Extrusion device and method for extruding chalcogenide glass optical fiber perform with superposition method

A technology of optical fiber preform and chalcogenide glass, which is applied in glass manufacturing equipment, glass production, manufacturing tools, etc. It can solve the problems of adverse effects on optical fiber quality, uneven structure and composition of preform, and low production efficiency, so as to facilitate performance testing , High production efficiency, ideal interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

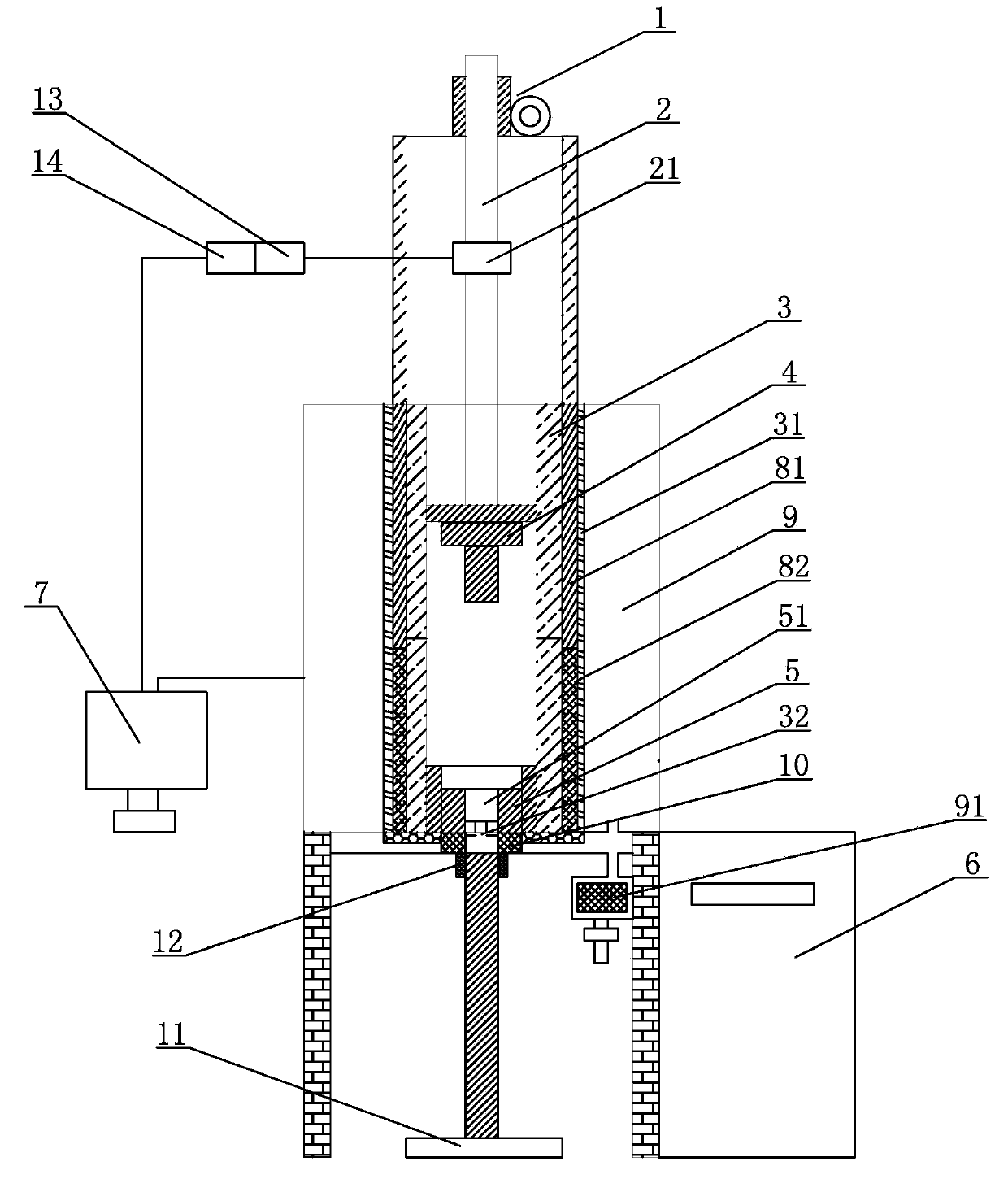

[0034] Example 1: Extrude an optical fiber preform from a chalcogenide glass whose components are sulfide, selenide and antimonide. The crystallization temperature of the glass, Tg is the transition temperature of the chalcogenide glass; the extrusion method includes the following steps: 1) Prepare multiple pieces of chalcogenide glass and polyethersulfone (PES), rinse with alcohol and dry, Put it into a vacuum container; 2) First take out a piece of polyethersulfone, then stack multiple pieces of chalcogenide glass on top of the piece of polyethersulfone, and then put the stacked polyethersulfone and chalcogenide glass together Extrude the cylinder, and place the polymer at the bottom of the extrusion cylinder; 3) Use a vacuum pump to evacuate the vacuum chamber, when the vacuum degree of the vacuum chamber is lower than 10 -2 Pa, add an inert gas to the vacuum chamber, the inert gas can be nitrogen or argon, so that the pressure in the vacuum chamber is the same as the exter...

Embodiment 2

[0035] Example 2: Extrude an optical fiber preform from a chalcogenide glass whose components are sulfide and selenide. Crystallization temperature, Tg is the transition temperature of the chalcogenide glass; the extrusion method includes the following steps: 1) Prepare a number of pieces of chalcogenide glass and polysulfone (PSU), rinse with alcohol, dry, and put them into a vacuum container Middle; 2) Take out a piece of polysulfone first, then stack several sheets of chalcogenide glass on top of the piece of polysulfone, then put the stacked polysulfone and chalcogenide glass into the extrusion cylinder together, and make The high molecular polymer is placed at the bottom of the extrusion cylinder; 3) Use a vacuum pump to evacuate the vacuum chamber, when the vacuum degree of the vacuum chamber is lower than 10 -2 Pa, add an inert gas to the vacuum chamber, the inert gas can be nitrogen or argon, so that the pressure in the vacuum chamber is the same as the external atmosp...

Embodiment 3

[0036] Example 3: Extrude an optical fiber preform from a chalcogenide glass whose components are sulfide, selenide and telluride. The crystallization temperature of the glass, Tg is the transition temperature of the chalcogenide glass; the extrusion method includes the following steps: 1) Prepare multiple pieces of chalcogenide glass and polyimide (PI), rinse with alcohol and dry , and put it into a vacuum container; 2) First take out a piece of polyimide, then stack multiple pieces of chalcogenide glass on top of the piece of polyimide, and then put the stacked polyimide and chalcogenide glass together The glass is put into the extrusion cylinder together, and the polymer is placed at the bottom of the extrusion cylinder; 3) Use a vacuum pump to evacuate the vacuum chamber. When the vacuum degree of the vacuum chamber is lower than 10 -2 Pa, add an inert gas to the vacuum chamber, the inert gas can be nitrogen or argon, so that the pressure in the vacuum chamber is the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com