Intermediate-frequency induction smelting furnace lining

An induction melting furnace and furnace lining technology, applied in the field of refractory materials, can solve the problems of loss of smelters, difficulty in uniform tamping, good thermal shock resistance, etc., and achieves simple construction method, labor saving, and good thermal shock stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 (smelting ZGMn13 high manganese cast steel):

[0024] A medium frequency induction melting furnace lining, the main component mass percentage of the material used is: Al 2 o 3 20%, MgO 55%, ZrO 2 Accounted for 8%, Cr 2 o 3 It accounts for 15%, and the rest is impurities; the particle size ratio of the materials used is: 3-6mm accounts for 30%, 1-3mm accounts for 15%, 0-1mm accounts for 15%, and 200 mesh accounts for 40%; the materials are dry mixed according to requirements Fully even.

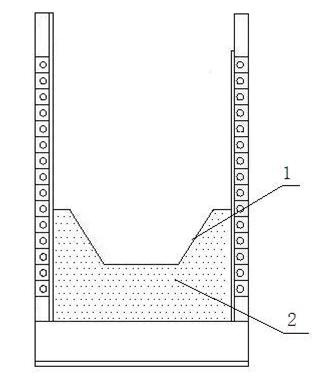

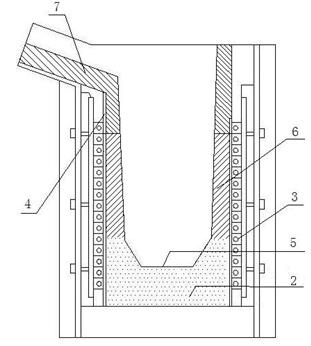

[0025] Such as figure 1 , figure 2 As shown, the knotting and knotting of the crucible of the intermediate frequency induction melting furnace includes the following structures: pit 1, hard sand layer 2, copper induction coil 3, dust-free asbestos cloth 4, furnace bottom 5, crucible wall 6, furnace collar And furnace mouth 7.

[0026] The construction and use method of the above-mentioned intermediate frequency induction melting furnace lining is as follows:

[00...

Embodiment 2

[0042] Example 2 (melting 304 stainless steel):

[0043] A medium frequency induction melting furnace lining, the main component mass percentage of the material used is: Al 2 o 3 Accounted for 23%, MgO accounted for 50%, ZrO 2 Accounting for 5%, Cr 2 o 3 It accounts for 20%, and the rest is impurities; the particle size ratio of the materials used is: 3-6mm accounts for 30%, 1-3mm accounts for 20%, 0-1mm accounts for 15%, and 200 mesh accounts for 35%; the materials are dry mixed according to requirements Fully even.

[0044] The method of construction and use of the above-mentioned intermediate frequency induction melting furnace lining is the same as that of Example 1.

[0045] The above-mentioned intermediate frequency induction melting furnace lining, the inspection results are as follows:

[0046] 1. After knotting the lining of the intermediate frequency induction melting furnace, pull out the iron core, and find that the bottom and wall of the furnace are smooth, ...

Embodiment 3

[0053] Embodiment 3 (smelting 45# carbon steel):

[0054] A medium frequency induction melting furnace lining, the main component mass percentage of the material used is: Al 2 o 3 20%, MgO 52%, ZrO 2 Accounted for 10%, Cr 2 o 3 It accounts for 16%, and the rest is impurities; the particle size ratio of the materials used is: 3-6mm accounts for 25%, 1-3mm accounts for 18%, 0-1mm accounts for 20%, and 200 mesh accounts for 37%; the materials are dry mixed according to requirements Fully even.

[0055] The method of construction and use of the above-mentioned intermediate frequency induction melting furnace lining is the same as that of Example 1.

[0056] The above-mentioned intermediate frequency induction melting furnace lining, the inspection results are as follows:

[0057] 1. After knotting the lining of the intermediate frequency induction melting furnace, pull out the iron core, and find that the bottom and wall of the furnace are smooth, clean and dense, without ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com