes; 9) filling paste under high pressure, namely filling cement paste into the core holes; 10) carrying out backfill consolidation grouting on a soil discharge area and an empty hole area close to the pile. The method provided by the invention is simple and feasible, the working period of filling pile quality defect remediation treatment is short, the remediation construction cost is low, the original engineering design change is small, the quality of the remedied pile is reliable, and he original defect pile can be remedied and can achieve the standard through low-stress dynamic repeated determination.

Owner:浙江省岩土基础有限公司

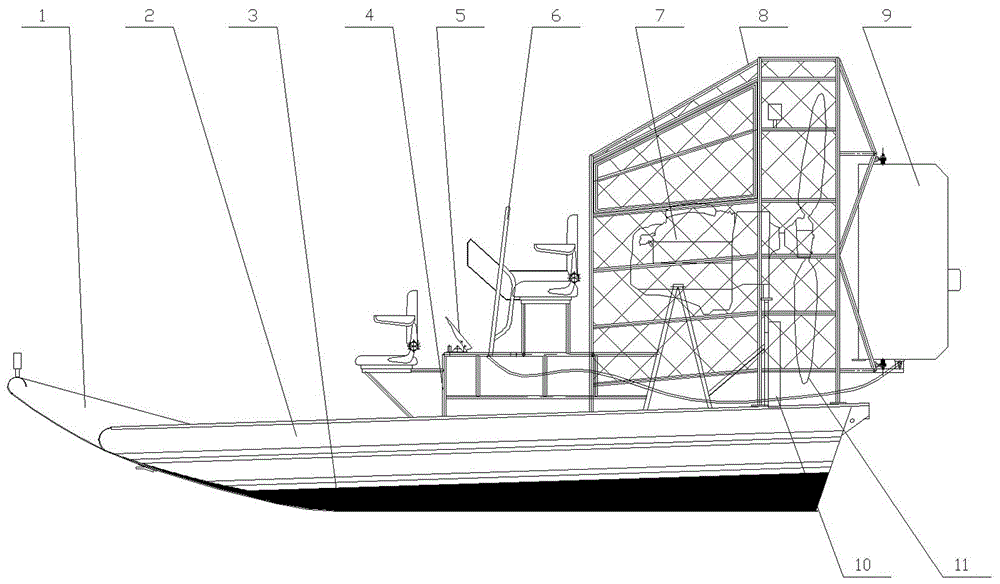

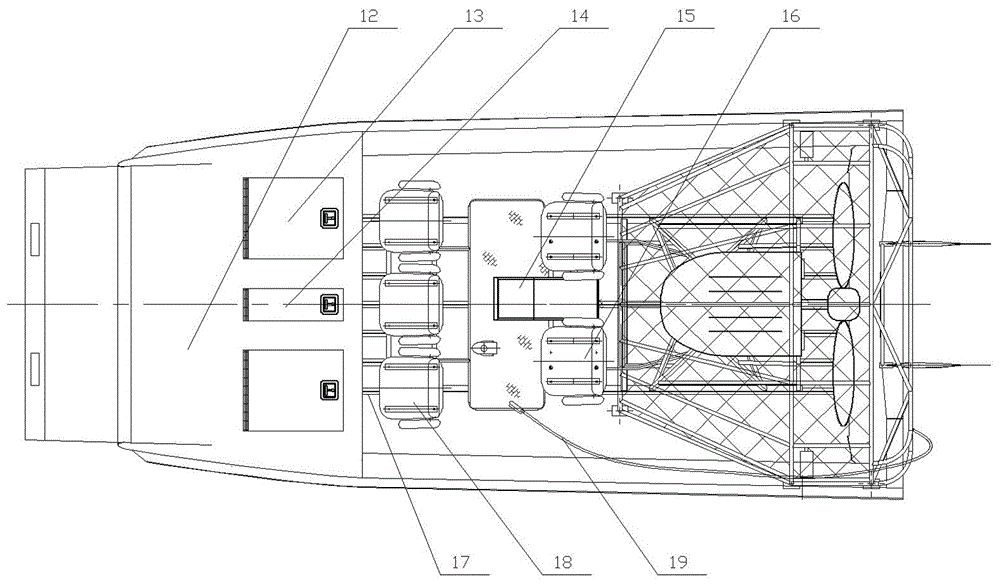

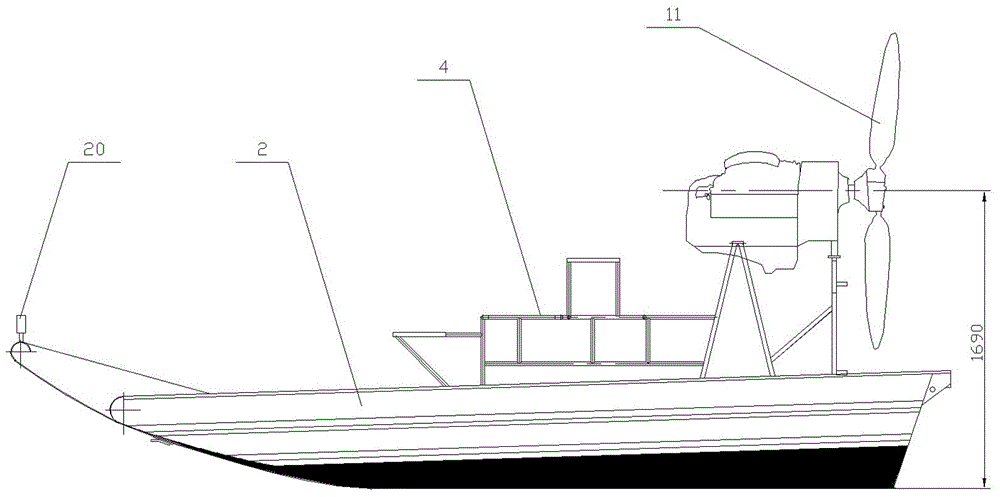

Air boat

InactiveCN105711790ACost-effective advantageEasy to maintain and repairPropulsion power plantsAir acting propulsive elementsPower performanceMarine engineering

The invention discloses an air boat which comprises a hull.An upper loading support is arranged in a cabin of the hull.A power device is installed on the upper loading support.A deck of the hull bends forward and is in a shape that the front is low and the rear is high.The power device is located at the one-third position of the rear portion of the hull.After the hull is in water, the deck is in a horizontal state naturally, and the axis of a rotating shaft of the power device is parallel to the plane of the hull bottom.Supra polymer PE plates are attached to the hull bottom and the two sides of the hull.The supra polymer PE plates and the hull are fixedly connected through countersunk head self-tapping screws and sealant.Power performance of the air boat is improved, the bearing ability of the hull is improved, and advancing resistance of the hull in the complex environment is reduced.

Owner:FUSHUN FUYUN ANYI LIFESAVING EQUIP

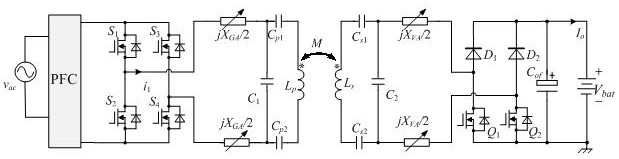

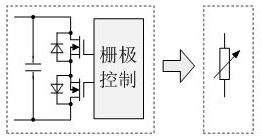

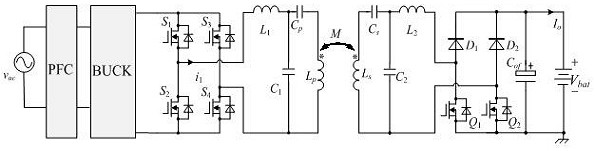

Wireless electric energy transmission device for improving system interoperability and control method

ActiveCN112994269AImprove interoperabilityHigh Efficiency Power TransmissionBatteries circuit arrangementsCharging stationsMode controlHemt circuits

The invention discloses a wireless electric energy transmission device for improving system interoperability and a control method. The device comprises a power factor correction circuit, an inverter circuit, a resonance unit, a rectification circuit, a filter circuit and a load which are sequentially cascaded, and also comprises a source side regulator, an inverter mode controller and a load side regulator. By switching the working modes of the inverter circuit and the rectifying circuit, with a bus voltage regulation and controllable rectifying technology, interoperation and high-efficiency electric energy transmission of the IPT system are realized, and multi-gear power level transmission requirements can be met in a wide load range and a wide coupling coefficient range. According to the invention, the interoperation requirements of three types of power levels and three types of energy transfer distances of EV WPT system vehicle-mounted end equipment are met by using one set of device, additional circuit elements do not need to be added in the aspect of circuit topology, the system cost and the installation space are effectively reduced, and the cost performance is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

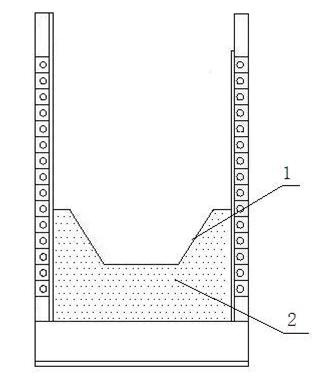

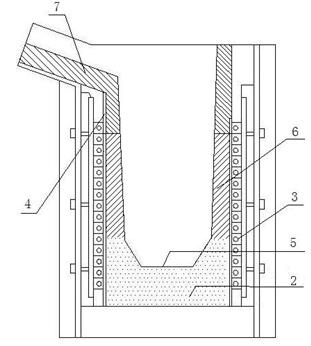

Intermediate-frequency induction smelting furnace lining

The invention provides an intermediate-frequency induction smelting furnace lining which comprises the following main components in percentage by mass: 20-25% of Al2O3, 50-55% of MgO, 5-10% of ZrO2, 15-20% of Cr2O3 and the balance of impurity. The material is prepared from the following components in the following particle sizes: 25-30% of 3-6mm component, 15-20% of 1-3mm component, 15-20% of 0-1mm component and 35-40% of 200-mesh component. The invention is suitable for an intermediate-frequency induction smelting furnace lining for smelting high manganese steel, stainless steel, alloy steel and carbon steel. The intermediate-frequency induction smelting furnace lining has the advantages of high refractory temperature, favorable alkali resistance, favorable neutral and weakly acidic slag corrosion resistance, long service life and high cost performance.

Owner:张君

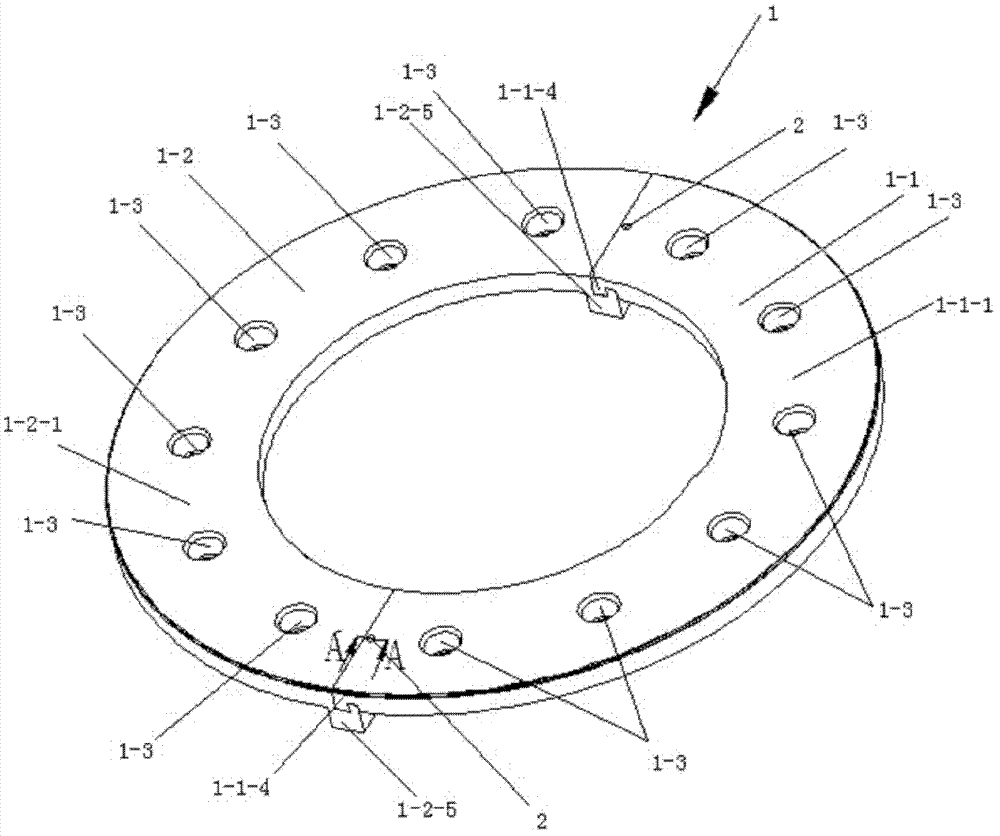

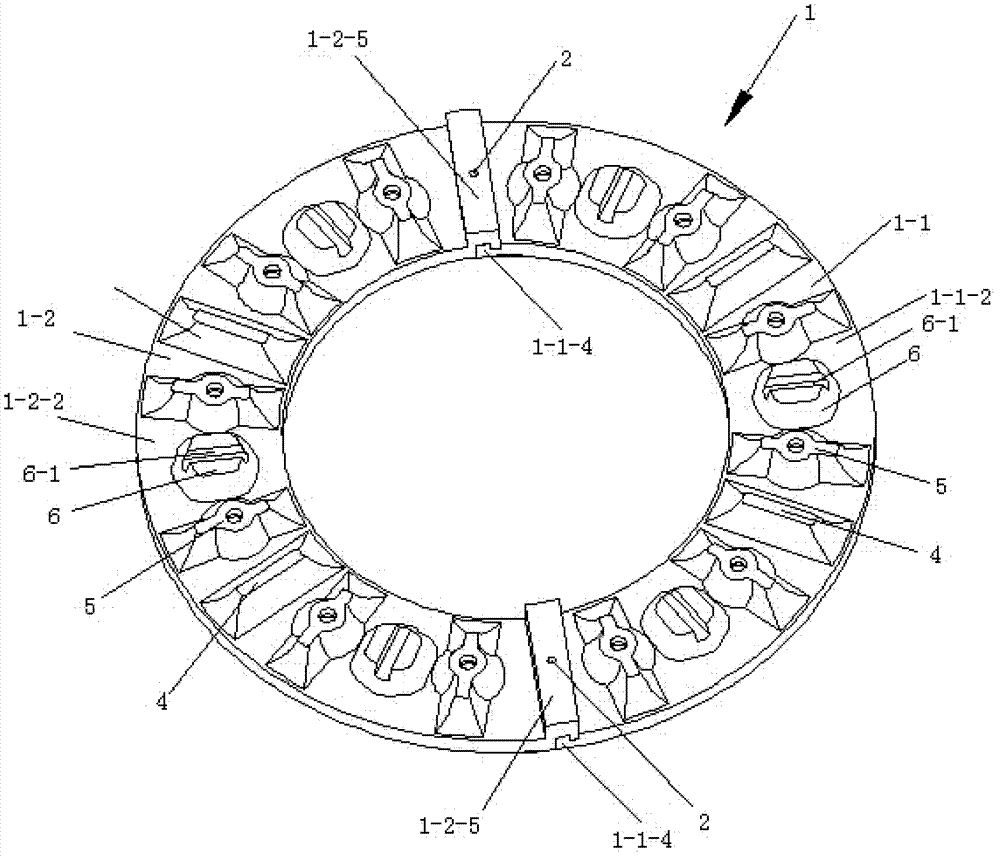

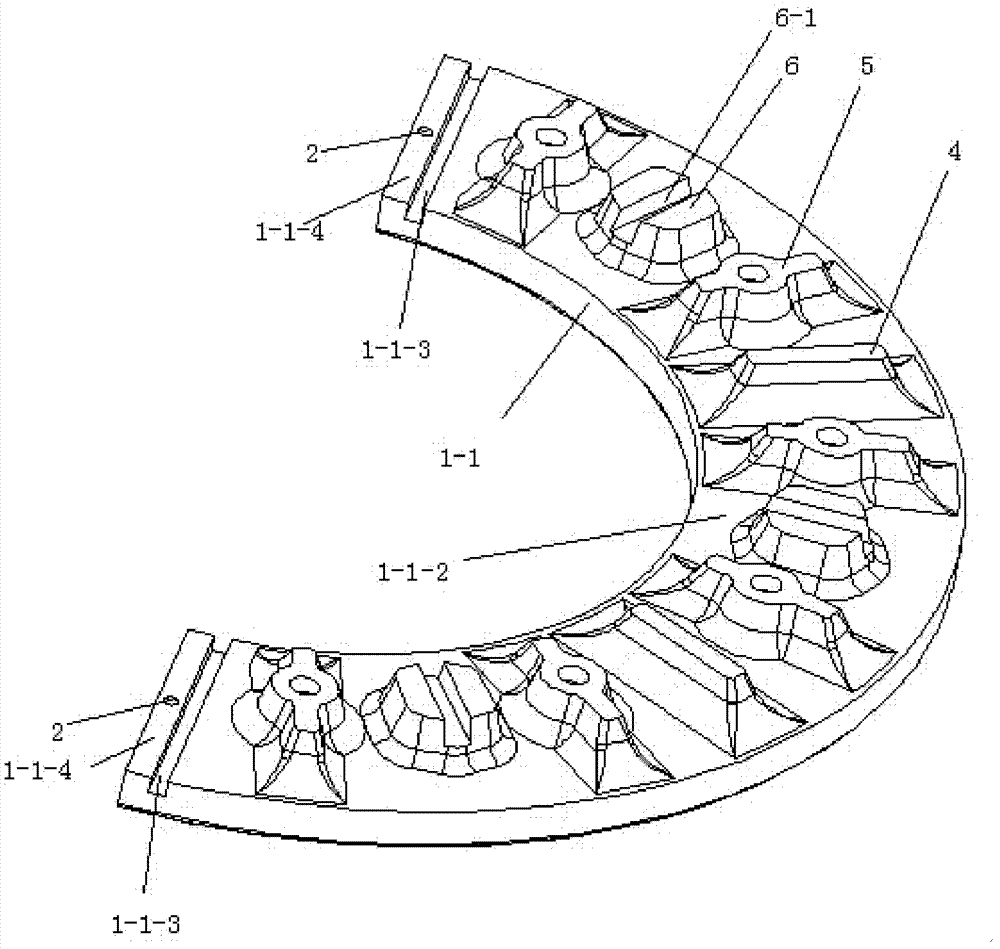

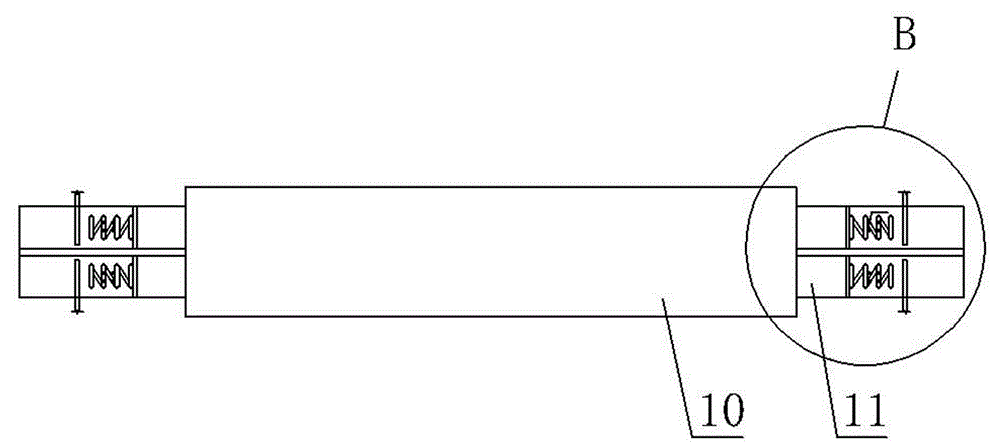

Split-type train brake disc

ActiveCN102900794ASimple connection structurePlay a positioning roleBraking discsEngineeringMechanical engineering

The invention discloses a split-type train brake disc which comprises a circular-ring-type disc body formed by assembling a first disc block and a second disc block; when the first disc block and the second disc block are assembled and connected, a first radial protrusion is positioned in a second radial groove; a second radial protrusion is positioned in a first radial groove; the first radial protrusion and the second radial groove are provided with communicated pin holes and / or the second radial protrusion and the first radial groove have communicated pin holes, and correspondingly, pin shafts pass through the corresponding pin holes on the first radial protrusion and the second radial groove and / or pin shafts pass through the corresponding pin holes on the second radial protrusion and the first radial groove. The split-type train brake disc provided by the invention is simple in connecting structure, and is convenient to position.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Mixed-mode quarter square multipliers for machine learning

ActiveUS10700695B1Cost-effective advantageGreat degreeElectric signal transmission systemsBiological modelsData transformationBinary multiplier

Multipliers are fundamental building blocks in signal processing, including in emerging applications such as machine learning (ML) and artificial intelligence (AI) that predominantly utilize digital-mode multipliers. Generally, digital multipliers can operate at high speed with high precision, and synchronously. As the precision and speed of digital multipliers increase, generally the dynamic power consumption and chip size of digital implementations increases substantially that makes solutions unsuitable for some ML and AI segments, including in portable, mobile, or near edge and near sensor applications. The present invention discloses embodiments of multipliers that arrange data-converters to perform the multiplication function, operating in mixed-mode (both digital and analog), and capable of low power consumptions and asynchronous operations, which makes them suitable for low power ML and AI applications.

Owner:FAR ALI TASDIGHI

Earthquake-proof wall and construction method thereof

InactiveCN104929277AReduced responseSimple structureWallsBuilding material handlingLarge earthquakesStructural rigidity

The invention discloses an earthquake-proof wall and a construction method thereof. According to the earthquake-proof wall, a rigidity enhancement structure is arranged between each end of anti-bending supports and a corner adjacent to the end on a square framework, wherein each rigidity enhancement structure comprises a first spring, a second spring, a first rigidity regulation plate which is fixed on a column of the corresponding corner and used for limiting the displacement of the first spring and a second rigidity regulation plate which is fixed on a beam of the corresponding corner and used for limiting the displacement of the second spring. The construction method of the earthquake-proof wall comprises the following steps that 1, the square framework is constructed, and the anti-bending supports are made; 2, the square framework and the anti-bending supports are connected. According to the earthquake-proof wall and the construction method thereof, when medium and small earthquakes occur, the existing anti-bending supports are mainly stressed and play a main energy consuming function; when a large earthquake occurs, the function of the rigidity enhancement structures is played, the structural rigidity is enhanced, and the structural response is reduced.

Owner:SHANDONG JIANZHU UNIV

High temperature-resistant polyaryloxadiazole nonwoven filter material and preparation method thereof

InactiveCN104801112AImprove continuous safe use performanceCost-effective advantageFiltration separationNon-woven fabricsFiberPolymer science

The invention relates to a high temperature-resistant polyaryloxadiazole nonwoven filter material and a preparation method thereof. The high temperature-resistant polyaryloxadiazole nonwoven filter material is prepared by blending 20-70wt% of a polyaryloxadiazole fiber with 30-80wt% of other heat resistant fibers. The polyaryloxadiazole fiber is added in the further blending of the original heat resistant fibers, so the filtering efficiency is guaranteed, and the continuous safe use performance of a filter felt in long-term high temperature environment is further improved. The filter felt and a filter bag made by adopting the filter material have higher cost performance than those made by adopting high temperature-resistant filter materials in the prior art.

Owner:SHANGHAI TANLON FIBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com