Broadband circular polarization high-gain low-profile microstrip slot antenna capable of loading hyper-surface

A technology of microstrip slots and circular polarization, which is applied in the direction of slot antennas, antennas, antenna grounding devices, etc., can solve the problems of high profile, complex feeding structure, narrow polarization bandwidth, etc., and achieve low profile, high gain, and processing convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

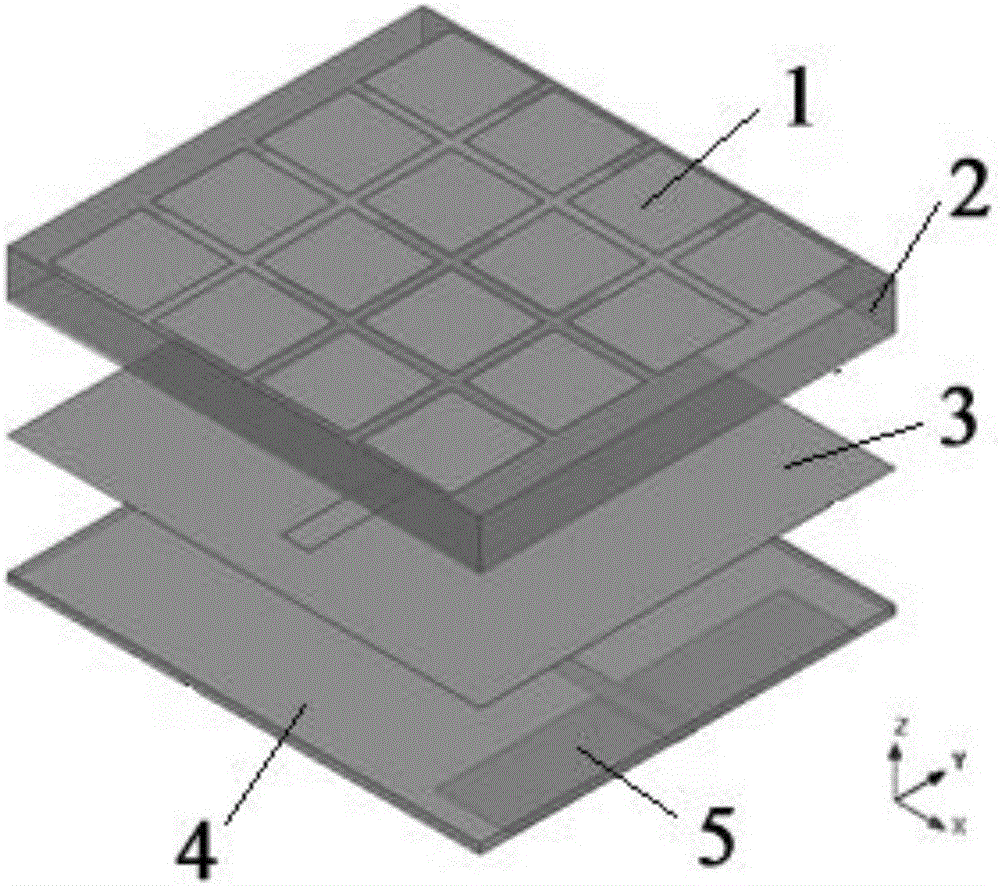

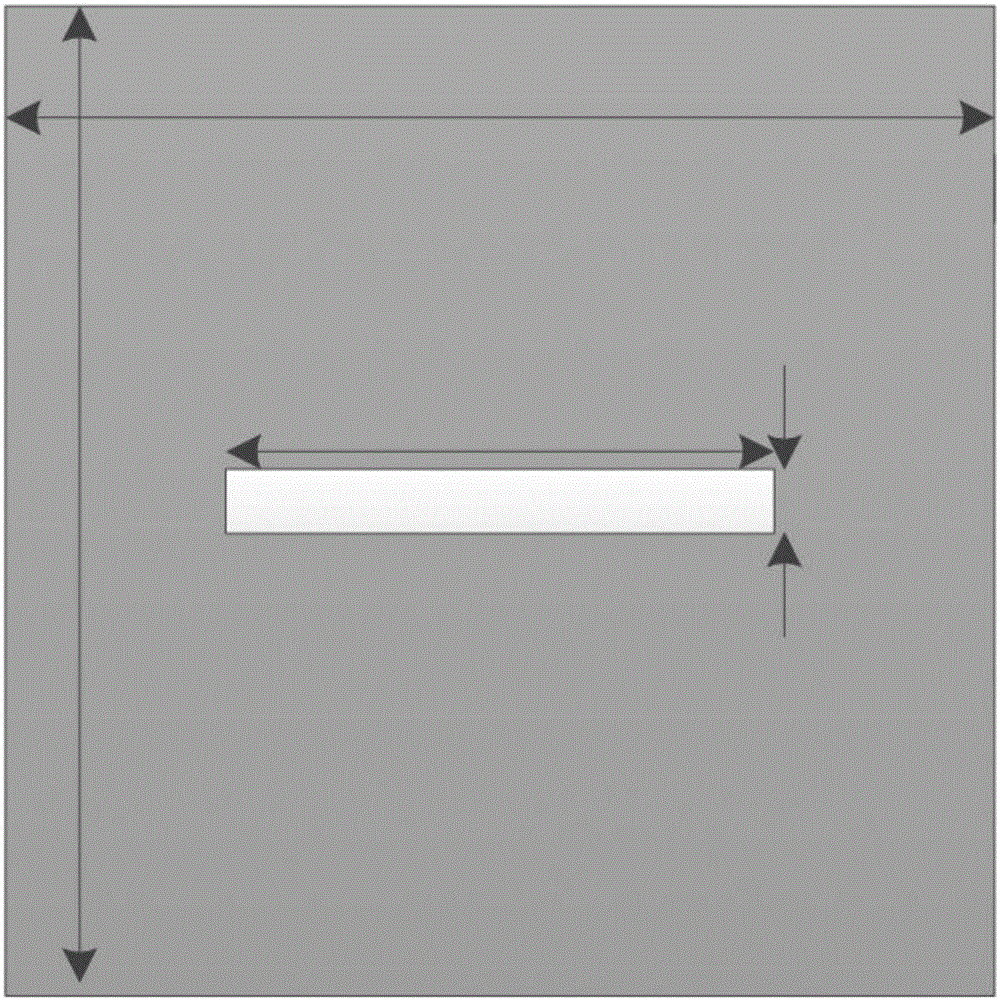

[0020] Such as figure 1 As shown, a wide-band circularly polarized high-gain low-profile microstrip slot antenna loaded with a metasurface can realize circularly polarized radiation in the 5.1-6.3GHz frequency band. A metal copper ground plate 3 with gaps and a lower dielectric substrate 4 , the upper surface of the upper dielectric substrate 2 is provided with a metal patch group 1 , and the lower surface of the lower dielectric substrate 4 is provided with a coplanar waveguide feeding structure 5 .

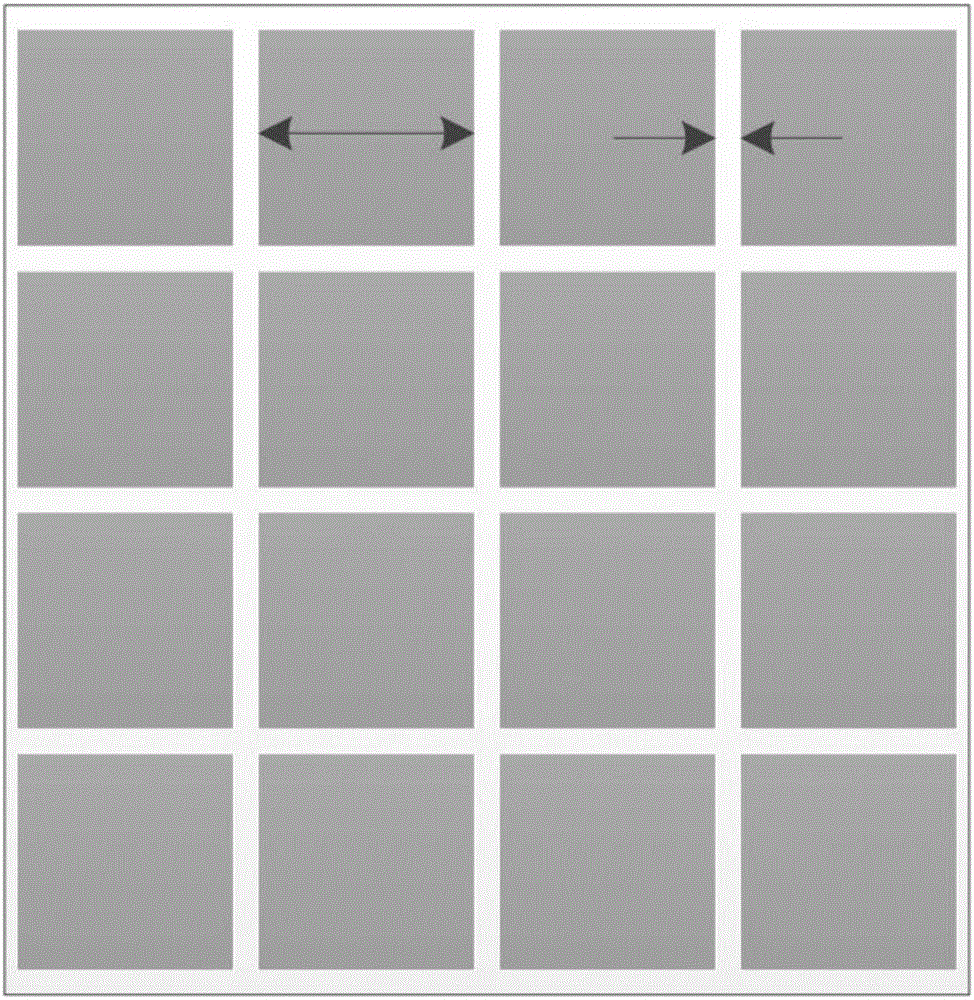

[0021] Such as figure 2 As shown, the metal patch group 1 is composed of 16 square chamfered metal patches arranged in a 4×4 array, the side length of the metal pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com