Automatic feeding equipment for symmetrical positions of paired workpieces

An automatic feeding and symmetrical technology, applied in the direction of conveyor objects, conveyor control devices, conveyors, etc., can solve the problems of unreasonable line laying and error superposition caused by many driving components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

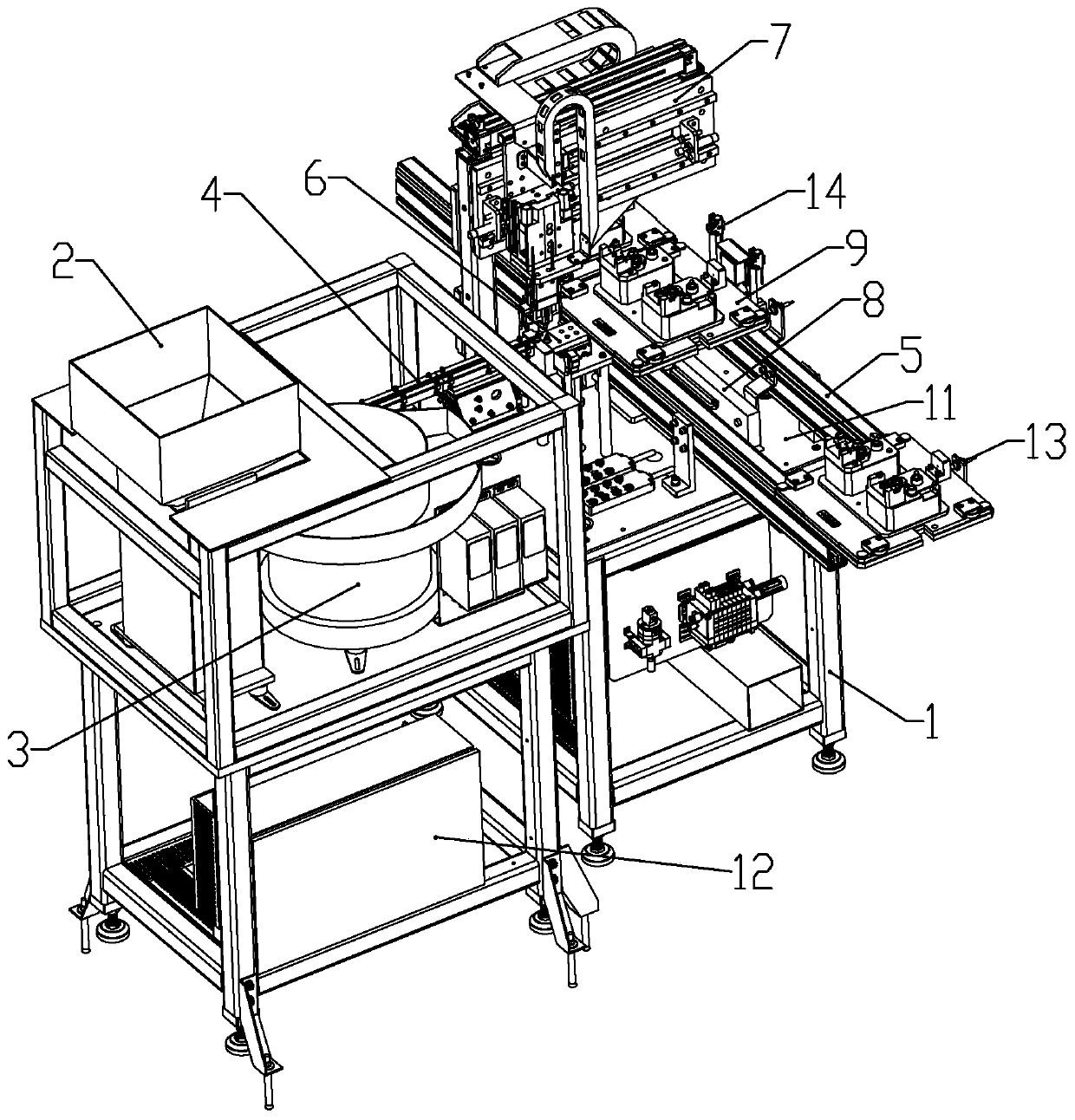

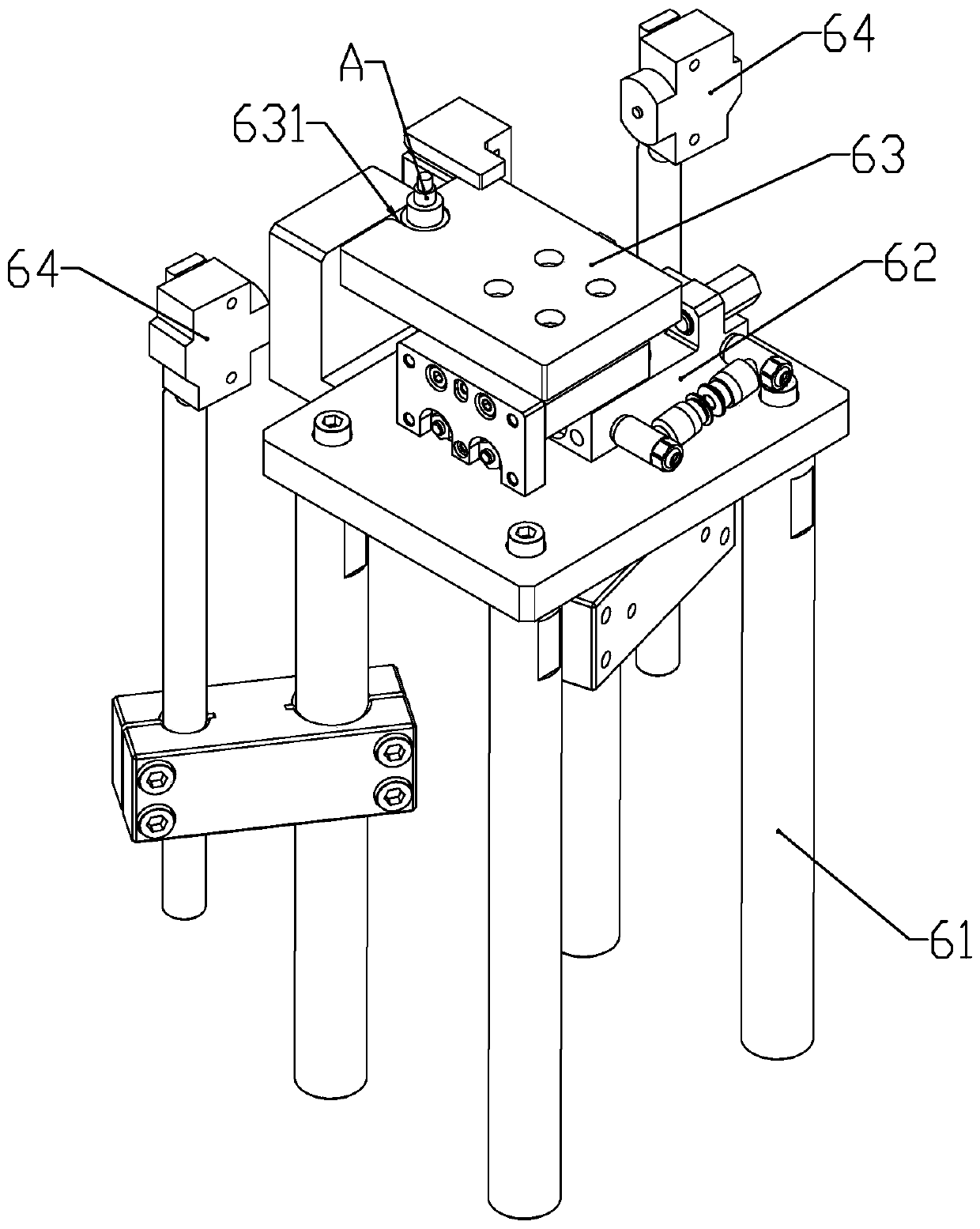

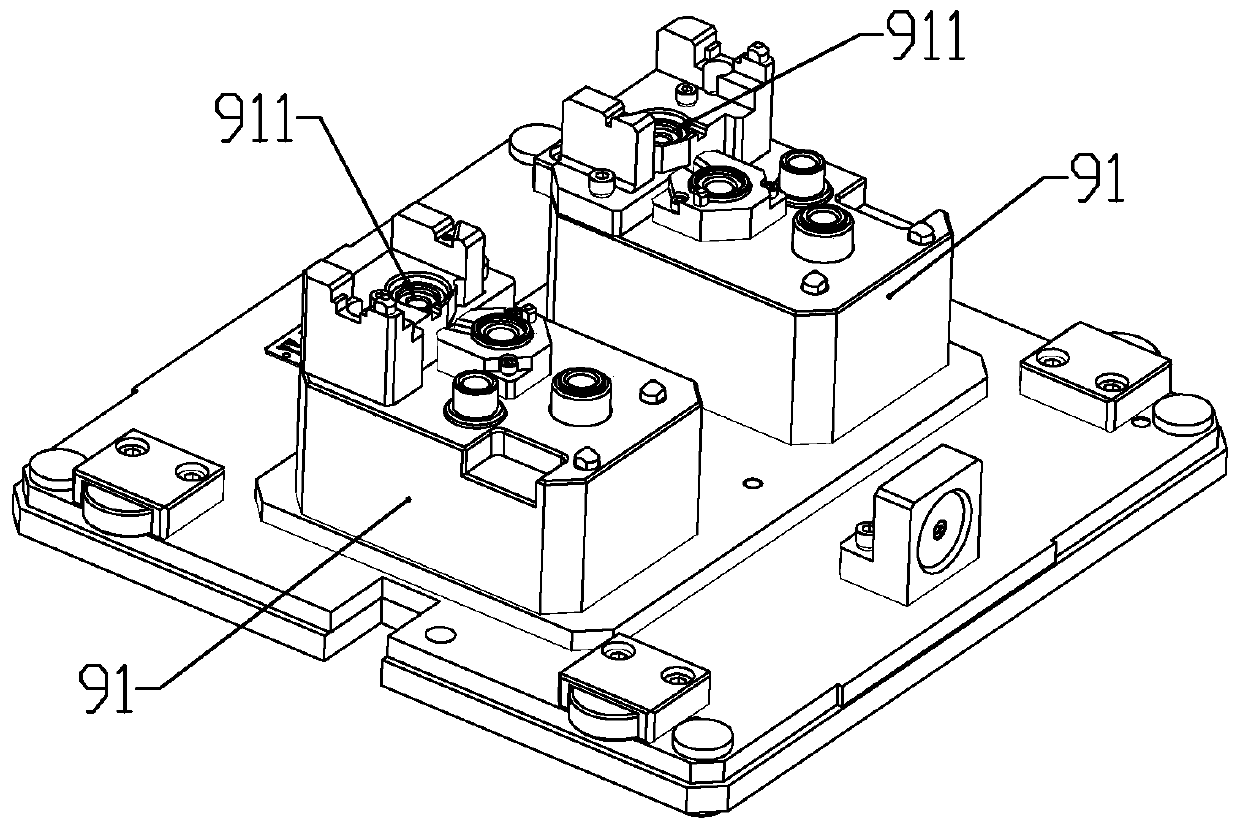

[0045] according to Figure 1 to Figure 12 As shown, a symmetrical position automatic feeding device for a pair of workpieces described in this embodiment includes a chassis 1, a hopper 2, a vibrating plate 3 installed on one side of the hopper for arranging the parts in sequence, and a vibrating plate installed on the The outlet of the vibrating plate is used to transport the feed rail 4 of the parts and the assembly line 5 installed on the chassis; the assembly line is provided with a carrier 9; the chassis is fixedly connected with a mounting plate 11; the mounting plate A material receiving part 6, a transplanting mechanism 7 for installing parts from the material receiving part on the carrier, and a positioning mechanism 8 for positioning the carrier are respectively installed on the upper part; the transplanting mechanism has no displacement along the direction of the assembly line and each The trajectory of the secondary movement is the same; the carrier moves to the su...

Embodiment 2

[0065] This embodiment makes the following improvements on the basis of Embodiment 1: no contact switch is installed on the transplanting mechanism; the third sensor only detects Components. In the initial state, the third sensor detects that there is no part in the corresponding part installation hole. After the transplanting mechanism grabs the part from the material receiving part, it controls the moving assembly to remain fixed. After the transplanting mechanism installs the part into the part installation hole , if there is a part detected by the third sensor, then the mobile assembly is controlled to work so that another part mounting hole is located at the third sensor, and at this time, the third sensor detects that there is no part in the part mounting hole, then repeat the above steps, and the rest of the steps Same as Embodiment 1; in the above steps, when the moving component moves the part installation hole located at the front end of the assembly line to the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com