Special color-mixing method and special color-mixing equipment

A color mixing and special-shaped technology, which is applied in printing devices, offset rotary printing machines, printing and other directions, can solve the problem of inability to achieve a variety of color mixing, and achieve the effect of being easy to master and ensuring the accuracy of movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

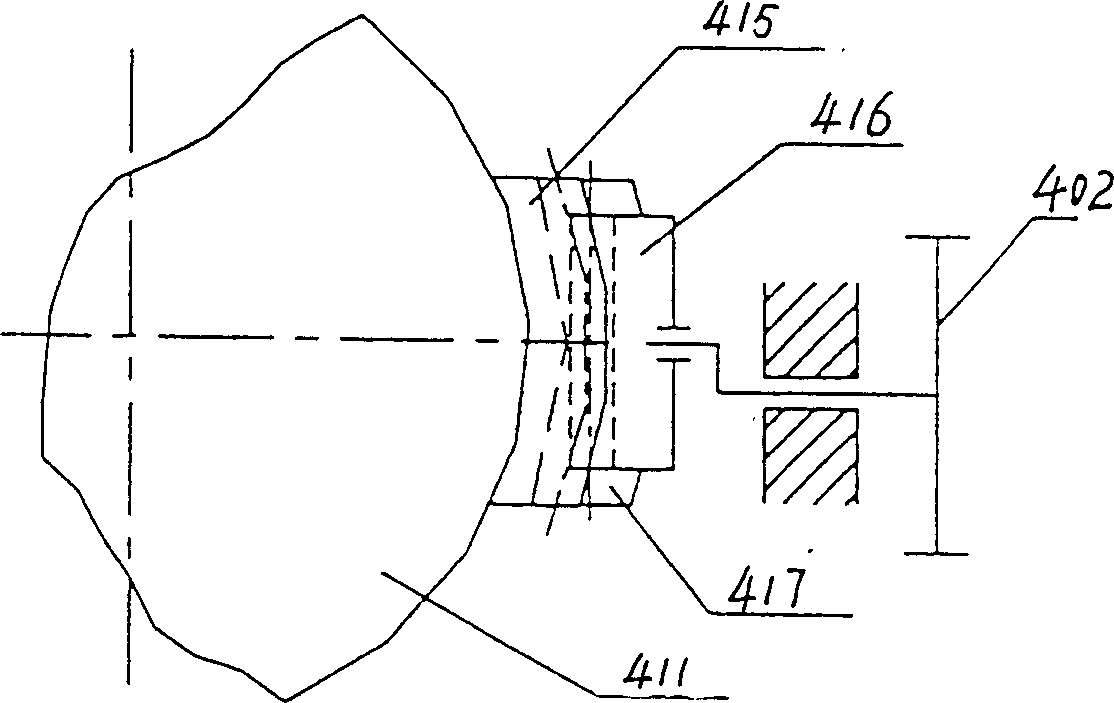

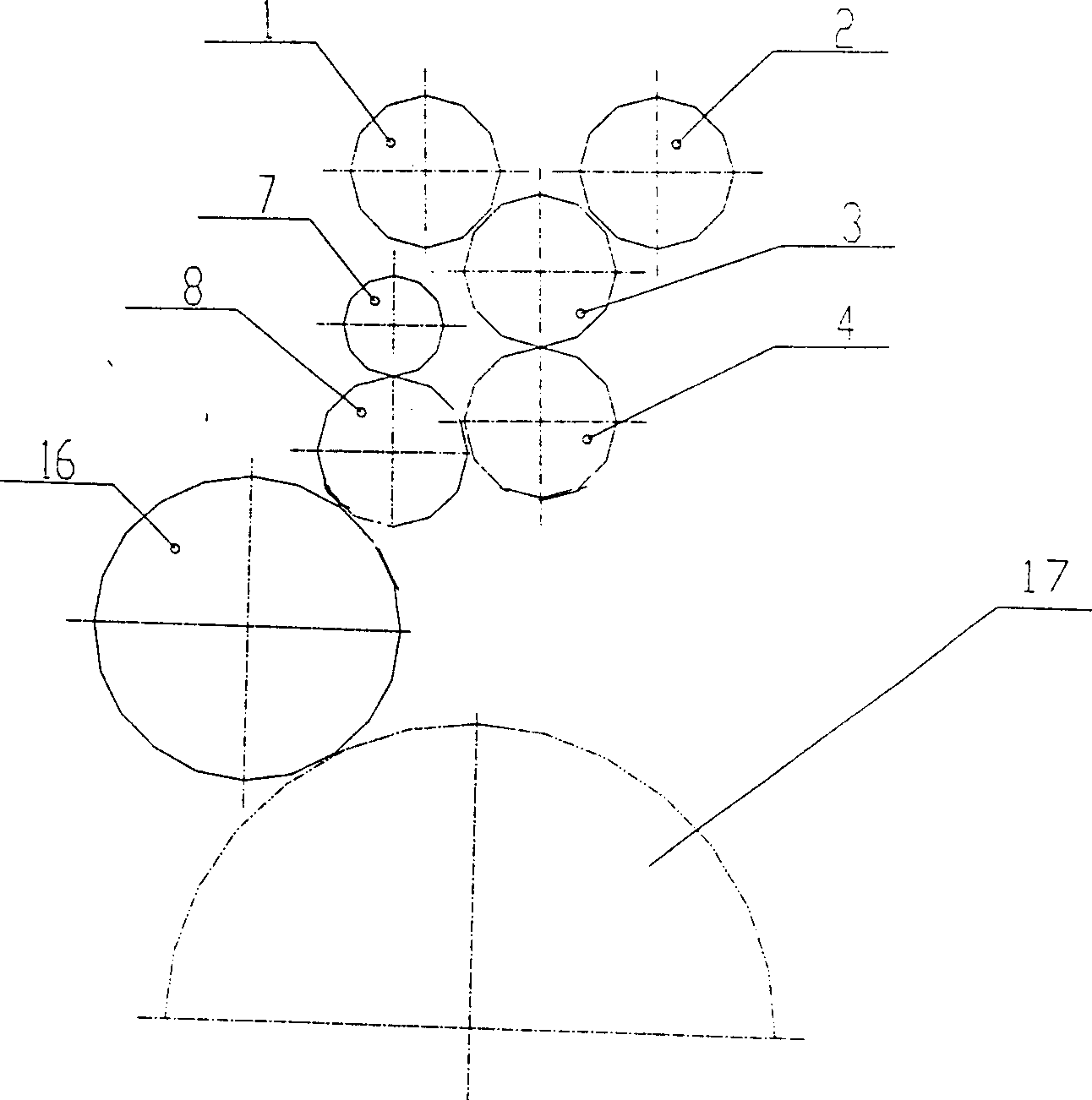

[0024] Such as figure 2 , 3 As shown, the special-shaped color mixing device proposed by the present invention includes at least two color mold rollers 1, 2, and a color collection roller 3 in rolling contact with the two color mold rollers. The color collection roller 3 transfers ink to the ink transfer roller 8 , the ink transfer roller 8 is in rolling contact with the ink distribution roller 7, and the ink transfer roller 8 transfers the ink to the form roller 16 (certainly, several ink transfer rollers 10, 13, 15, etc., and several ink transfer rollers can be set as required. Ink distribution rollers 9, 11, 12, 14, etc., such as Figure 2A shown), wherein at least one special-shaped color mixing roller 4 is arranged between the color collecting roller 3 and the ink transfer roller 8, and the special-shaped color mixing roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com