Method for repairing and treating quality defect of cast-in-place pile

A technology of quality defect and treatment method, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., to achieve the effect of low comprehensive cost, less process and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

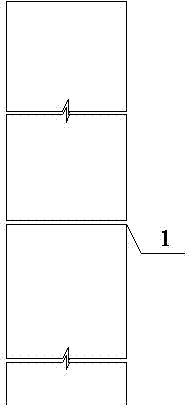

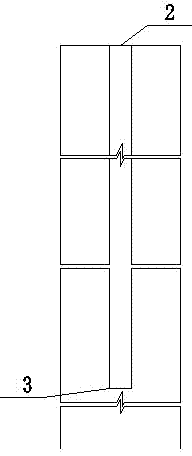

[0059] The pile foundation of this embodiment is a broken part (such as Figure 1 to Figure 4 shown), the specific process is as follows:

[0060] 1) According to the defect position 1 and defect degree of each pile obtained from the low-strain measurement, as well as the situation of the project, determine the depth of drilling and coring of each defective pile, prepare the construction plan and draw the chart and report to the project department, The construction parameters will be issued to the construction team, and the technical disclosure will be made to the workers of the team.

[0061] 2) Use a drilling machine to drill a hole ≥ 10cm on the pile top of the defective pile. When the diameter of the pile body is ≤ 80cm, place 1 hole in the center of the pile. Two, when the diameter of the pile body is ≥120cm, three or more holes are evenly distributed;

[0062] The coring depth exceeds the defect position, and the excess depth is 1-2 times the diameter of the pile body;...

Embodiment 2

[0075] Such as Figure 1 to Figure 4 Shown: the present embodiment pile foundation is a broken part.

[0076] Its specific technological process is as follows:

[0077] 1) According to the defect position 1 and defect degree of the pile obtained from the low-strain measurement,

[0078] 2) The diameter of the pile body is 1m. Use a drilling machine to drill two holes on the pile top of the defective pile, with a diameter of 11cm. In the same way, determine the defect location depth and defect degree again.

[0079] When drilling and coring the top of the pile, keep the drilling machine at a high level to ensure good verticality of the drilling.

[0080] 3) Lower the high-pressure rotary grouting drill pipe into the hole, use high-pressure water to spray and cut the defect position 1 times, cut and rinse, and remove the filling materials such as concrete debris and a small amount of mud at the defect position. Until the filling materials such as mud block and fine sand in d...

Embodiment 3

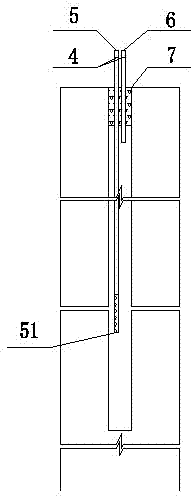

[0091] Such as Figure 5 to Figure 8 As shown: the pile foundation of this embodiment has two defective parts, and the specific method steps of the remedial treatment when the two defective parts are basically the same as that of embodiment 2, but because there are two defective parts, so the specific operation has its special place :

[0092] 1) According to the low-strain measurement, the upper and lower defect positions 1, 1' and the degree of defect of the pile, as well as the situation of this project, determine the depth of drilling and coring of the defect pile 。

[0093] 2) When the diameter of the pile body is 80cm, use a drilling machine to drill an 11cm hole in the center of the pile top of the defective pile, drill the core to a defect position below the pile body 1' below, and the depth beyond the pile body is 1.5 times the diameter;

[0094] When drilling and coring the top of the pile, keep the drilling machine at a high level to ensure good verticality of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com