Rare earth permanent magnet material and preparation method thereof

A technology of rare earth permanent magnets and magnets, which is applied in the fields of magnetic materials, metal material coating technology, inductance/transformer/magnet manufacturing, etc., can solve the problems of limited coercive force improvement, low efficiency, waste of heavy rare earth metals, etc., and achieve Significant coercive force, high efficiency, and reduced heavy rare earth content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

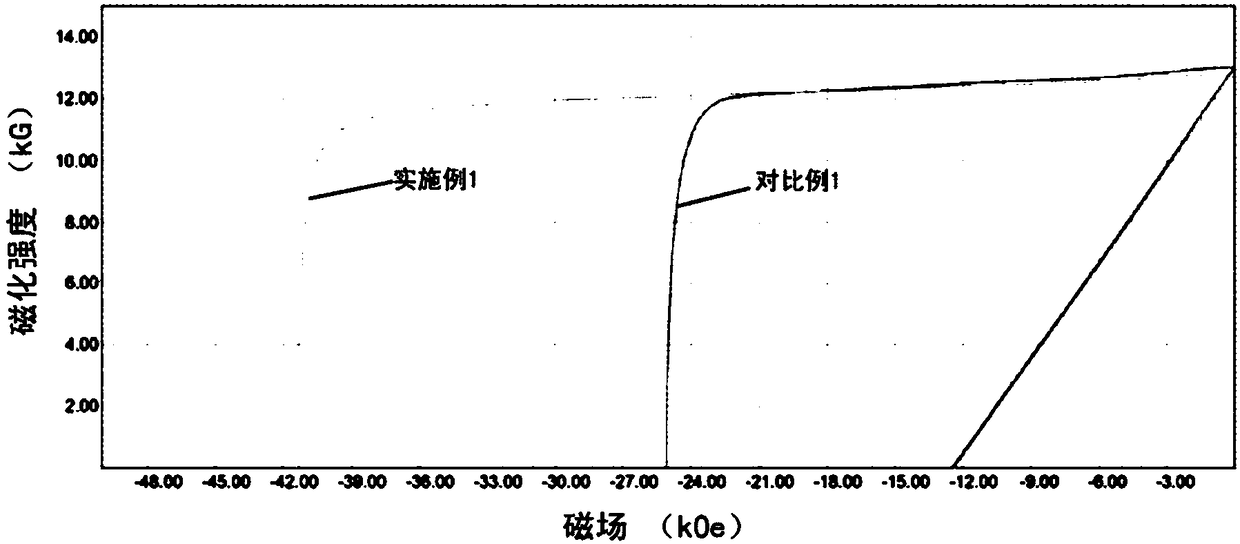

Embodiment 1

[0034] (1) According to the powder composition formula (TbF 3 ) 95 Nd 2 al 3 (The suffix in the formula is the atomic percentage of the corresponding element) Composite powder configuration: take TbF3 powder (particle size: -150 mesh), metal Nd powder (particle size: -150 mesh), metal Al powder (particle size: -150 mesh) , mix the above powders evenly, pass through a 150-mesh sieve, and take the undersize as a composite powder, wherein the powder mixing and sieving process is carried out under a nitrogen environment.

[0035] (2) NdFeB commercial magnetic powder (ingredient distribution ratio: Nd 9.2 PR 3 Dy 1.2 Tb 0.6 Fe 80 B 6 , where the subscript is the atomic percentage of the corresponding component) is loaded into a cemented carbide mold, and at the same time, a 20 μm thick composite powder configured in step (1) is laid on the surface layer perpendicular to the orientation, using spark plasma sintering technology, in a vacuum 10 -3 pa, pressure 30Mpa, hot pre...

Embodiment 2

[0041] (1) According to the powder ratio formula (DyF 3 ) 95 Nd 1 al 4 (The subscript in the formula is the atomic percent of corresponding element) configures composite powder. Weigh DyF 3 Powder, -150 mesh; metal Nd powder, -150 mesh; metal Al powder, -150 mesh; mix the above powders evenly, and sieve through 150 mesh, and the powder mixing and sieving process is carried out under nitrogen environment.

[0042] (2) NdFeB commercial magnetic powder (ingredient distribution ratio: Nd 10.8 PR 3 Tb 0.4 Fe 79.8 B 6 , where the subscript is the atomic percentage of the corresponding component) into a cemented carbide mold, and at the same time lay the powder described in (1) with a thickness of 25 μm on the surface layer in the vertical direction, using spark plasma sintering technology, in a vacuum of 10 -3 pa, pressure 30Mpa, hot pressing at 750°C to obtain surface curing adhesion (DyF 3 ) 95 Nd 1 A l4 NdFeB magnet with powder solidification layer; the orientation d...

Embodiment 3

[0048] (1) According to the powder ratio formula (TbF 3 ) 95 Cu 5 (The subscript in the formula is the atomic percent of corresponding element) configures composite powder. Weigh TbF 3 Powder, -150 mesh; Metal Cu powder, -150 mesh; Mix the above powders evenly, and sieve through 150 mesh, and the powder mixing and sieving process is carried out under nitrogen environment.

[0049] (2) NdFeB commercial magnetic powder (ingredient distribution ratio: Nd 11.9 PR 3 Dy 0.1 Fe 79 B 6 , where the subscript is the atomic percentage of the corresponding component) into a cemented carbide mold, and at the same time lay the powder described in (1) with a thickness of 30 μm on the surface layer oriented vertically, using spark plasma sintering technology, vacuum 10 -3 pa, pressure 50Mpa, hot pressing at 780°C to obtain surface curing adhesion (TbF 3 ) 95 Cu 5 NdFeB magnet with powder solidification layer; the orientation direction is 12mm thick.

[0050] (3) The magnet that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com