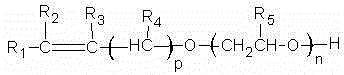

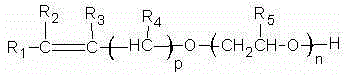

Polyether polycarboxylic acid water reducing agent and preparation method therefor

A technology of water reducing agent and polycarboxylic acid, applied in the field of polyether polycarboxylate water reducing agent, can solve the problems of reducing water reducing ability, difficulty in production and operation, etc., achieving low material cost, improving comb molecular structure, and improving operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

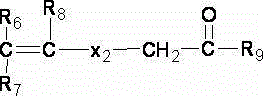

Method used

Image

Examples

Embodiment 1

[0044] Add 84g of methallyl polyoxyethylene ether macromonomer (molecular weight 2400) into a four-necked glass flask as a reaction kettle equipped with a stirrer, a thermometer, and a peristaltic pump dropping device, and then add 36g of allyl polyoxyethylene ether macromer Add 75g of water to oxyethylene ether (molecular weight: 2400), stir and dissolve at 30°C under normal pressure to form a fully dissolved solution.

[0045] Add 15.5g of acrylic acid into the beaker of material A, and dissolve it with 10.3g of water to make material A for use.

[0046] Add 0.4g of potassium sodium tartrate, 0.6g of mercaptoacetic acid, and 0.6g of mercaptopropionic acid into the beaker of material B, and dissolve it with 26.6g of water to prepare material B for use.

[0047] Add 1.67g of 30% hydrogen peroxide into the reactor, and at the same time use the peristaltic pump dripping device to start adding materials A and B into the reactor, and drop them at a constant speed within 4 hours.

...

Embodiment 2

[0052] Add 101g of methallyl polyoxyethylene ether macromonomer (molecular weight 2400) into a four-necked glass flask as a reaction kettle equipped with a stirrer, a thermometer, and a peristaltic pump dropping device, and then add 22g of allylpolyoxyethylene ether macromonomer (molecular weight: 2400). Add 77g of water to oxyethylene ether (molecular weight: 1200), stir and dissolve at 30°C under normal pressure to form a fully dissolved solution.

[0053] Add 18.6g of acrylic acid into the beaker of material A, and dissolve it with 10.3g of water to make material A for use.

[0054] Add 0.5gV to the material B beaker C , 1.4g of sodium methacrylate was dissolved in 26.6g of water to make material B and set aside.

[0055] Add 1.93g of 30% hydrogen peroxide to the reactor, and at the same time use the peristaltic pump dripping device to start adding materials A and B to the reactor, and drop them at a constant speed within 4 hours.

[0056] The reaction kettle was heated u...

Embodiment 3

[0060] Add 111g of methallyl alcohol polyoxyethylene ether macromonomer (molecular weight 2400) into a four-necked glass flask as a reaction kettle equipped with a stirrer, a thermometer, and a peristaltic pump dropping device, and then add 12g of allyl alcohol polyoxyethylene ether macromonomer (molecular weight: 2400). Add 77g of water to oxyethylene ether (molecular weight: 600), stir and dissolve at 30°C under normal pressure to form a fully dissolved solution.

[0061] Add 20.4g of methacrylic acid into the beaker of material A, and dissolve it with 13.6g of water to make material A for use.

[0062] Add 0.6gV to the material B beaker C , 0.8g mercaptoacetic acid, 0.8g mercaptopropionic acid, dissolved in 35.1g water to make material B, set aside.

[0063] Add 2.19g of potassium persulfate to the reactor, and at the same time use the peristaltic pump dripping device to start dripping materials A and B into the reactor, and drop them at a constant speed within 4 hours.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com