Magnetic density order descending array demagnetizing plate

A technology of magnetic density and degaussing plate, applied in the electromagnetic field, can solve the problems of low speed, lack of degaussing effect, high energy consumption, and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

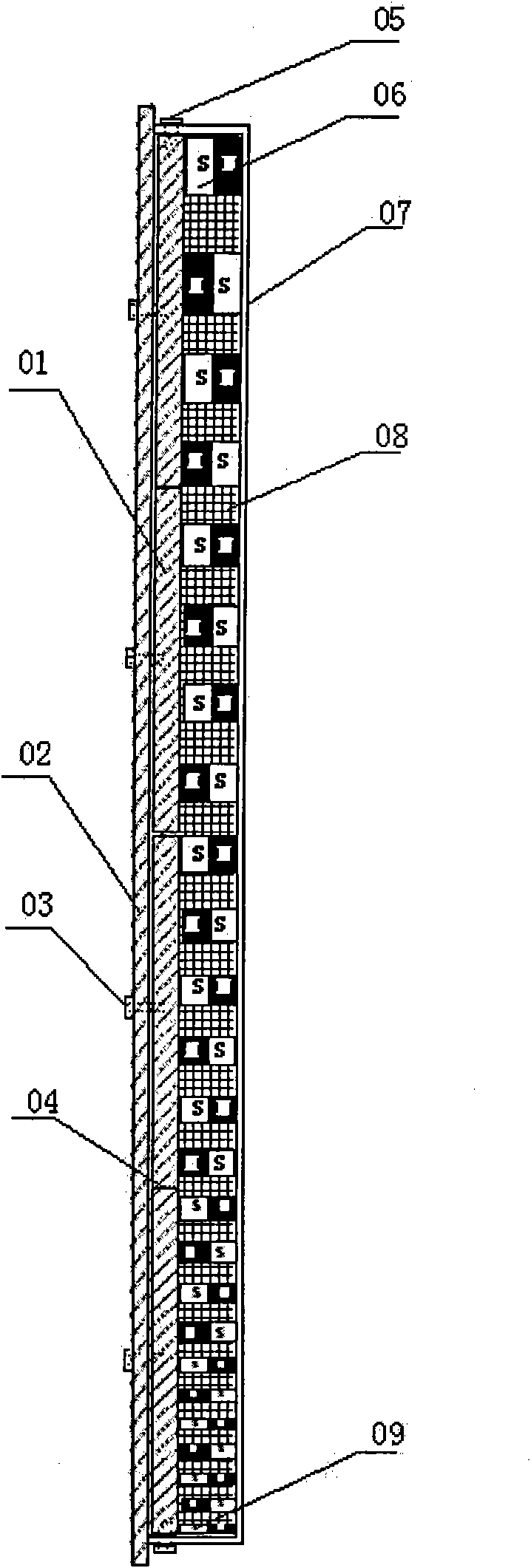

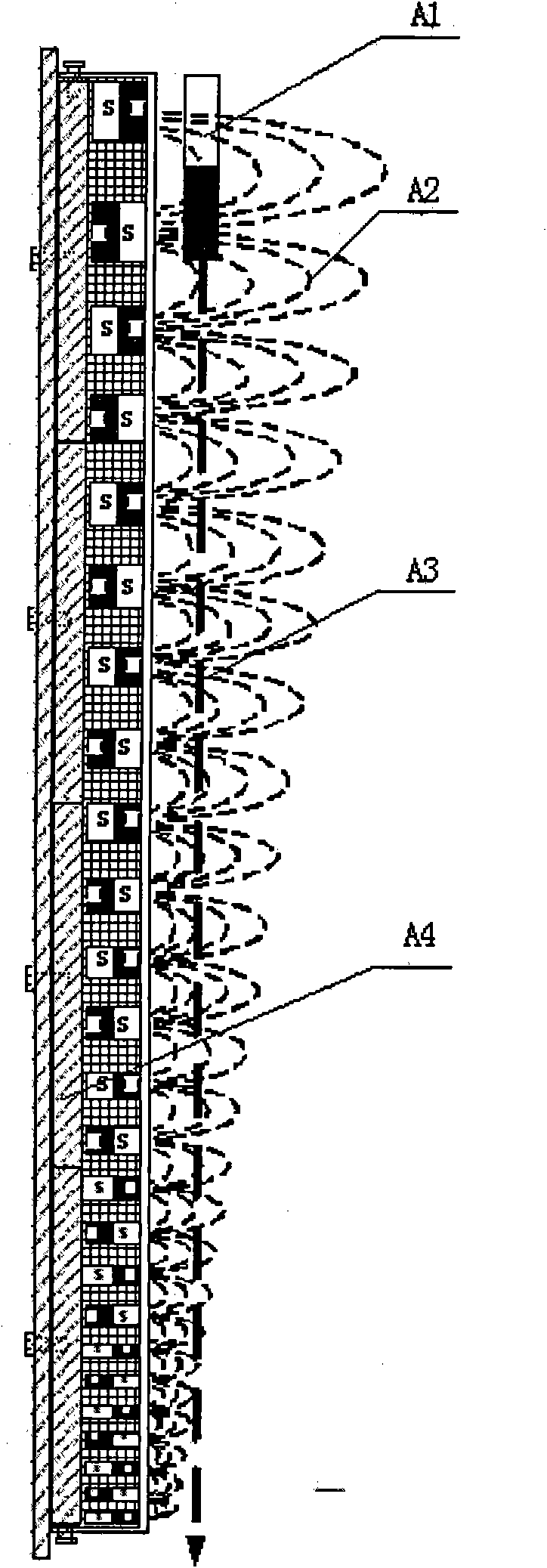

[0041] Magnetic density descending array degaussing plate structure of the present invention: 01 (A4) is the magnetic steel array base plate unit, 20 pieces of 01 (A4) magnetic steel array base plate units constitute the magnetic steel array base plate, and 03 and 05 are fixing bolts fixed on the combined magnetic plate. Steel array base plate 02. 04 is the seam of the combined magnetic steel array bottom plate unit. 06 is permanent magnetic steel (the first piece has the highest magnetic strength), arranged from top to bottom, from large to small, crossing from north to south; 07 is a non-magnetic protective cover. 08 is a wooden strip of non-magnetic material embedded between two magnetic steels; 09 is a permanent magnetic steel (the last piece has the smallest magnetic strength).

[0042] Permanent magnets 06 with S and N staggered arrangements are arranged on the base plate of the magnet array, and the permanent magnets are arranged from top to bottom with magnetic streng...

Embodiment 2

[0049] Except for the following differences, the premise is the same as in Embodiment 1, and the magnetic density descending array degaussing plate of the present invention is formed to degauss the steel wire-lined conveyor belt.

[0050] The magnetic strength of the permanent magnetic steel array is 5000gs-100gs in descending order, and 12 pieces of 01 (A4) magnetic steel array bottom plate units constitute the magnetic steel array bottom plate, that is, the magnetic strength of every two adjacent permanent magnetic steel drops to (5000-100 )÷12=408gs. And the magnetic intensity curve presents an approximately oblique linear gradient change.

[0051] The magnetic density descending array degaussing plate of this embodiment is used for degaussing the steel wire-lined conveyor belt with residual magnetization (magnetization) in the steel plant. The conveyor belt passes over the surface of the magnetic density descending array degaussing plate of the present invention at a runn...

Embodiment 3

[0053] Except for the following differences, the premise is the same as in Embodiment 1, and the magnetic density descending array degaussing plate of the present invention is formed to degauss the steel wire-lined conveyor belt.

[0054] The magnetic strength of the permanent magnets is 5000gs-100gs in descending order, and 8 pieces of 01 (A4) magnetic steel array bottom plate units constitute the magnetic steel array bottom plate, that is, the magnetic strength of every two adjacent permanent magnets drops to (5000-100) ÷8=612gs. And the magnetic intensity curve presents an approximately oblique linear gradient change.

[0055] The magnetic density descending array degaussing plate of this embodiment is used for degaussing the steel wire-lined conveyor belt with residual magnetization (magnetization) in the steel plant. The conveyor belt passes over the surface of the magnetic density descending array degaussing plate of the present invention at a running speed of 5-10 m / s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com