Preparation method of gradient precursor of cathode material for lithium ion batteries

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that the precursors are difficult to achieve uniform distribution of metal elements, hinder the practical application of materials, and have low tap density. High, cost-effective, short residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] NiSO 4 , CoSO 4 , MnSO 4 The molar ratios are Ni:Co:Mn=0.33:0.33:0.33 and 0.8:0.1:0.1 to prepare solutions: 1 and 2. The volume of solutions 1 and 2 are 18L and 23.5L respectively, and the total concentration is 2.0mol / L, prepare a 7.8mol / L sodium hydroxide solution, prepare a 11.0mol / L ammonia solution, use a metering pump to add solution 1 to solution 2 at a speed of 0.4L / h, and stir 150r / min at the same time, and stir evenly After that, solution 2, sodium hydroxide solution, and ammonia solution are simultaneously pumped into the reaction kettle with a metering pump. The flow rate of solution 2 is 0.6L / h, the flow rate of sodium hydroxide solution is 0.4L / h, and the ammonia solution is 0.15L / h. Under the condition of nitrogen protection, the gas flow rate is 0.1m3 / h, the temperature of the reaction kettle is controlled to 55°C, the pH value is 11.8, and the stirring speed is 750r / min. , The reaction can be stopped after both solutions 1 and 2 are consumed at the same...

Embodiment 2

[0034] NiCl 2 , CoCl 2 , MnCl 2 Prepare solutions 1 and 2 according to the molar ratio of Ni:Co:Mn=0.6:0.2:0.2 and 0.9:0.05:0.05 respectively. The volumes of solutions 1 and 2 are the same, the concentration is both 2.0mol / L, and 5.0mol / L is prepared Sodium hydroxide solution, the concentration of 8.5mol / L ammonia solution, use a metering pump to add solution 2, sodium hydroxide solution and ammonia solution into the reaction system at the same time, the flow rate of solution 2 is 180L / h, The flow rate of sodium solution is 100L / h, and the flow rate of ammonia water is 70 / / h. Inert gas is introduced, the nitrogen flow is 10m3 / h, the reaction volume temperature is 40℃, the pH value is 13.5, the stirring speed is 220r / min, and the reaction time (after 5h), the solution 1 is added to the solution with a constant flow pump In 2, the flow rate is 30L / h. Stir evenly at a speed of 150r / min. After the two solutions are beaten, the reaction ends. The whole reaction process does not ov...

Embodiment 3

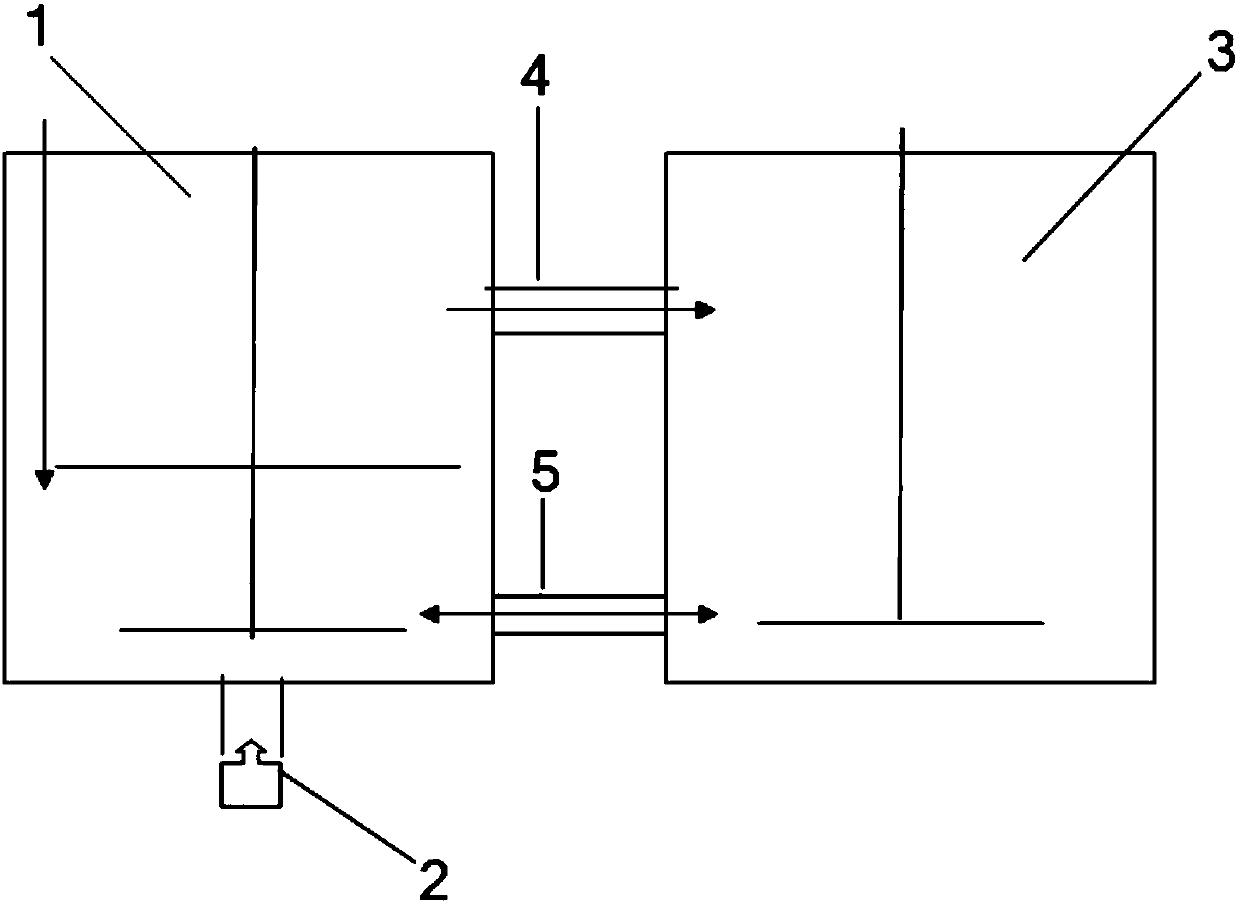

[0036] Use the designed reactor, with attached figure 1 The reactor is realized. Use NiSO 4 , CoSO 4 , AlSO 4 Prepare 1.9mol / L solution 1, the ratio is NCA=0.8:0.1:0.1. Use NiSO 4 , CoSO 4 Prepare 1.9mol / L solution 2, the ratio is N:C=0.8:0.2. Solutions 1 and 2 have the same volume. Prepare 6.0 mol / L potassium hydroxide solution, prepare 12.0 mol / L ammonia solution, add solution 1 to solution 2 with a constant flow pump at a speed of 20L / h, stir evenly at 150r / min, then add the solution 2. Sodium hydroxide solution and ammonia water are simultaneously added to the reaction system with a metering pump, where the flow rate of solution 2 is 280L / h, the flow rate of sodium hydroxide solution is 150L / h, the flow rate of ammonia water is 80L / h, and the flow rate is nitrogen. 5m3 / h, control the temperature of the reaction vessel to 65°C, the pH value to 12.2, the stirring speed to 320r / min, and the amount of solution 1 and 2 to stop the reaction after the reaction is completed. Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com