Method for cleaning copper or copper alloy sputtering target material

A technology for sputtering target materials and copper alloys, applied in liquid cleaning methods, cleaning methods and utensils, sputtering coating, etc., which can solve problems such as increased cleaning agent usage, reduced cleaning efficiency, and increased cleaning agent costs , to achieve the effect of ensuring cleaning efficiency, good cleaning effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

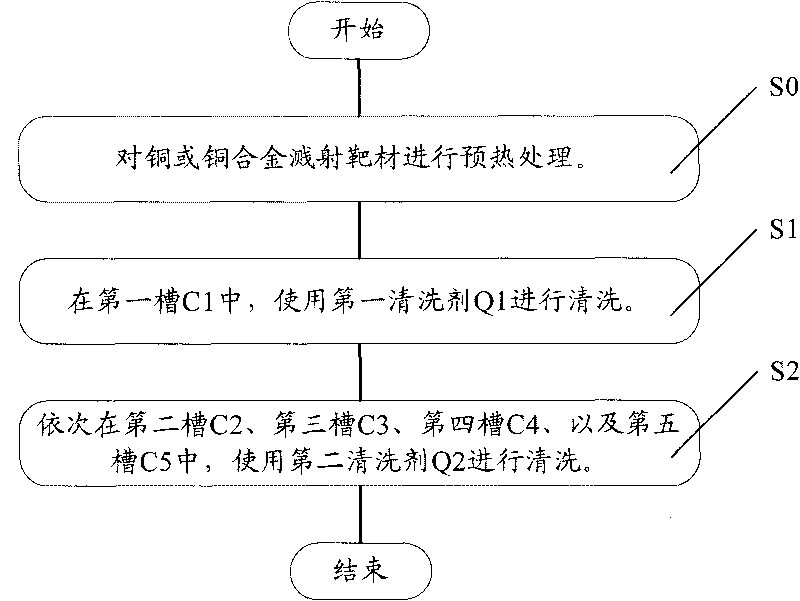

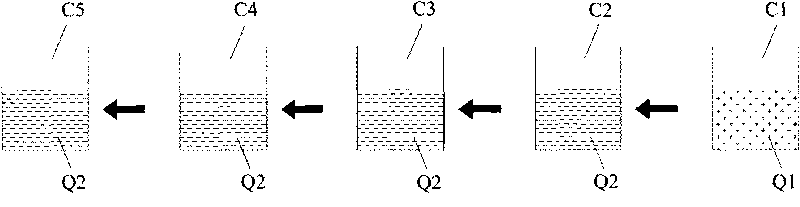

Method used

Image

Examples

Embodiment 1

[0043] Prepare 5 pure copper disc-shaped sputtering target samples with a diameter of Φ300 mm and a thickness of 30 mm, respectively numbered 1 to 5, and use the above five samples as the first group of cleaning samples. The target is preheated by means of warm air, so that the temperature of the target is 30°C.

[0044] First cleaning stage:

[0045] Use aviation kerosene pure solution as the first cleaning agent with a volume of 50L. Use an ultrasonic cleaning device to clean the first group of cleaning samples in a cleaning tank. The temperature of the cleaning solution is 30°C and the cleaning time is 5 minutes. The length of the inner tank of the cleaning tank is 50cm, the width is 40cm, the height is 40cm, and the number of vibrators is 12. The ultrasonic power of the device is 1200W, and the frequency is 28KHz.

[0046] Second cleaning stage:

[0047] Use liquid isopropanol with a purity of more than 99.98% and a water content of less than 0.01% as the second cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com