Gravity-based material bin for charging and discharging of grinder truss

A technology of loading and unloading and working truss, which is applied in the direction of grinding frame, manufacturing tools, grinding bed, etc. It can solve the problems of low efficiency, inconvenient loading and unloading, and troublesome adjustment of silo, so as to improve work efficiency, up and down Convenient material and ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

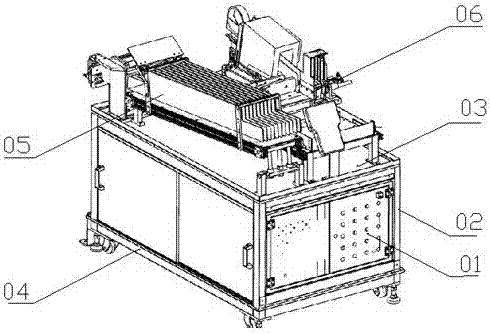

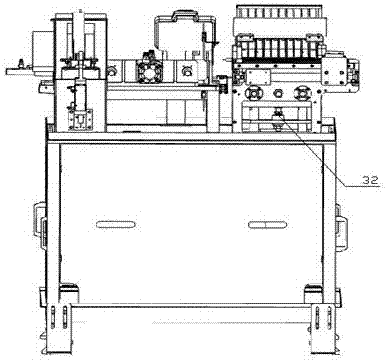

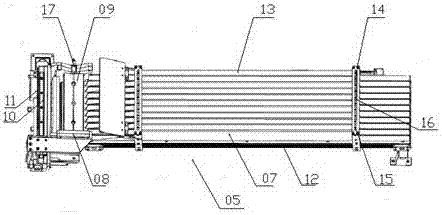

[0015] Refer to attached Figure 1-4 , a mill truss loading and unloading gravity bin, which includes an electric control box 01, a bin frame 02, an upper bin 05, and a lower bin 06, the electric control box 01 is arranged at the front of the bin frame 02; the bin The frame 02 includes an oil receiving tray 04 and a table top 03. The oil receiving tray 04 is located at the lower part of the warehouse frame 02, the table top 04 is located at the upper part of the warehouse frame 02, and both sides of the table top 04 are provided with an upper material bin 05 and an upper material bin 06; The warehouse 05 includes a blank material channel 07, a positioning baffle plate 08, a blank material channel 09, a guide rail 10, a jacking cylinder 32, and a positioning cylinder 11. V-shaped blank material trough 09, the bottom of the blank material trough 09 is fixed on the jacking cylinder 32, and the jacking cylinder 32 drives the blank material trough 09 to move up and down. A photoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com