Mechanical test fixture and limiting stopper mechanical test apparatus

A mechanical test and limiter technology, which is applied in the testing of instruments, mechanical components, and machine/structural components. It can solve the problems of high development cost and long development time, and achieve wide versatility and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

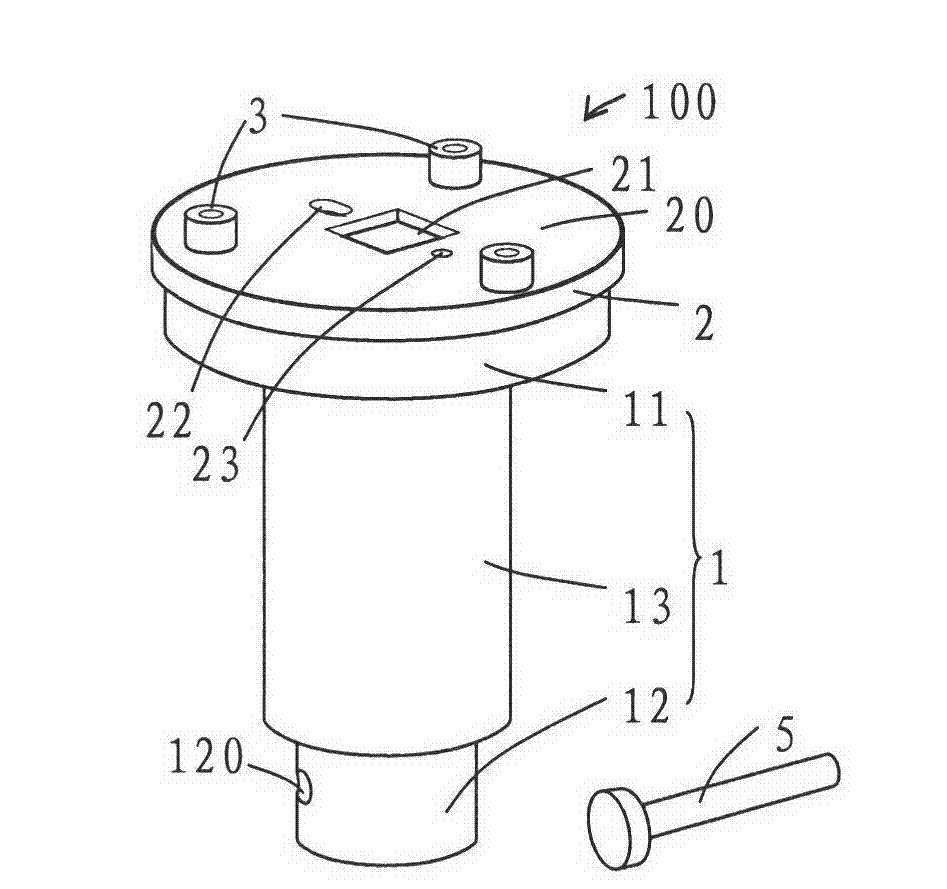

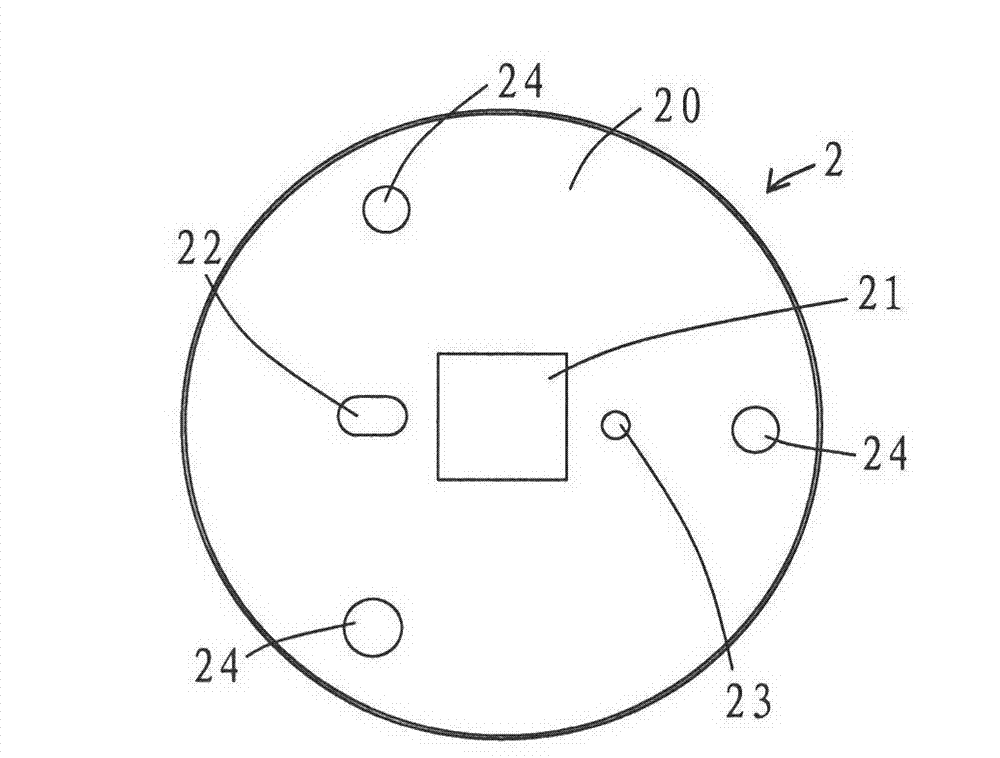

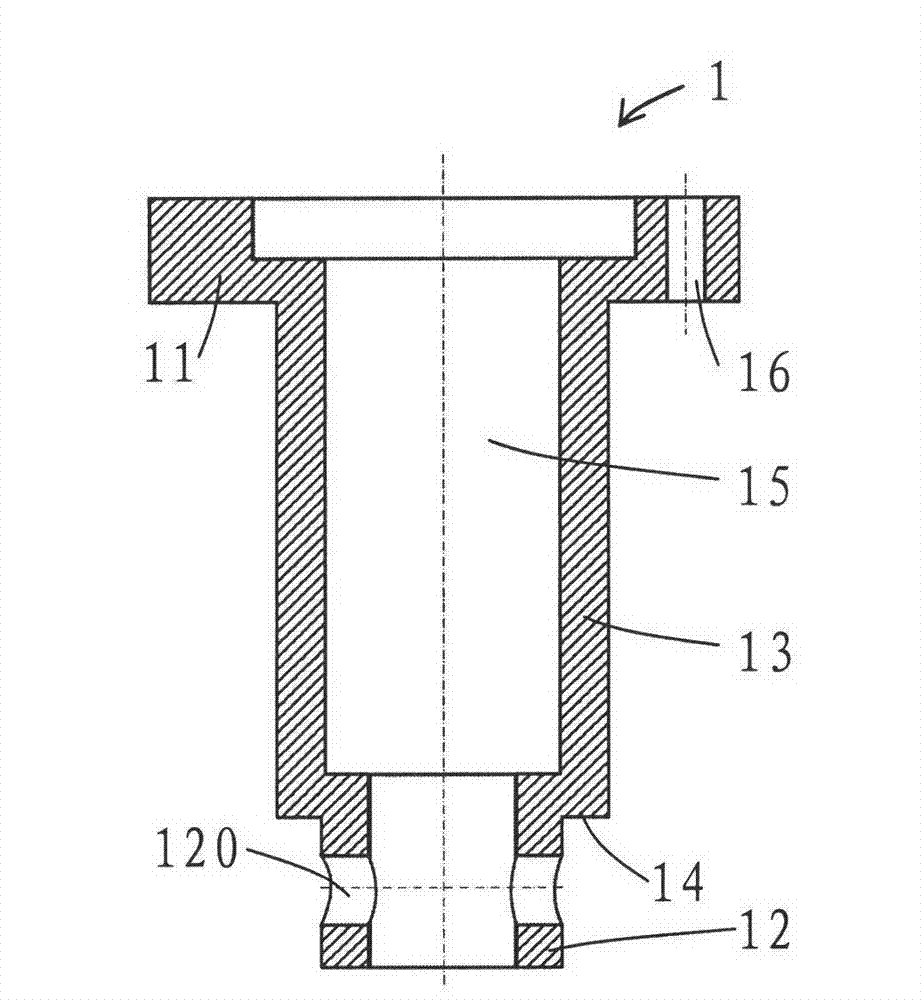

[0031] Figure 1 to Figure 3 A structural diagram of a mechanical test fixture of a specific embodiment of the present invention is disclosed, wherein, figure 1 is an overall structural diagram of the mechanical test fixture 100, figure 2 is a top view of the cover body 2 of the mechanical test fixture 100, and image 3 It is a cross-sectional view of the fixture main body 1 of the mechanical test fixture 100 . Now refer to Figure 1 to Figure 3 As shown, a mechanical test fixture 100 according to a specific embodiment of the present invention includes a fixture main body 1 and a cover body 2 that are fixedly connected to each other. Wherein, the fixture main body 1 includes a first connection part 11 and a second connection part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com