Pipeline demagnetizer based on permanent magnet structure and application of pipeline demagnetizer

A demagnetization and pipeline technology, applied in the direction of permanent magnets, magnets, magnetic objects, etc., can solve the problems of residual magnetism not being eliminated, influence of magnetic flux leakage detection accuracy, adverse effects of pipeline maintenance and welding, etc., to achieve convenient pipeline maintenance and emergency repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

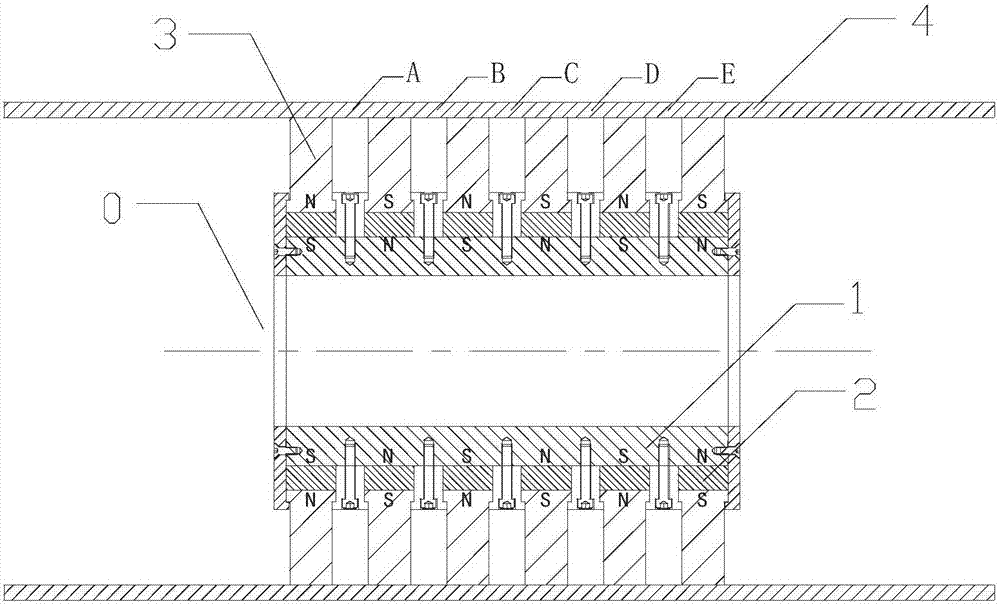

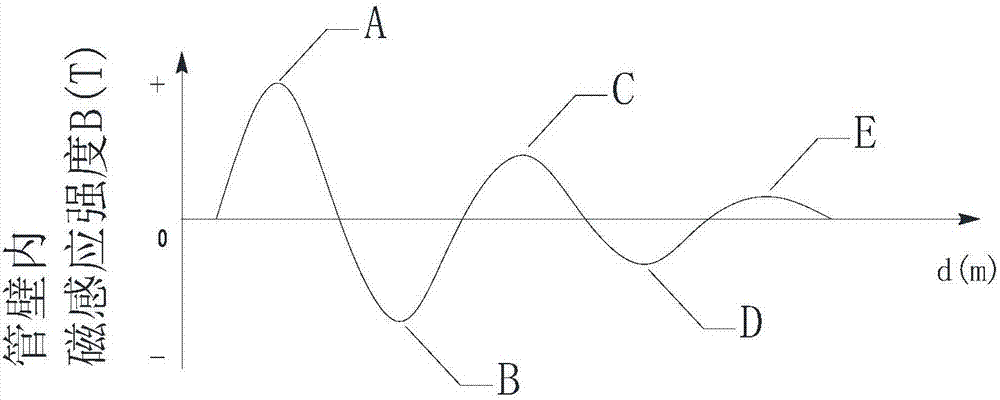

[0063] A pipeline demagnetization device based on a permanent magnet structure, its structure is as follows figure 1 As shown, it consists of an iron core 1 and permanent magnets 2 distributed on the iron core 1 .

[0064] The iron core 1 can be made of magnetically permeable material to form a magnetic circuit; it can also be partially non-magnetically permeable. The selected material is mainly for the purpose of forming a suitable magnetic circuit. The permanent magnet 2 used is a single annular magnet, and a radially magnetized annular magnet is used. The annular magnet can be a magnetic ring magnetized in the entire radial direction, or spliced by multiple magnetic steels. The single ring magnets are placed at intervals along the axial direction of the center piece, and the magnetization directions are alternately reversed one by one. The magnetization performance of the single ring magnets arranged along the axial direction of the center piece is gradually reduced, an...

Embodiment 2

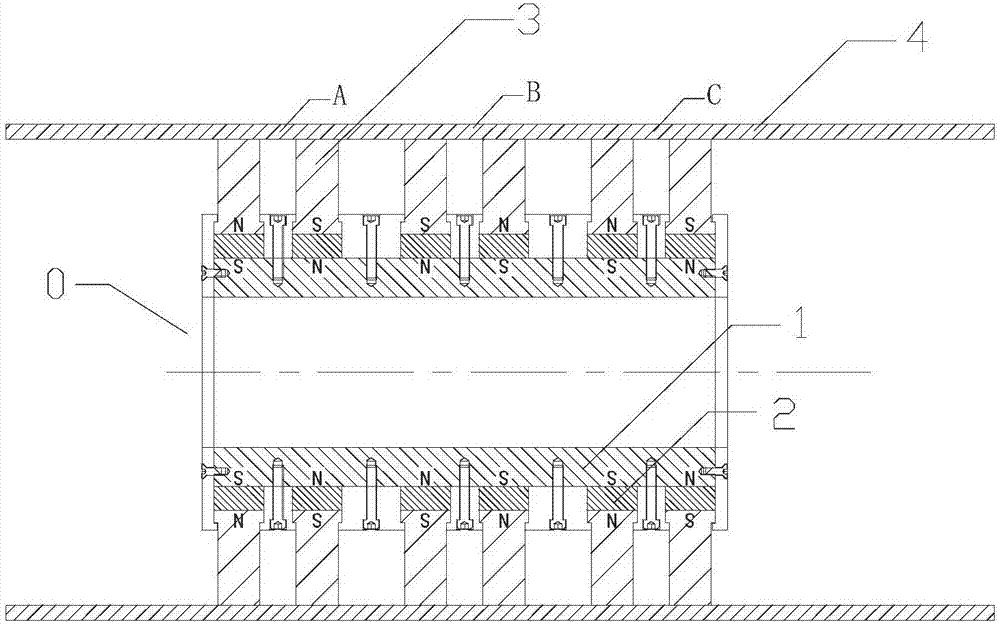

[0067] A pipeline demagnetization device based on a permanent magnet structure, its structure is as follows image 3 As shown, it consists of an iron core 1 and permanent magnets 2 distributed on the iron core 1, which is roughly the same as in Embodiment 1, except that the permanent magnet 2 used in this embodiment is a series structure composed of double ring magnets. Two ring magnets radially magnetized and magnetized in opposite directions form a series group. Each group of double ring magnets consists of two ring magnets with radial magnetization and opposite magnetization directions. The radial ring magnets can be spliced by multiple magnetic steels, or can be a whole radial magnetization ring. Each group of double ring magnets forms a polarity in a certain direction in the tube wall. Multiple groups of ring magnets are placed at intervals along the axial direction, and the magnetization directions formed in the tube wall are alternately reversed in groups one by one,...

Embodiment 3

[0069] A pipeline demagnetization device 0 based on a permanent magnet structure. The device is a built-in structure and is used for demagnetization inside a long pipeline. It is pulled forward by pressure in the pipeline so that the magnetized pipeline undergoes the process of alternating attenuation magnetic field to achieve demagnetization.

[0070] When performing magnetic pigging operation or magnetic flux leakage detection operation on long-distance natural gas and oil pipelines, the magnetic pig 5 will move forward along the pipeline under the action of the pressure inside the pipeline. A strong magnet will be installed on the magnetic pig 5, and wherever the equipment goes, the pipe wall will be saturated and magnetized, so that the entire long-distance pipeline will be severely magnetized.

[0071] For long-distance natural gas and oil pipelines, the pipeline demagnetization device 0 adopts a built-in structure. The demagnetization device can be a single device, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com