Earthquake-proof wall and construction method thereof

A wall and square technology, applied in the direction of walls, earthquake resistance, building components, etc., can solve the problems of inconspicuousness, increase structural rigidity, limit energy consumption capacity, etc., and achieve the effect of easy operation, simple structure, and low construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

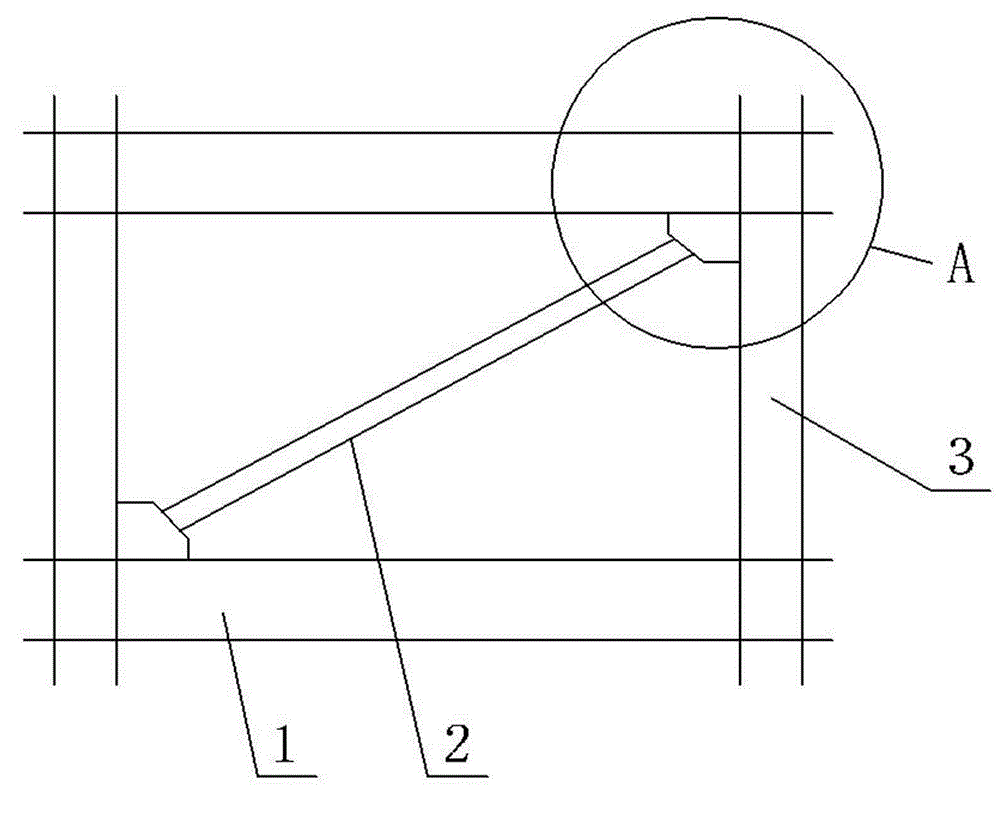

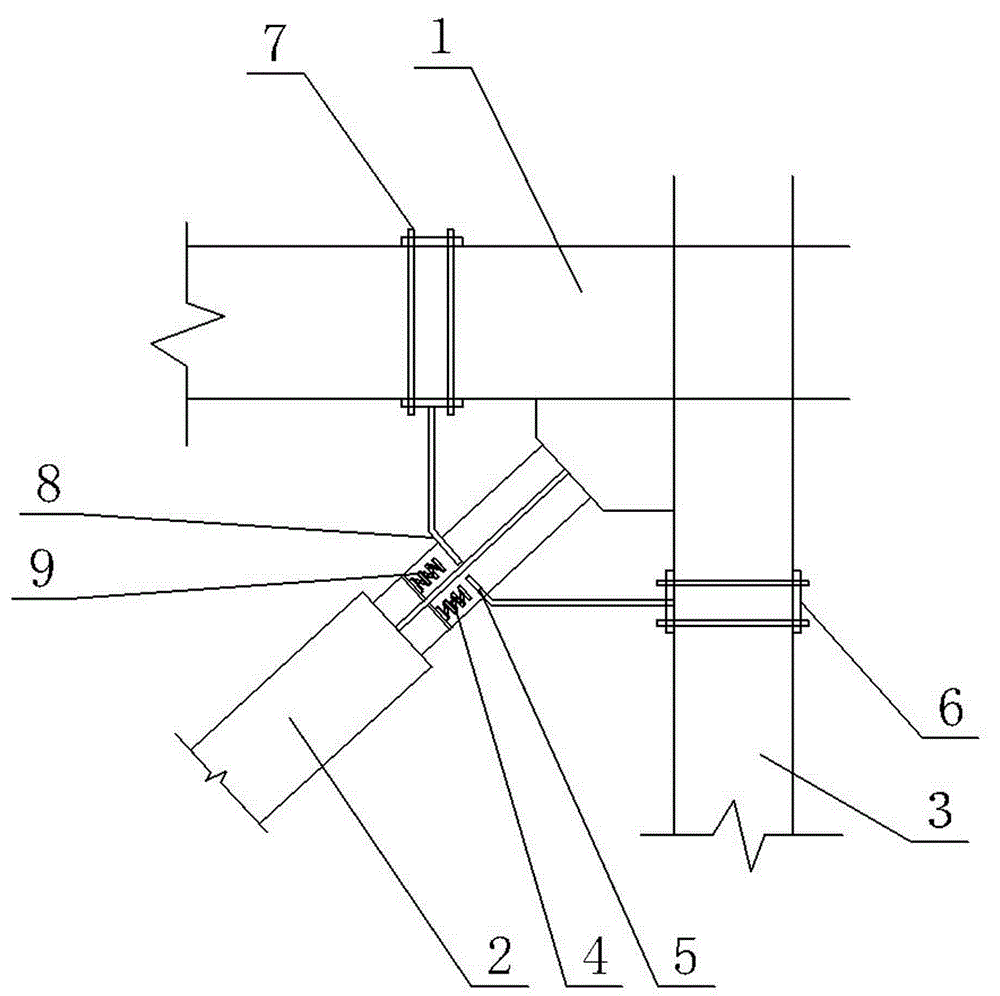

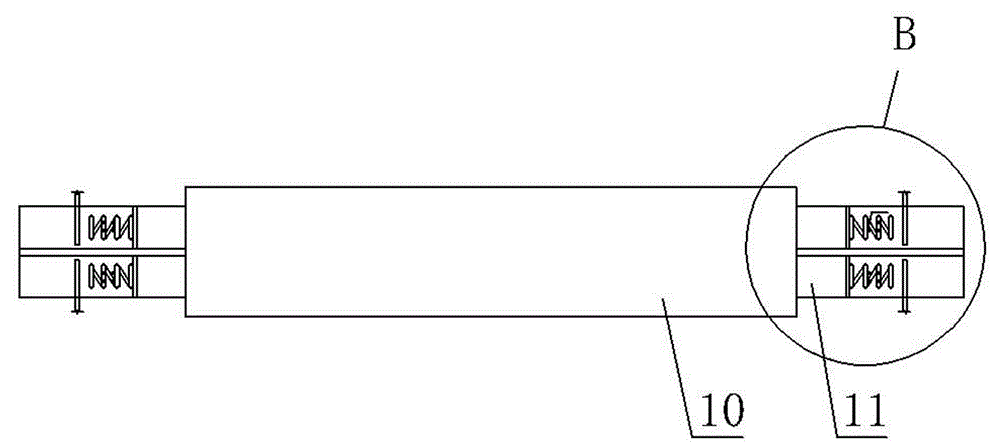

[0020] As shown in Figure 1, an anti-seismic wall consists of a square frame composed of beams 1 and columns 3, and two opposite corners of the square frame are connected with anti-buckling supports 2, which include the core stress Unit 11, external restraint unit 10 and isolation layer unit, the core force unit 11, external restraint unit 10 and isolation layer unit are connected by the existing connection method, and the two ends of the core force unit 11 are exposed on the external restraint unit 10, the two ends of the core force bearing unit 11 are respectively connected with the vertices of the two corners of the square frame.

[0021] On the basis of above-mentioned prior art, this specific embodiment has been improved as follows:

[0022] Each end of the anti-buckling support 2 and the adjacent corner of the square frame are provided with a stiffness enhancement structure, and each stiffness enhancement structure includes a first spring 4, a second spring 9, and a spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com