Patents

Literature

125results about How to "Convenient performance testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

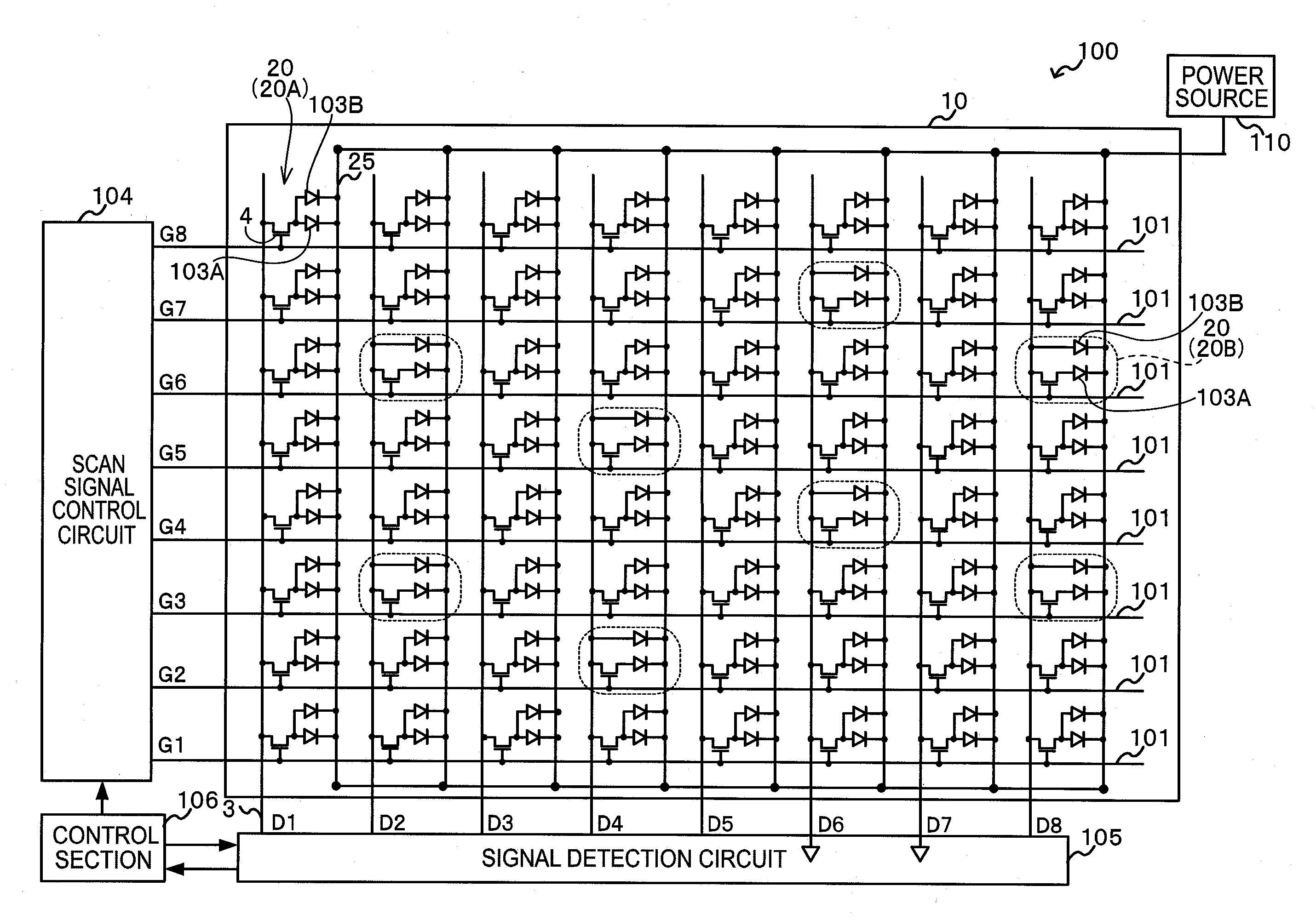

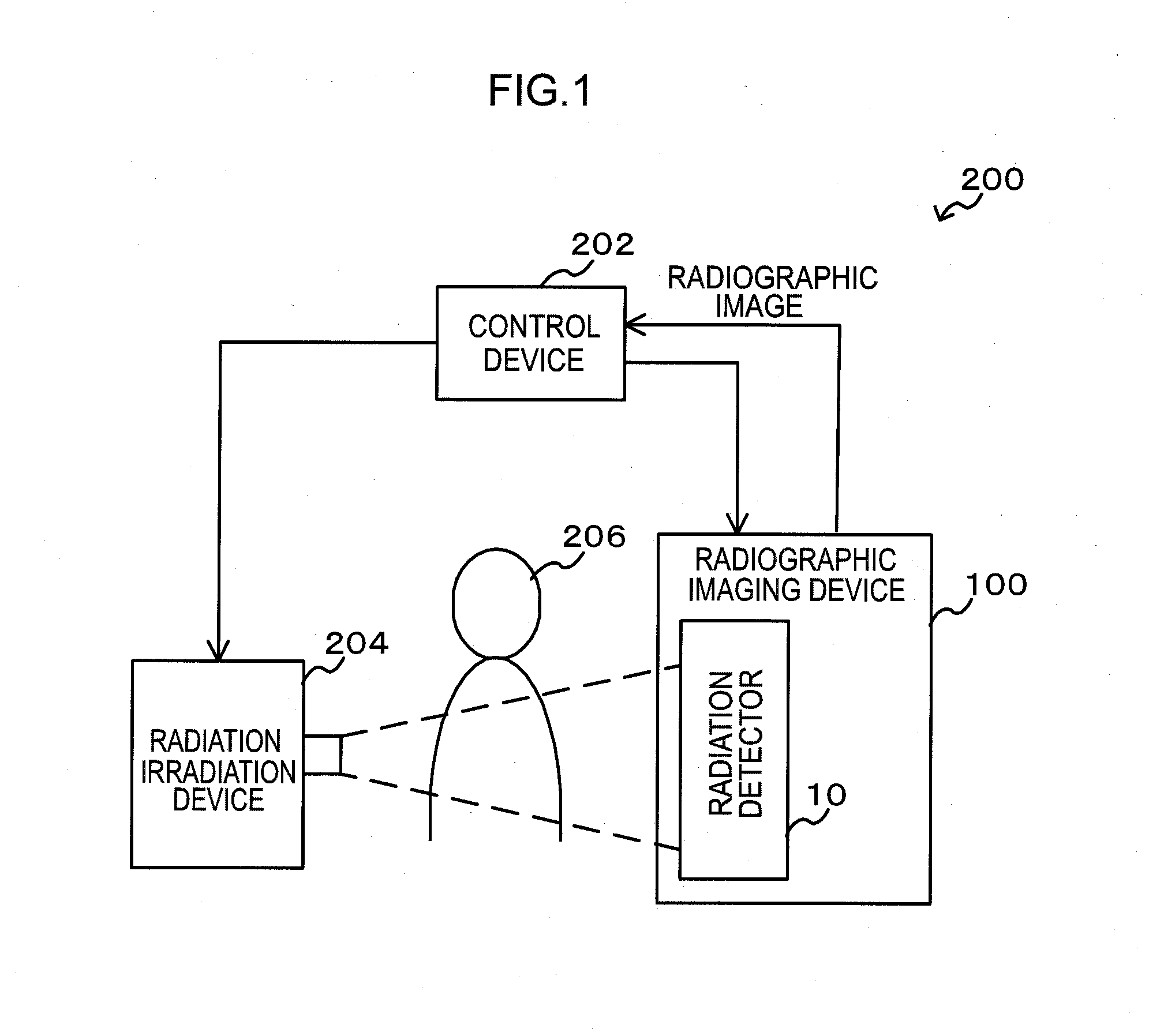

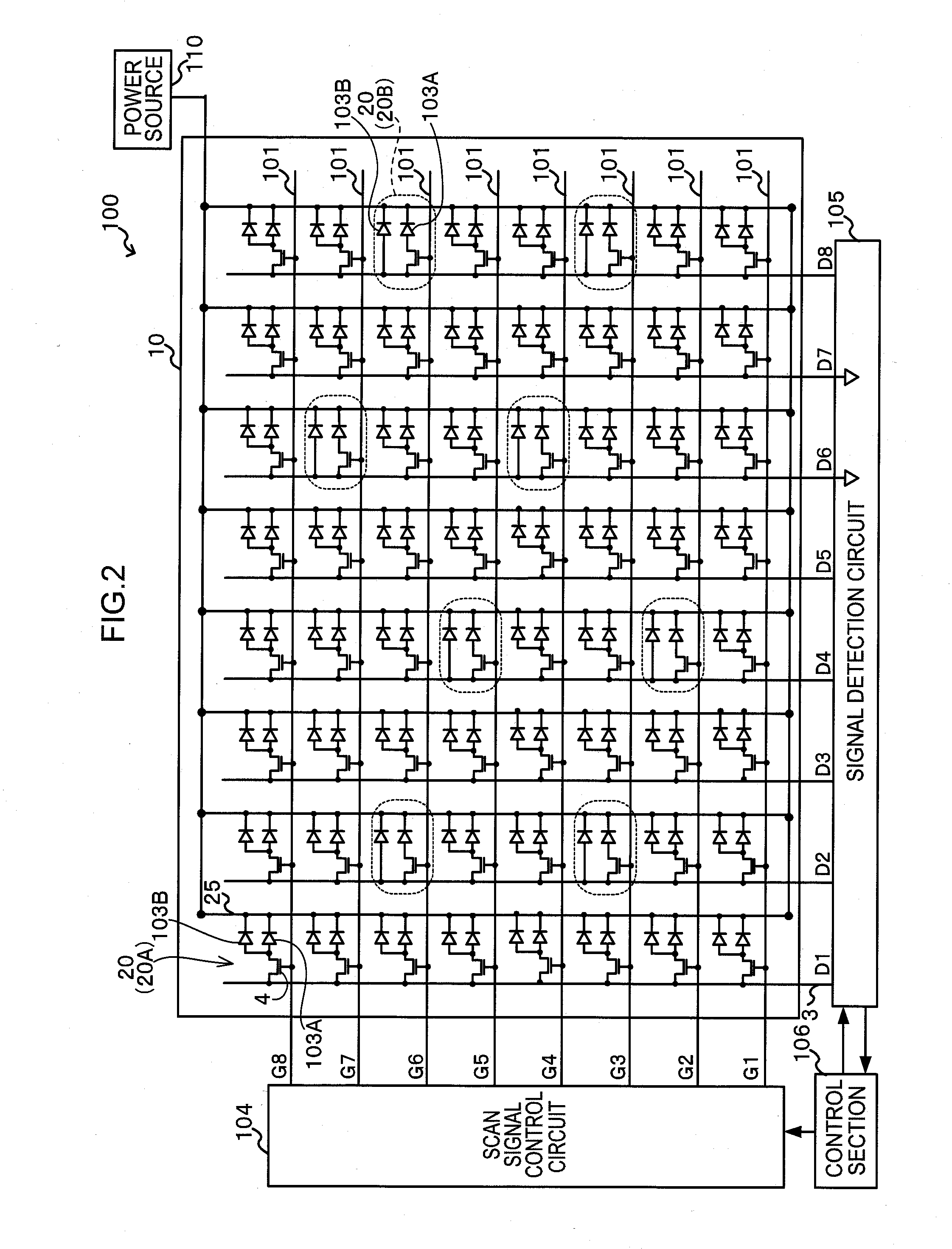

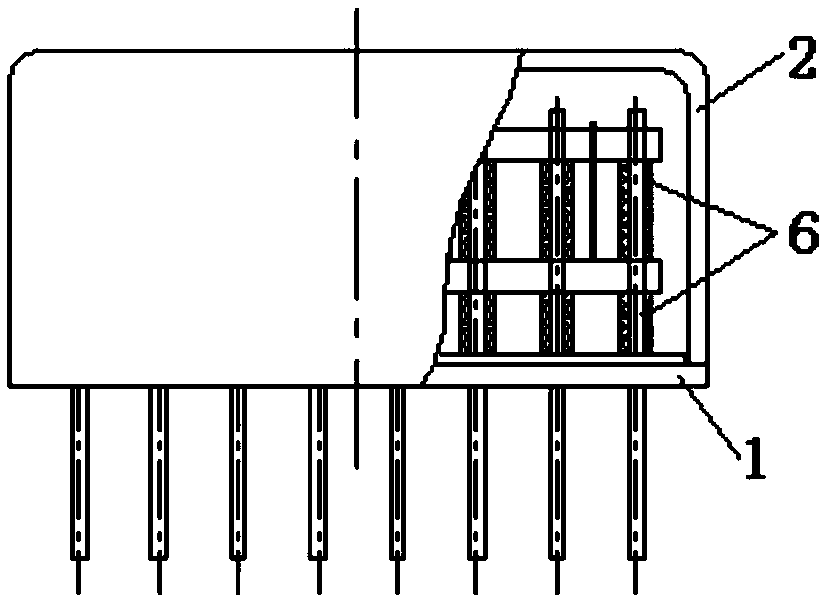

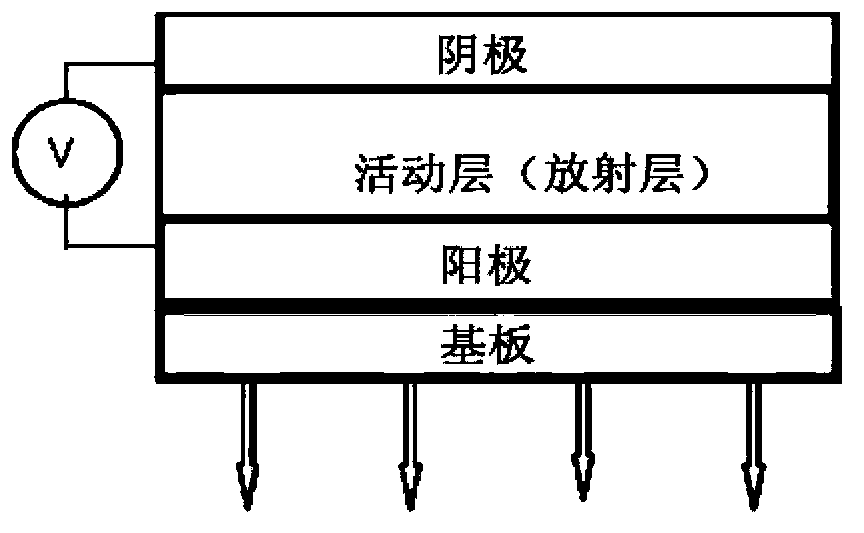

Radiation detector, radiographic imaging device and radiographic imaging system

ActiveUS20130009069A1Good precisionEasy to testSolid-state devicesMaterial analysis by optical meansRadiographyImage system

The present invention provides a radiation detector, a radiographic imaging device, and a radiographic image system that may be easily tested and may precisely detect radiation. Namely, pixels each includes a sensor portion A and a sensor portion B. In imaging pixels, the sensor portion A and the sensor portion B are connected by a connection line, and charges generated in the sensor portion A and in the sensor portion B are read by a TFT switch and output to a signal line. In radiation detection pixels, charges generated in the sensor portion A are read by a TFT switch and output to a signal line. Further, in the radiation detection pixels, the sensor portion B and the signal line are directly connected by a connection line, and the charges generated in the sensor portion B are output to the signal line as they arise.

Owner:FUJIFILM CORP

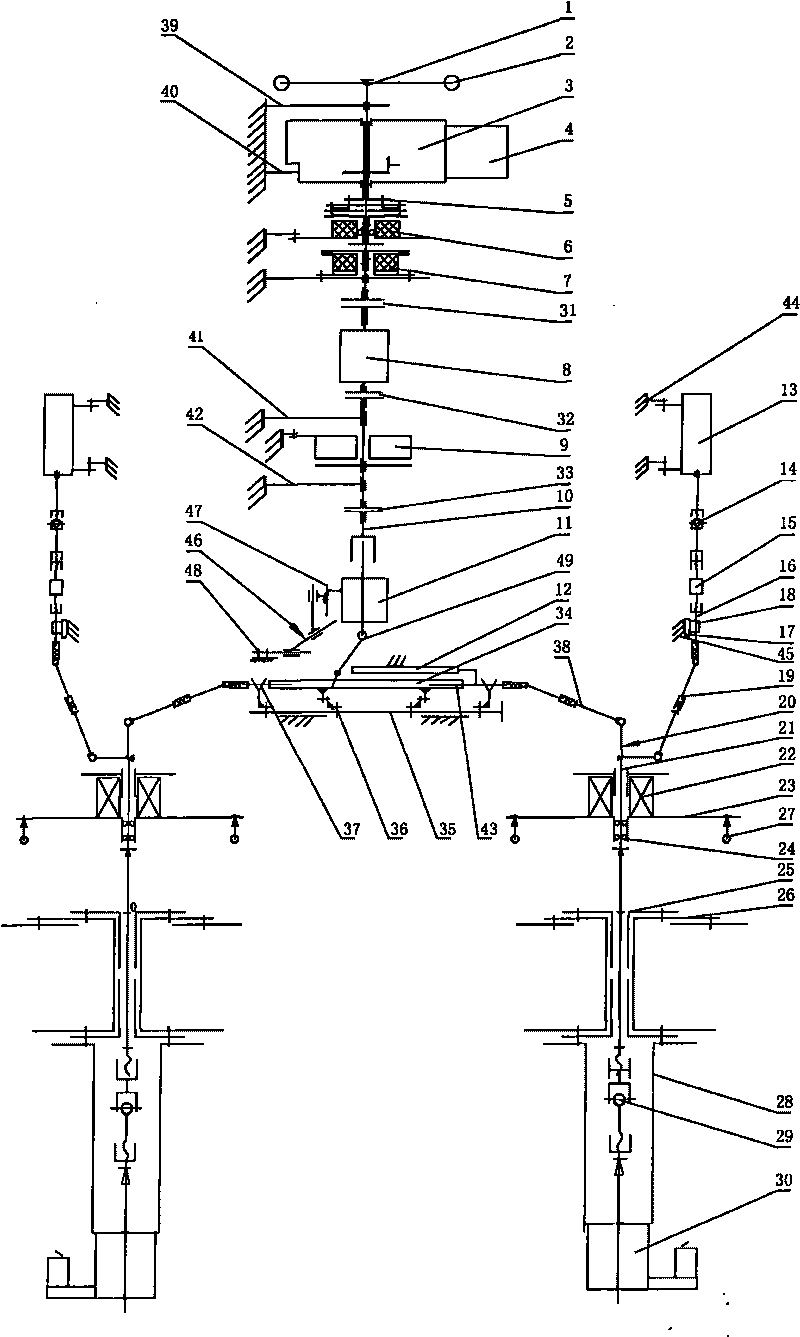

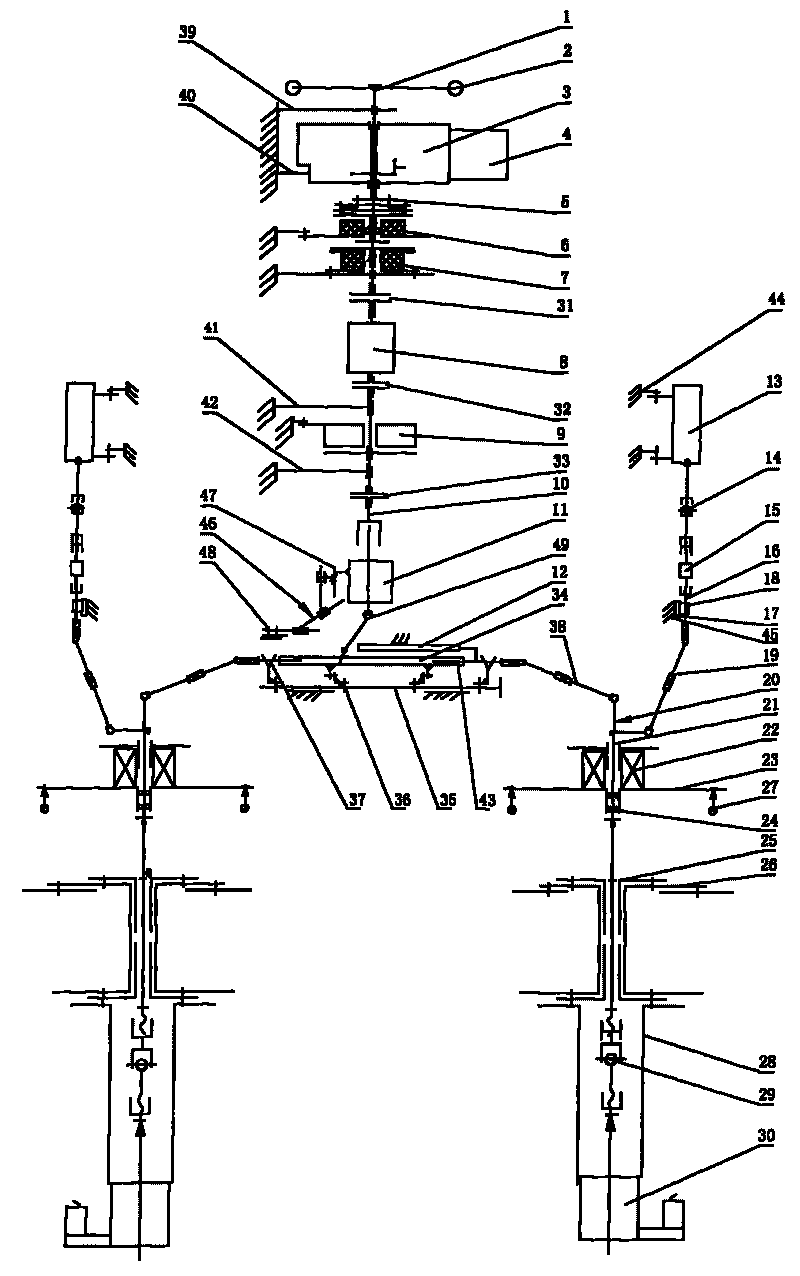

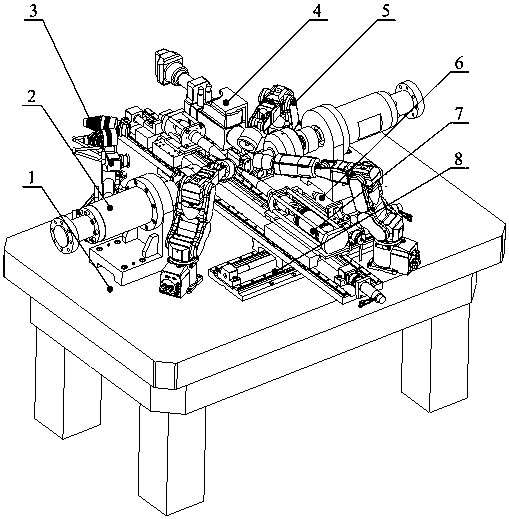

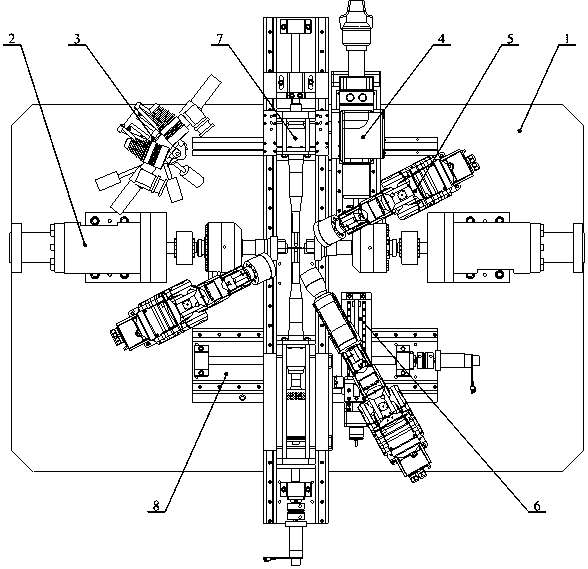

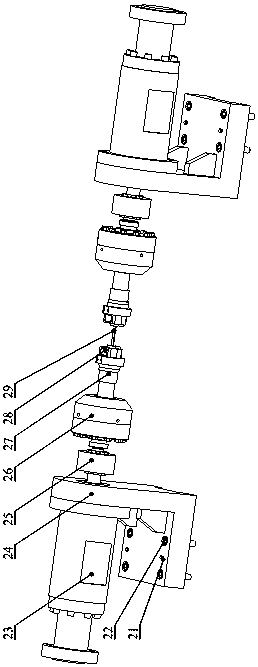

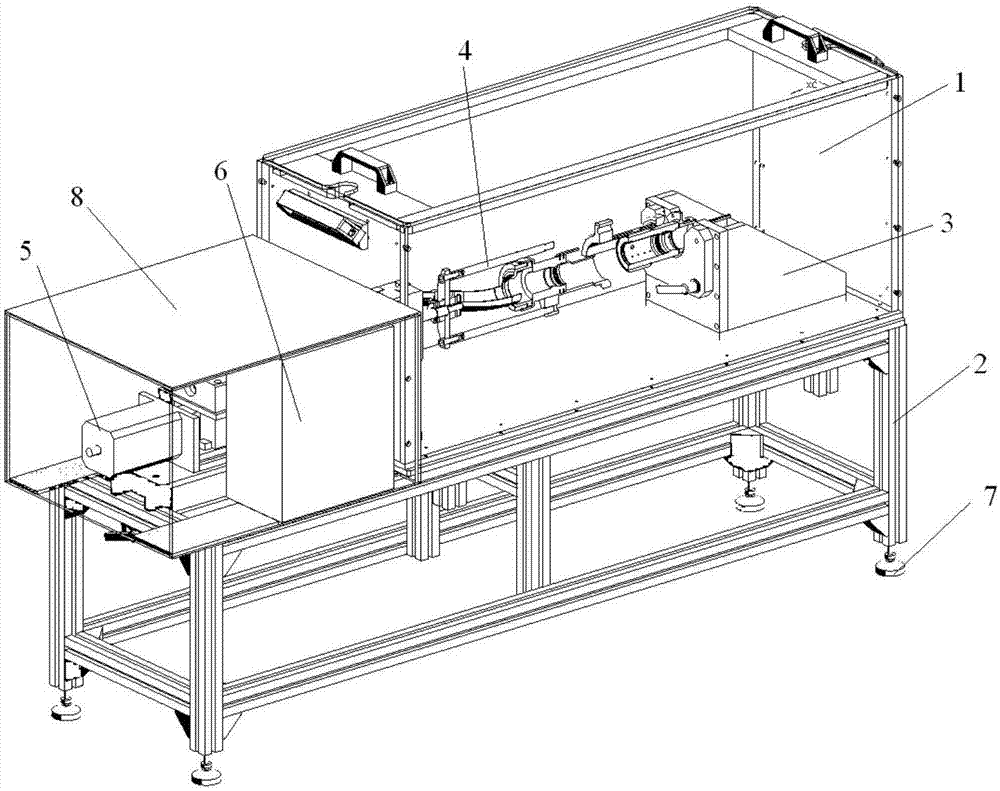

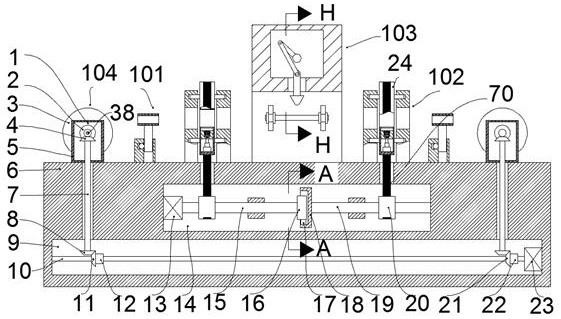

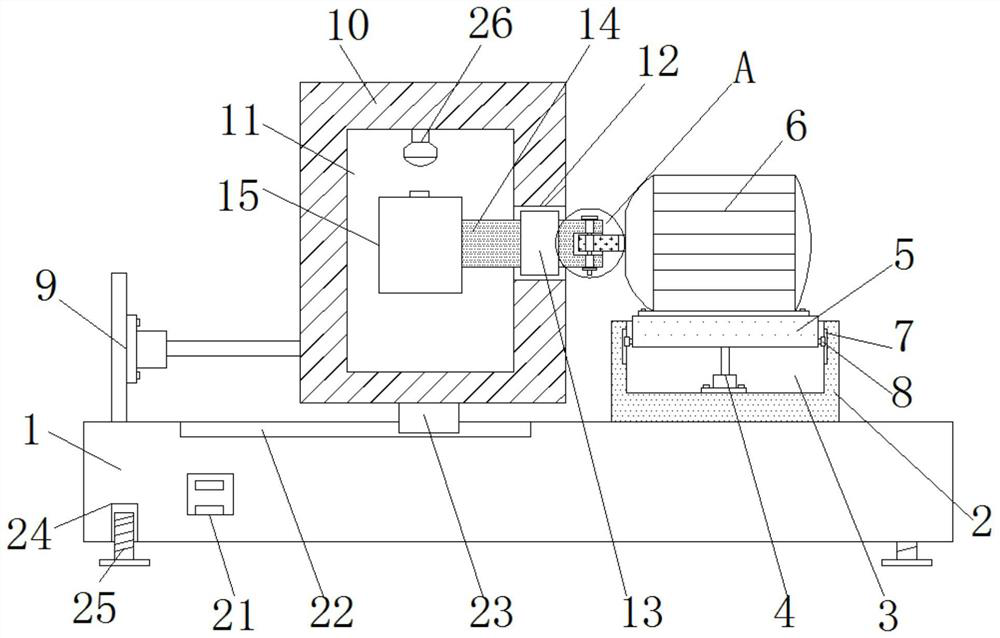

Device for testing performance of automotive steering system

InactiveCN101696908AReliable test resultsCompact structureVehicle steering/rolling behaviourTest performanceSteering column

The invention discloses a device for testing the performance of an automotive steering system, comprising a steering simulating system, an axial loading system, a suspension fork simulating system and an automotive steering system, wherein the steering simulating system is used for simulating the rotation of a steering wheel in an automatic and manual mode; the axial loading system is used for simulating a steering load and loading the steering load to the automotive steering system (comprising a steering column, a steering gear, a tie rod and a simulation steering knuckle) through a Bell mechanism; the suspension fork simulating system is used for simulating wheel jumpiness during driving. The device for testing the performance of the automotive steering system is used for experimenting and testing the steering performance of an automotive steering in various driving conditions, such as experiments and tests of kinematic and mechanic parameters of full angle, transmission ratio characteristic, transmission clearance characteristic, transmission efficiency characteristic, driving moment, rigidity, relationship between steering performance and suspension fork jumpiness and the like. The device directly simulates the steering wheel to load the automotive steering through the Bell mechanism, so that the testing result is closer to a real working condition.

Owner:CHONGQING UNIV OF TECH

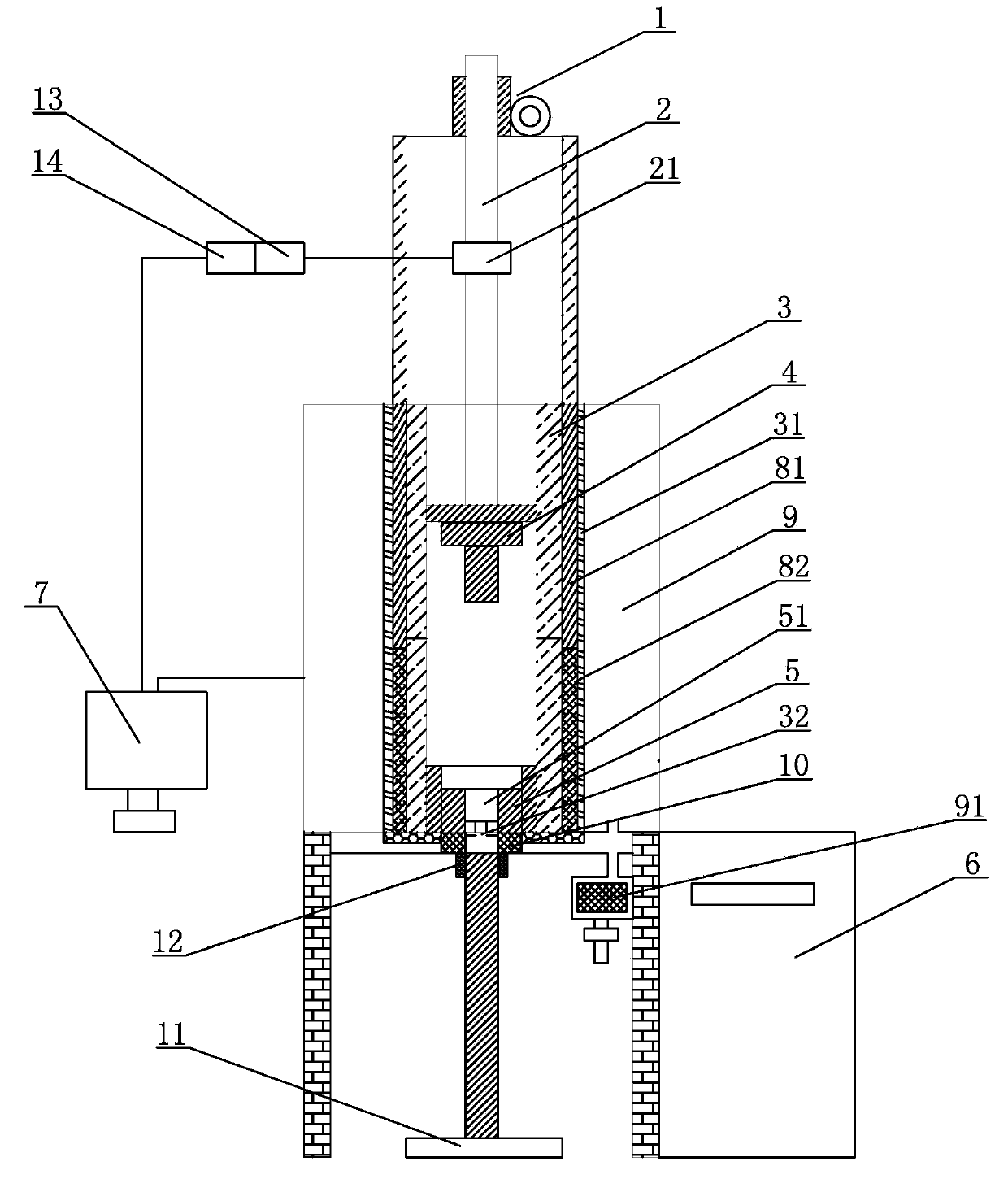

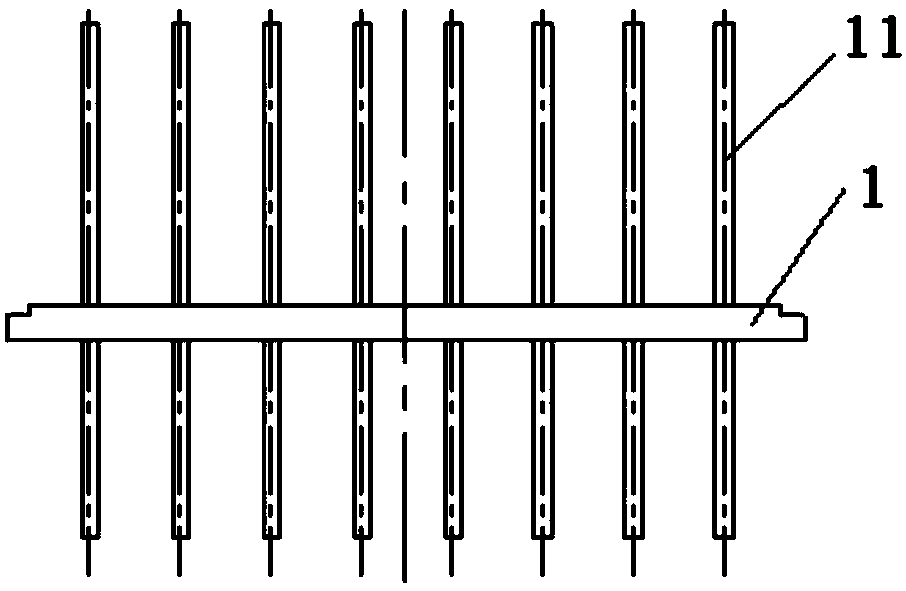

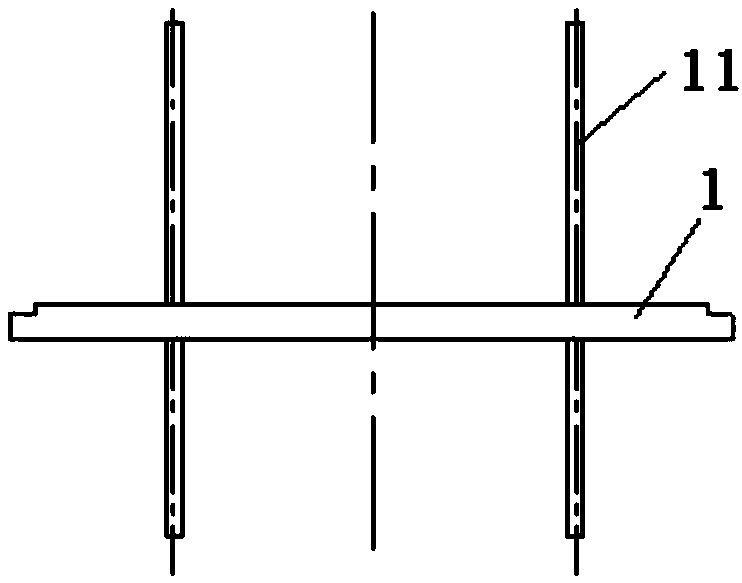

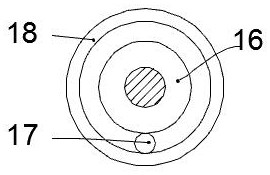

Extrusion device and method for extruding chalcogenide glass optical fiber perform with superposition method

ActiveCN103466933AUniform structureSmooth inside and outsideGlass making apparatusGlass productionSurface layerChalcogenide glass

The invention discloses an extrusion device and method for extruding a chalcogenide glass optical fiber perform with a superposition method. A pushing mechanism of the extrusion device is arranged above an extrusion container, and an extrusion rod is fixedly connected with the pushing mechanism; a heating furnace set used for heating the extrusion container is arranged outside the extrusion container, and a vacuum chamber is arranged outside the heating furnace set and is connected with a vacuum pump; an extrusion pad is arranged in the extrusion container, and an extrusion outlet is formed in the lower end of the extrusion container; a mould is arranged at the bottom of the extrusion container, and a mould hole of the mould is communicated with the extrusion outlet; a heat reducing furnace used for annealing the extruded optical fiber perform is arranged at the bottom of the extrusion container, and a traction device is arranged at the lower part of the heat reducing furnace. The extrusion device and the method have the characteristics of good controllability and high production efficiency.; the superposition method is adopted to extrude chalcogenide glass, and the obtained optical fiber perform has uniform structural composition, smooth inner and outer surfaces and a perfect interface; a surface layer is provide with a protective layer composed of high-molecular polymers, so that a performance test after drawing optical fibers is facilitated.

Owner:NINGBO UNIV

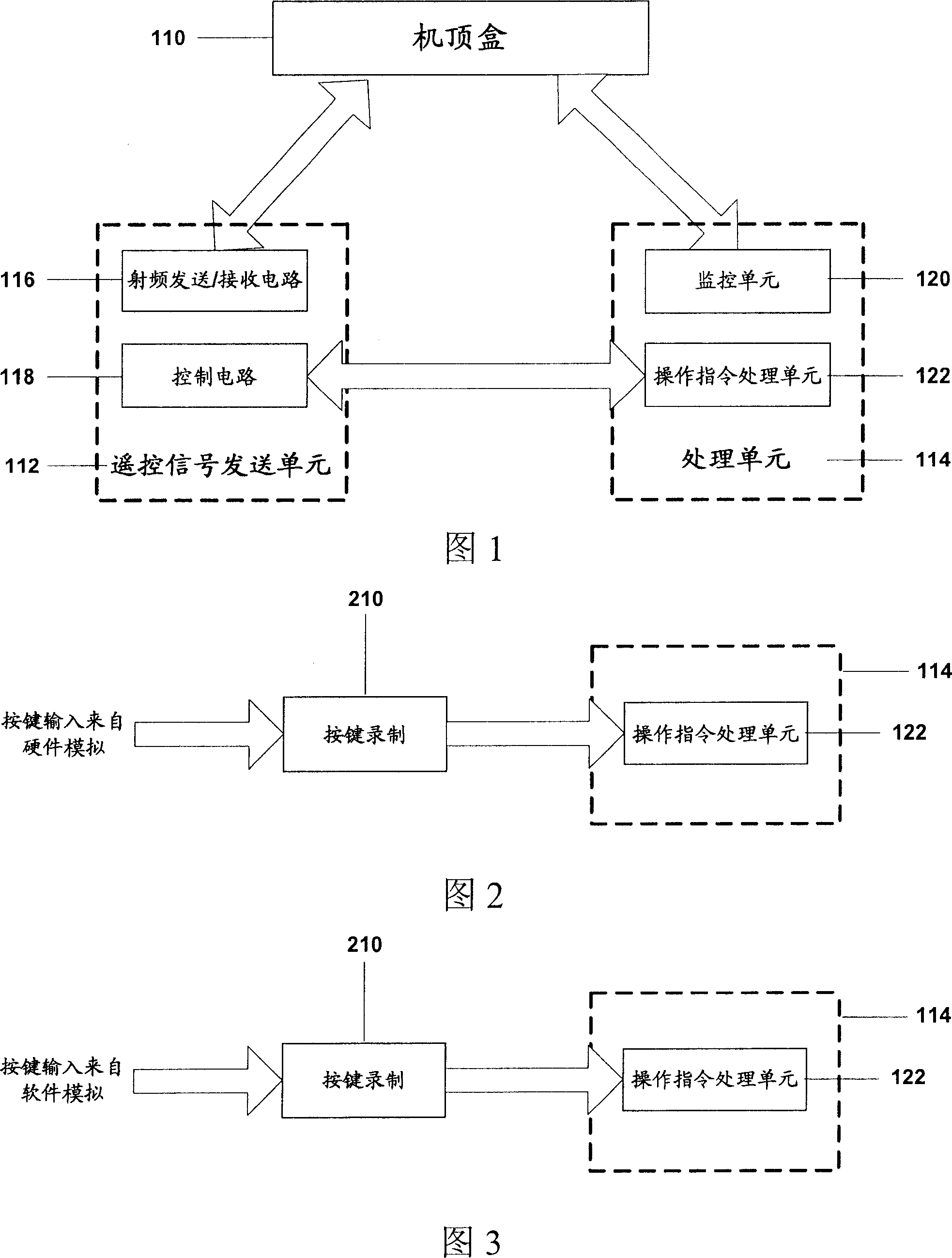

A test system and method for set top box

InactiveCN1953564APerformance testing is accurateConvenient performance testingTelevision system detailsElectric signal transmission systemsKey pressingInstruction processing unit

The invention relates to a testing system of set-top box, which comprises input unit, operation command processor, remote-control signal sender, and detector. Wherein, the invention also provides a relative testing method which comprises that receiving the command at first format; converting said command into second format; using serial communication interface to send the signal at second format to the sender; the sender sends the remote-control signal to the set-top box to respond the signal at second format. The invention has high accuracy.

Owner:UTSTARCOM TELECOM CO LTD

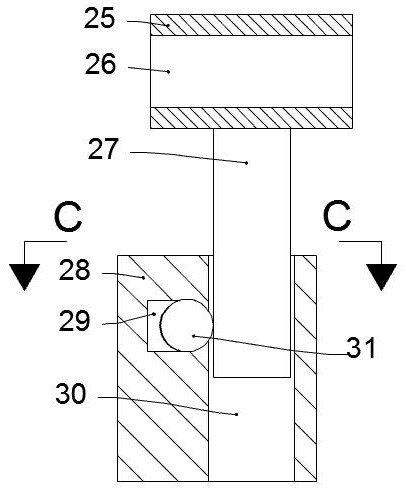

High-temperature high-frequency in-situ test device for material mechanical property

PendingCN107941624ASimple structureCompact layoutMaterial strength using tensile/compressive forcesHigh frequencyInstrumentation

Owner:JILIN UNIV

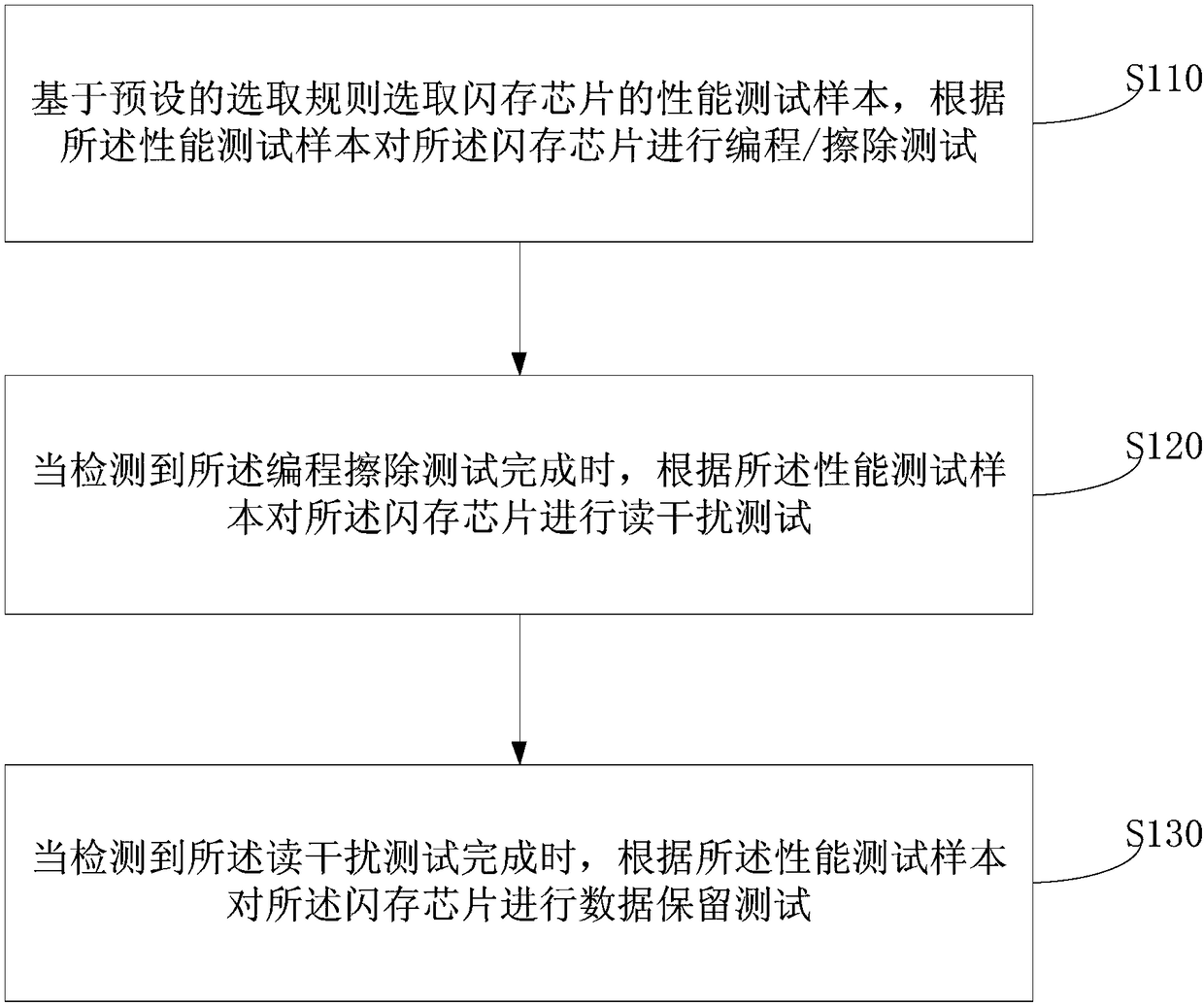

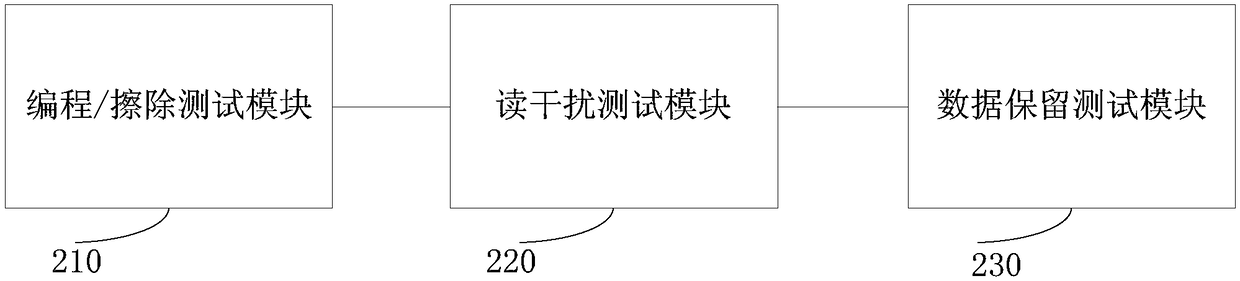

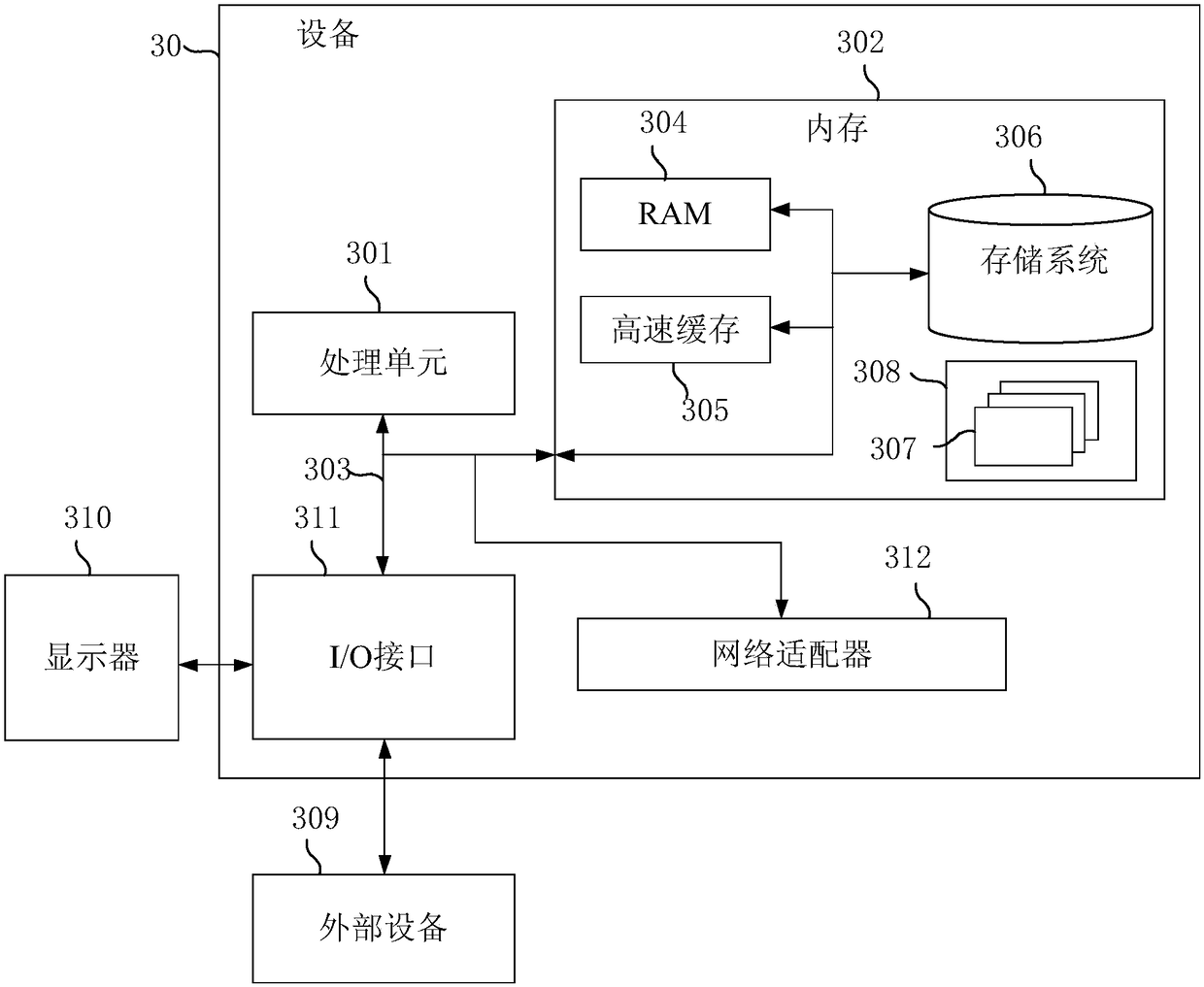

Method, device and equipment for performance test of flash memory chip, and storage medium

The invention discloses a method, a device and equipment for a performance test of a flash memory chip and a storage medium. The method comprises the steps of selecting a performance test sample of the flash memory chip based on a preset selection rule, and performing a programming / erasing test on the flash memory chip according to the performance test sample; when detecting that the programming / erasing test is completed, performing a read interference test on the flash memory chip according to the performance test sample; and when detecting that the read interference test is completed, performing a data retention test on the flash memory chip according to the performance test sample. With the technical scheme of the embodiment, the problem in the prior art of no unified flash memory performance test flow is solved and the effect of the flash memory performance test is achieved conveniently and rapidly.

Owner:GIGADEVICE SEMICON (BEIJING) INC

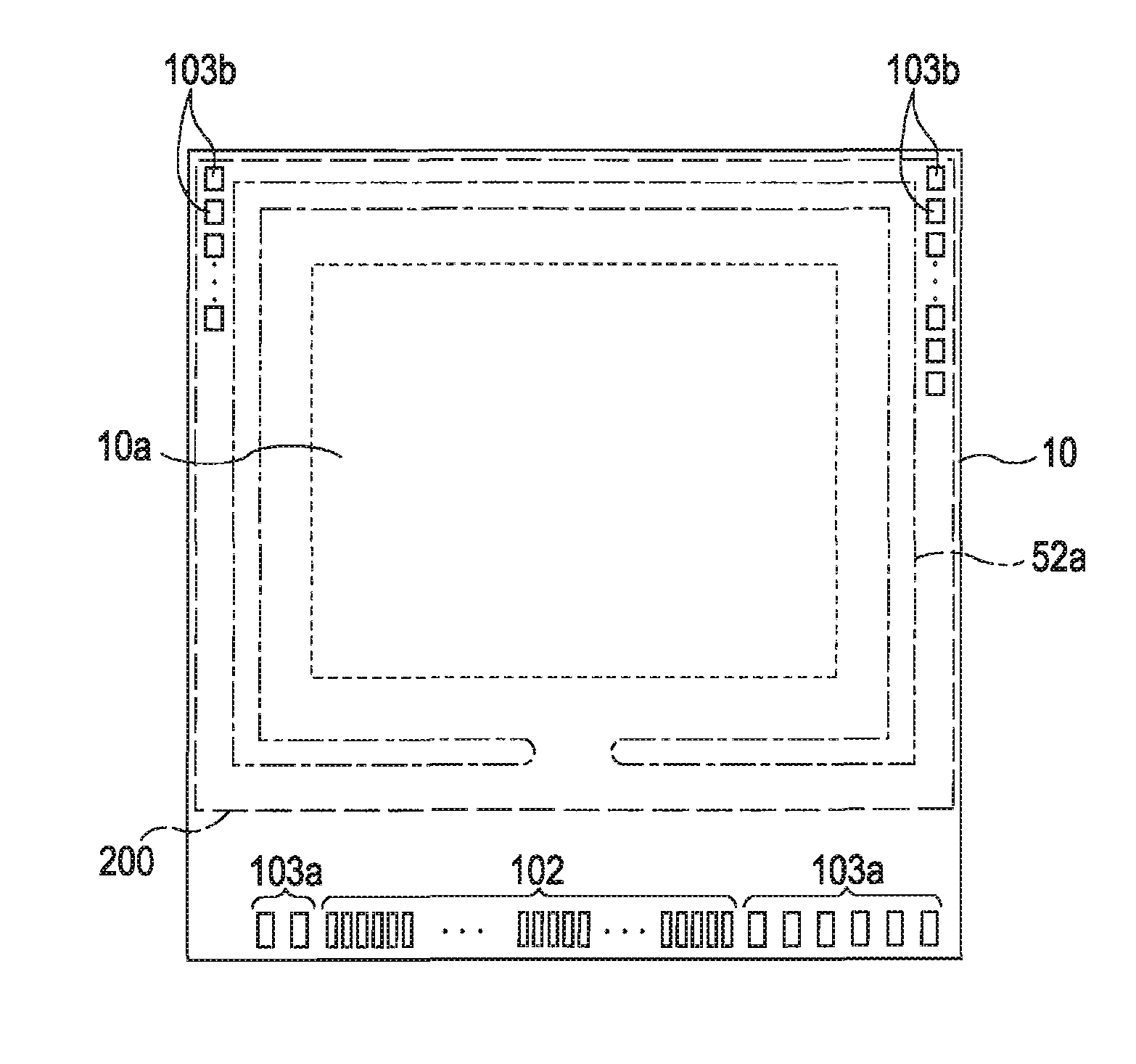

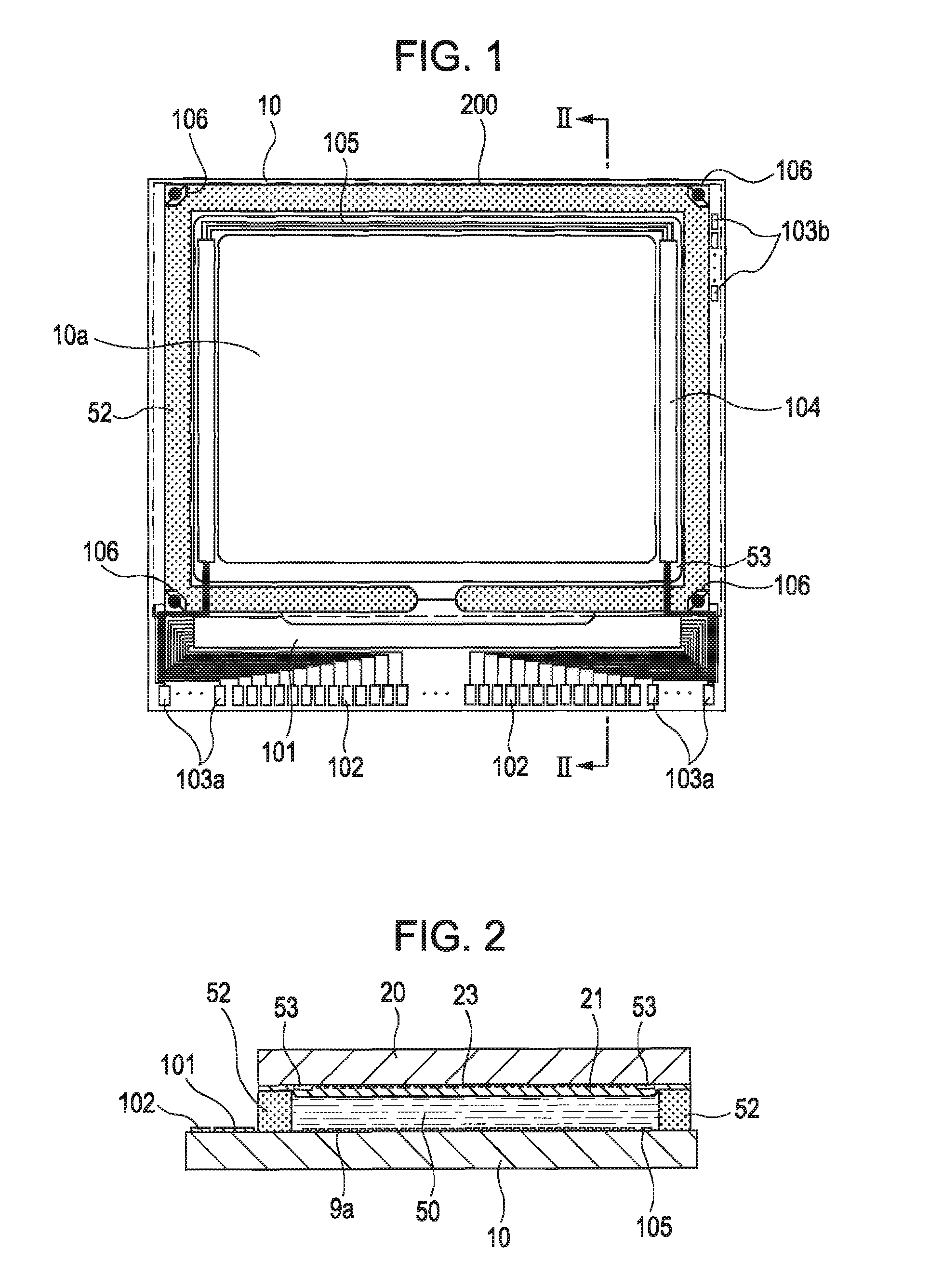

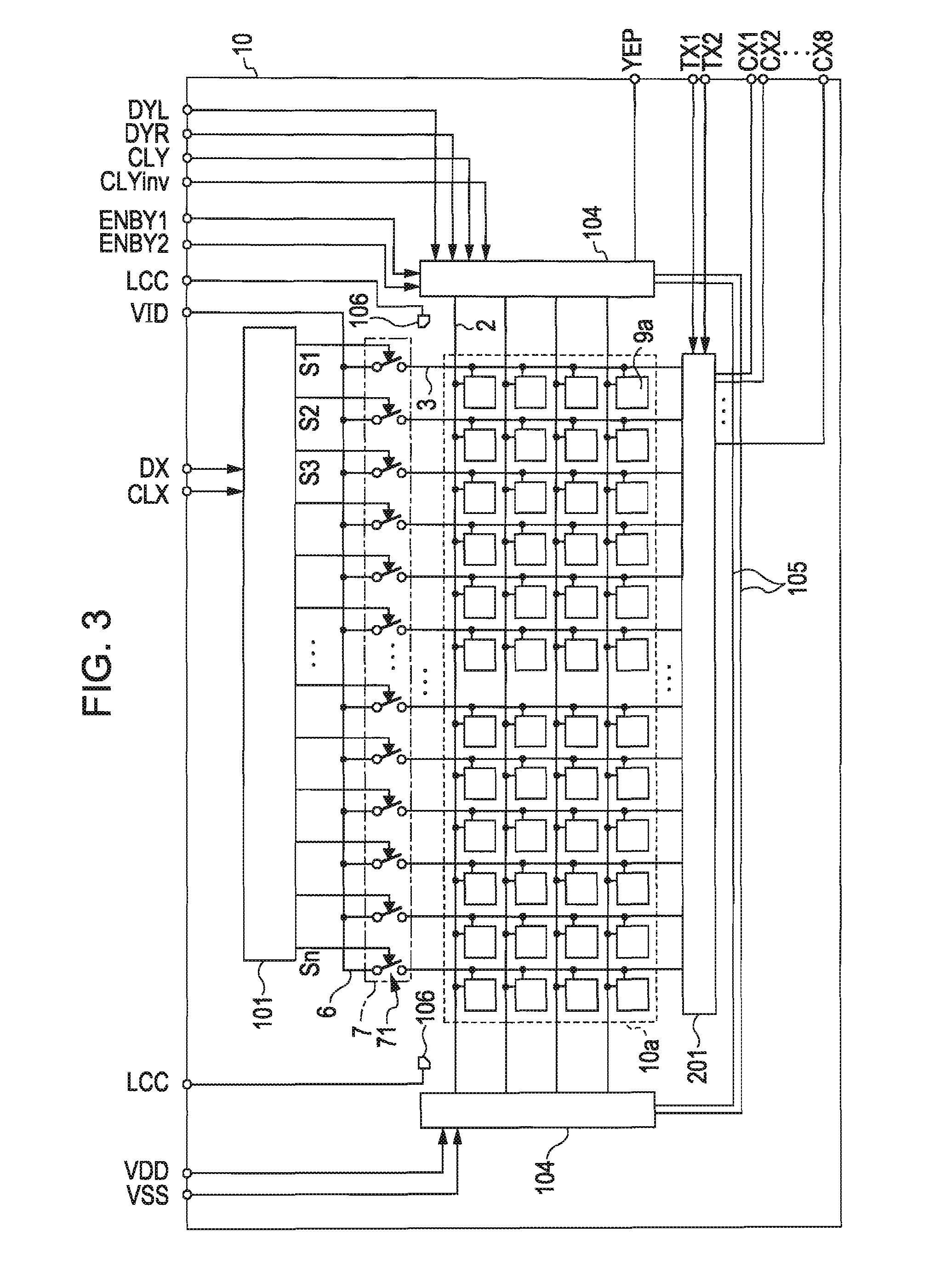

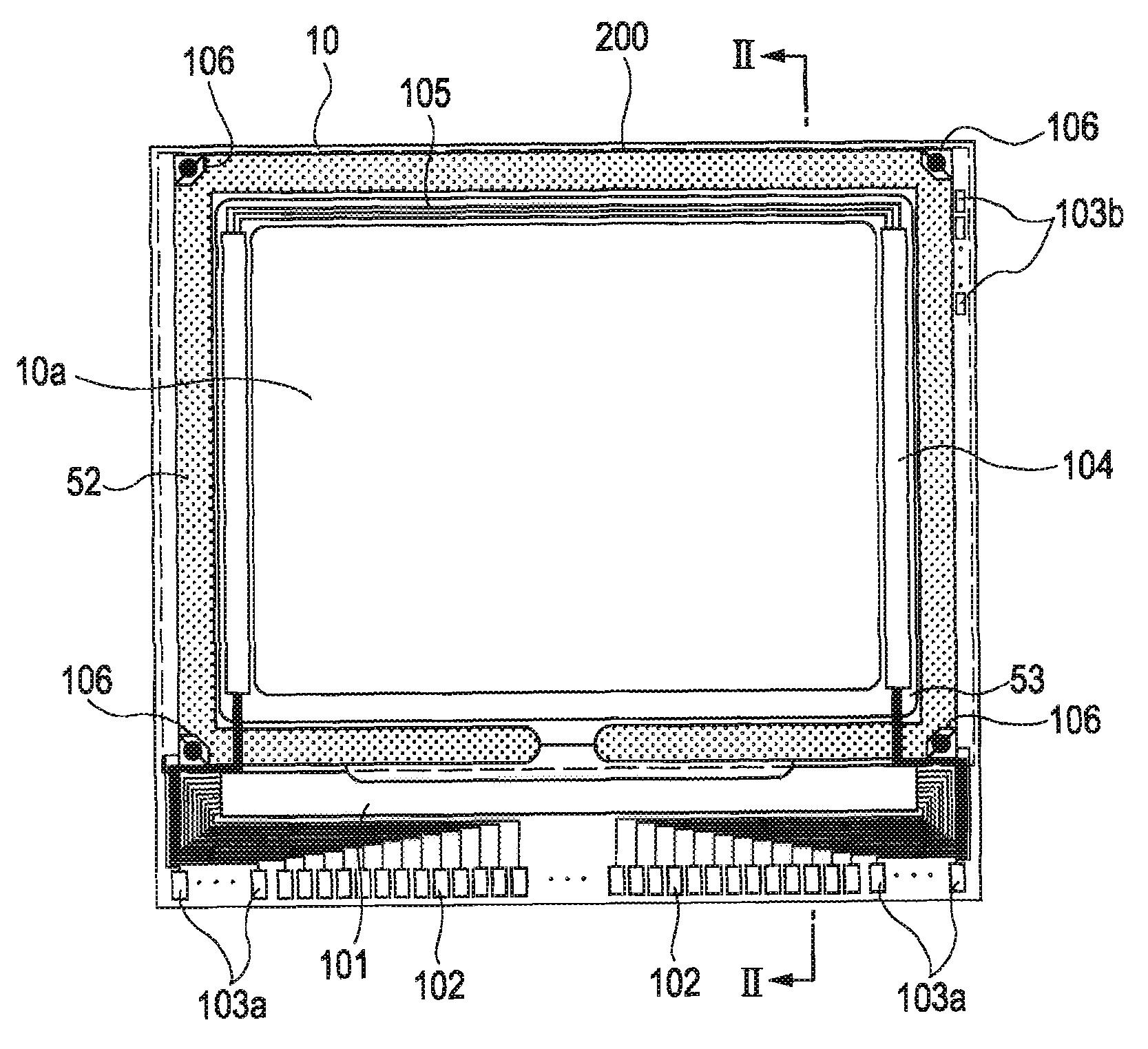

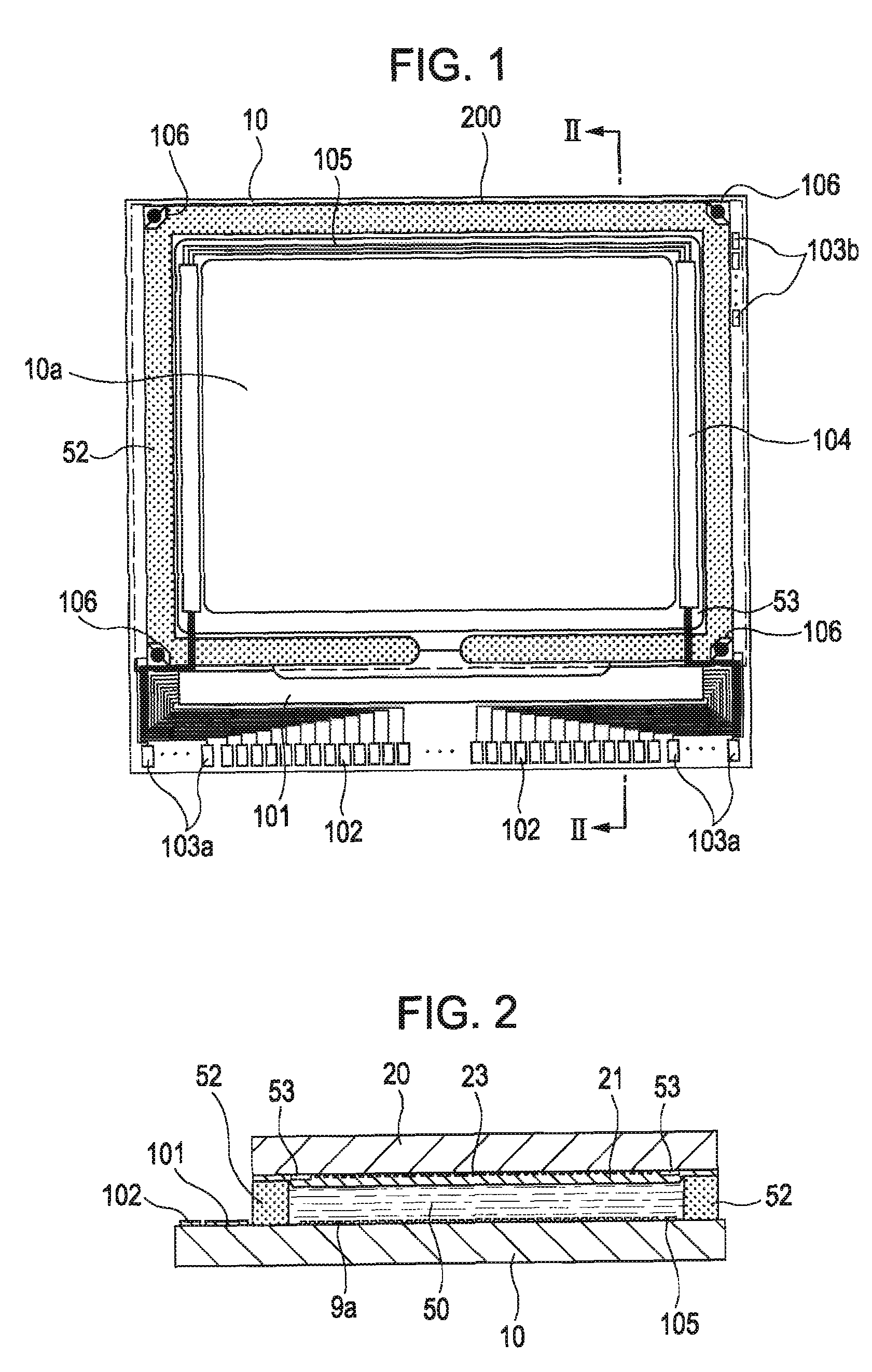

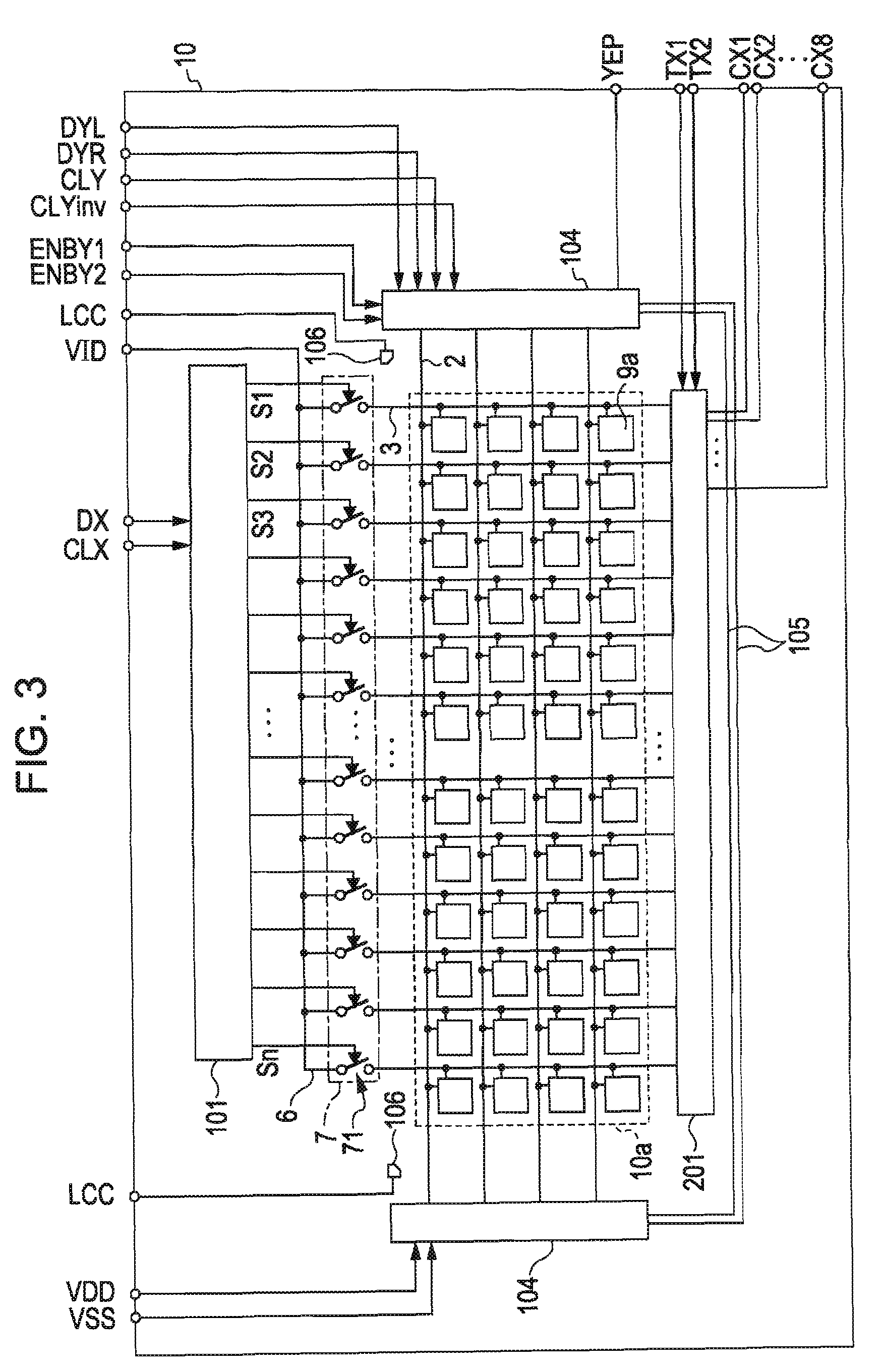

Electro-optical device, method of testing the same, and electronic apparatus

ActiveUS20070040983A1Small sizeConvenient performance testingNon-linear opticsControl signalEngineering

An electro-optical device includes: a counter substrate; an element substrate comprising a protruding region protruding from one side of the counter substrate and being bonded to the counter substrate; a plurality of pixel units that are arranged in a pixel region on the element substrate; a plurality of external circuit connecting terminals which are arranged in the protruding region on the element substrate and to which various signals including image signals and control signals for allowing the plurality of pixel units to display an image are supplied; and a plurality of test terminals that are provided at both ends of an array of the plurality of external circuit connecting terminals in the protruding region and are supplied with test signals, wherein a distance between adjacent test terminals is longer than a distance between adjacent external circuit connecting terminals.

Owner:SEIKO EPSON CORP

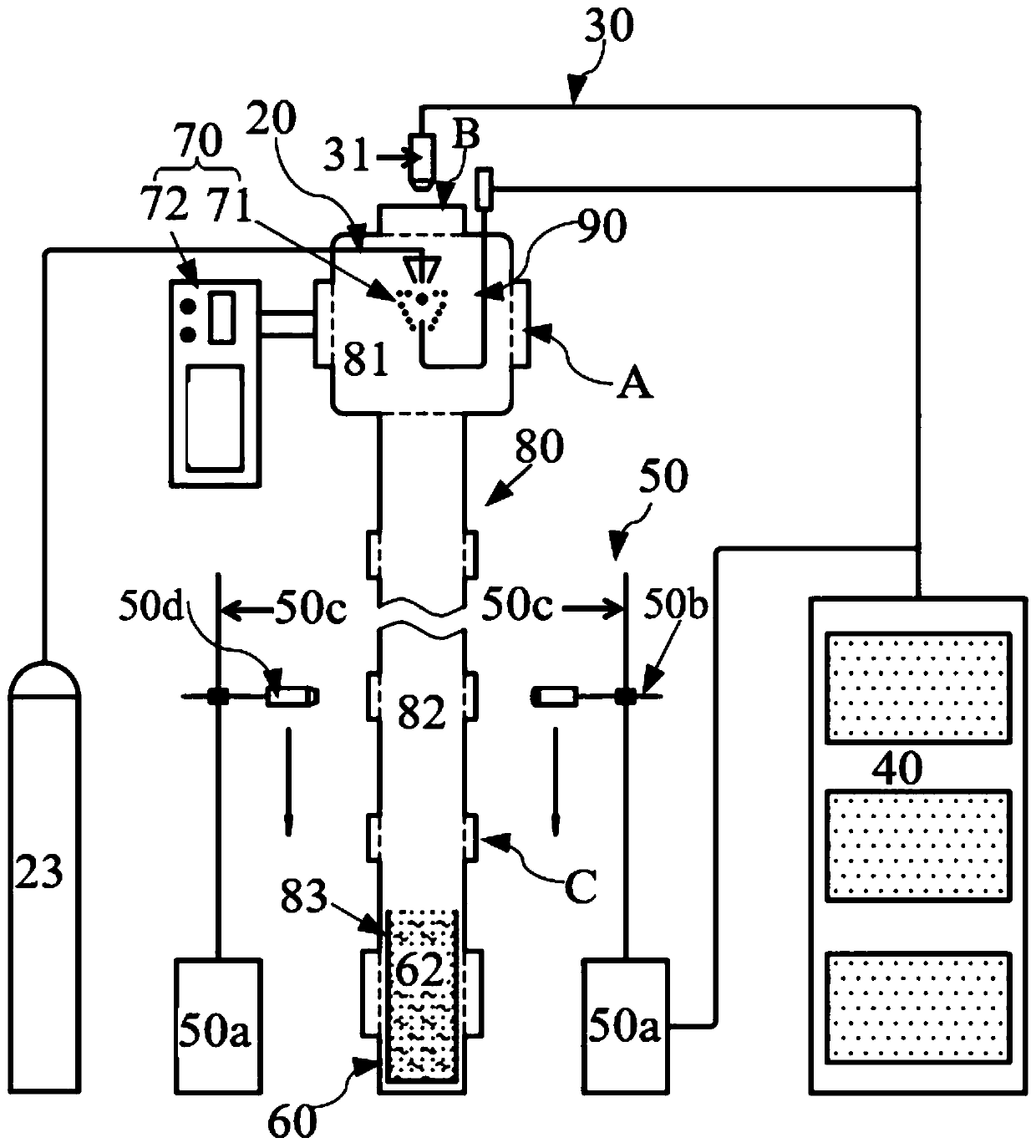

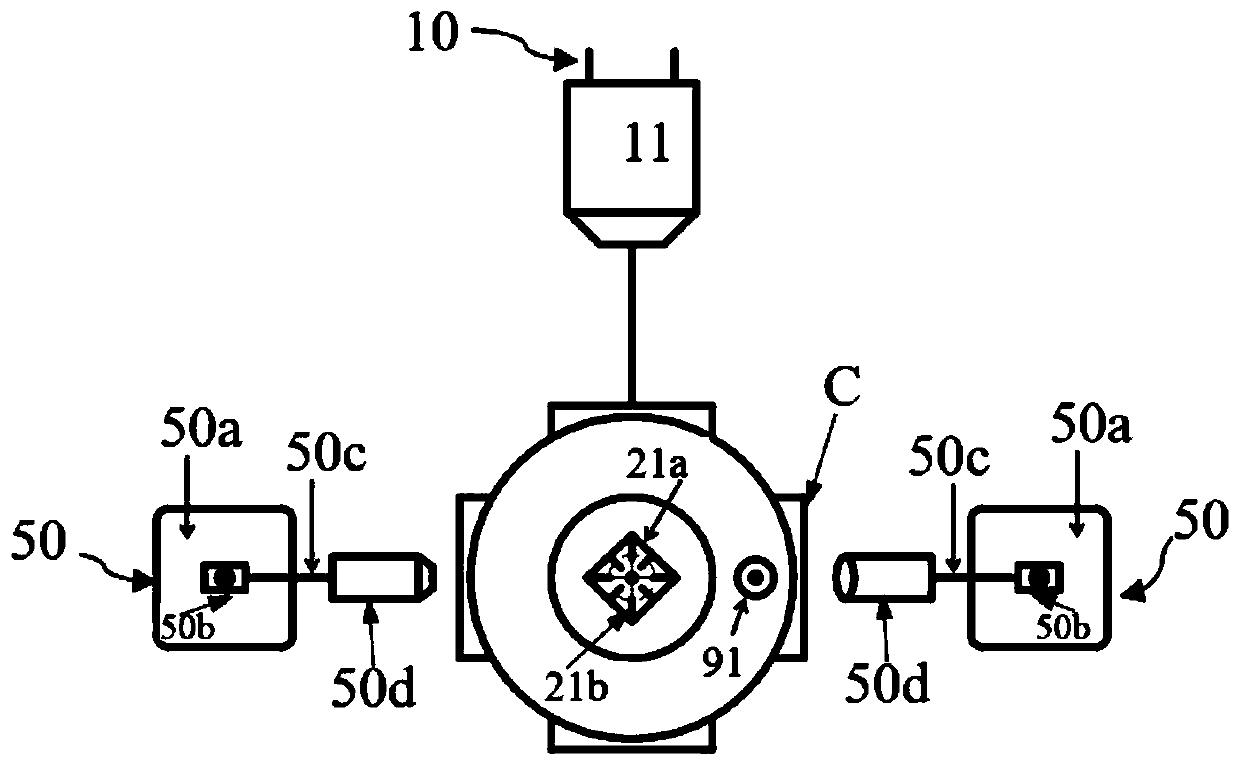

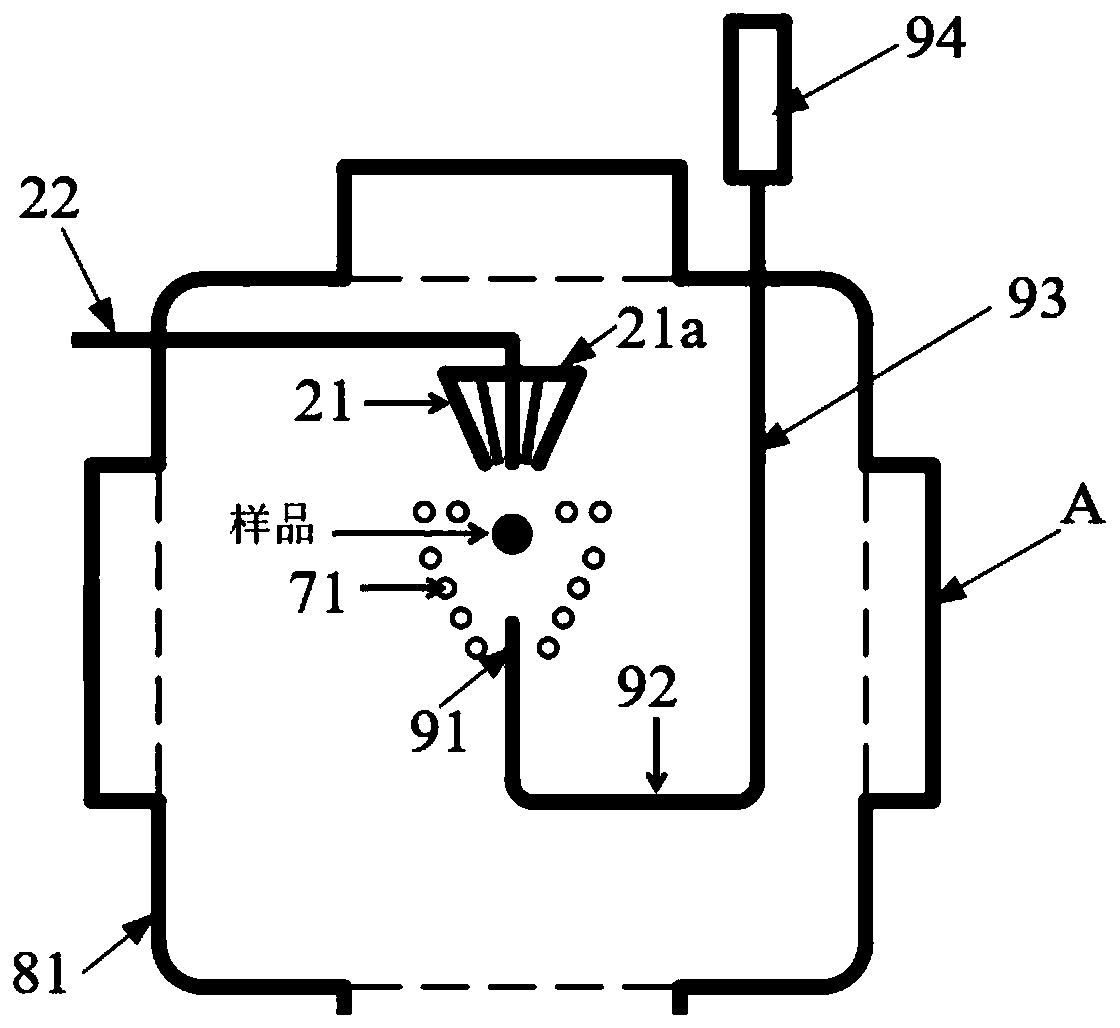

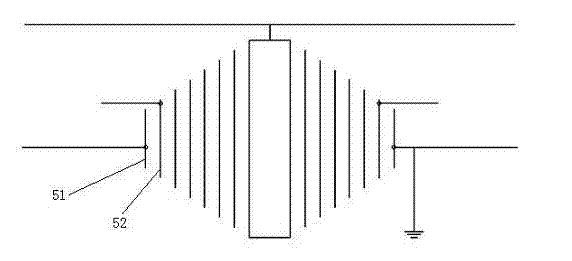

Rapid solidification system and method for suspension large-dimension metal liquid drops under micro-gravity condition

The invention relates to a rapid solidification system for suspension large-dimension metal liquid drops under a micro-gravity condition. The rapid solidification system comprises a vacuum cavity, a suspension induction heating device, a motion detecting device and a rapid liquid quenching device, wherein the vacuum cavity comprises an electromagnetic suspension cavity, a micro-gravity cavity anda rapid liquid quenching cavity which are connected from top to bottom; the suspension induction heating device is provided with a tapered suspension induction coil which is formed by spiral winding,and the coil is arranged on the center of the electromagnetic suspension cavity for melting and suspending an alloy sample; the micro-gravity cavity is a hollow tube body, so that the alloy sample obtains micro-gravity; the motion detecting device is used for continuously and dynamically acquiring a temperature and a form of the alloy sample in dropping motion; and the rapid liquid cooling deviceis provided with a quenching cooling medium for realizing rapid liquid quenching solidification for the alloy sample. The rapid solidification system avoids heterogeneous nucleation generated by wallcontact while the sample is molten, so that the sample is deeply super-cooled, and therefore, tissue segregation caused by gravity effect is eliminated, and rapid solidification from millimeter-grademetal liquid drops to the centimeter-grade metal liquid drops is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

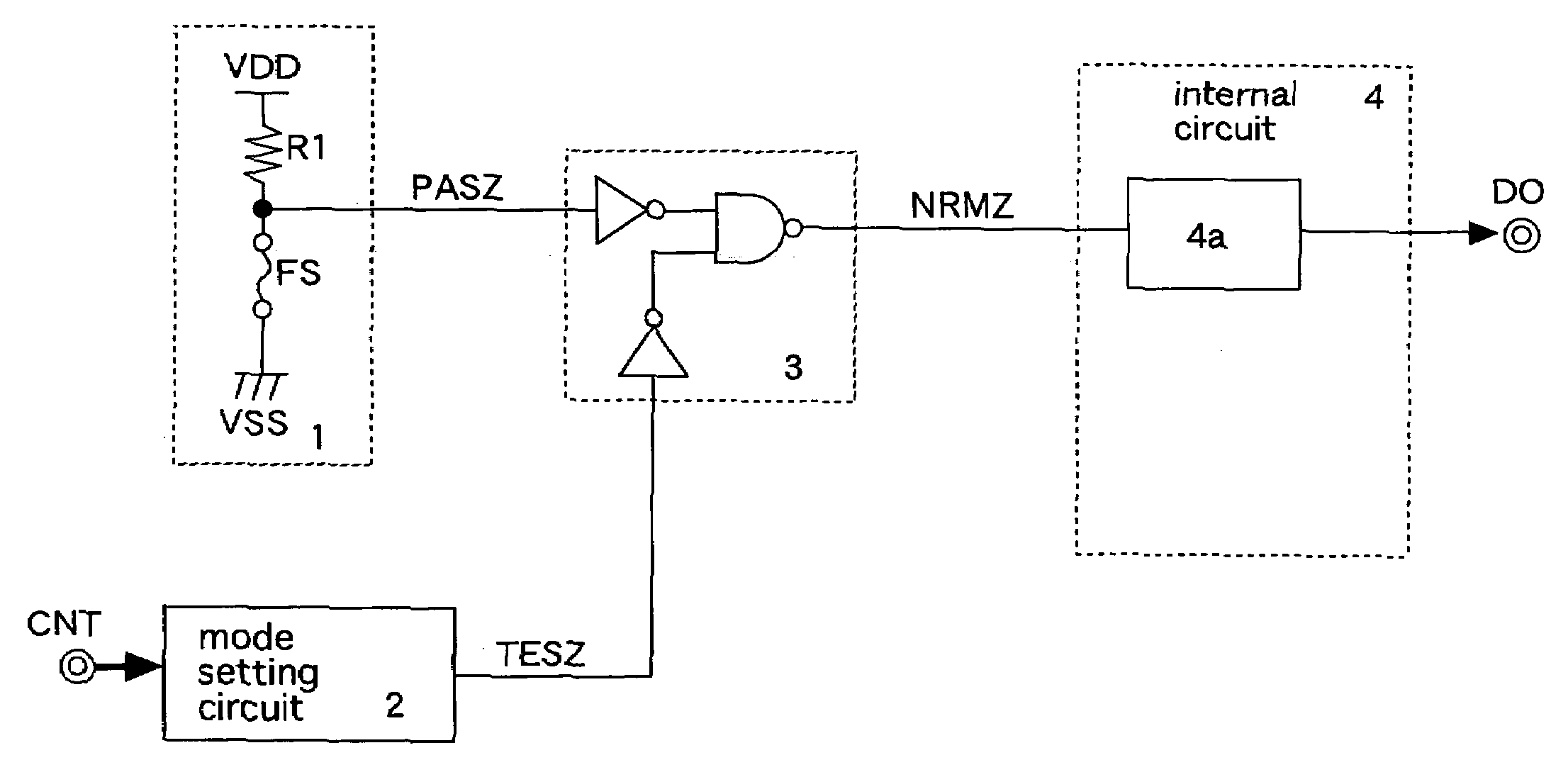

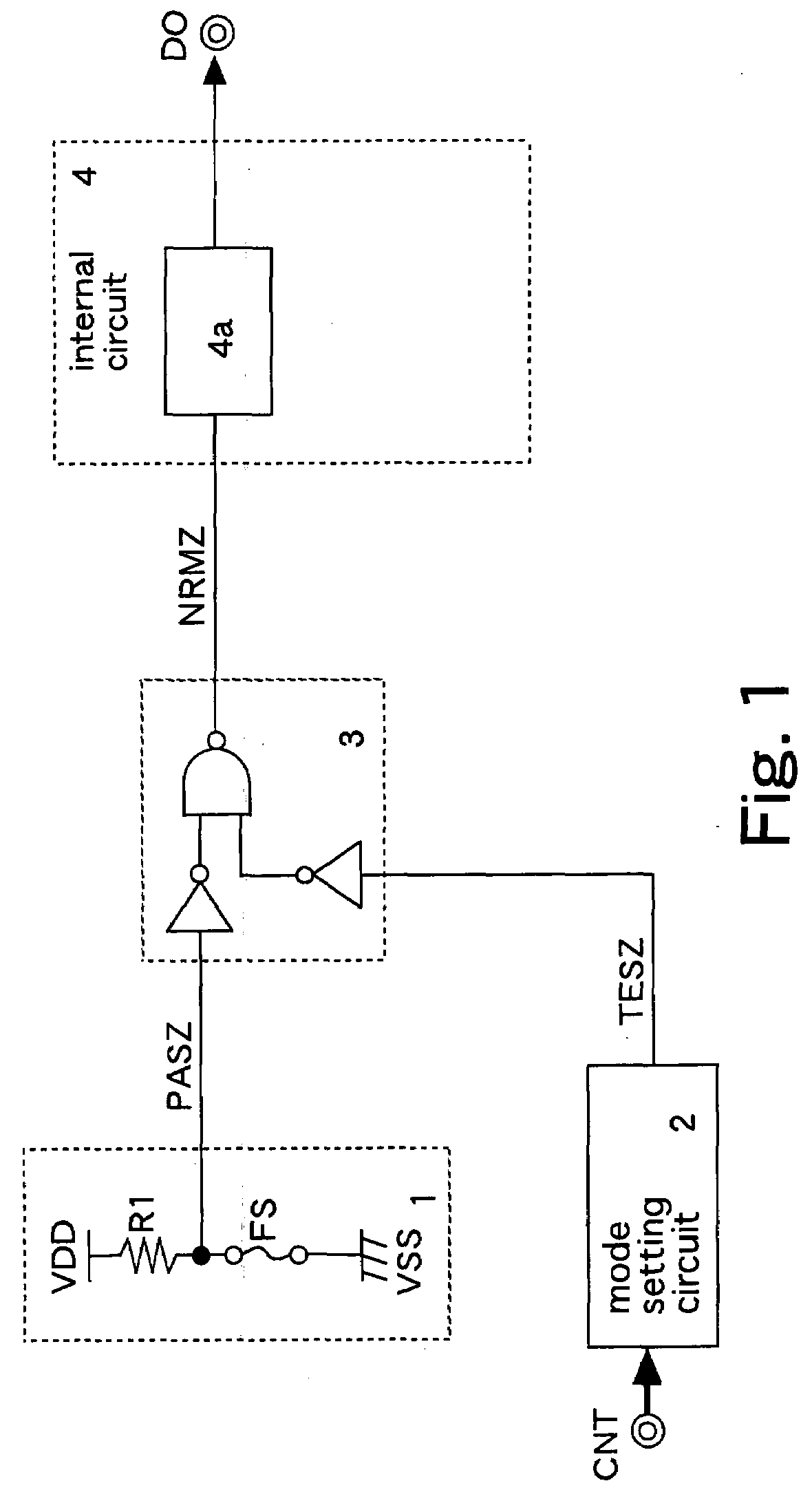

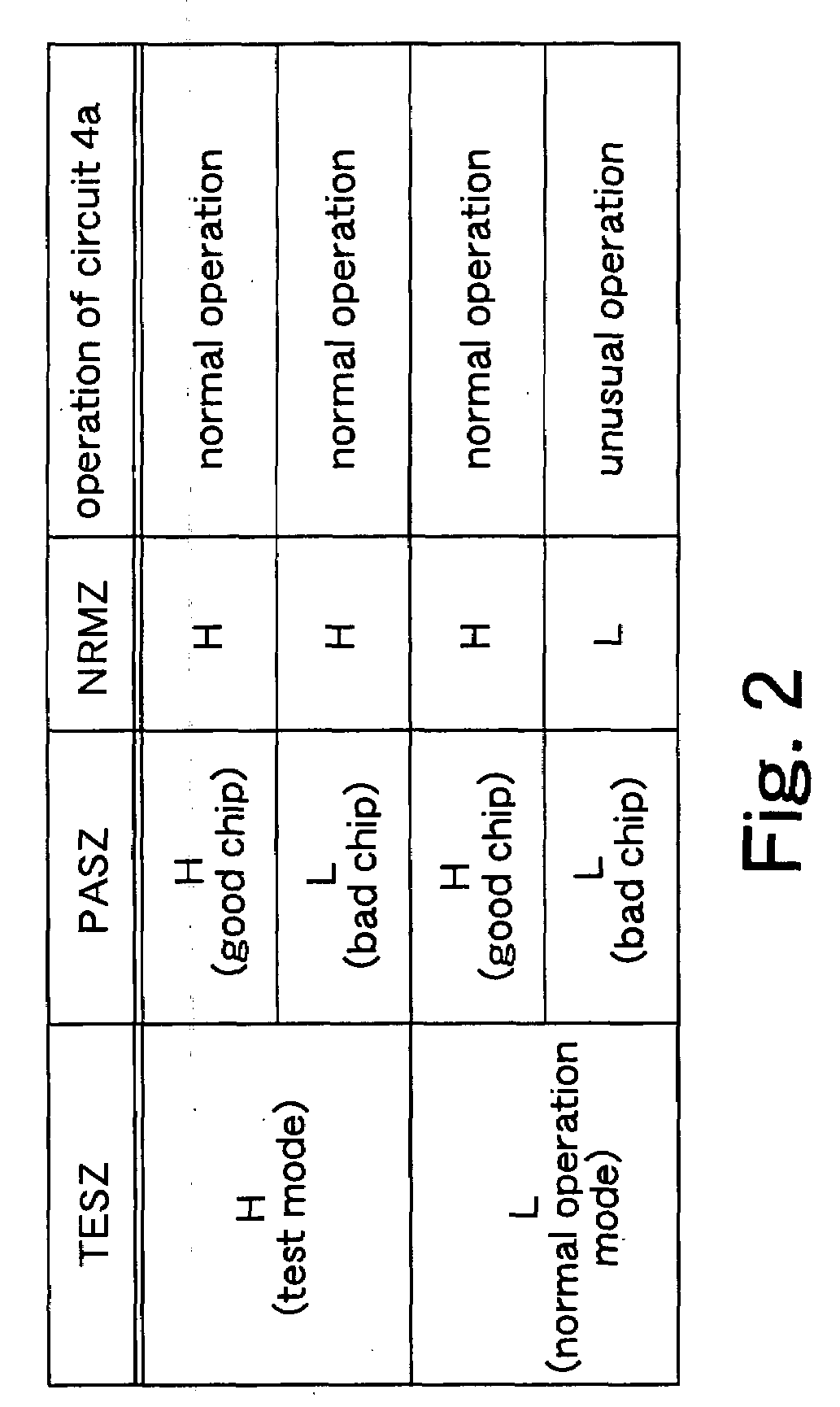

Semiconductor integrated circuit and testing method of same

InactiveUS20080048703A1Easy to identifyConvenient performance testingSemiconductor/solid-state device testing/measurementElectronic circuit testingOperation modeProgram unit

A program circuit activates a pass signal when a first program unit is programmed. The first program unit is programmed when a test of an internal circuit is passed. A mode setting circuit switches an operation mode to a normal operation mode or a test mode by external control. A state machine allows a partial circuit of the internal circuit to perform an unusual operation different from a normal operation when the pass signal is inactivated during the normal operation mode. By recognizing the unusual operation during the normal operation mode, it can be easily recognized that a semiconductor integrated circuit is bad. Since a failure can be recognized without shifting to the test mode, for example, a user who purchases the semiconductor integrated circuit can also easily recognize the failure.

Owner:SOCIONEXT INC

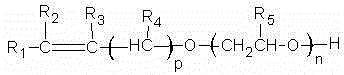

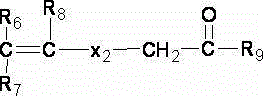

Polyether polycarboxylic acid water reducing agent and preparation method therefor

The present invention discloses a polyether polycarboxylic acid water reducing agent and a preparation method therefor. Macromonomers with relatively weak activity are used to replace part of macromonomers with better activities but with higher prices; unsaturated acid with lower cost is used to replace part of unsaturated acid with a higher price; a suitable redox initiation system is chosen; and by adjusting a proportion of an initiator, a molecular weight regulator, and a comonomer, polymerization is performed at the temperature of 25-30 DEG C, and a high performance polycarboxylic acid water reducing agent that is suitable for preparing low-grade concrete is prepared; and the method is low in material cost, simple in operation, and green and environmentally friendly; the water reducing performance of the water reducing agent can be equivalent to the performances of naphthalene-series and aliphatic water reducing agents, and the water reducing agent has an advantage of high cost performance.

Owner:CHINA BUILDING MATERIALS ACAD +1

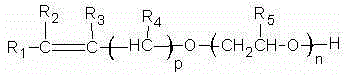

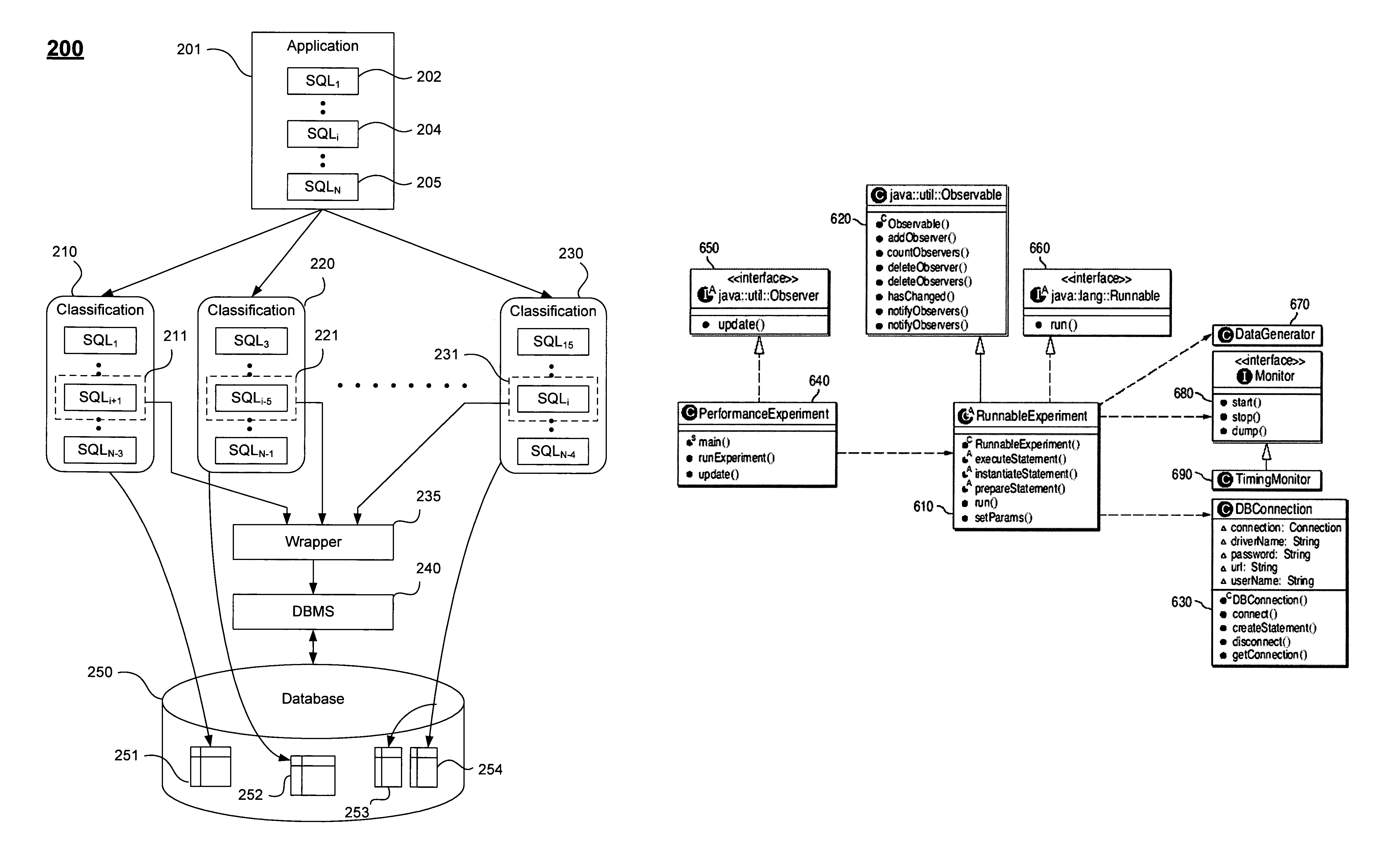

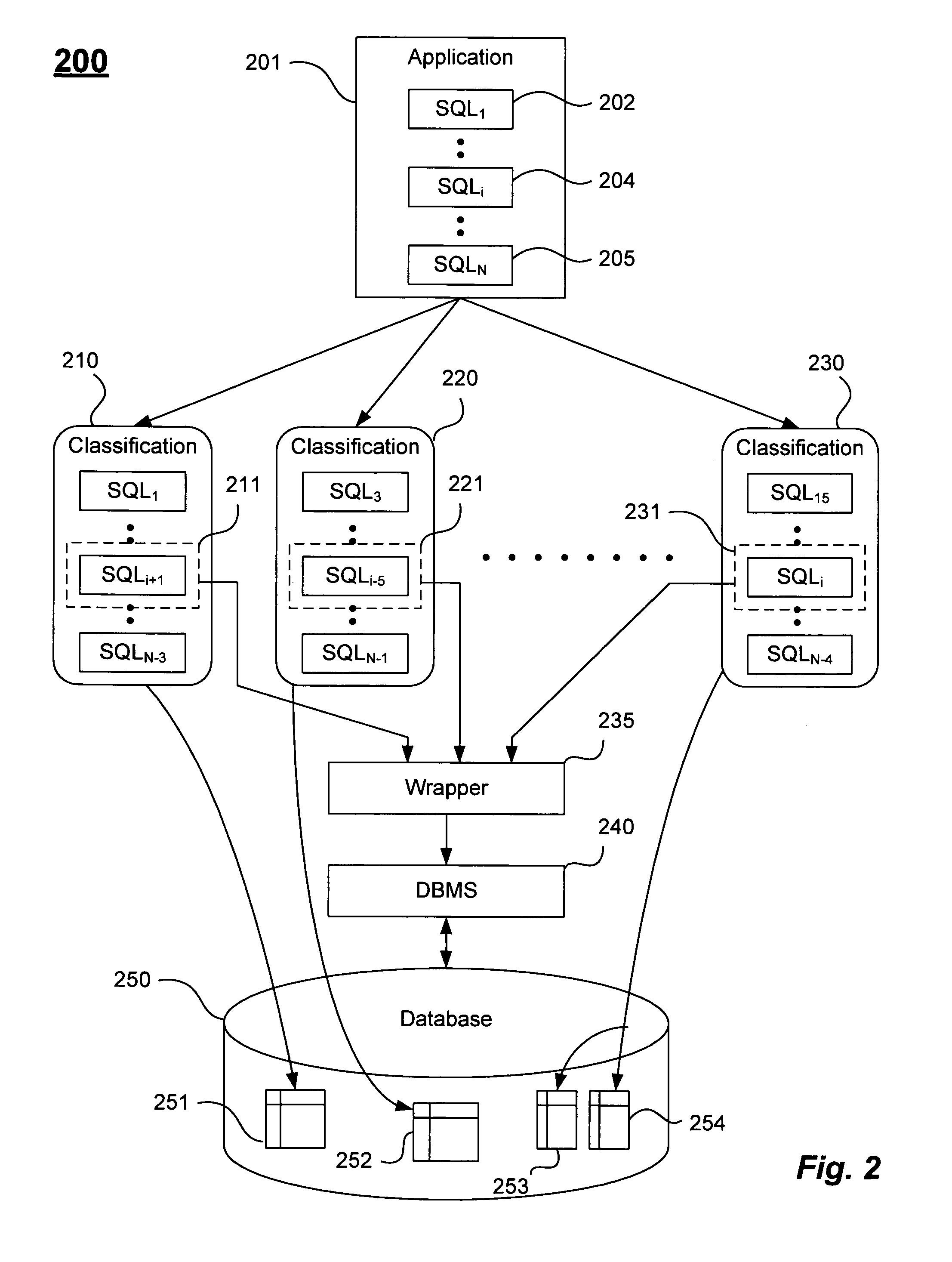

Systems and methods for repeatable database performance testing

ActiveUS7403954B2Improve database performance testingConvenient performance testingData processing applicationsError detection/correctionApplication softwareDatabase transaction

Embodiments of the present invention improve database performance testing. In one embodiment, the present invention includes a method of testing the performance of an application running transactions against a database comprising specifying performance critical database transaction statements in the application corresponding to one or more tables and separately executing each performance critical database transaction statement against the database a predetermined number of times, wherein the database is in a predetermined initial state at the beginning of each execution.

Owner:SAP AG

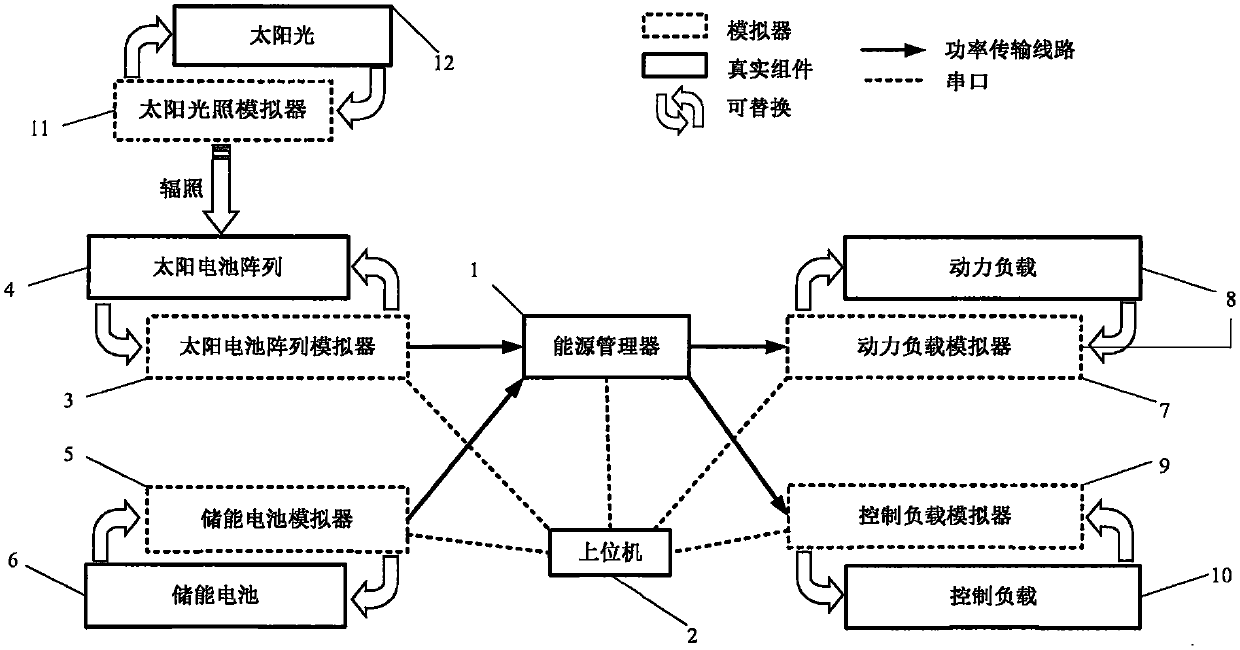

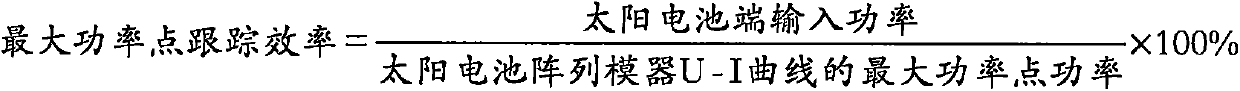

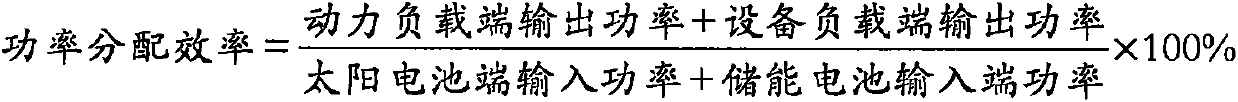

Renewable energy system simulation test and semi-physical simulation system

InactiveCN105373009AOptimization logicConvenient performance testingSimulator controlSolar cellBalance performance

The invention belongs to the renewable energy system field and relates to a renewable energy system simulation test and semi-physical simulation system. According to a solar cell array, an energy storage battery and a load in the renewable energy system simulation test and semi-physical simulation system, physical objects and simulators can replace each other, and the number and type of the physical objects of the assemblies can be adjustable, and therefore, a variety of work conditions can be simulated. The renewable energy system simulation test and semi-physical simulation system is not limited by weather and space. With the renewable energy system simulation test and semi-physical simulation system adopted, logical and performance testing of an energy manager can be facilitated; the energy flow process of a whole renewable energy system can be simulated; simulation testing can be performed on energy supply and demand balance performance of the energy system; and test and analysis conclusions can provide references for the design of the hardware of the energy manager.

Owner:NAT UNIV OF DEFENSE TECH

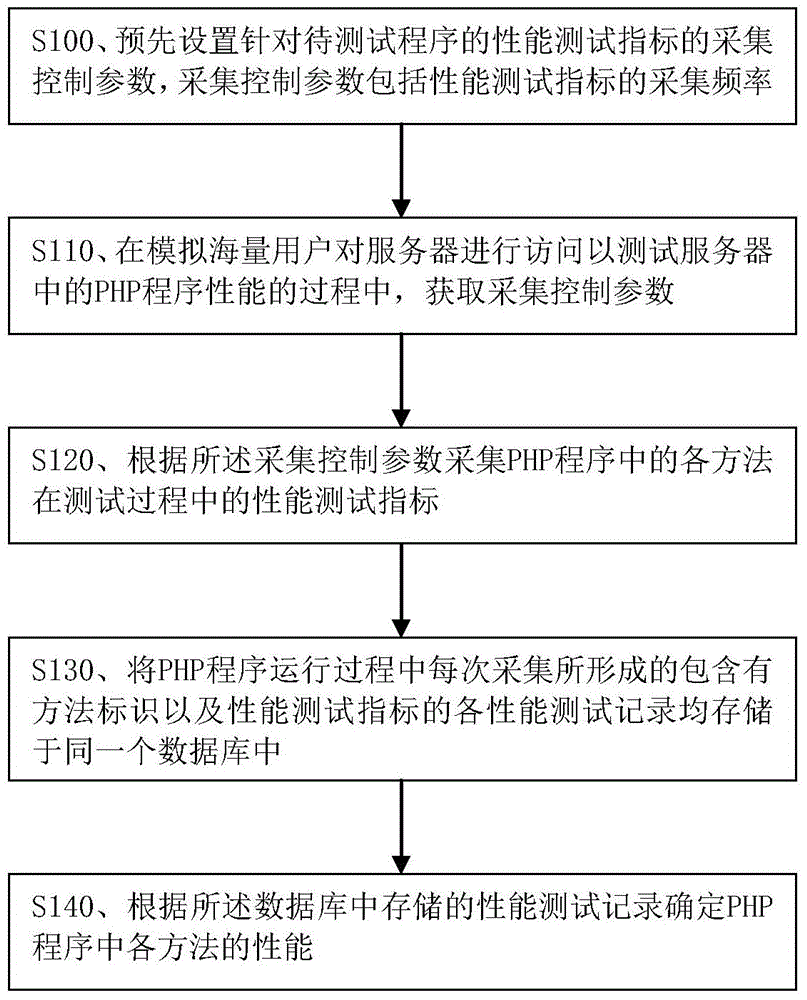

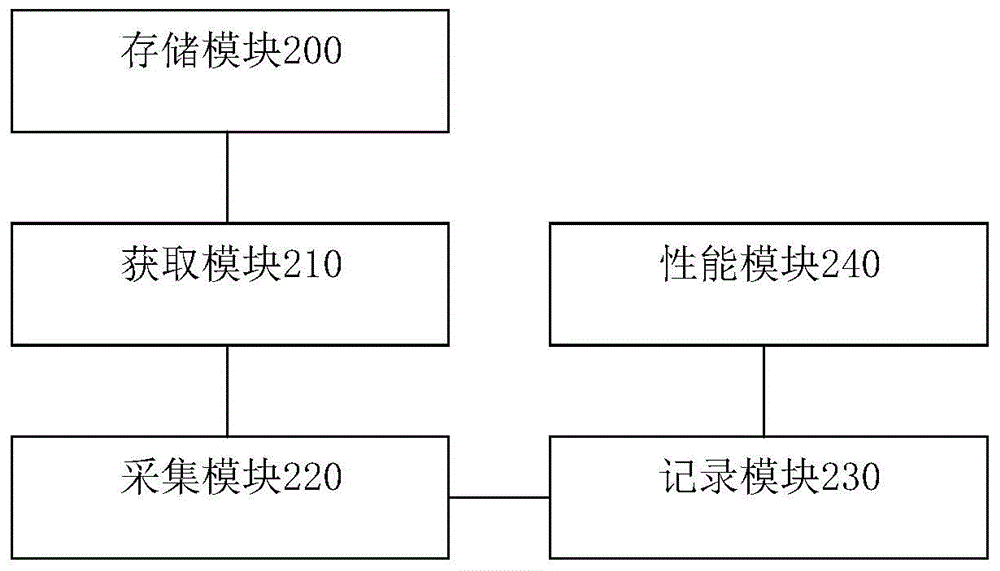

Program performance test method and device

InactiveCN105335280AReduce server resource consumptionImprove accuracySoftware testing/debuggingControl parametersSoftware engineering

The invention discloses a program performance test method and device, and aims at carrying out PHP program performance test on the basis of Xhprof. The method comprises the following steps: presetting a collection control parameter in allusion to a performance test index of a PHP program, wherein the collection control parameter at least comprises a collection frequency of the performance test index; obtaining the collection control parameter in a process of accessing to a server by a large amount of users to test the PHP program performance in the server; collecting the performance test index of each function in the server in the test process according to the collection control parameter; storing collected the performance test records which comprises function identifications and performance test indexes in the PHP program running process in a same database; and determining the performance of the functions in the PHP program according to the performance test records stored in the database.

Owner:BEIJING QIHOO TECH CO LTD +1

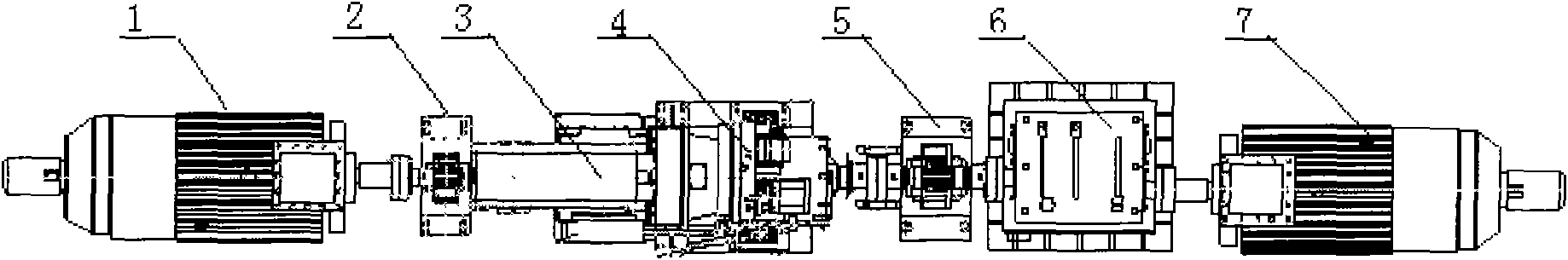

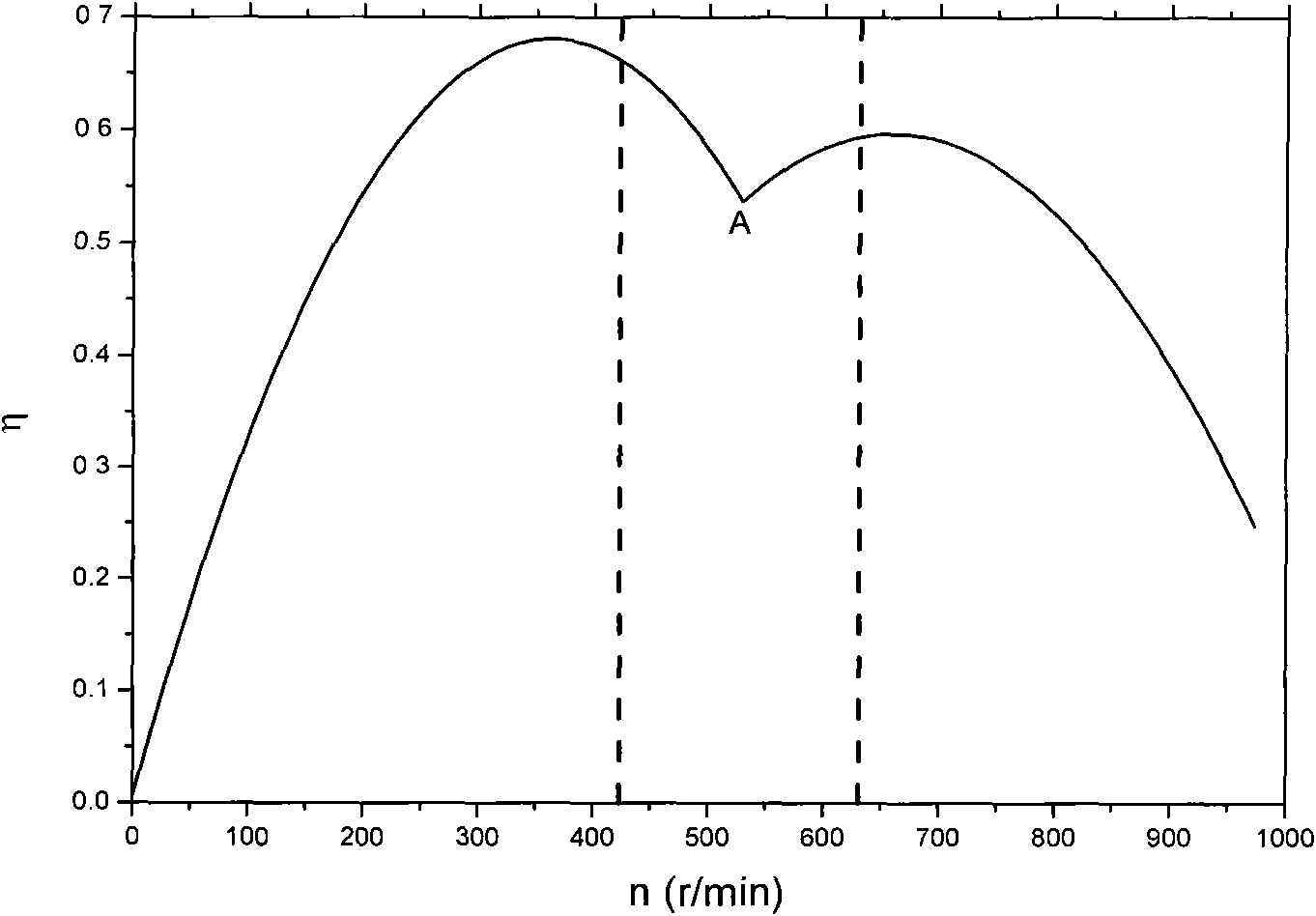

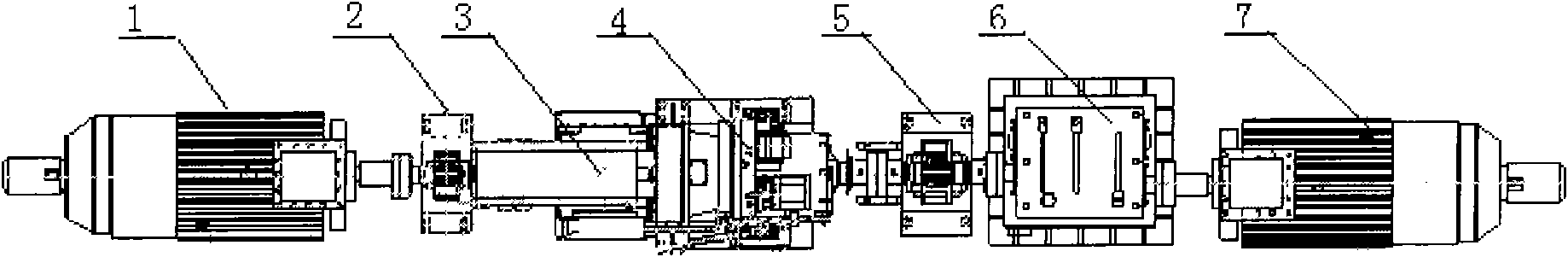

Overrunning clutch reliability test method and test bed

InactiveCN102062680ATruly reflect the load situationTaking into account the reliability index testMachine gearing/transmission testingIndex testPhase change

The invention provides an overrunning clutch reliability test method and a test bed, and belongs to the test method of a clutch. The method comprises the following steps of: constructing a speed changing box assembly performance test bed, wherein a power source and loading equipment adopt alternating-current variable frequency motors, and the rotating speed and the rotating torque of each of the alternating-current variable frequency motors can be regulated; detecting the transmission efficiency of a speed changing box assembly; and drawing a relation curve between the transmission efficiency and the output rotating speed of the speed changing box according to a test result, wherein a phase change point in the curve represents working states of separation and combination of the overrunning clutch. Seven components of the special test bed, namely a power alternating-current motor, an input rotating torque and rotating speed sensor, a transmission shaft, a speed changing box torque converter assembly, an output rotating torque and rotating speed sensor, a six-gear transmission box and a loading alternating-current motor are connected in sequence. The overrunning clutch reliability test method and the test bed have the advantages of truly representing the working condition of the overrunning clutch and facilitating the speed changing box performance test and the overrunning clutch reliability index test.

Owner:XCMG CONSTR MACHINERY

Method for testing underwater plugging-unplugging performance of underwater wet type connector

ActiveCN108008240AImprove test efficiencySimple test methodElectric connection testingMeasurement instrument housingMarine engineeringUnderwater

The invention relates to a method for testing the underwater plugging-unplugging performance of an underwater wet type connector. The method comprises: S1, an underwater wet type connector plug is fixed at a front clamp and an underwater wet type connector socket is fixed at a rear clamp; S2, cables of the underwater wet type connector plug and the underwater wet type connector socket are connected with an external testing device; S3, a motor assembly is started and drives the front clamp to drive the underwater wet type connector plug and the underwater wet type connector socket to be plugged; S4, according to a display result of the external testing device, the performance of the underwater wet type connector is determined; and S5, the motor assembly is turned off and testing is ended. According to the invention, the front clamp and the rear clamp are installed in the water tank to connect the connector plug and the connector socket respectively and fixedly and thus the connector performance is tested in an underwater state, so that the accuracy of the underwater wet type connector is improved; the cables of the plug and the socket are led out respectively and are connected withindicator lamps and the connector performance is determined by observing the on-off situation of display lamps.

Owner:CSSC SYST ENG RES INST +1

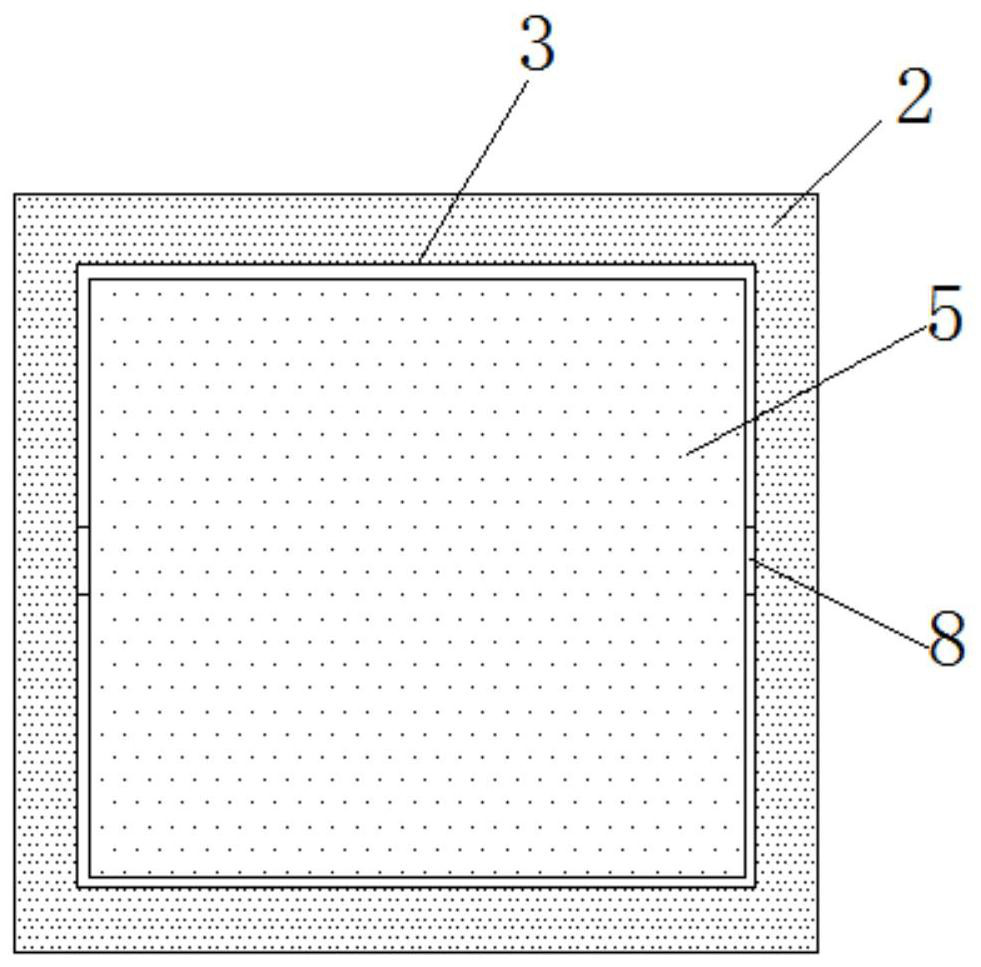

A thick film substrate miniaturized metal tube shell encapsulation structure

PendingCN109244045AConvenient performance testingReduce the difficulty of testingSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceMiniaturization

The invention discloses a thick film substrate miniaturized metal tube encapsulation structure. Upper layer and lower layer PCB boardS with a set distance are sleeved on the pins of the tube case base, and the upper layer and the lower layer PCB boards are electrically connected through pins or pins. The upper and / or lower surfaces of the lower two layers of PCB are provided with surface mountingelements. A ceramic substrate is soldered to the upper surface of the upper PCB, and a metal cap is covered on the base of the shell to seal the two layers of PCB. The circuit unit and the resistor which require high resistance precision are printed on the ceramic substrate by adopting a thick film process, which is favorable for active fine adjustment of the resistor and easy operation; Reasonable division of circuit layout is conducive to the circuit performance test of each board and reduces the difficulty of test.

Owner:NORTH ELECTRON RES INST ANHUI CO LTD

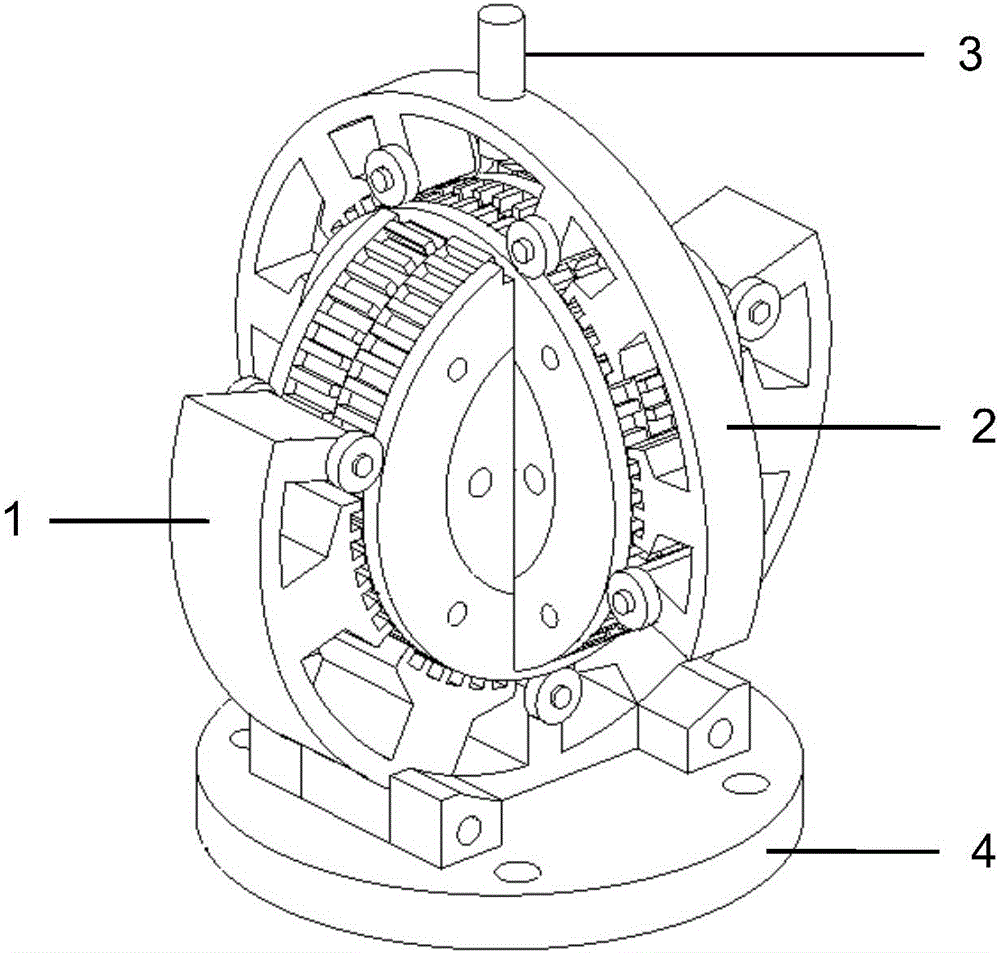

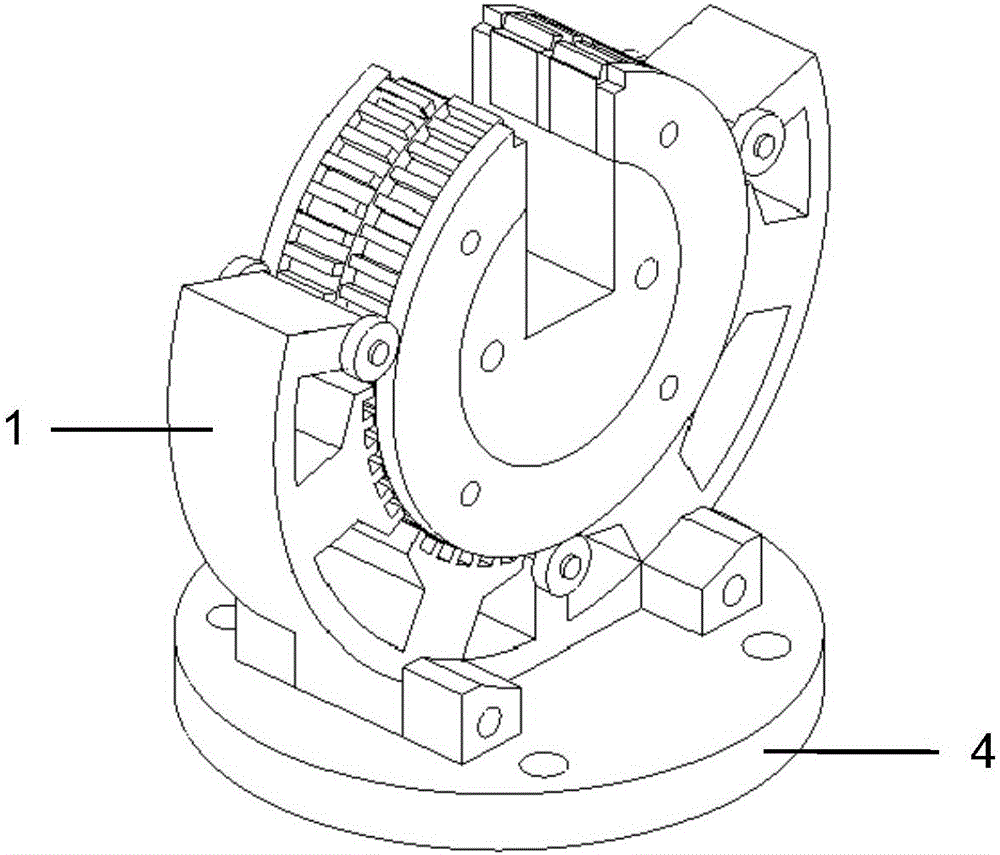

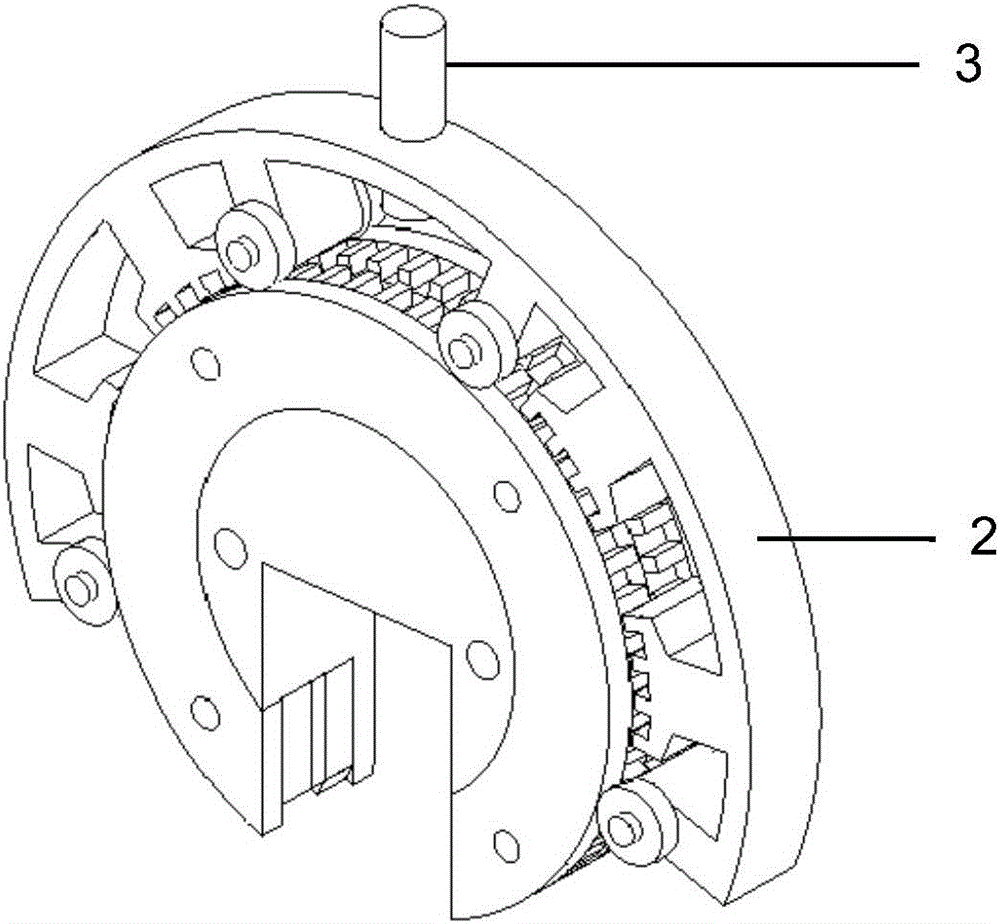

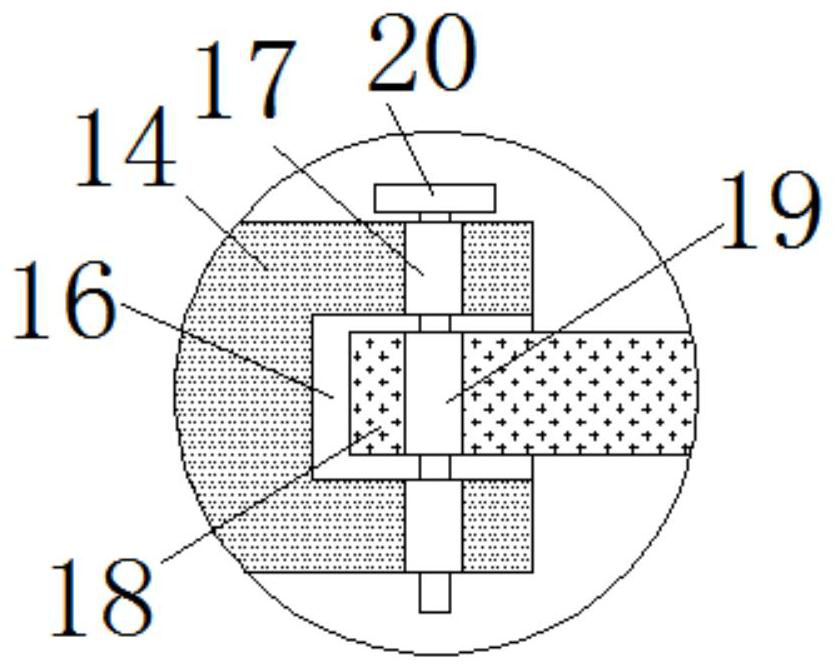

Two-freedom-degree hybrid stepping motor for bionic eyeballs of robot

InactiveCN106451994AHighly integratedHigh material utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsManufacturing technologyTwo degrees of freedom

The invention discloses a two-freedom-degree hybrid stepping motor for bionic eyeballs of a robot. The stepping motor comprises a first freedom degree motor, a second freedom degree motor and output shafts, wherein the first freedom degree motor is of a circular structure with a notch, the second freedom degree motor is of a circular structure with an opening, the notch is matched with the opening, and the planes of the two motors are perpendicularly orthogonal; the first freedom degree motor and the second freedom degree motor both comprise stators and rotors, the stators and the rotors can relatively move in the planes of the motors, and the two-freedom-degree movement of the output shaft of one freedom degree motor can be achieved through respective independent movement of the two freedom degree motors. The two-freedom-degree hybrid stepping motor has the advantages of being simple in structure and manufacture technology, convenient in analysis design, high in mechanical integration level, high in open-loop operation location accuracy, easy in performance experiment test and favorable for shortening the development period of products and improving the performance and the competitiveness of the products.

Owner:SHANDONG UNIV

Electro-optical device, method of testing the same, and electronic apparatus

ActiveUS7884892B2Small sizeConvenient performance testingNon-linear opticsControl signalHemt circuits

An electro-optical device includes: a counter substrate; an element substrate comprising a protruding region protruding from one side of the counter substrate and being bonded to the counter substrate; a plurality of pixel units that are arranged in a pixel region on the element substrate; a plurality of external circuit connecting terminals which are arranged in the protruding region on the element substrate and to which various signals including image signals and control signals for allowing the plurality of pixel units to display an image are supplied; and a plurality of test terminals that are provided at both ends of an array of the plurality of external circuit connecting terminals in the protruding region and are supplied with test signals, wherein a distance between adjacent test terminals is longer than a distance between adjacent external circuit connecting terminals.

Owner:SEIKO EPSON CORP

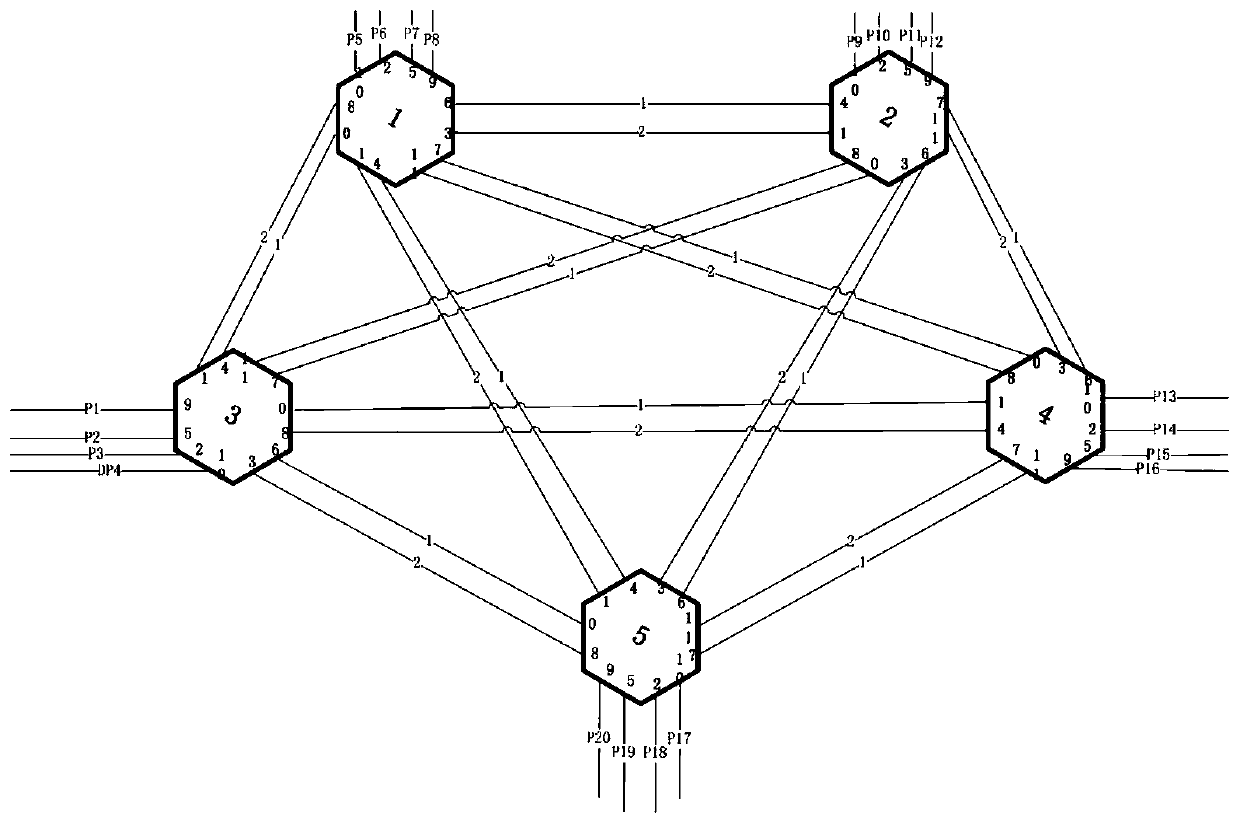

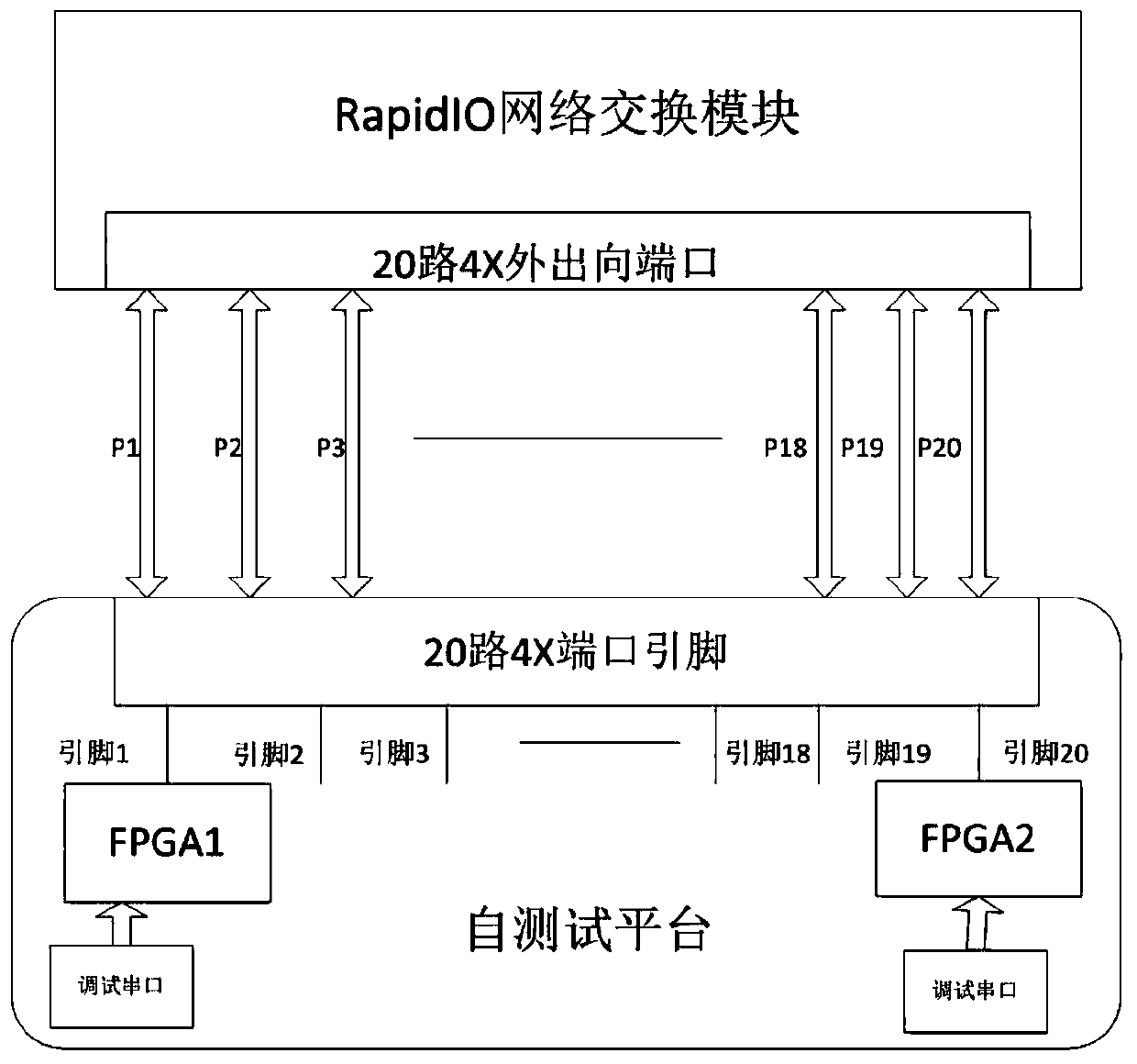

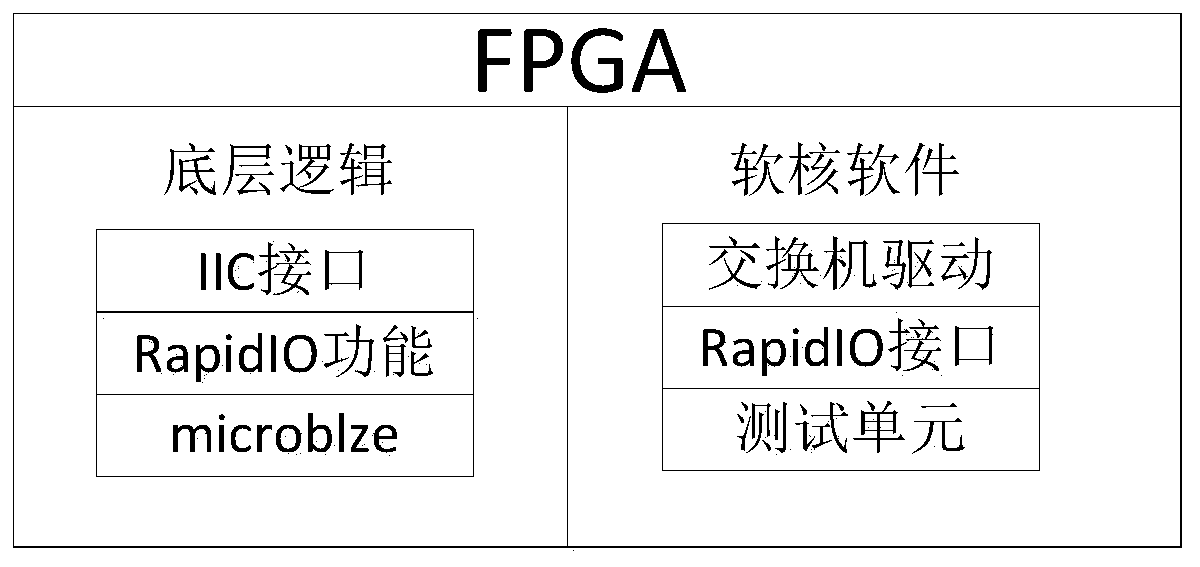

Self-test platform for testing serial RapidIO network switching module

ActiveCN111522700AAccelerate the development progressConvenient performance testingFaulty hardware testing methodsEnergy efficient computingTestwareTest platform

The invention discloses a self-test platform for testing a serial RapidIO network switching module, and the platform comprises bottom plate hardware and test software, and the bottom plate hardware comprises a plurality of port pins, two FPGA chips, and two debugging serial ports. The port pins are used for leading each outer outgoing port of the switching module to a bottom plate, and a self-loopback relation is formed between any two port pins by adopting an external self-loopback mode; the debugging serial port is used for outputting a test request to the FPGA chip; one SRIO interface is led out of the two FPGA chips to be connected with any port pin in an external jumper mode according to test requirements, and the same test software resides in the two FPGAs; and the test software comprises a switch driver, a RapidIO controller and a function test unit and is used for completing various test items. Under the condition of not depending on a system testing environment, the platform is suitable for testing functions and performances of various customized serial RapidIO network switching modules.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

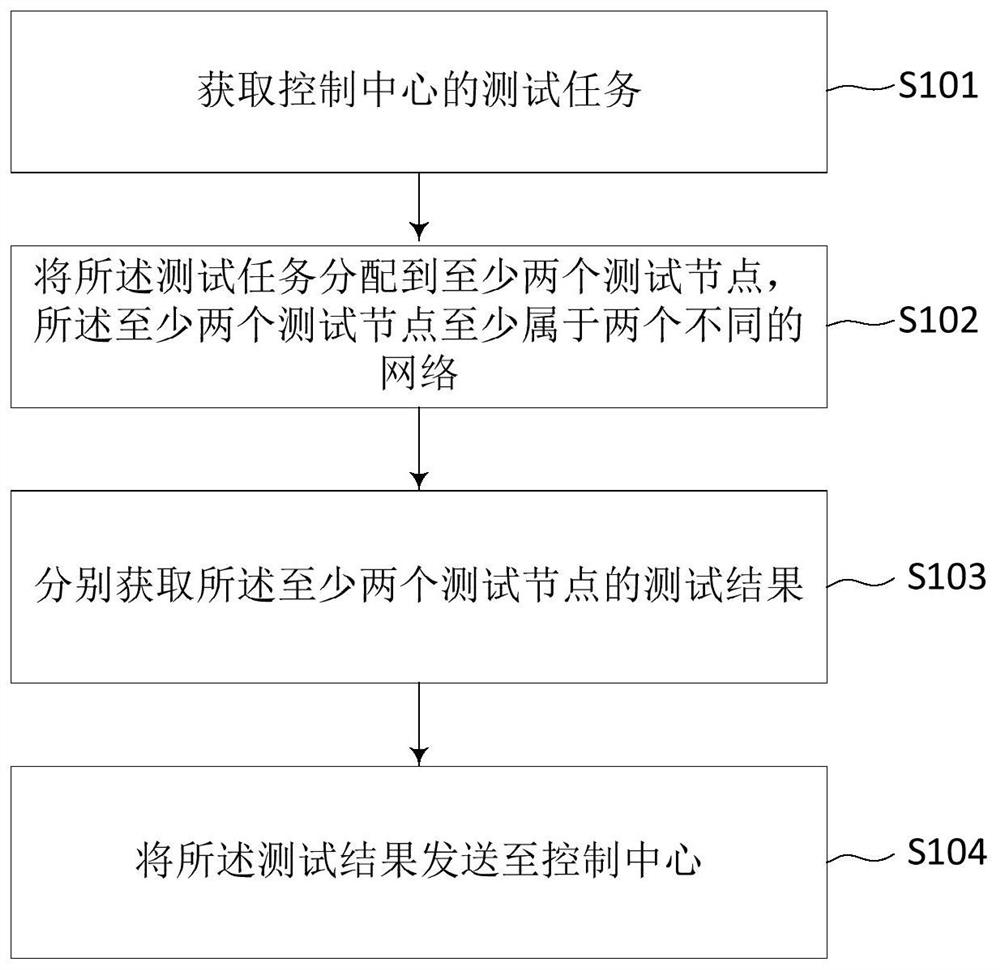

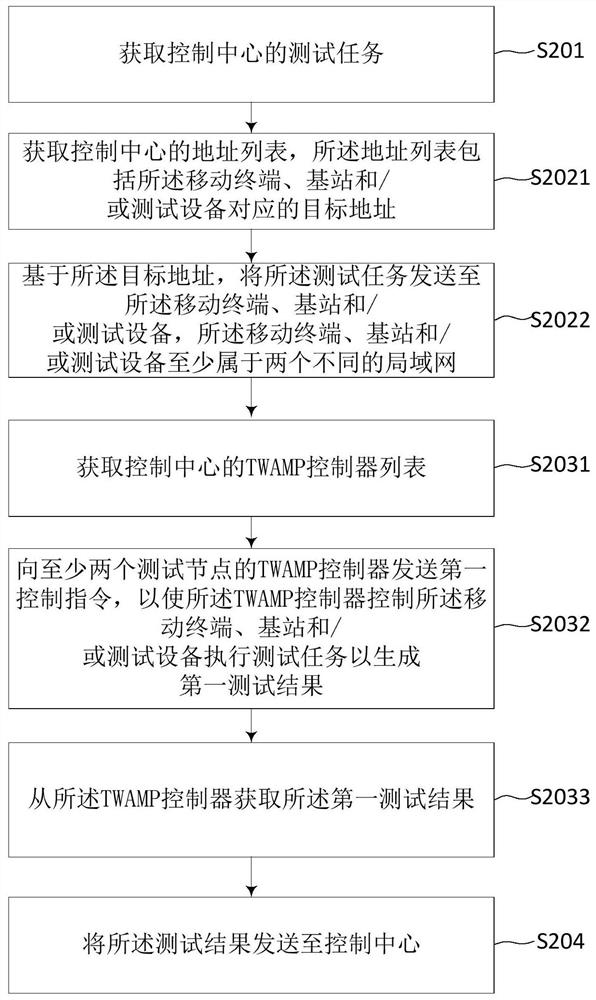

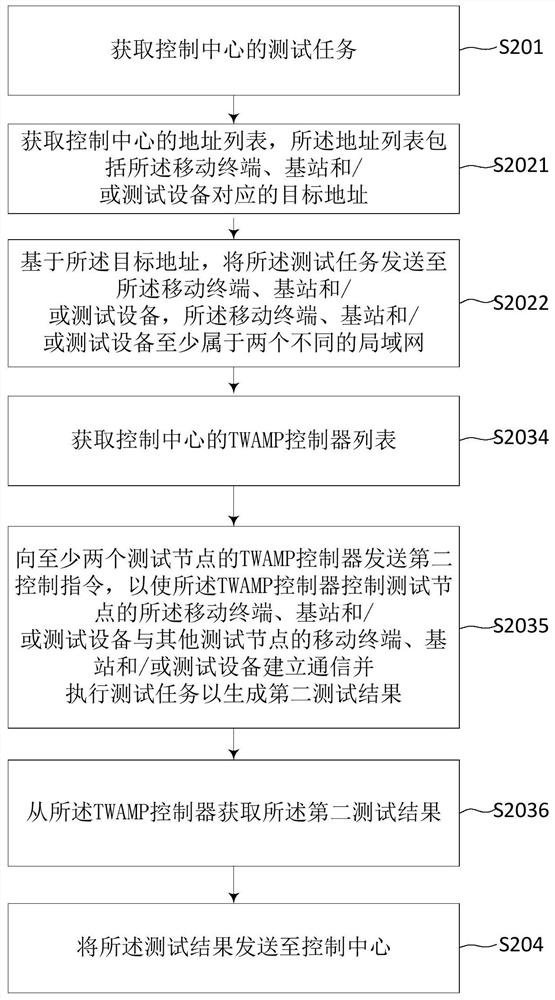

Distributed network performance test method and system, server and storage medium

ActiveCN111817913AImplement performance testingRealize evaluationData switching networksTotal factory controlEngineeringDistributed computing

The invention provides a distributed network performance test method which is executed by a management node and comprises the following steps: acquiring a test task of a control center; distributing the test task to at least two test nodes, wherein the at least two test nodes at least belong to two different networks; respectively obtaining test results of the at least two test nodes; and sendingthe test result to a control center. The invention further provides a distributed network performance test system, cross-network performance test and comprehensive evaluation are realized by distributing the test tasks to the test nodes of different local area networks, so that the distributed network performance test is more convenient.

Owner:北京红山信息科技研究院有限公司

Automatic comprehensive cable detector

InactiveCN111735727AShorten the timeAvoid damageMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesCopper wireStructural engineering

The invention discloses an automatic comprehensive cable detector. The detector comprises a shell, and driving devices for controlling a cable to move are symmetrically arranged on the left and rightpositions of the upper surface of the shell. Each driving device comprises a first rotating box fixedly arranged on the upper surface of the shell. Guiding devices for lifting and guiding the cable are symmetrically arranged on the left and right positions of the upper surface of the shell between the two driving devices. The detector is simple in structure, is convenient to use, can test the bending performance, twisting performance and insulating layer depth of the cable at the same time, and saves the time for testing the performance of the cable. Meanwhile, a height-adjustable guide head is arranged, so that the phenomena of pulling, winding and the like are prevented from damaging a copper wire in the cable and influencing a test result. A driving device is arranged, the cable can becontrolled to move left and right, performance testing can be conveniently conducted on the cable at different positions, and the credibility of the result is improved.

Owner:杭州昊斯科技有限公司

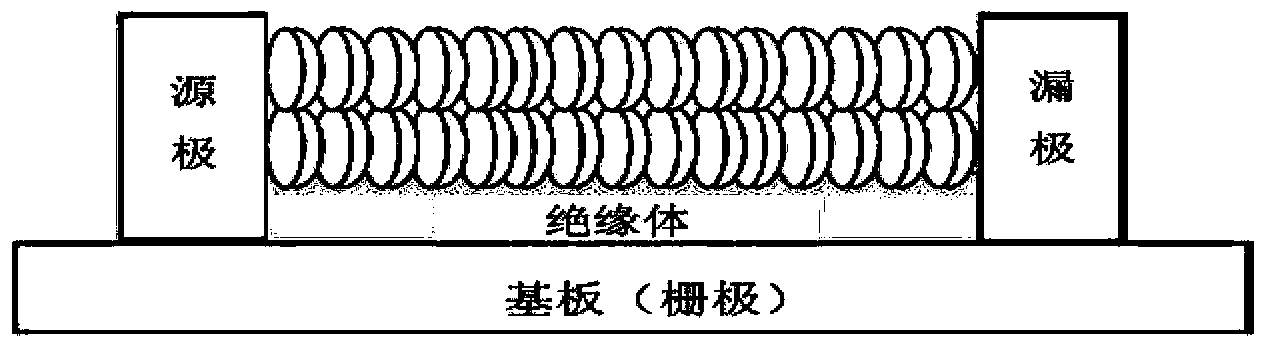

Synthon and method for preparing dibenzocoronene compounds by same

ActiveCN103570714AImprove solubilityEasy to purifyLiquid crystal compositionsOrganic chemistryCoroneneSynthon

The invention relates to a synthon and a method for preparing dibenzocoronene compounds by the same. The synthon is a tetrahydroxy-substituted perylene bisimide compound, and has a structure as shown in general formula (I), wherein R is a C1-C18 linear chain primary alkyl or a primary alkyl with a branched chain. According to the invention, dibromo-perylene anhydride or mixtures are used for preparing dibromo-imide; dibromo-imide and phenylboronic acid substituted by alkoxys at 3 and 4 positions are subjected to a Suzuki coupling reaction under the catalysis of Pd(PPh3)4 to prepare aryl-substituted perylene bisimide compounds; further dealkylation reaction is carried out under the action of boron tribromide so as to form tetrahydroxy-substituted perylene bisimide compound synthon; then the synthon is used as a raw material to synthesize charge transfer compounds of coronene compounds with imide groups at two sides of the molecule. The synthetic method of the invention is simple, high in yield, and widely applicable to organic light-emitting diodes, field effect transistors, and solar cells. The general formula (I) is shown in the description.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

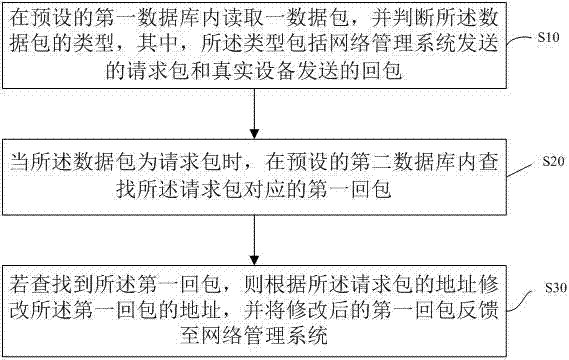

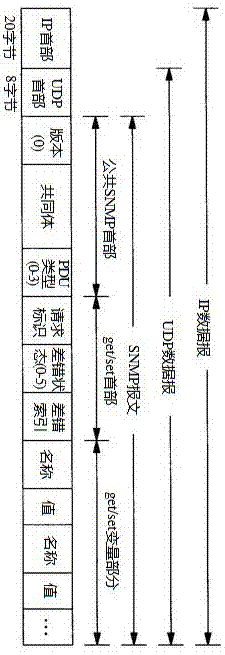

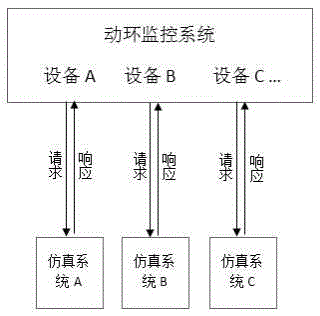

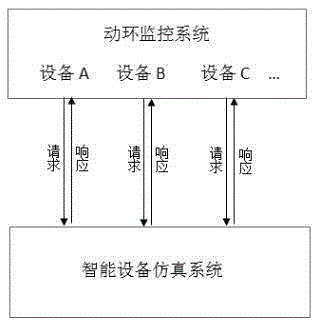

Network simulation test method, simulation server and storage medium

InactiveCN107579879AImprove versatilityEasy to test pressureData switching networksNetwork packetNetwork management

The invention discloses a network simulation test method, a simulation server and a storage medium. The method comprises the steps that a data packet is read in a preset first database, and when the data packet is a request packet, a first reply packet corresponding to the request packet is looked up in a preset second database; and if the first reply packet is found, the address of the first reply packet is modified according to the address of the request packet, and the modified first reply packet is fed back to a network management system. According to the method, by configuring a real device of a network device, multiple simulation devices of a network device can be simulated, and convenience is brought to stress testing and performance testing of the network management system. In addition, the network device simulator system does not achieve an SNMP Agent of a concrete type of network device directly and reads the reply packet of the request packet from the real device, and therefore the test method has the high universality.

Owner:GENEW TECH

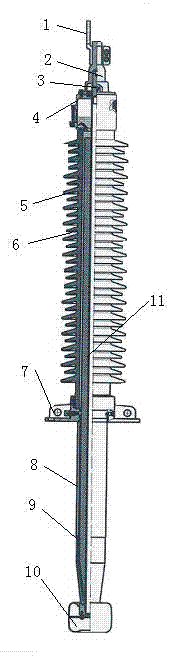

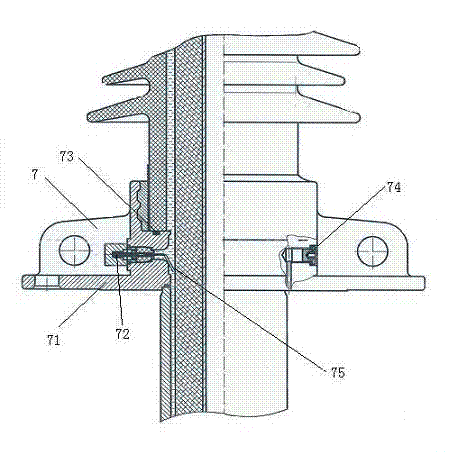

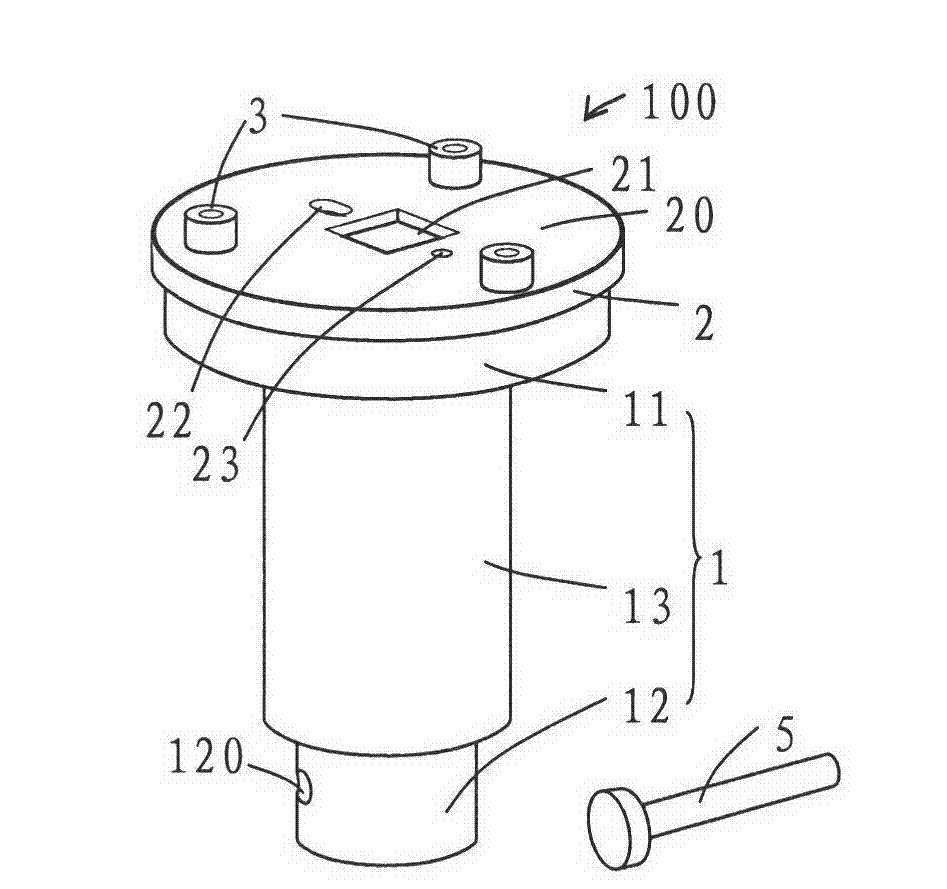

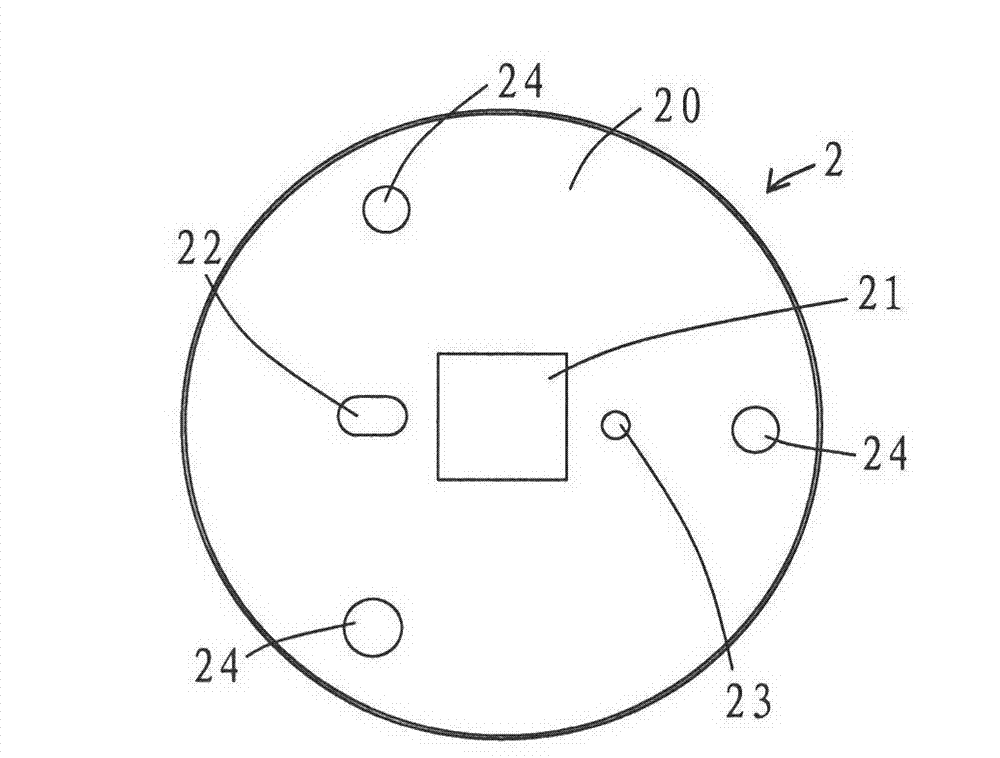

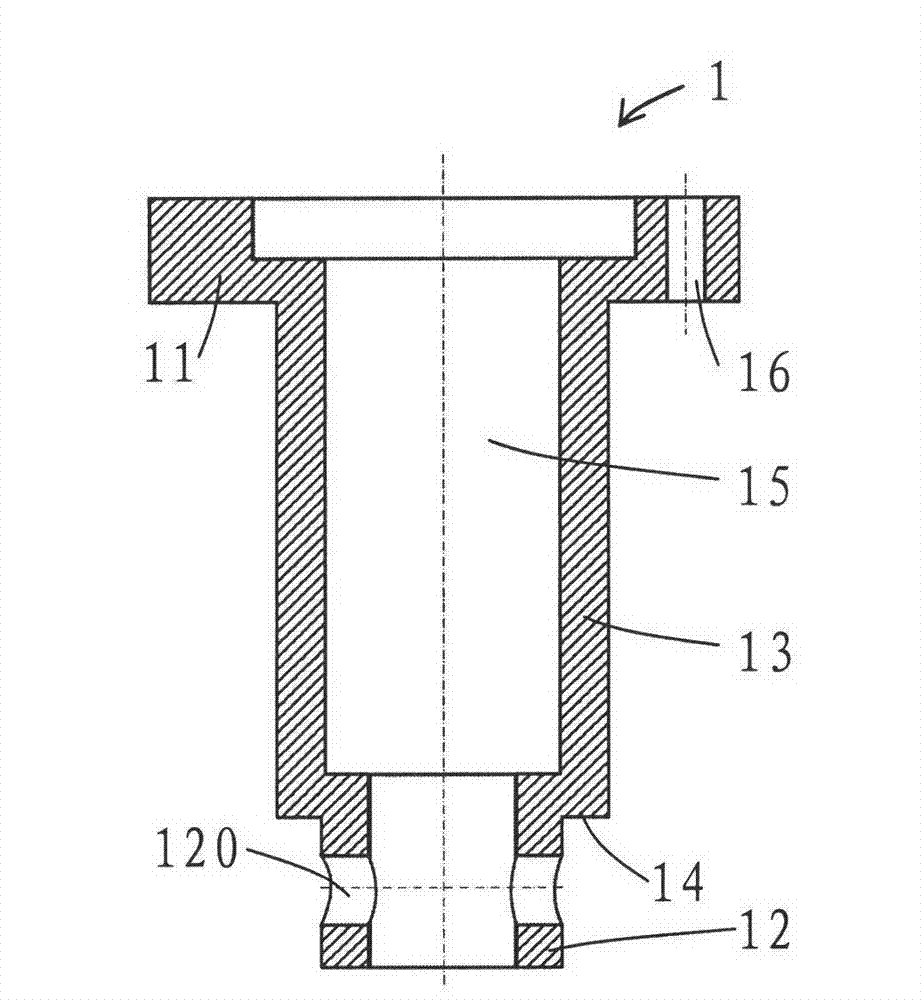

Transformer bushing

InactiveCN103093943AFirmly connectedEasy to observeTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention relates to a transformer bushing used in power industries. The transformer bushing is composed of a connecting bar, a general cap, a joint, an oil pillow, a bushing, a porcelain sleeve, a flange, a shielding bushing, an insulating barrel, a voltage-sharing ball and a conducting tube, the shielding bushing is fixedly mounted on the flange, the voltage-sharing ball is arranged on the lower portion of the shielding bushing, the conducting tube is mounted in an inner cavity of the shielding bushing in an inserted manner, the bushing is mounted on the periphery of the conducting tube in a sleeved manner, the bushing is an insulating capacitor provided with multiple leading-out taps, and the lower end of the porcelain sleeve is connected with the flange. The multiple leading-out taps are arranged on the bushing and connected with a detecting device, so that detecting process can be more reliable; the taps are led out from an outermost-layer electrode and a secondary outer-layer electrode of the bushing respectively, and a low-power power source of with certain voltage can be obtained between the two electrodes during equipment running, so that a power source is provided for the detecting device; connection between test taps and the flange is reliable and compact, so that performance testing is facilitated; and grounding seats are arranged in the test taps, so that grounding is facilitated integrally.

Owner:JIANGSU SIYUAN HERTZ TRANSFORMER

Mechanical test fixture and limiting stopper mechanical test apparatus

ActiveCN103115756AWide versatilityWide range of applicationsMachine part testingEngineeringTest fixture

The invention discloses a mechanical test fixture and a limiting stopper mechanical test apparatus, wherein, the mechanical test fixture includes a fixture main body and a cover body. The fixture main body includes a first connecting part and a second connecting part. The second connecting part is provided with a connecting structure which is used for connecting with a tester in a detachable mode. The cover body is fixed with the first connecting part of the fixture main body, and the cover body is provided with an installing structure used for installing test parts. Thus, the test parts to be tested can be fixed on the tester conveniently and quickly, and the tester can further complete relevant performance tests for the test parts to be tested conveniently.

Owner:SAIC GENERAL MOTORS +1

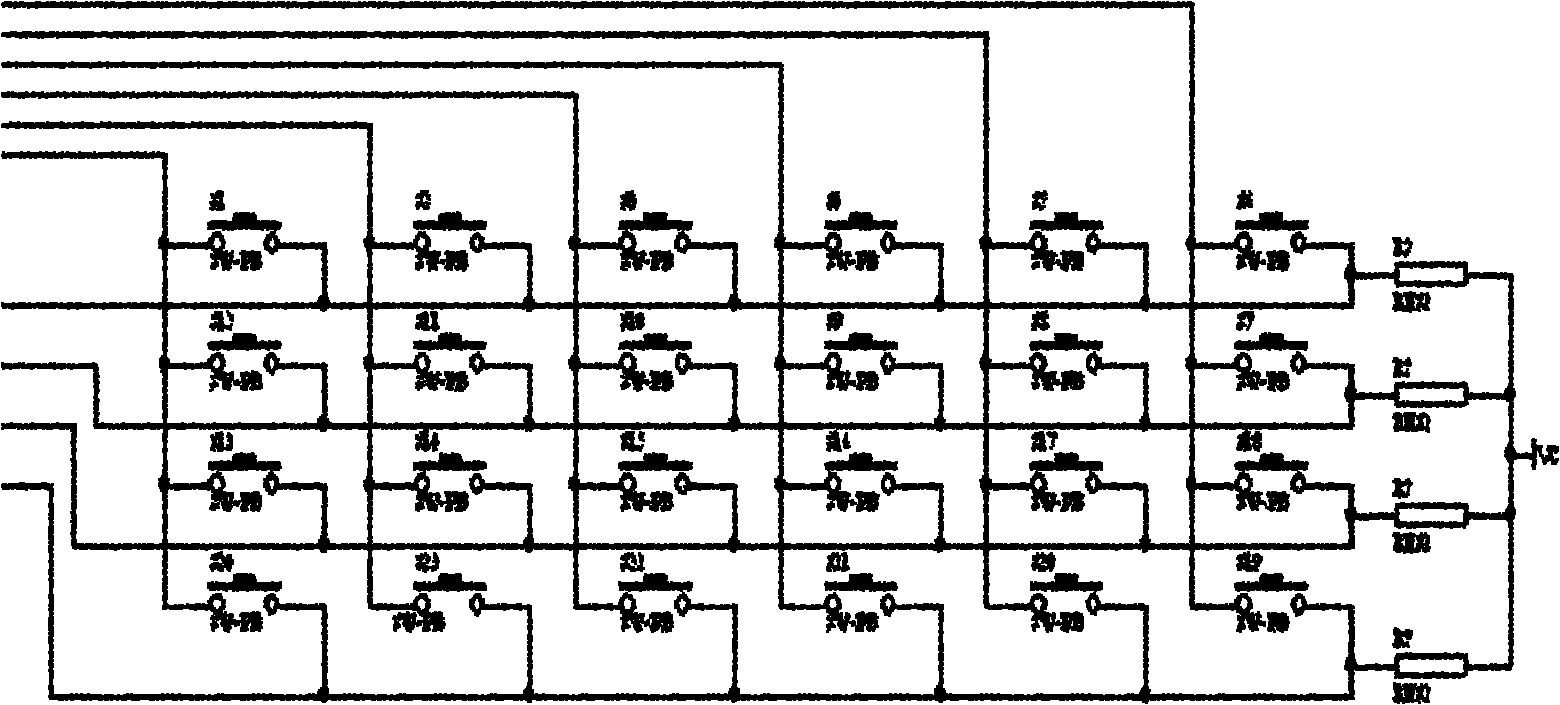

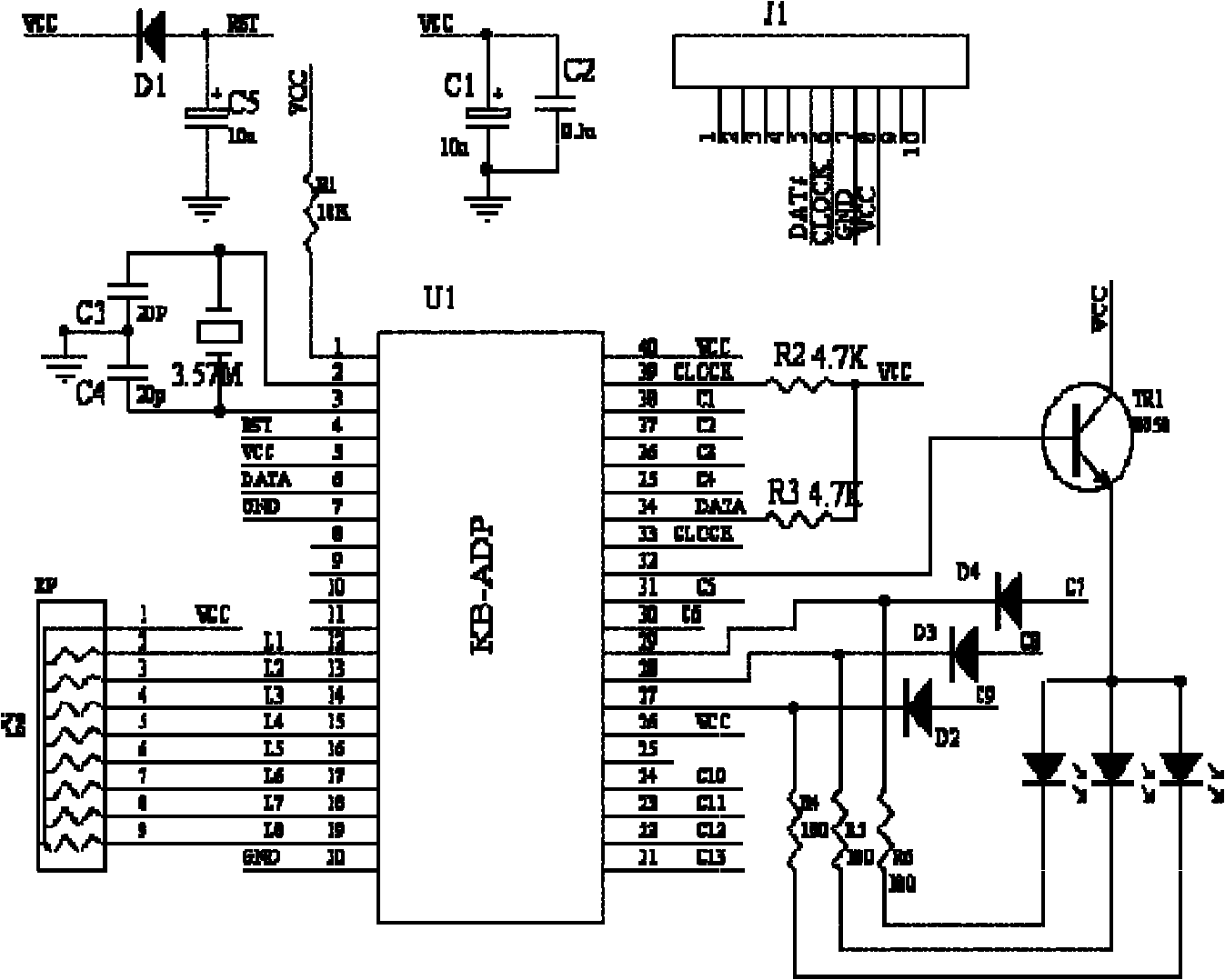

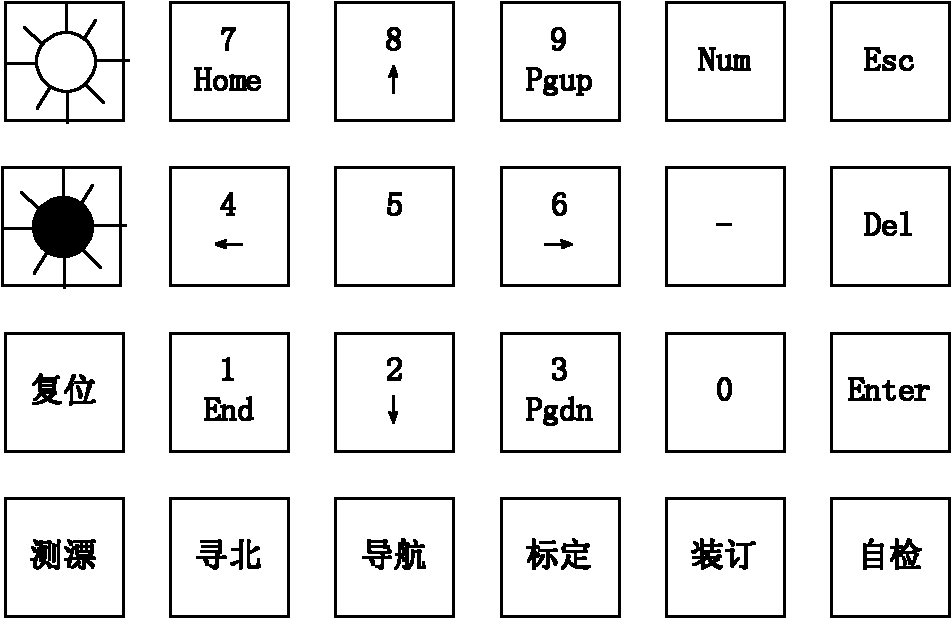

Matrix keyboard for detector of positioning orientating system

InactiveCN102156542AGuaranteed portability and reliabilityFacilitates performance testing and troubleshootingInput/output for user-computer interactionSelf checkingMarine navigation

The invention discloses a matrix keyboard for a detector of a positioning orientating system, which comprises 6 special functional keys, two luminance control keys, 12 number / control keys, a confirming key, an escape key, a delete key, and a reset key, wherein the 6 special functional keys are as follows: a shift-detecting key, a north-searching key, a navigation key, a demarcating key, a binding key and a self-checking key; the 12 number / control keys are as follows: 0-9 ten number keys, a number switching num key and a symbolic key; the number keyboard can be used as a direction key when the function of number switching num key is not started; data can be inputted normally after the function of number switching num key is started; and a decoding plate is used for converting the key signal into the code which can be identified by the windows XP operation system and directly connecting to a keyboard port of the PC104 computer board. By externally connecting the matrix keyboard, the portability and the reliability of the detector are ensured, thereby ensuring the butt joint with a vehicle-loaded positioning orientating navigation system and performing the property test and fault diagnosis.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Robot servo motor performance testing device

InactiveCN112462084AConvenient performance testingSimple structureEngine testingLinear/angular speed measurementElectric machineMotor shaft

The invention discloses a robot servo motor performance testing device, which comprises an operation table and a connecting rod; a fixed block is fixedly mounted on the right side of the upper surfaceof the operation table, an adjusting groove is formed in the middle of the upper surface of the fixed block, and a first electric-hydraulic push rod is fixedly mounted in the middle of the inner wallof the bottom end of the adjusting groove. A first electric-hydraulic push rod is controlled to work, an adjusting plate can be pushed to move up and down in an adjusting groove, a rotating rod of aservo motor is further adjusted to be flush with a connecting rod, a second electric-hydraulic push rod is controlled to work, a mounting block can be pushed to stably move left and right on an operation table, and the left end of the rotating rod penetrates through the connecting groove; a positioning bolt penetrates through a first fixing hole and a second fixing hole, so that a connecting rod is fixedly connected with a rotating rod, a servo motor is controlled to work and rotate, the rotating rod can further drive a rotating block to rotate, a rotating speed sensor can detect the rotatingspeed of the rotating block and further detect the rotating speed of a motor shaft of the servo motor, and the use efficiency is high.

Owner:芜湖赛宝机器人产业技术研究院有限公司

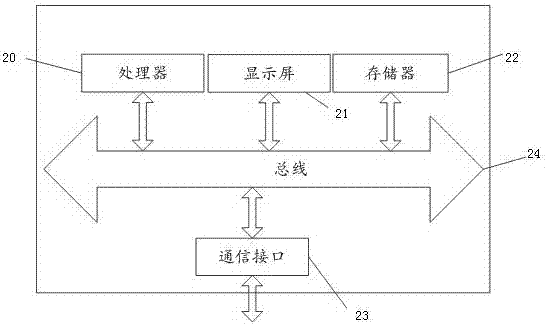

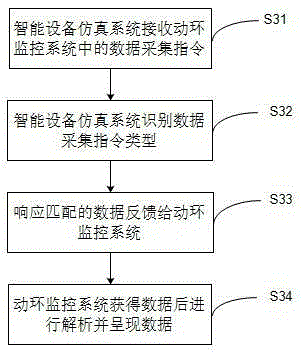

Intelligent equipment simulation method

ActiveCN105245623AImprove scalabilityConvenient performance testingTransmissionFile/folder operationsMonitoring systemIntelligent equipment

The invention discloses an intelligent equipment simulation method, which adopts an intelligent equipment simulation system for providing simulation data to a dynamic environment monitoring system including a plurality of sets of intelligent equipment, the intelligent equipment simulation system is internally provided with a plurality of script files respectively corresponding to the intelligent equipment of the dynamic environment monitoring system, and each script file is used for providing simulation data to the corresponding intelligent equipment thereof. The intelligent equipment simulation method can simultaneously support various types of intelligent equipment to conduct simulation, and solves the problems of a simulation system that the number of equipment types is limited and the equipment data presentation form is single.

Owner:GOSUNCN TECH GRP

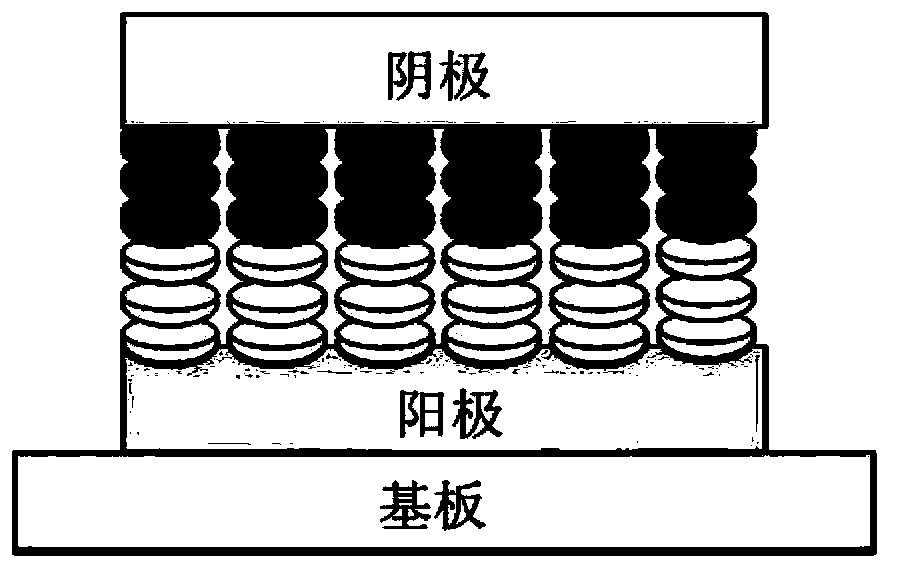

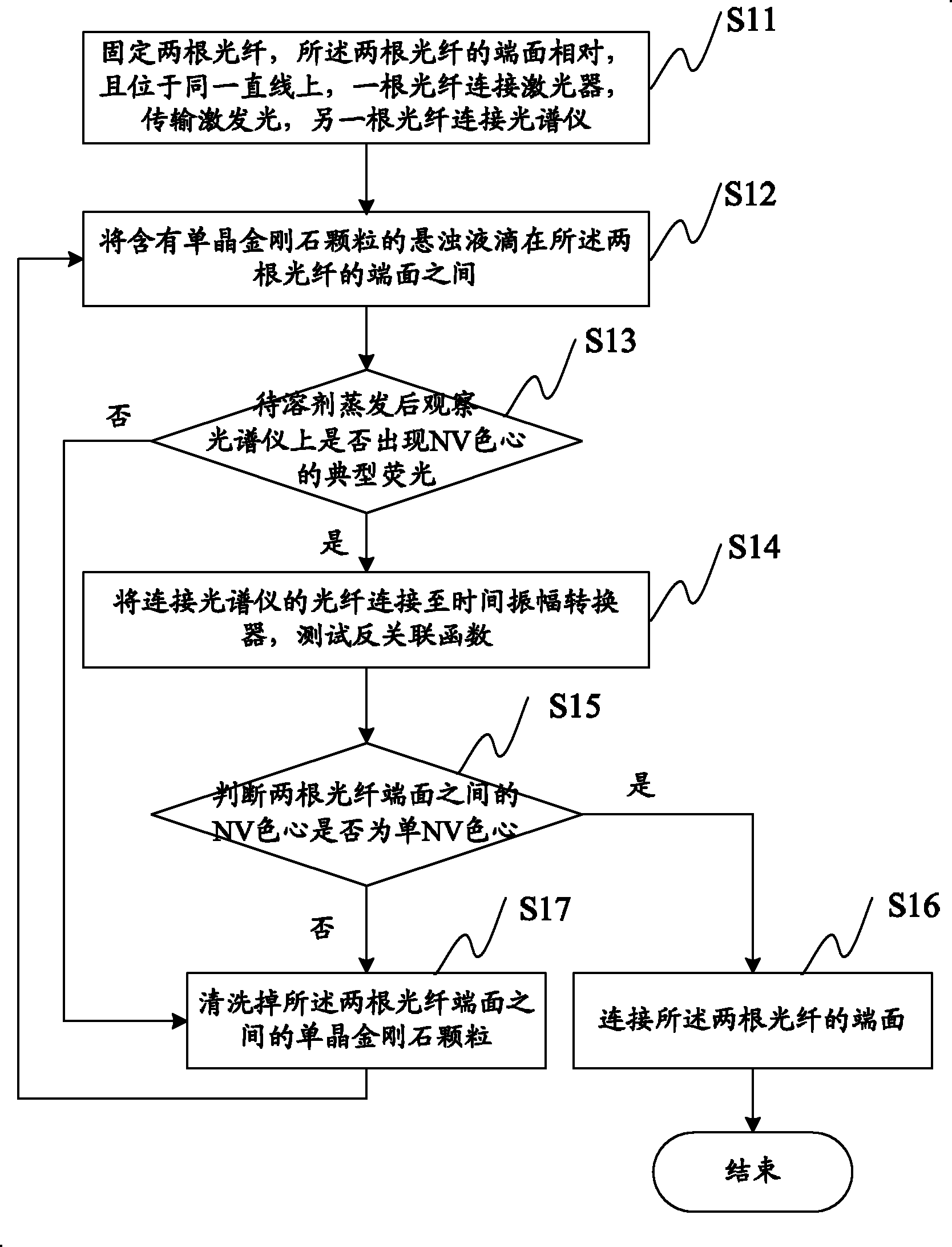

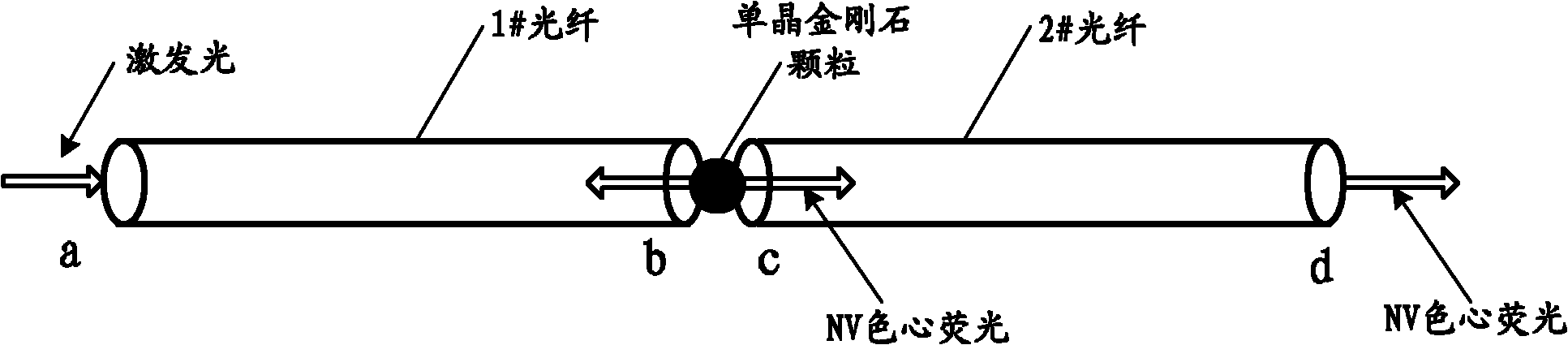

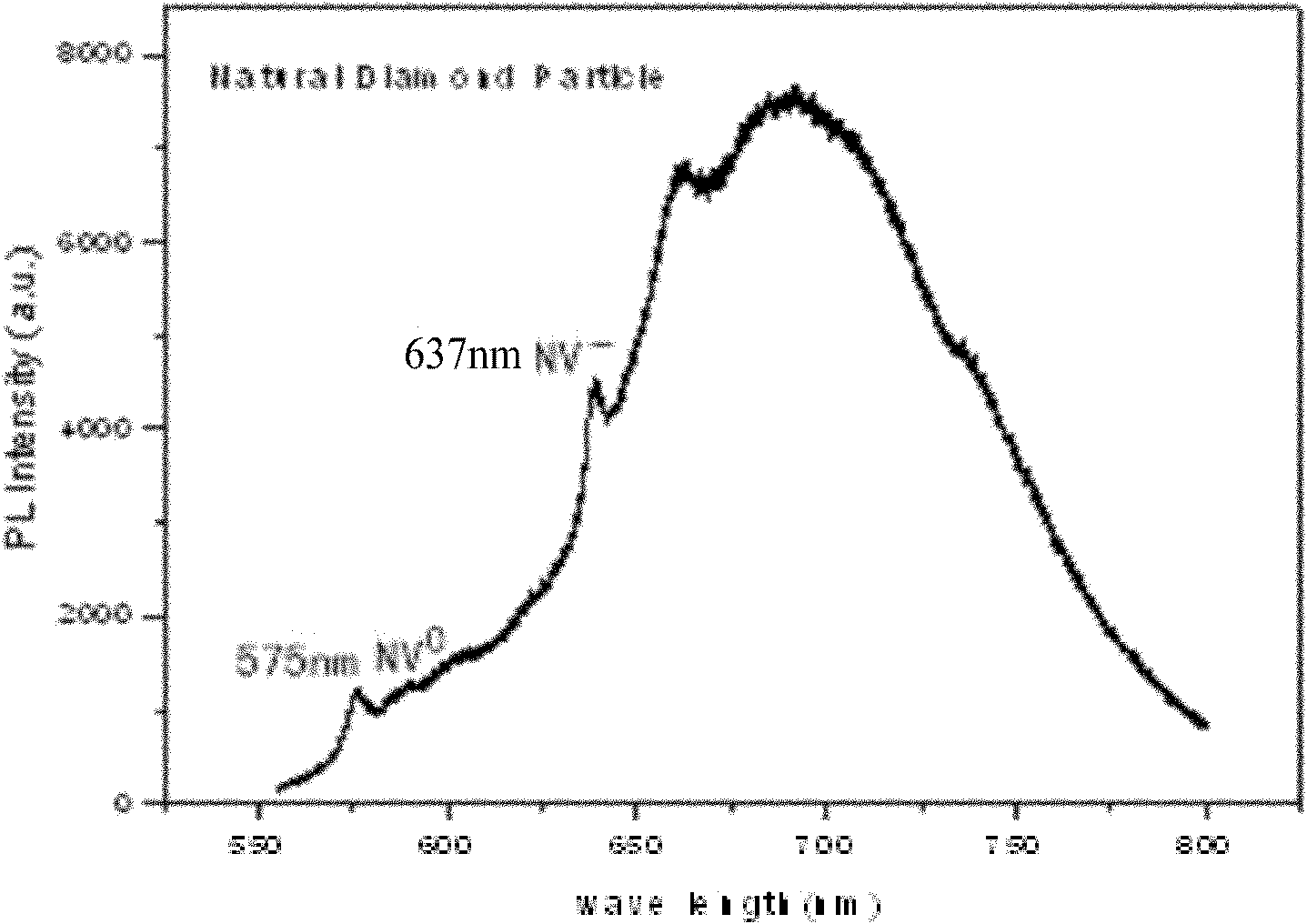

Method for packaging single NV color center and single NV color center device

InactiveCN102185252AReduce the impactLow costLaser active region structureNanoopticsColour centreFluorescence

The embodiment of the invention discloses a method for packaging a single NV color center and a single NV color center device. The method comprises the following steps: a), fixing two optical fibers, wherein end faces of the two optical fibers are opposite, the first optical fiber is connected with a laser and used for transmitting exciting light, and the second optical fiber is connected with a spectrometer; b), dropping turbid liquids containing single-crystal diamond particles between the two end faces of the two optical fibers, observing whether typical fluorescence of the NV color center appears on the spectrometer after the turbid liquids are evaporated, executing the c) step if the typical fluorescence appears on the spectrometer, and executing the e) step if the typical fluorescence does not appear on the spectrometer; c), connecting the second optical fiber to a TAC (time-to-amplitude converter), measuring a reverse correlation function, judging whether to be the single NV color center, if so, executing the d) step, and otherwise, executing the e) step; d), connecting the two end faces of the two optical fibers to finish the package; and e), washing away the single-crystal diamond particles between the two end faces of the two optical fibers, and repeating the b) step. According to the invention, the process of searching and positioning the single NV color center is simplified, the cost of searching and positioning the single NV color center is reduced, and the research and application of the single NV color center are convenient.

Owner:UNIV OF SCI & TECH OF CHINA

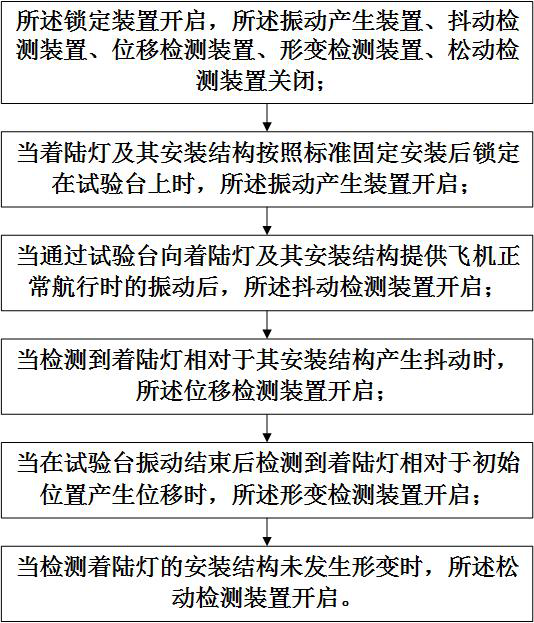

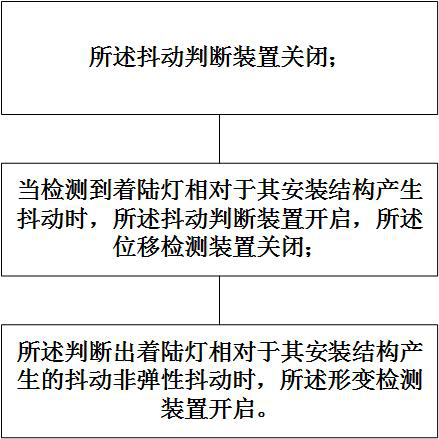

Landing lamp test device, system and method and storage medium

ActiveCN114563165AConvenient performance testingOptical apparatus testingVibration testingEngineeringMechanical engineering

The invention relates to a landing lamp test device, system and method and a storage medium, and belongs to the technical field of lamp test, and the device comprises a locking device, a vibration generation device, a jitter detection device, a displacement detection device, a deformation detection device and a looseness detection device. The locking device is used for fixedly mounting the landing lamp and the mounting structure thereof according to a standard and then locking the landing lamp and the mounting structure thereof on the test bed; and the vibration generating device is used for providing vibration and the like for the landing lamp and the mounting structure of the landing lamp during normal navigation of an airplane through the test bed. Through orderly matched starting of the locking device, the vibration generation device, the jitter detection device, the displacement detection device, the deformation detection device and the looseness detection device, defects existing in the landing lamp mounting structure can be rapidly tested and positioned, and the potential safety hazards can be eliminated in the test process; and the test blank of the section is filled.

Owner:成都盛及航空科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com