A gradient color manufacturing method for 3D printing enamel

A technology of 3D printing and manufacturing method, which is applied in the directions of manufacturing tools, glass forming, glass manufacturing equipment, etc., to achieve the effects of convenient operation, improved viewing, and uniform gradient color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

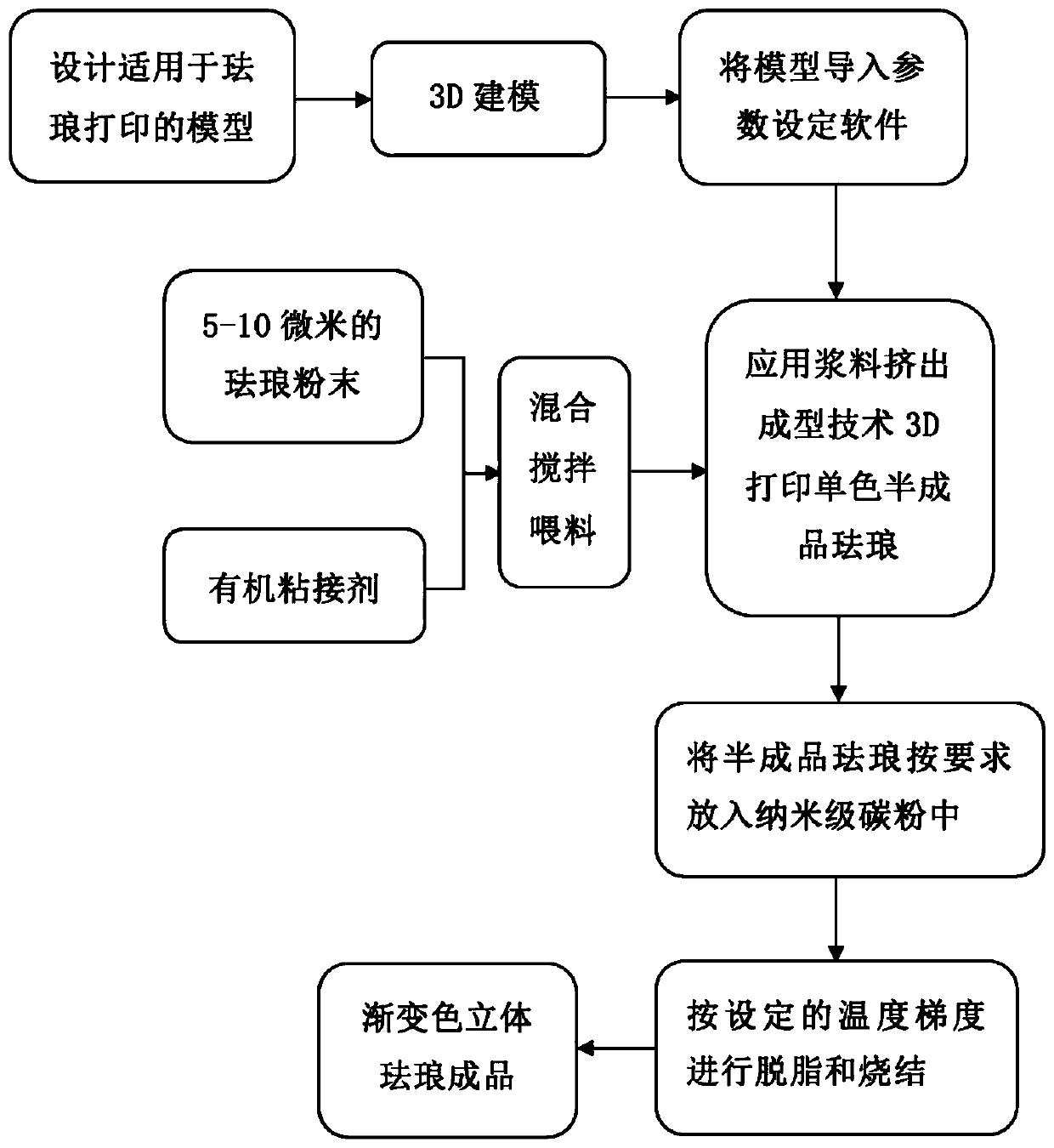

[0018] Please refer to figure 1 , the embodiment of the present invention provides a kind of gradient color production method of 3D printing enamel, comprises the following steps:

[0019] Model of S1 design enamel;

[0020] S2. Carry out 3D modeling according to the enamel model designed in step S1, and import it into the parameter setting software;

[0021] S3. Apply slurry extrusion molding technology to 3D print monochrome semi-finished enamel according to the model parameters in the imported parameter setting software. The semi-finished enamel is a three-dimensional structure without substrate support; apply slurry extrusion molding technology to 3D print monochrome The raw material of the semi-finished enamel is single color, the particle size ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com